Casting blank cutting control device, cutting system and cutting method based on programmable logic controller (PLC)

A control device and billet technology, applied in the direction of manufacturing tools, gas flame welding equipment, welding equipment, etc., can solve the problems of increasing exhaust gas emissions, environmental pollution, waste of gas and oxygen, etc., and achieve the effect of reducing pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

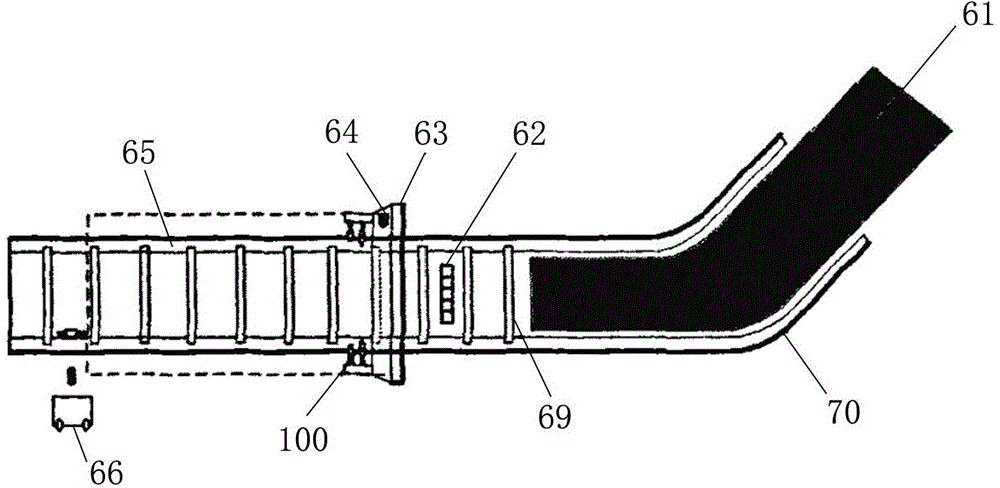

[0024] figure 1 is a schematic diagram of a continuous casting cutting device according to an embodiment of the present invention.

[0025] refer to figure 1 , the casting slab 61 can advance along the running track 65 under the drive of the roller table 69 . The automatic ignition cutting device according to the embodiment of the present invention (including parts such as the cutting torch body 100 ) can move on the slab 61 , for example, the cutting torch body 100 can be installed on the cart frame 63 . The cart frame 63 relies on the hydraulic system to move up and down, and can move horizontally along the running track 65 under the drive of the motor; the cutting gun body 100 is installed on the cart frame 63, and moves horizontally with the cart frame 63. Driven by the motor, it moves in a direction perpendicular to the longitudinal direction of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com