Novel grinding tool for inner bore

A technology for grinding tools and inner holes, which is applied in the direction of manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, grinding heads, etc., which can solve the problems of decreased production efficiency and increased production costs, and achieve short working hours and constant concentricity , the effect of high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

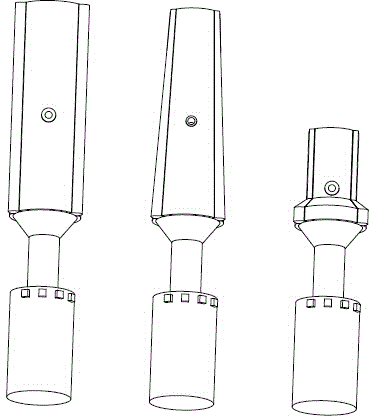

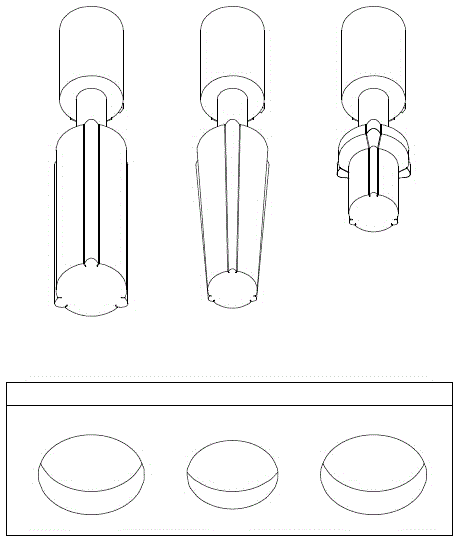

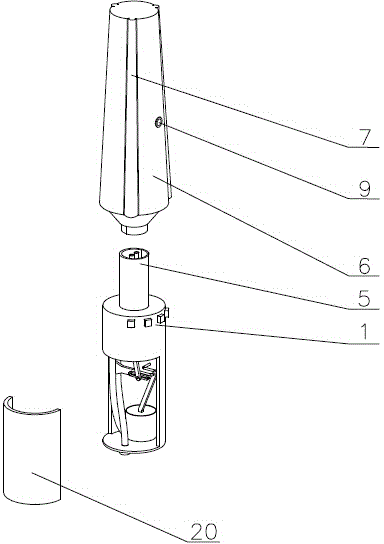

[0018] A sort of new type Inner hole grinding tool, the tool includes a fixed handle 1 and a grinding rod 6; the fixed handle 1 is provided with a cavity, the cavity is provided with an outer cover 20, and the cavity is provided with an air inlet pipe 2; the grinding rod 6 is hollow, and the grinding rod 6 is There are three or more inflatable grinding rod capsules 7 evenly distributed on the surface, and the grinding rod capsule 7 is extruded with grinding parts 8, and the grinding rod is provided with cleaning air holes 9, and the air inlet pipe 2 passes through the shunt pipe 25 is connected with grinding rod 6 hollows; Grinding rod 6 is connected with grinding rod capsule body 7, and cleaning air hole 9 is connected with the air intake pipe 2 of fixed handle with grinding rod hollow. The structure of the two air intake pipes in the fixed handle is rotating, and the grinding rod capsule 7 can also be provided with a helical structure.

[0019] The grinding rod 6 is integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com