Automatic stop mechanism of honing machine

A technology for automatic shutdown and honing machines, which is applied in the direction of honing machine tools, grinding drive devices, and parts of grinding machine tools, etc. It can solve the problems of affecting the quality of honing processing, inaccurate feed control, and easy out-of-tolerance honing parts. , to improve the quality, control the feed rate accurately, and avoid honing out-of-tolerance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further explained below in conjunction with the drawings and specific embodiments.

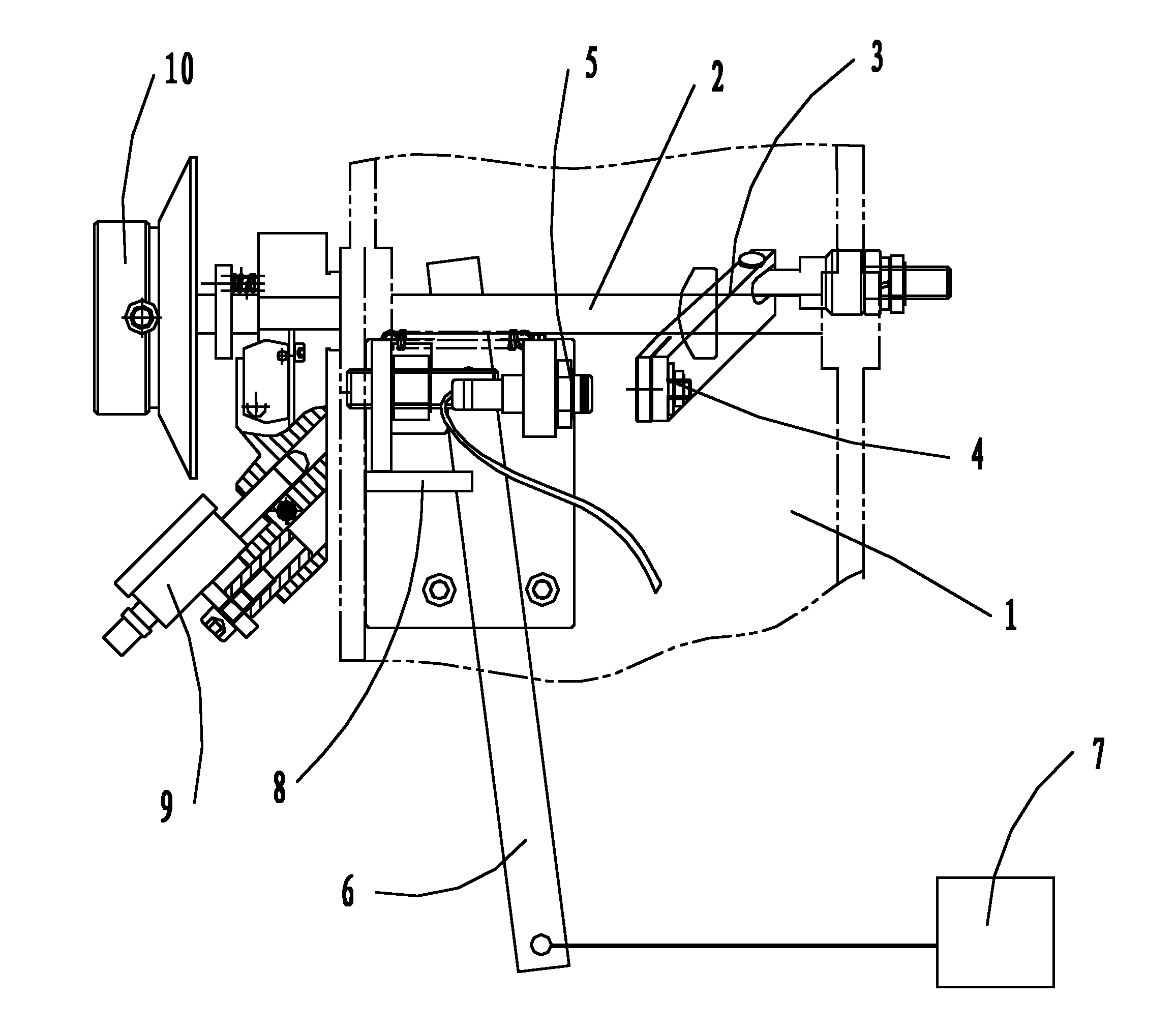

[0015] See figure 1 As shown, an automatic stopping mechanism for a honing machine includes a headstock 1, a feed screw 2 rotatably arranged on the headstock 1, and the feed screw 2 is distributed in a horizontal forward and backward direction, which is also which is figure 1 The left and right directions in the middle, where the front refers to the right and the rear refers to the left. In this embodiment, the feed motion of the feed screw 2 in the forward and backward directions is realized by the rotation of the handwheel 10, and the feed It can be read from the display table 9. A lever 3 is fixedly connected to the front end of the feed screw 2, an induction block 4 is provided on one end of the lever 3, and an electromagnetic induction switch 5 is fixedly connected to the inner side wall of the rear end of the spindle box 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com