An all-wheel drive transfer case electronic control device

An electronic control device and all-wheel drive technology, which is applied in the direction of transmission control, belt/chain/gear, and components with teeth, can solve problems such as error-prone, cumbersome operation, and low efficiency, so as to prolong life and avoid Abrasion or damage, the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

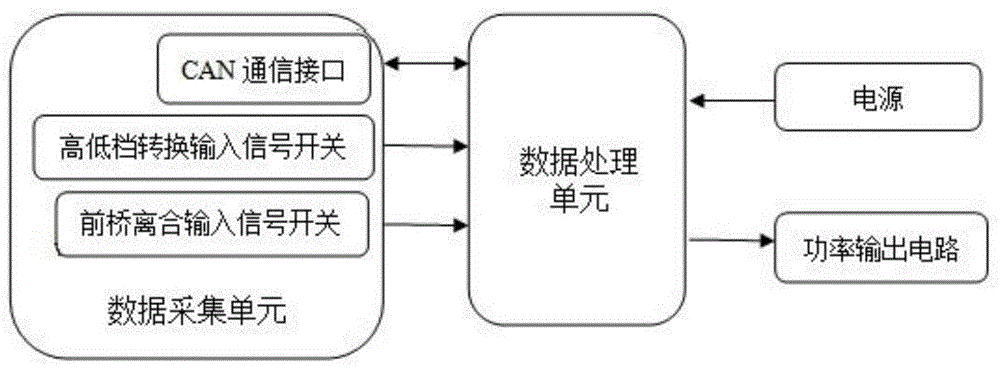

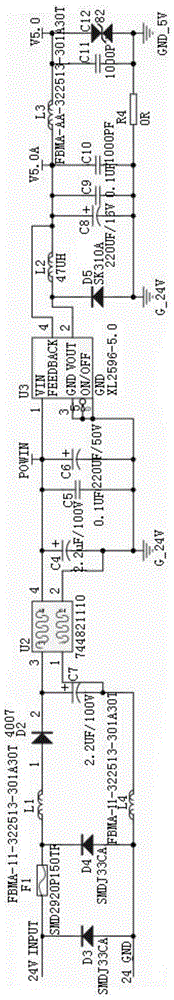

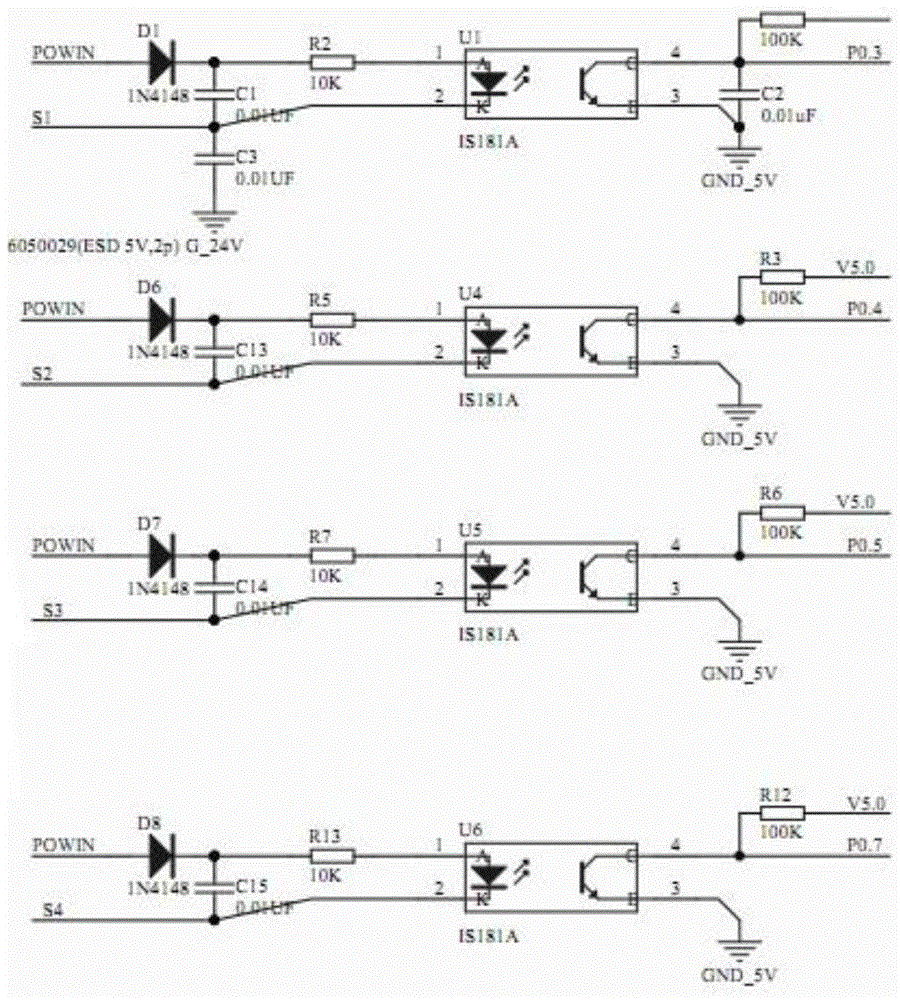

[0022] Such as figure 1 The shown electronic control device for an all-wheel drive transfer case includes a main control data processing unit, a data acquisition unit for signal acquisition, a power supply, and a power output unit connected to the data processing unit. The data acquisition unit includes a high-low gear conversion input signal switch, a front axle clutch input signal switch, and a CAN communication interface; the data processing unit is used to calculate and compare the collected data, and according to the calculation and comparison results The power of each channel is output through the power output unit. The schematic diagram of each part of the circuit is as follows Figure 2-Figure 6 shown.

Embodiment 2

[0023] Embodiment 2 The transfer control device described in Embodiment 1 implements the control method

[0024] a. High-end and low-end mode conversion:

[0025] Press the high and low shift switch button, when the corresponding high or low gear indicator lights up, the transfer case is in the high or low gear state, at this time release the control switch, the transfer case is in the high or low gear state.

[0026] The solenoid valve is controlled by the corresponding switch, and the high and low gear air circuit is used to realize the conversion of high and low gear. Figure 7 As shown, 1 inlet air, the pressure F pushes the two pistons to move to the left to the limit position, the piston pushes the fork shaft to the left, the fork handle is pushed to the left with the gear sleeve, and the gear sleeve is connected with the input shaft and the low gear at the same time. Engaged, power is transmitted through the low gear teeth, and the transfer case is in the low gear to c...

Embodiment 3

[0031] 1) The logic description of the control device described in Embodiment 1 is shown in Table 1

[0032] Table 1 Logic description table of the control device described in Embodiment 1

[0033]

[0034] 2) The wiring principle of the control device described in the present invention is as follows: Figure 9 and shown in Table 2

[0035] Table 2 Description of the wiring principle of the control device of the present invention

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com