Overload protecting electric screw press

An electric screw, overload protection technology, applied in the direction of presses, punching machines, forging/pressing/hammering machines, etc., can solve the problems of no overload protection drive device, difficult manufacturing, complex structure, etc., to eliminate adverse effects , The effect of good coaxiality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

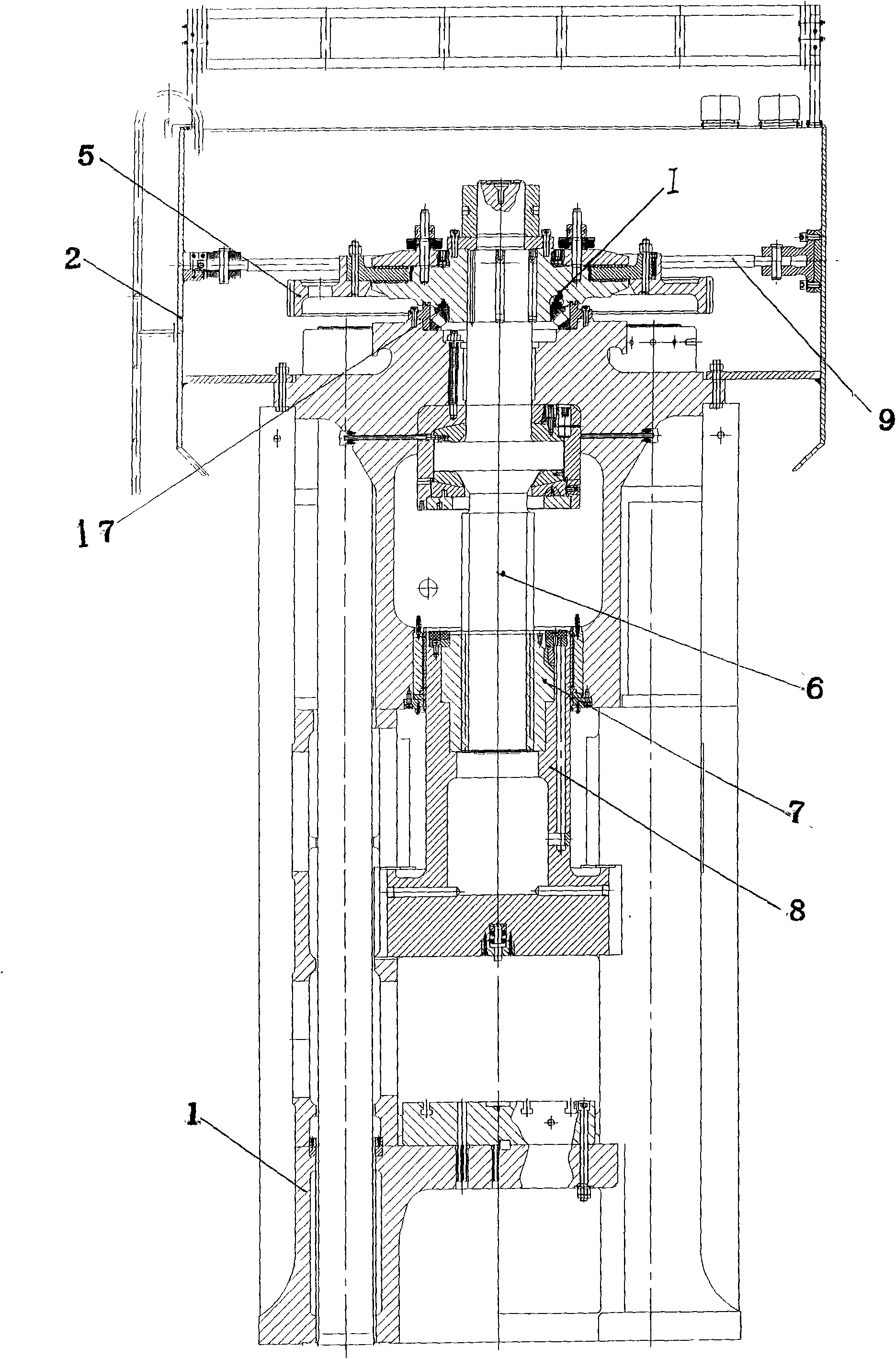

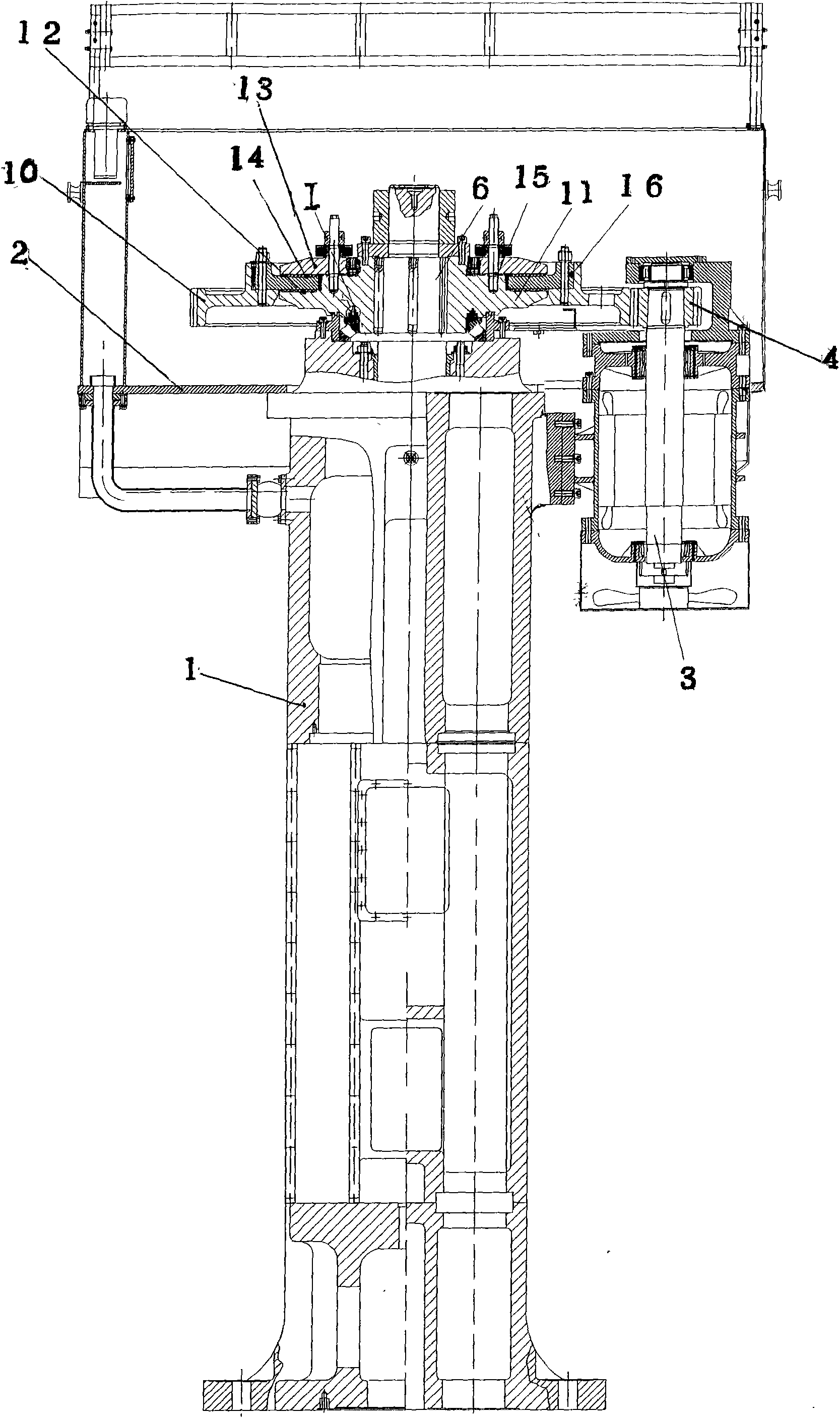

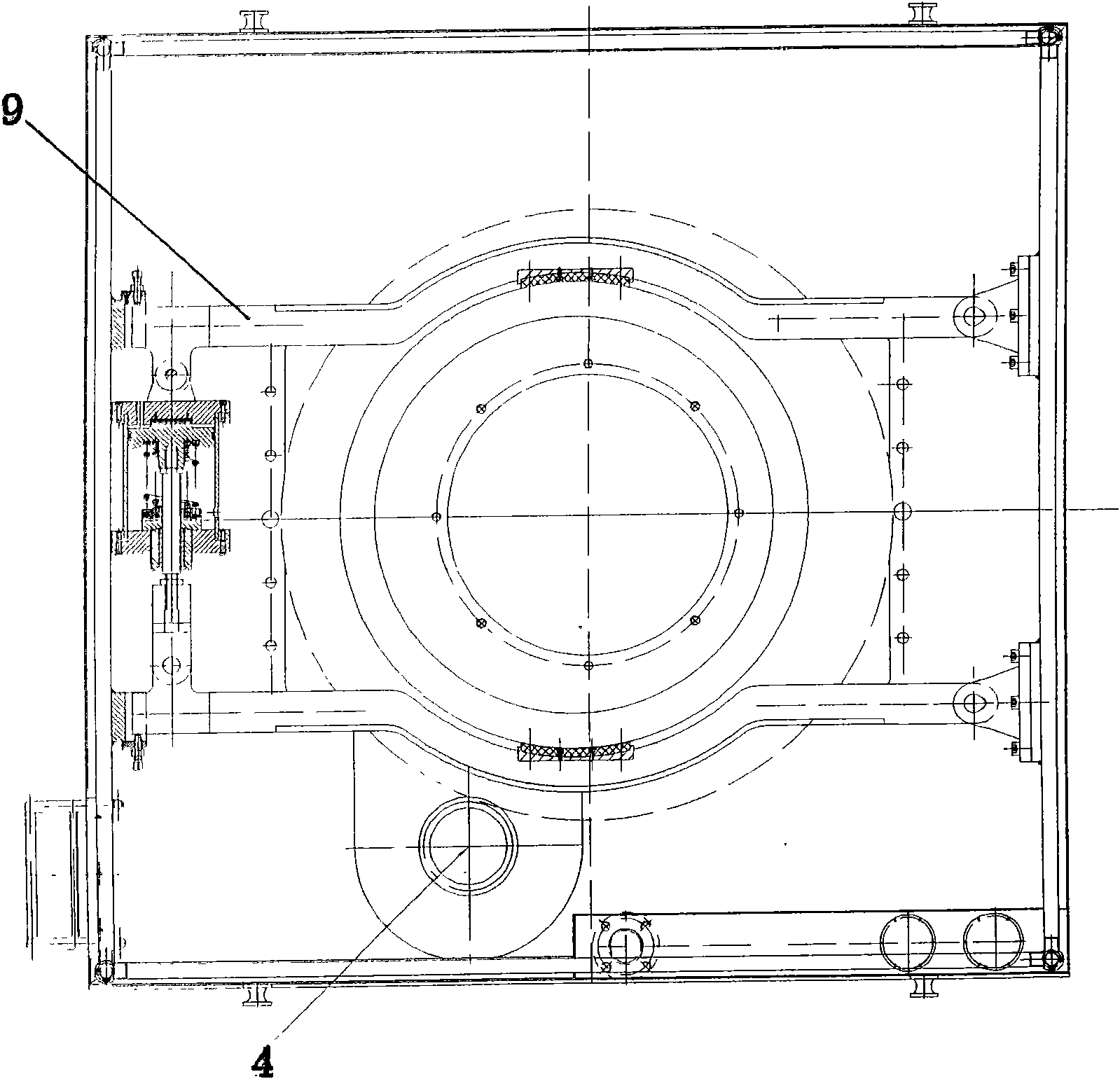

[0031] exist Figure 1 ~ Figure 4 Among them, the overload protection type electric screw press of the present invention includes a fuselage 1, a platform 2 installed above the fuselage, a special drive motor 3 placed vertically and installed on the beam of the fuselage, and directly installed on the output shaft of the special drive motor The small driving gear 4 on the top, the friction slip type large flywheel 5 driven by the small driving gear through gear meshing transmission, the screw rod 6 fixed on the flywheel through pins, the nut 7 driven by the screw rod, and the slider fixed with the nut 8. The outer brake shoe type brake 9 installed on the platform for braking the flywheel.

[0032] The overload protection type electric screw press of the present invention, said friction slip type large flywheel 5, comprises the tooth-shaped outer wheel body 10 driven by the small driving gear, the lower wheel body 11 fixed on the screw rod by pins, embedded in the lower wheel T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com