Magnetic Bearing Concentricity Adjustment Method

An adjustment method and magnetic bearing technology, applied in the field of magnetic bearings, can solve the problems of difficult control of precision, difficulty in meeting the high-precision requirements of the inner hole coaxiality of magnetic bearings, and difficult processing, so as to improve precision, reduce difficulty, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

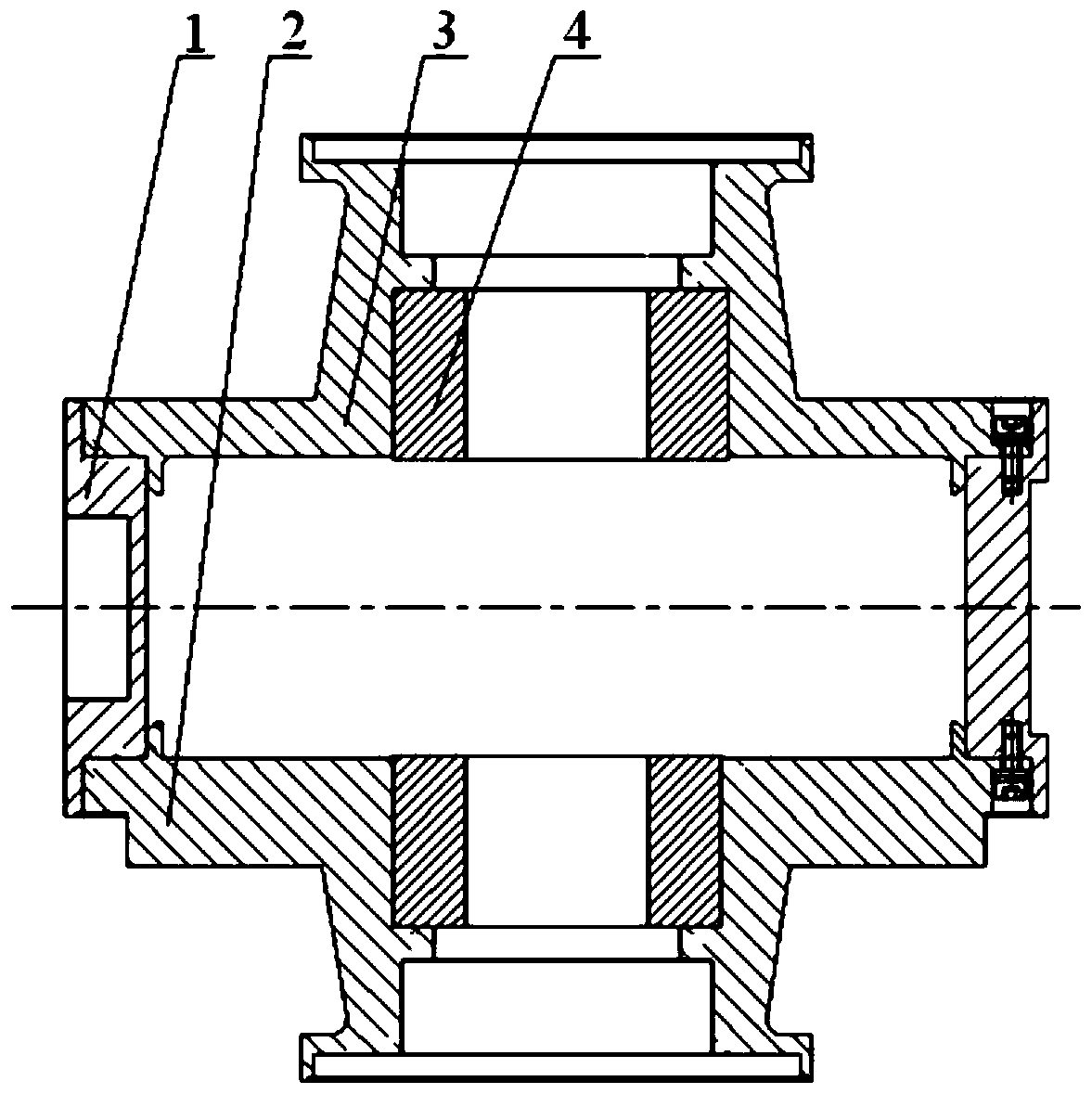

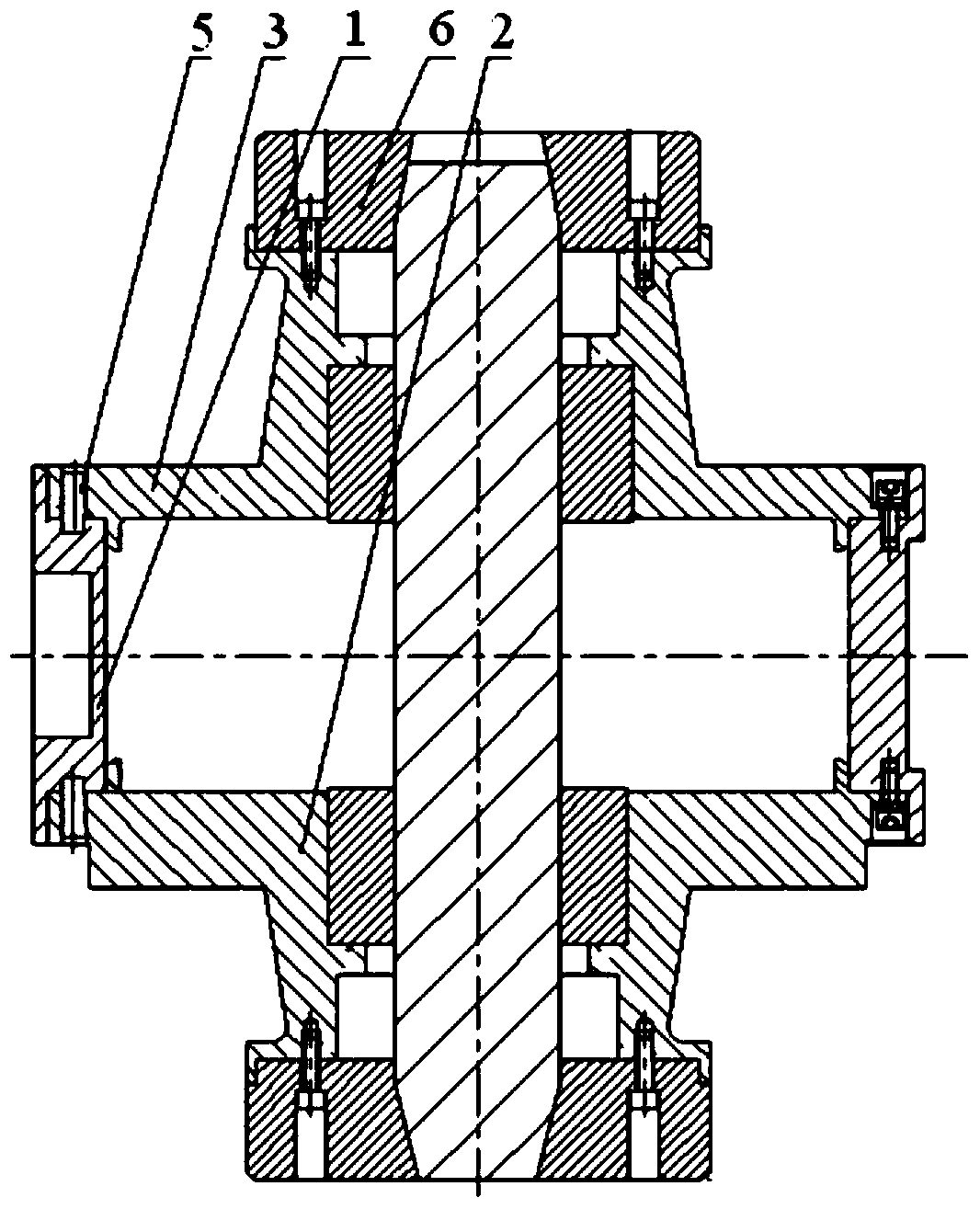

[0020] The purpose of the present invention is to provide a new method for adjusting the coaxiality precision of the magnetic bearing in order to overcome the requirement that the existing processing technology is difficult to ensure the high-precision coaxiality of the magnetic bearing. include:

[0021] (1) The small end faces of the left and right gyro houses of the magnetic levitation control moment gyro are respectively equipped with adjustment blocks, and the adjustment blocks and the left (right) gyro houses are fastened with screws;

[0022] (2) Combined processing of the inner hole of the magnetic bearing and the taper hole of the adjustment block in the left and right gyroscope rooms to ensure the concentricity of the inner hole of the magnetic bearing and the taper hole of the adjustment block. The taper hole of the adjustment block has high-precision centering and coaxial functions. The concentricity accuracy of the inner hole of the magnetic bearing has a great in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com