A plunger cylinder utilizing gap sealing

A technology of plunger cylinder and clearance, applied in the field of hydraulic cylinder, can solve the problems of reduced reliability of seals and systems, and achieve the effects of improving running stability, reducing processing cost and increasing guide length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

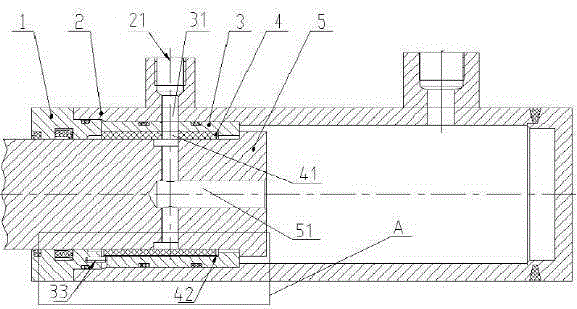

[0027] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

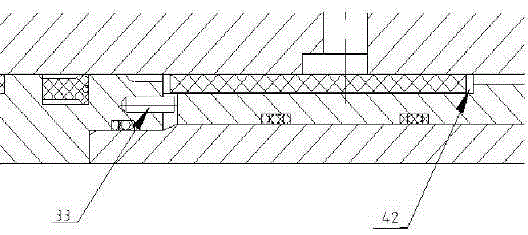

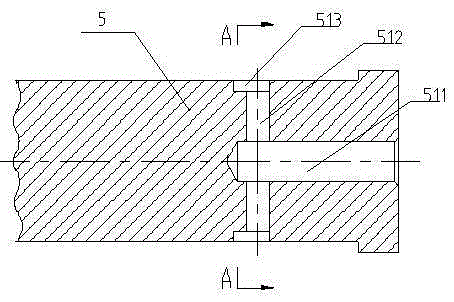

[0028] Such as figure 1 with figure 2 As shown, a plunger cylinder utilizing gap sealing includes a cylinder 2, a piston rod 5 and a gland 1; a guide sleeve 3 is provided on the inner cylindrical surface of the left end of the cylinder 2, and the right end of the gland 1 compresses the guide sleeve 3 , so that the guide sleeve 3 is fixed on the inner cylindrical surface of the cylinder barrel 2; a pressure signal port 21 communicating with the inside and outside of the cylinder barrel 2 is opened on the cylindrical surface of the cylinder barrel 2, and a pressure signal port 21 communicating with the pressure signal port 21 is opened on the guide sleeve 3 Oil passage hole I31, on the piston rod 5, there is an oil inlet 51 connecting the high-pressure chamber of the cylinder barrel 2 and the oil passage ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com