High-precision vertical internal oil injection diamond reamer

A high-precision, diamond technology, used in reamers, metal processing equipment, manufacturing tools, etc., can solve problems such as deformation and affect the machining accuracy of workpieces, and achieve the effect of improving surface roughness, reducing workpiece deformation, and long guiding parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

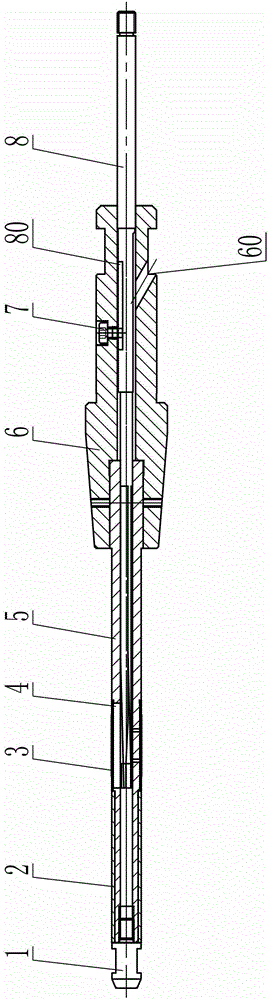

[0016] Such as figure 1 A high-precision vertical oil-injection diamond reamer shown includes a reamer rod 5, a reamer rod sleeve 6 connected to the rear of the reamer rod 5, and a reamer sleeve set in the middle of the reamer rod 5 3. The taper rod 8 arranged inside the reamer rod 5 and the reamer rod sleeve 6. Specifically:

[0017] The front part of the reamer bar 5 is covered with a leading guide sleeve 2; the front end of the reamer bar 5 is provided with an adjusting nut 1; the middle part of the reamer bar 5 is provided with a groove, and the reamer sleeve 3 is set in the groove. Because the inside of the reamer sleeve 3 is manufactured in a cylindrical shape, the versatility is strong, and the reamer sleeve 3 with wear, different particle sizes or different sizes can be replaced at any time according to the needs, which greatly saves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com