Airplane ground air-conditioning vehicle utilizing exhaust waste heat of diesel engine

A technology for diesel engines and air-conditioned vehicles, which is applied in ground installations, aircraft parts, vehicle parts, etc., can solve the problems of inability to provide continuous heating, poor heating effect, and low heating efficiency, and achieve good heating effect, good and instant heating. performance, low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

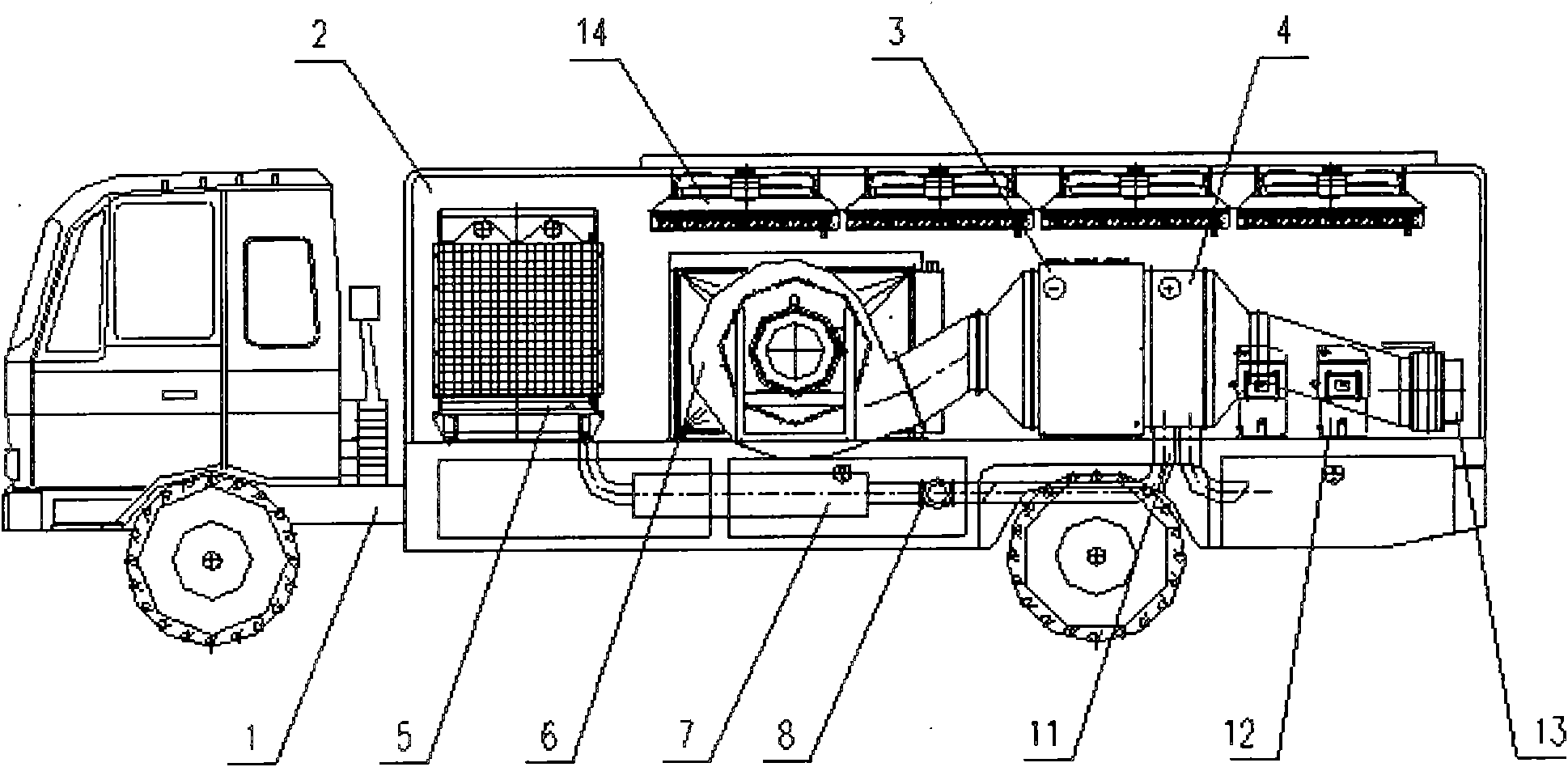

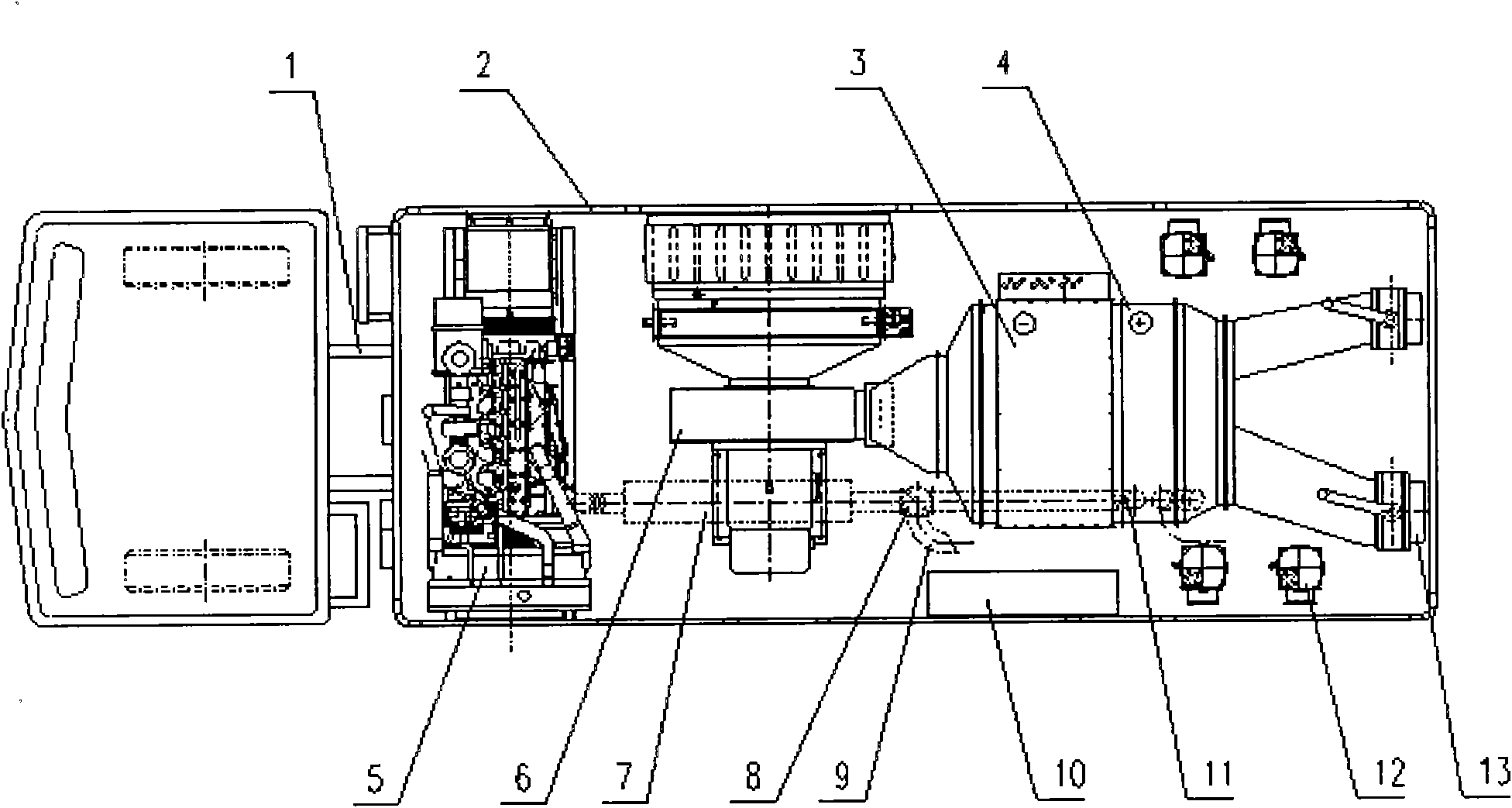

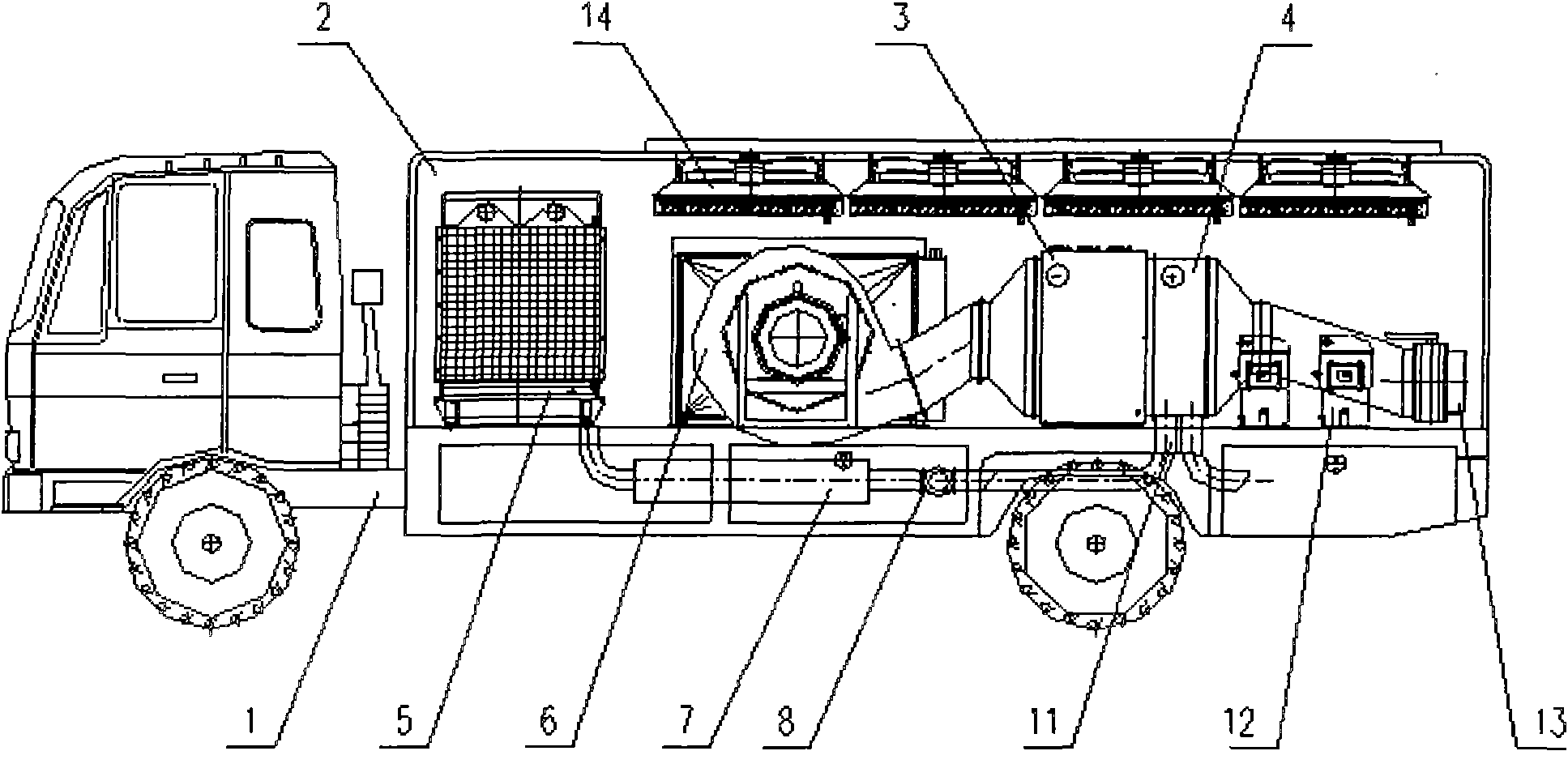

[0012] Such as figure 1 , 2 As shown, the aircraft ground air-conditioning vehicle utilizing diesel engine exhaust waste heat of the present invention mainly comprises chassis 1, and carriage body 2 is installed on chassis 1, and power supply power system, air pressurization conveying system, air cooling system, Air heating system and operation control system, diesel generator 5, fan 6, refrigeration compressor 12, refrigeration heat exchanger 3, air-cooled condenser 14, operation control cabinet 10, exhaust waste heat recovery heat exchanger 4, air supply pipe Interface 13, diesel engine exhaust muffler 7, exhaust connecting pipeline 11, exhaust three-way control valve 8, bypass exhaust pipeline 9.

[0013] The air pressurized conveying system includes a fan 6, the inlet of the fan 6 is connected to the air inlet installed on the wall of the car body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com