Device for producing nanometer silicon dioxide through rice husk deep oxidation

A nano-silica, oxidation device technology, applied in the direction of silica, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of production scale limitation, open flame combustion, high cost, etc., and achieve thermal energy regeneration Utilize, increase oxidation speed, and balance temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

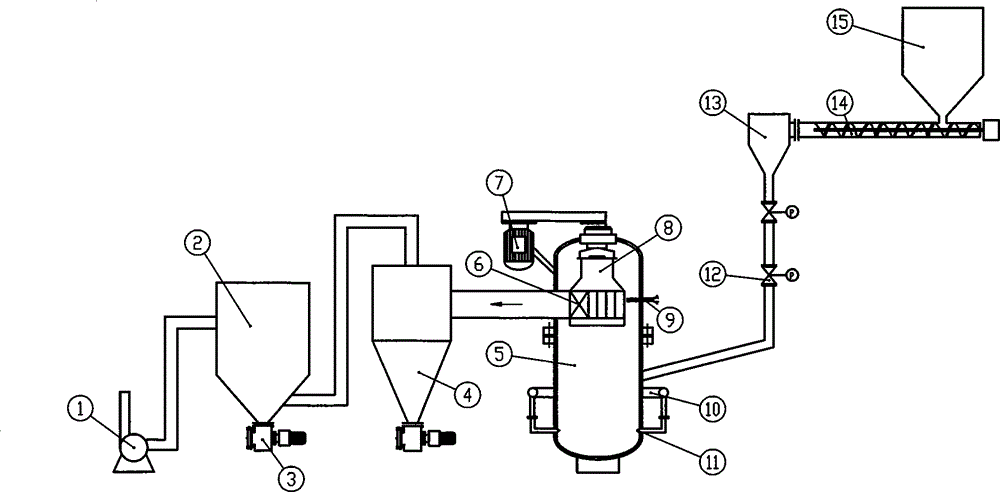

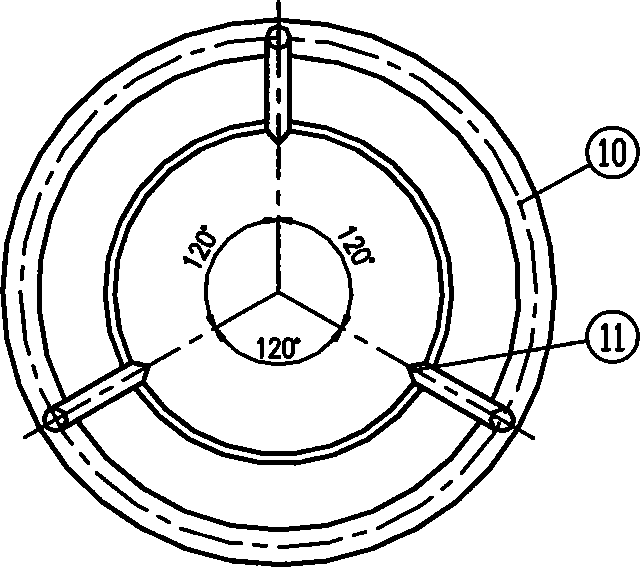

[0027] Such as figure 1 As shown, the temperature-controlled oxidation device of the present invention includes an oxidation cylinder (5), a particle selector (8), a group of high-speed air nozzles (11), a feed inlet and a feed outlet (6). Two pneumatic gate valves (12) are arranged on the upper end of the feed inlet, which are connected with the lower hopper (13) and the screw conveyor (14). The discharge port is connected with the external high-temperature-resistant cyclone separator (4), the high-temperature-resistant filter (2), and the high-temperature-resistant and high-pressure induced draft fan (1). The oxidation cylinder body (5) is made of high-temperature-resistant stainless steel, lined with wear-resistant and high-temperature-resistant alloy steel or lined with wear-resistant and high-temperature resistant ceramics or silicon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com