Atomization-vaporization heat dissipating type LED lamp

A technology of LED lamps and atomization evaporation, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, point light sources, etc., can solve the problems of poor heat dissipation effect, low heat dissipation efficiency, and shortened service life of LED lamps, etc. To achieve the effect of large heat dissipation surface, improve service life, and facilitate connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the following, the present invention will be further described in conjunction with the embodiments:

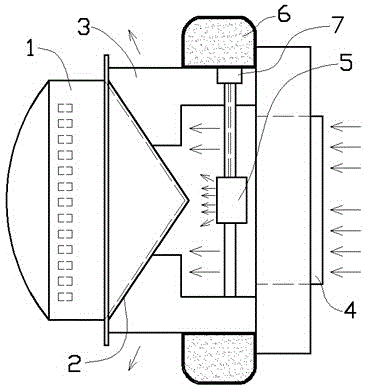

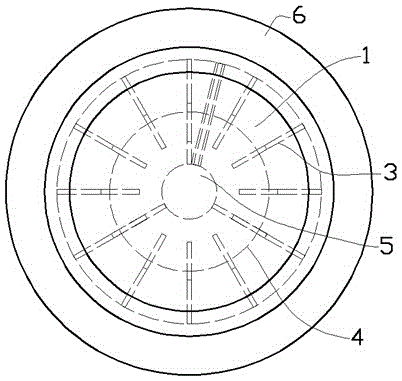

[0012] Such as figure 1 with figure 2 As shown in the embodiment, the present atomized evaporative heat dissipation type LED lamp includes a lamp panel 1, and LED lamp caps evenly distributed on the lamp panel 1. The LED lamp caps are gathered in the front part of the lamp panel 1 layer by layer in a ring shape. The lamp panel 1 is equipped with a circuit structure; the rear of the lamp panel 1 is covered with a conical heat dissipation main board 2 which divides the lamp into two parts which are isolated from the front and the back. The rear part of the heat dissipation main board 2 is designed with heat sinks 3 uniformly distributed along the axis of the lamp panel 1. One end of the heat sink 3 is fixedly connected to the surface of the heat dissipation main board 2, and the other end of the heat sink 3 is fixedly connected with The blowing fan 4 is coaxially assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com