High-energy clutch screw press

A screw press and clutch technology, applied in the field of screw presses, can solve the problems of large installed capacity of electric screw presses, high use costs, large power grid impact, etc., and achieve significant energy-saving effects, high striking speed, and low power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

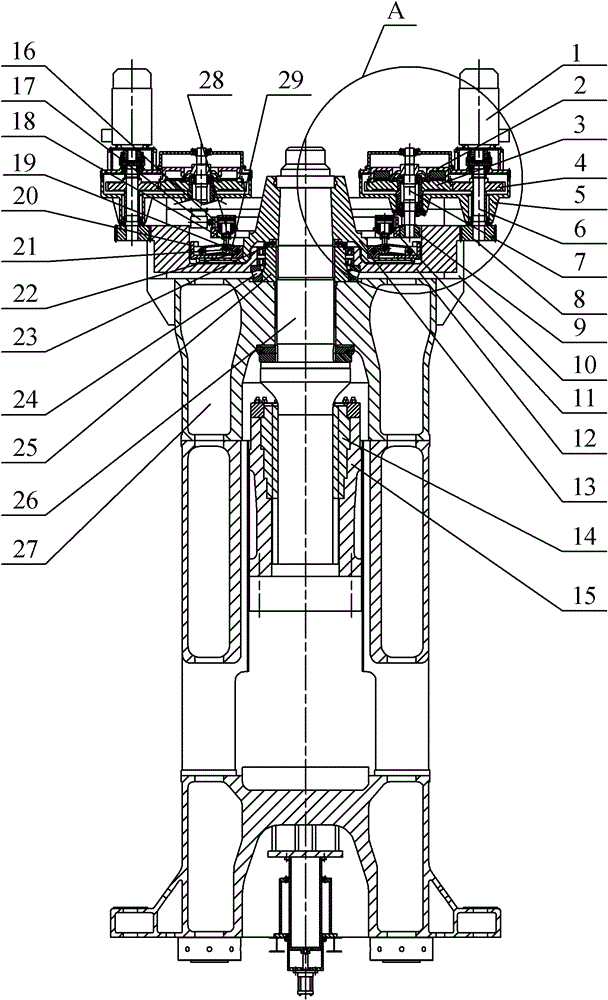

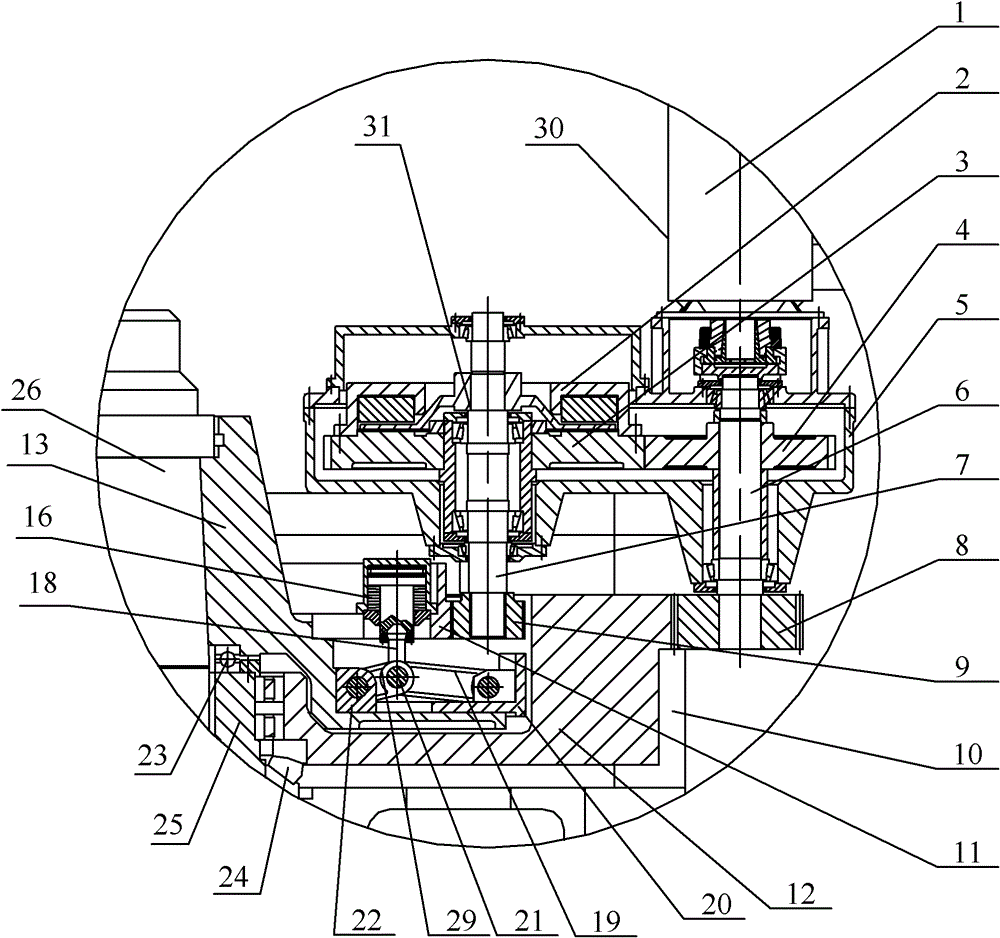

[0017] The present invention relates to a clutch screw press, see figure 1 , comprising a frame 27, a drive mechanism 30, a slide block 15 and a flywheel 12 arranged in the frame 27, the drive mechanism 30 is connected with the outer circle of the flywheel 12, and drives the flywheel 12 to rotate, and the flywheel 12 is For the flywheel with clutch, the frame 27 is also provided with a longitudinal movement disc 13, which is the longitudinal movement disc of the clutch, and the longitudinal movement disc 13 is connected with the slide block 15 through a screw pair. A nut 14 is fixed inside the slider 15 , and a screw rod 26 is fixed inside the longitudinal movement disc 13 , and the nut 14 is connected with the screw rod 26 to form a screw pair. The longitudinal disc 13 is also provided with a toggle clutch mechanism 28 and a return disc 11, the toggle clutch mechanism 28 is connected with the inner circle of the flywheel 12 through a friction block 20, and the outer circle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com