Patents

Literature

65results about How to "Act as overload protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

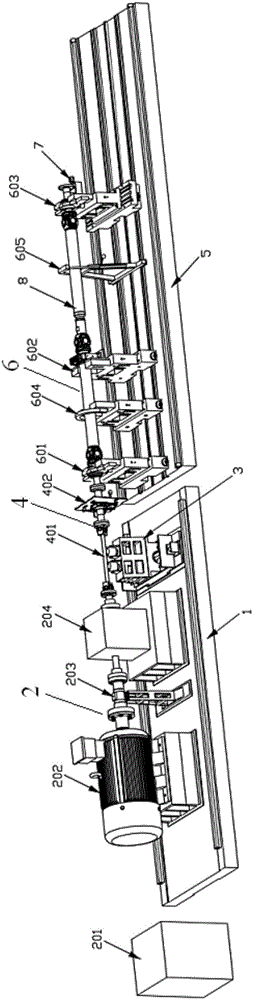

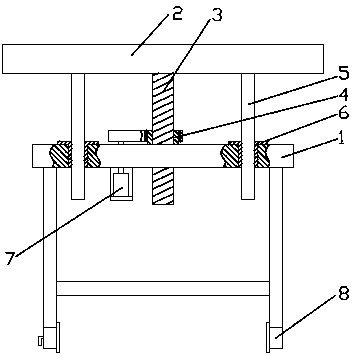

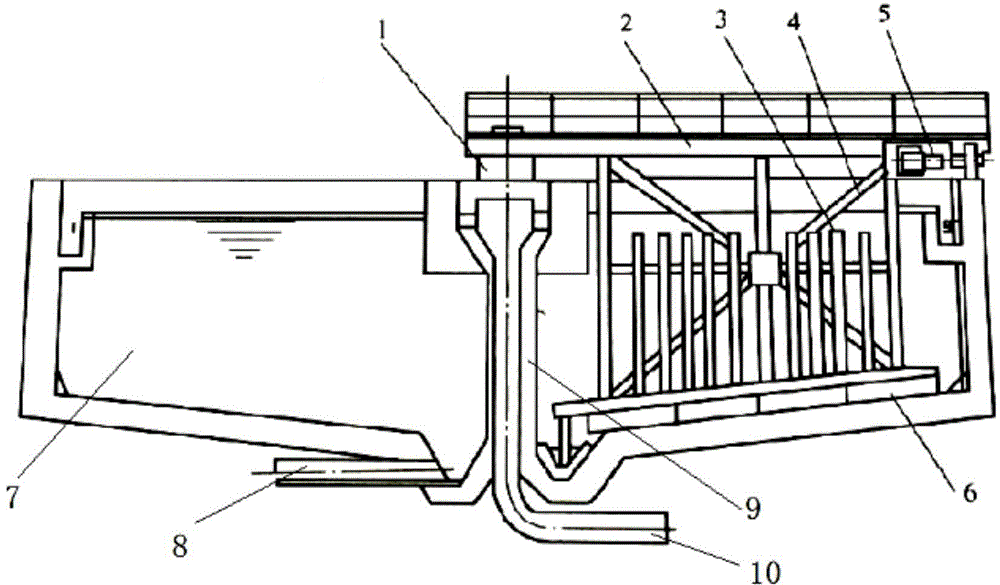

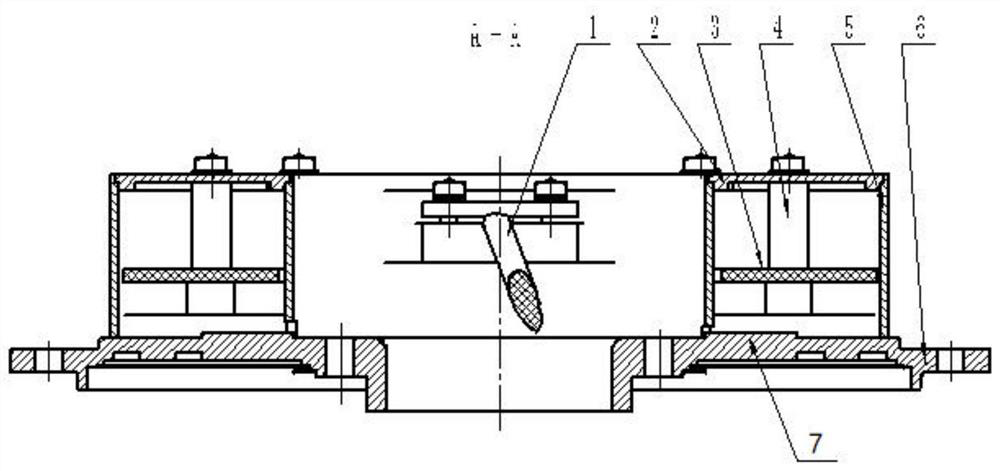

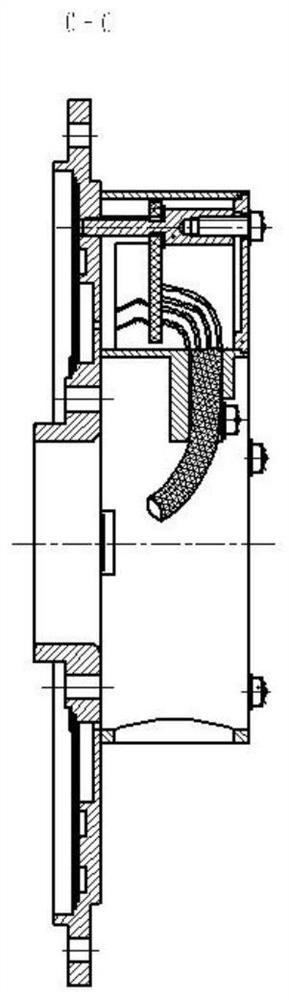

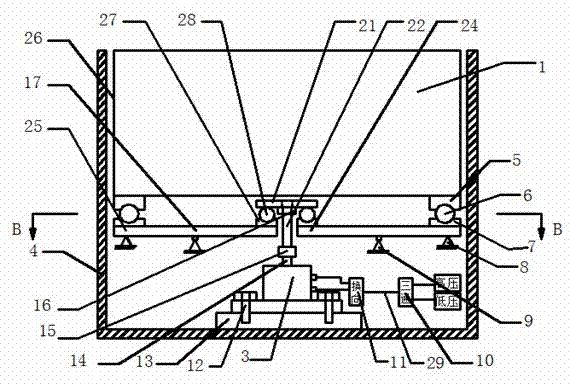

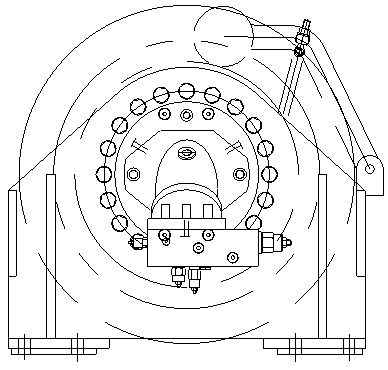

Actual-vehicle-simulated vibration test-bed for transmission shafts with different specifications

InactiveCN106226070ARealize measurementSolve the problem of single state variable of simulated real vehicleMachine gearing/transmission testingSupporting systemTest room

The invention relates to an actual-vehicle-simulated vibration test-bed for transmission shafts with different specifications and belongs to the actual-vehicle-simulated vibration test-bed for the transmission shafts with different specifications. A first rack and a second rack are fixed on the foundation of a test room side by side, the second rack is located at the right side of the first rack, a power output system is arranged on the first rack, a vibration excitation device is arranged on the first rack at the right side of a power output device, a safety braking system is arranged above the vibration excitation device, the left end of the safety braking system is connected with the power output system, the right end is fixedly connected with a first right end fixing cover of the first rack, a supporting system is arranged on the second rack, and a loading device is mounted at the tail end of the supporting system. The test-bed has the advantages that the measurement on the vibration of a transmission shaft assembly is realized, and the defect that most of traditional vehicle transmission shaft vibration test-beds cannot sufficiently perform corresponding simulation tests according to different vehicle model parameters and road conditions and cannot quickly adjust angles of the transmission shafts is overcome.

Owner:JILIN UNIV

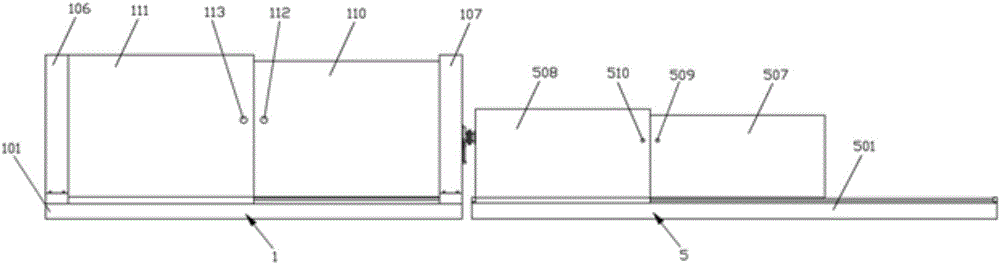

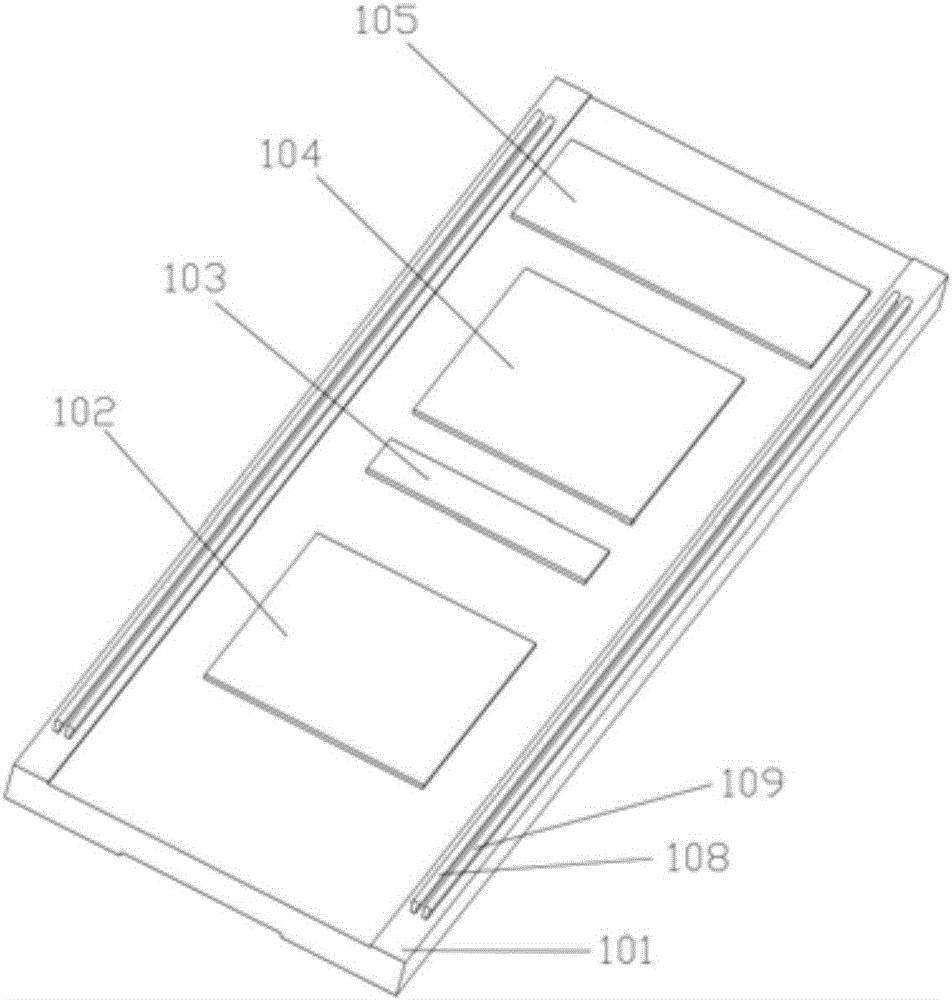

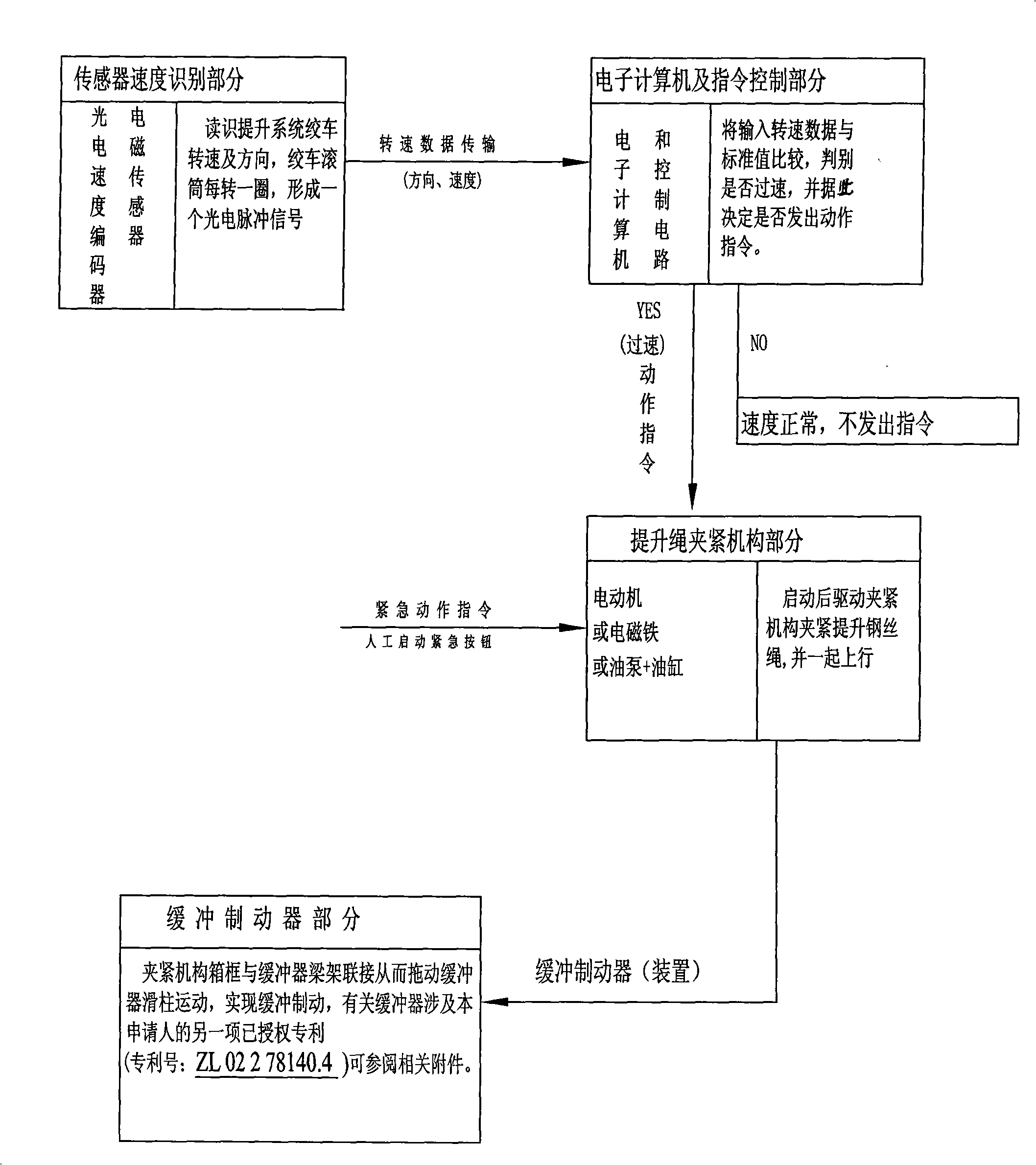

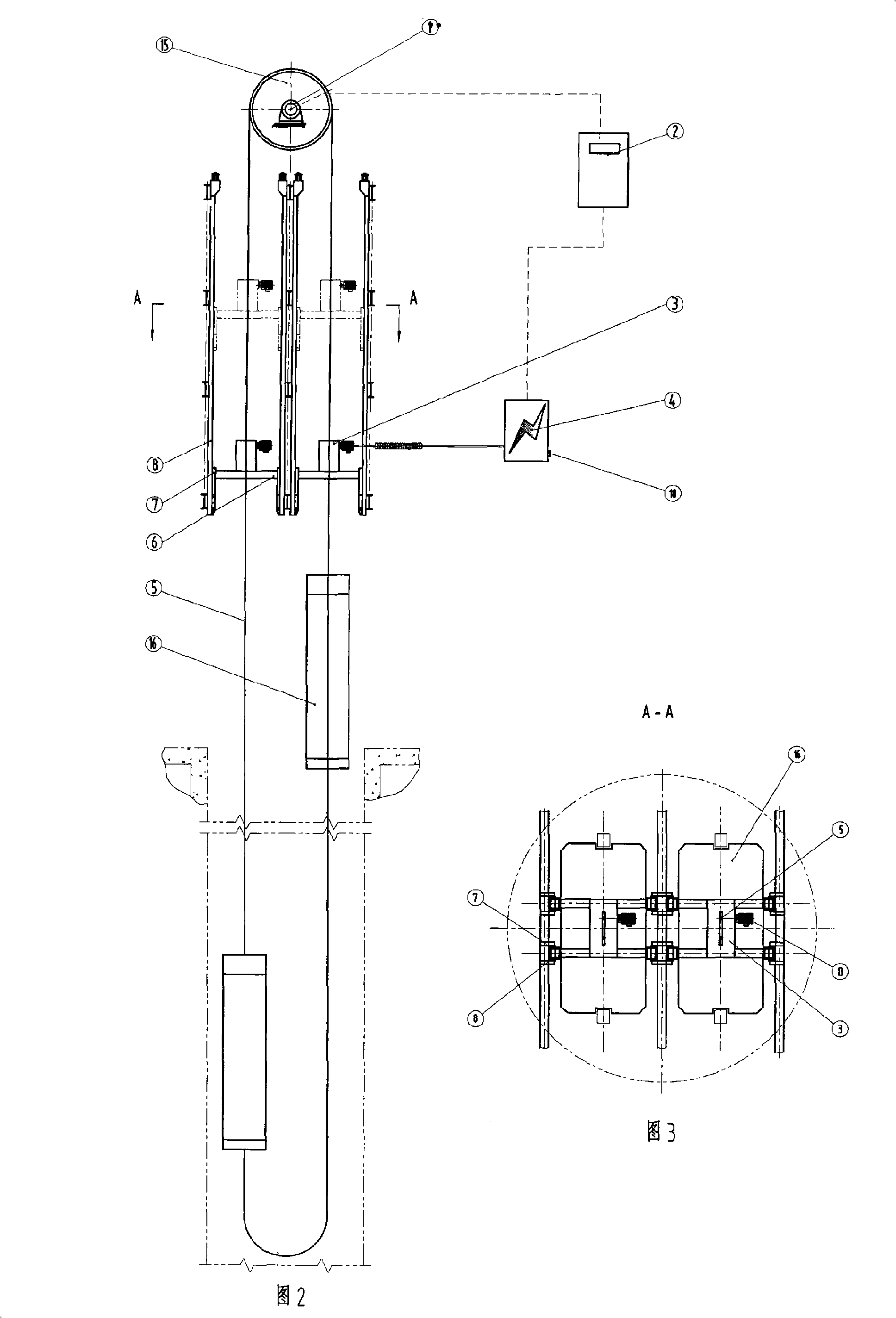

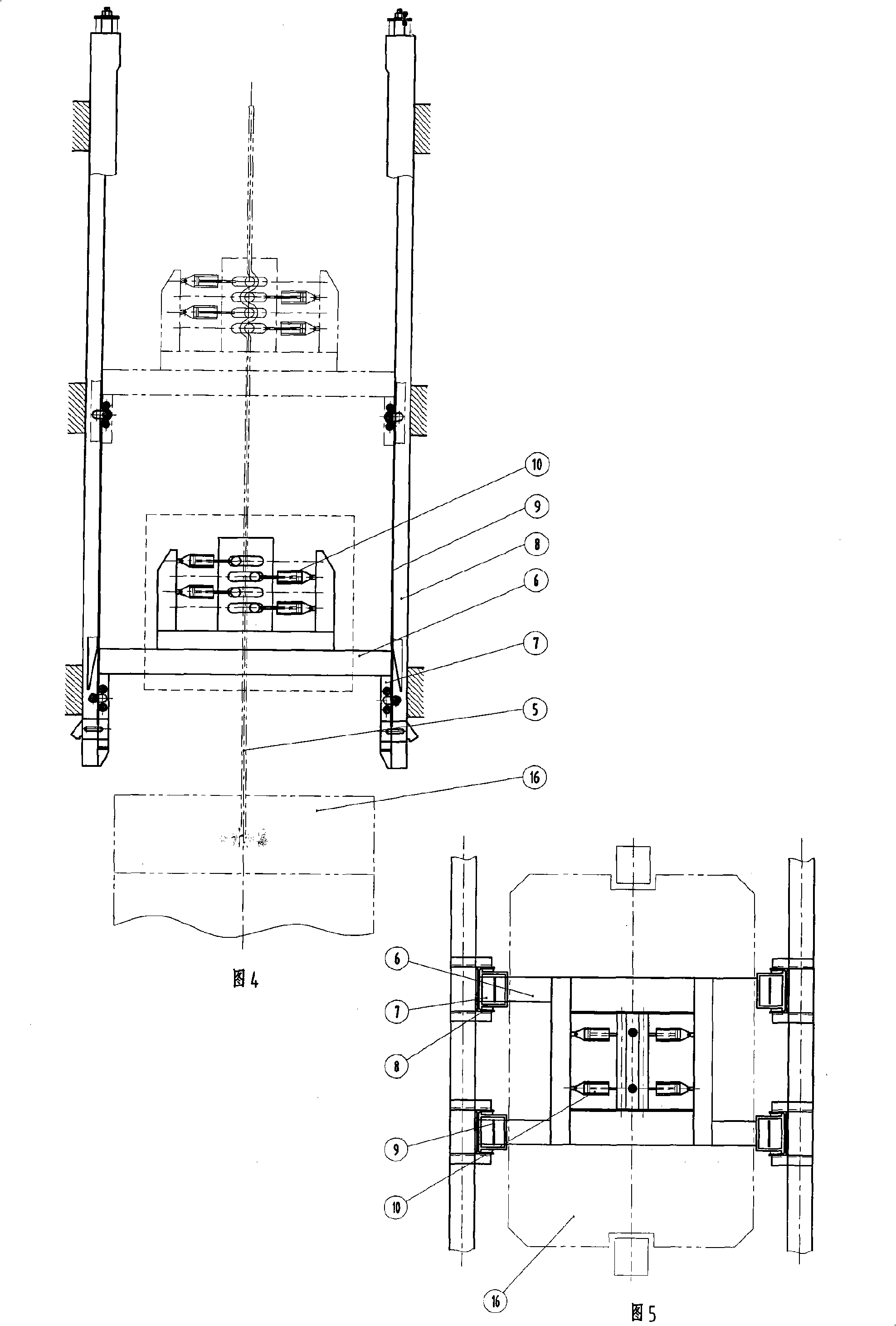

Rope type flexible hoisting overspeed overtravel protection buffering braking system

ActiveCN101402438ASmooth brakingAvoid failureWinding mechanismsElectromagnetic inductionBraking system

The invention discloses a rope flexible hoisting overspeed overwinding protection buffer braking system. A photoelectric encoder and / or an electromagnetic induction sensor of the system are / is connected with a computer control cabinet; the computer control cabinet is connected with a dynamic control cabinet of a clamping mechanism; the dynamic control cabinet is connected with a hoisting rope clamping mechanism, and the clamping mechanism is connected with a buffer device. If a hoisting machine runs with overspeed, mechanisms of the system can generate linkage action; finally the dynamic control cabinet controls the hoisting rope clamping mechanism, and allows the hoisting rope clamping mechanism to act on a press roll set so as to change the relative positions among the press roll set and clamp a hoisting wire rope passing through the press roll set; and the clamping mechanism is connected with a cross beam of the buffer device, thereby achieving the compulsory buffer braking of a hoisting container. The system is sensitive and reliable; and once the hoisting speed exceeds the set value, a loading mechanism (loading press roll set) acts immediately, so as to avoid the failure of a buffer braking device on the hoisting cycle terminal due to the fact that overspeed exceeds the applicable range of the speed, thereby preventing serious hoisting accidents caused by the overspeed overwinding, overspeed driving, and the like.

Owner:WUHAN YUNZHU ELECTROMECHANICAL NEW TECH DEV CO LTD

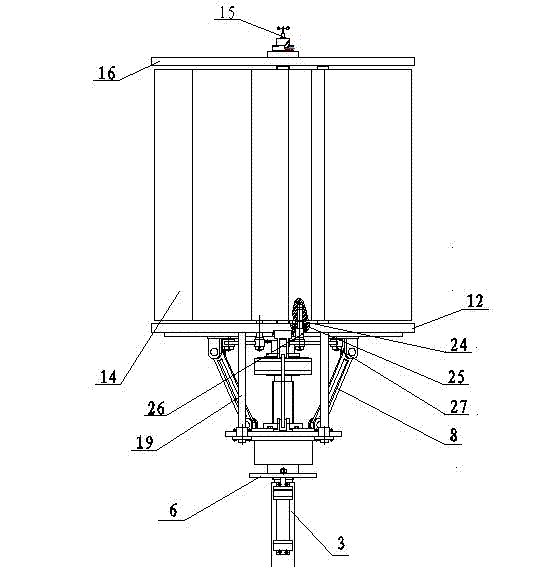

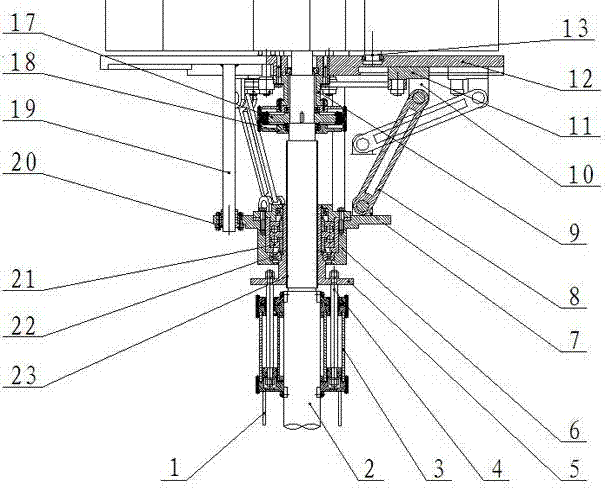

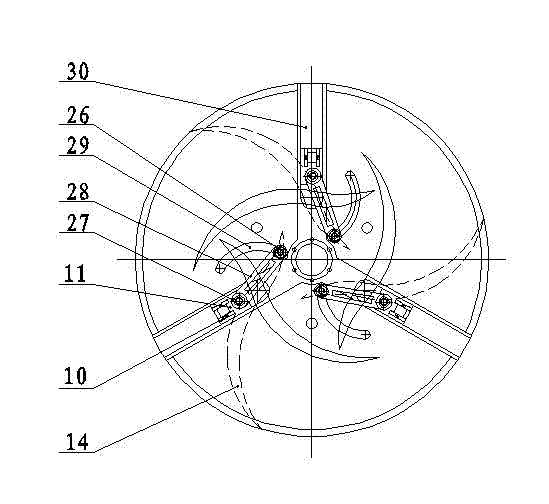

Vertical axis wind wheel connecting rod combination variable pitch wind power generation device

InactiveCN103089548AAdjustability of sweeping areaAdjust the sweeping areaWind motor controlWind motor combinationsBlade plateVertical axis wind turbine

The invention relates to an adjustable wind power generation device, namely a vertical axis wind wheel connecting rod combination variable pitch wind power generation device. The vertical axis wind wheel connecting rod combination variable pitch wind power generation device includes a lower support plate, an upper support plate which are sleeved on the central shaft of the wind wheel, and a wind wheel blade plate which arranged between the upper support plate and the lower support plate. A power generation rotor is fixedly connected with the lower supporting plate, and the stator is fixed on the central shaft of the wind wheel. A blade plate support shaft is arranged between the upper support plate and the lower support plate, and the wind wheel blade plate is arranged on the blade plate support shaft and rotates around the blade plate support shaft. A variable pitch system capable of adjusting the working position of the wind wheel blade plate is arranged on the central shaft of the wind wheel. The vertical axis wind wheel connecting rod combination variable pitch wind power generation device can effectively lower the rotating speed of the wind wheel, reduced the wind energy conversion rate of the vertical axis wind wheel, and achieves the overload protection for a permanent magnet generator.

Owner:HENAN UNIV OF SCI & TECH

Traction method and system for rail transportation

The invention relates to a traction method and a system for rail transportation. A soft elastic composite material is used as an elastic vibration-damping structure; a center pivot block is connected with a traction pin by an elastic nylon center pin sleeve, and the nylon sleeve with certain elasticity avoids the rigid shock between the center pivot block and the traction pin and simultaneously realizes the unconstrained rotation between the traction pin and the center pivot block when a vehicle makes a turning; two traction pads are respectively arranged in the front and at the back between the center pivot block and a bogie frame in the traction direction, the traction pads are rubber-metal compound elastic elements, two end plates of the traction pads are respectively provided with a connecting pin, and the connecting pin on the traction pad is directly inserted into a connecting hole for the center pivot block and the bogie frame; and the two traction pads connect the center pivotblock and the bogie frame, transfer traction force and brake force and buffer the shock load in transverse direction, vertical direction and other directions, so that the vehicle has better dynamicalperformance in operation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Moving type automatic-adjustment steel jacking and pushing device

InactiveCN104355268ABurn out preventionImprove practicalityWelding/cutting auxillary devicesLifting framesEngineeringMechanical engineering

The invention discloses a moving type automatic-adjustment steel jacking and pushing device, and belongs to the field of steel conveying devices. The moving type automatic-adjustment steel jacking and pushing device comprises a support base, a jacking platform and a screw rod, wherein one end of the screw rod is fixedly connected with the jacking platform; the other end of the screw rod is sleeved by a screw nut and is in threaded connection with a support base; a motor is arranged on the support base; the output shaft of the motor is in transmission connection with a screw nut belt; two guide holes are formed in the support base; bushings are arranged inside the guide holes; the jacking platform is connected with two guide rods which respectively extend into the bushings; rollers with brake plates are connected to the bottom of the support base. With guidance of the guide rods, the jacking and the conveying are relatively stable and reliable, materials can be fed into different pieces of equipment, different welding heights are met, the welding quality is ensured, the applicability is high, and due to belt transmission, not only is relatively accurate height achieved, but also an overload protection function is achieved.

Owner:SICHUAN HUATIE STEEL STRUCTURE

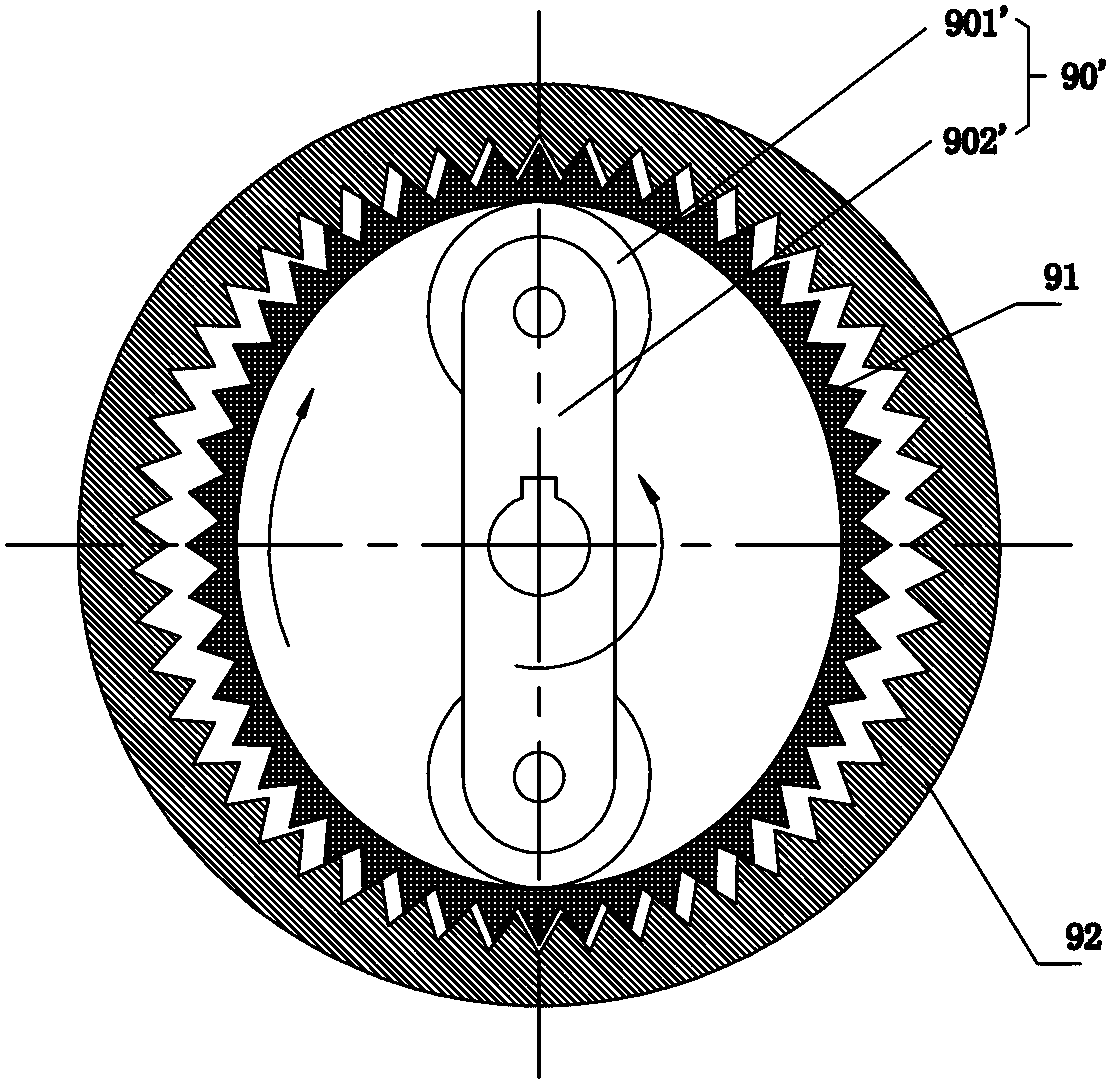

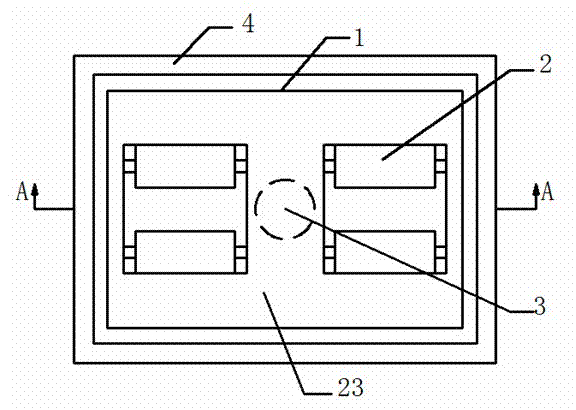

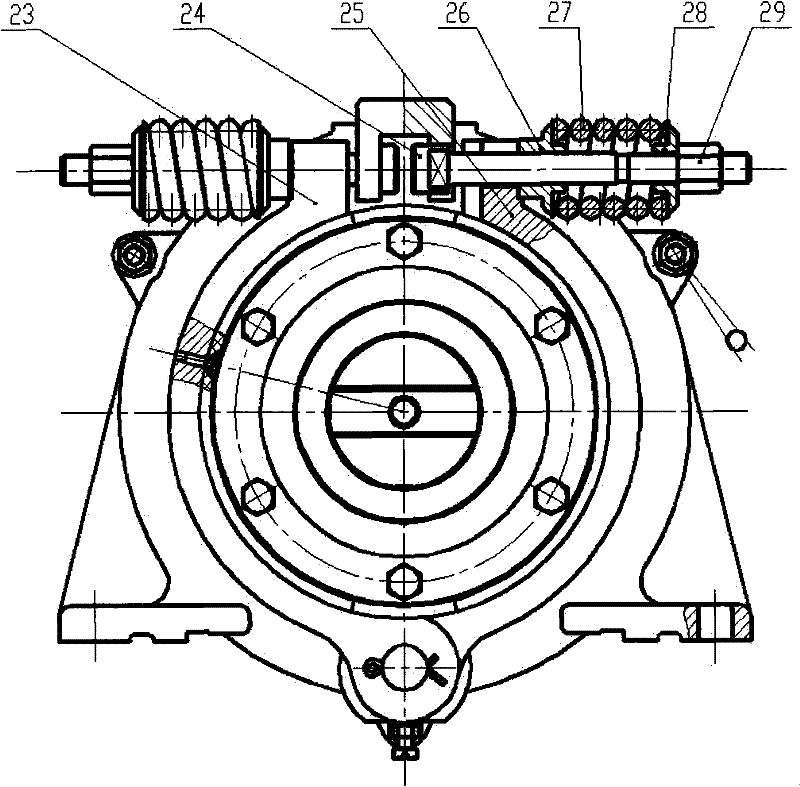

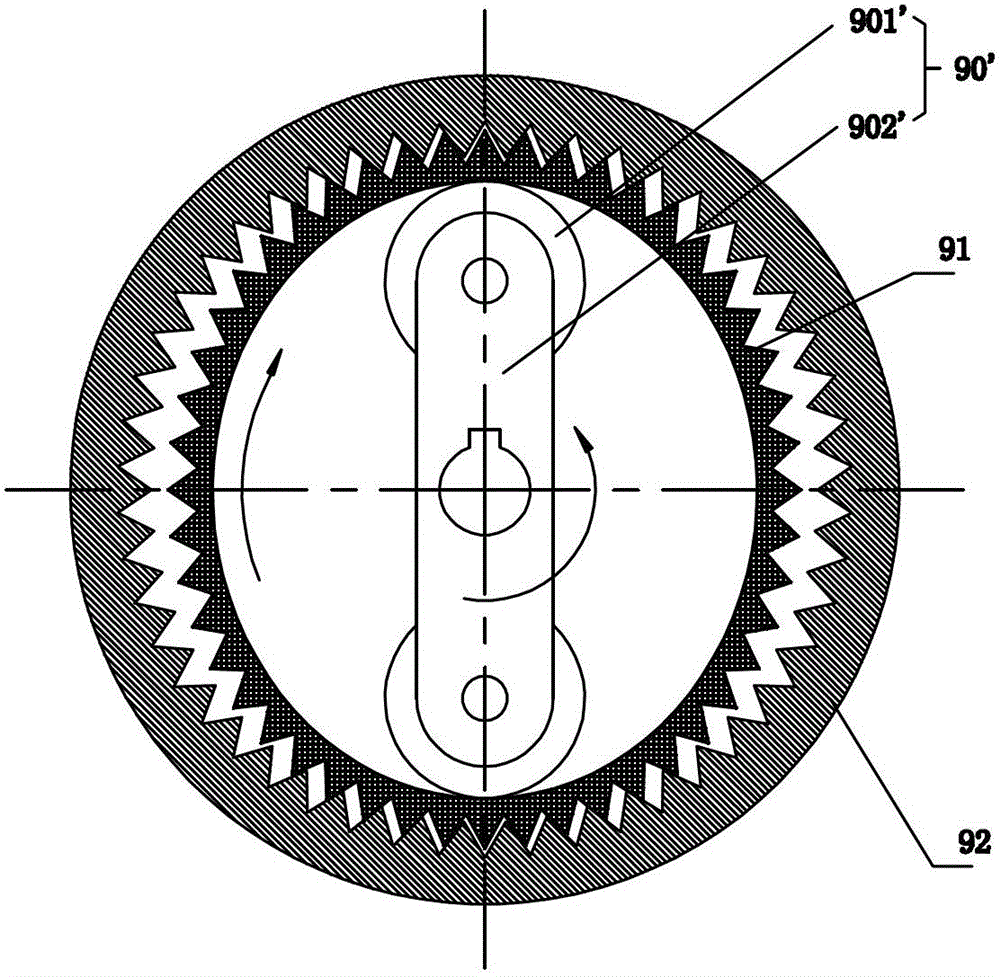

Method for reducing drive eccentric errors of harmonic gear and automatic aligning wave generator

The embodiment of the invention discloses a method for reducing drive eccentric errors of a harmonic gear and an automatic aligning wave generator. The automatic aligning wave generator comprises a turn plate driven by an input shaft and an elastic floating mechanism provided with two rollers. The elastic floating mechanism is flexibly arranged inside the turn plate in a sliding manner in the long axis direction of the automatic aligning wave generator. The elastic floating mechanism comprises two roller brackets symmetrically distributed relatively to the centre of the turn plate and an elastic element arranged between the roller brackets; the elastic element elastically resists against the two roller brackets, and the two rollers are respectively arranged on the two roller brackets, elastically resist against an inner circle of a flexible gear under the action of the elastic element and force the flexible gear to form an ellipse from a round shape, so that gear teeth of the flexible gear are tightly meshed with gear teeth of a rigid gear. The automatic aligning wave generator can reduce the eccentric errors caused by processing and assembling of parts, can remove the gear backlash between the gear teeth of the flexible gear and the gear teeth of the rigid gear and play an overload protection role.

Owner:深圳市东汇精密机电有限公司

Coal mining machine and travel unit overload protective device thereof

The invention provides a coal mining machine and a travel unit overload protective device thereof. The travel unit overload protective device of the coal mining machine comprises a first connecting piece, a second connecting piece and a friction piece, wherein the first connecting piece is connected with a low-speed end of a transmission system of a traction unit of the coal mining machine; the second connecting piece is connected with a travelling wheel of the travel unit of the of the coal mining machine; and friction surfaces of the friction piece are respectively tightly pressed on the first connecting piece and the second connecting piece, so that the first connecting piece and the second connecting piece can be in overload slipped connection with each other. The travel unit overload protective device of the coal mining machine has the beneficial effects that when the overload phenomenon occurs, the first connecting piece and the second connecting piece can slip to realize overload protection, so that overload protection parts can not be damaged; and as the first connecting piece is connected with the low-speed end of the transmission system of the traction unit of the coal mining machine, the overload protection effect can be played within the shortest time, so that damage to transmission parts and components due to overload can be avoided.

Owner:SANY HEAVY EQUIP

Highly-applicable rolled steel conveying device matched with conveying height

InactiveCN104355102AStable and reliable jacking and conveyingGuarantee welding qualityConveyor partsLeather beltEngineering

The invention discloses a highly-applicable rolled steel conveying device matched with the conveying height, and belongs to the field of rolled steel conveying devices. The highly-applicable rolled steel conveying device comprises a supporting seat, a jacking table, and a screw, wherein one end of the screw is detachably connected with the jacking table, and the other end is sleeved with a nut and in threaded connection with the supporting seat; a motor is arranged on the supporting seat; an output shaft of the motor is in belt driving connection with the nut; two guide holes are formed in the supporting seat; bushes are arranged in the guide holes; the jacking table is detachably connected with two guide rods which respectively extend into the bushes; a positioning rod is arranged on the supporting seat; a hard stop block is detachably arranged on the positioning rod; a damper is arranged at the lower end of the hard stop block. With guiding of the guide rod, the jacking and conveying operation can be more stable and reliable; the height of the hard stop block can be correspondingly arranged according to different conveying heights, and the jacking table is raised to the required height, and then is propped against the hard stop block for positioning, so that the applicability is greatly improved, and the jacking table can be correspondingly dismounted and replaced according to different types of the rolled steel.

Owner:SICHUAN HUATIE STEEL STRUCTURE

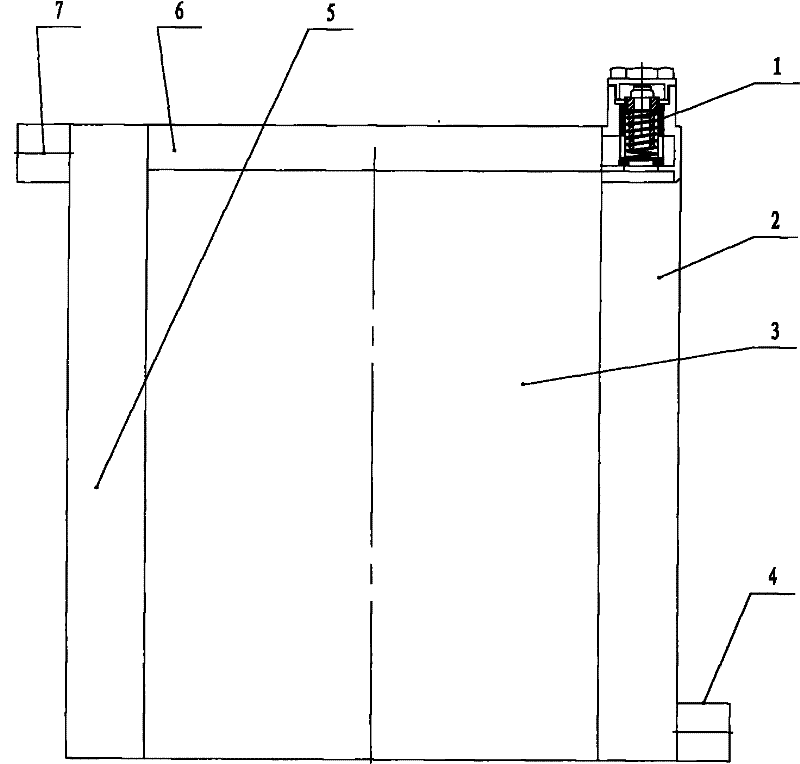

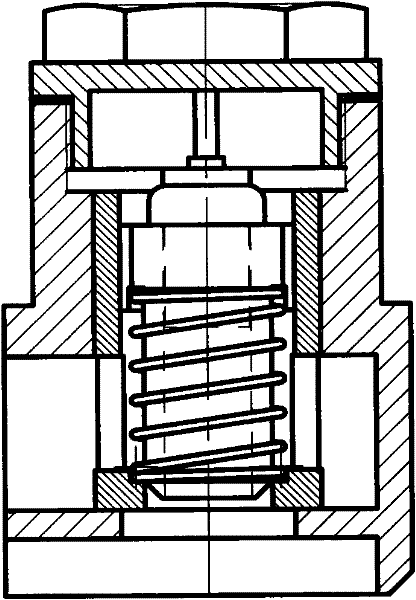

Plate-fin heat exchanger with pressure-temperature control valve

InactiveCN102192665APlay the role of low temperature overload protectionIncrease temperatureStationary conduit assembliesHeat exchange apparatusEngineeringHigh pressure

The invention relates to a plate-fin heat exchanger with a pressure-temperature control valve. The heat exchanger comprises a core body, a first end enclosure, a second end enclosure and a by-pass pipe, wherein the first end enclosure, the core body and the second end enclosure are connected sequentially; the first end enclosure is provided with an oil inlet; the second end enclosure is provided with an oil outlet; and the first end enclosure and the by-pass pipe are communicated through the pressure-temperature control valve. The plate-fin heat exchanger provided by the invention simultaneously has the capabilities of low-temperature overloading protection and instant high-pressure overloading protection, and is good in reliability and long in service life.

Owner:WUXI MAIXIN TECH INDAL

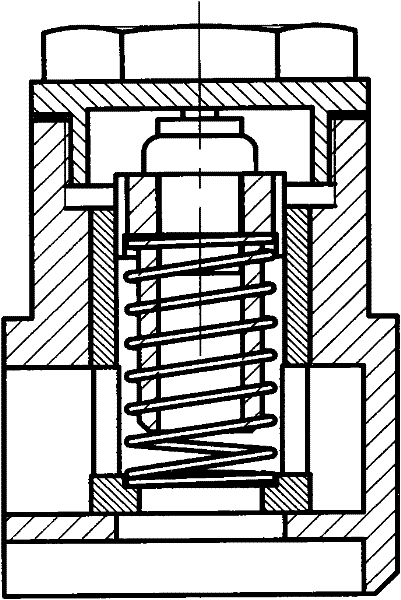

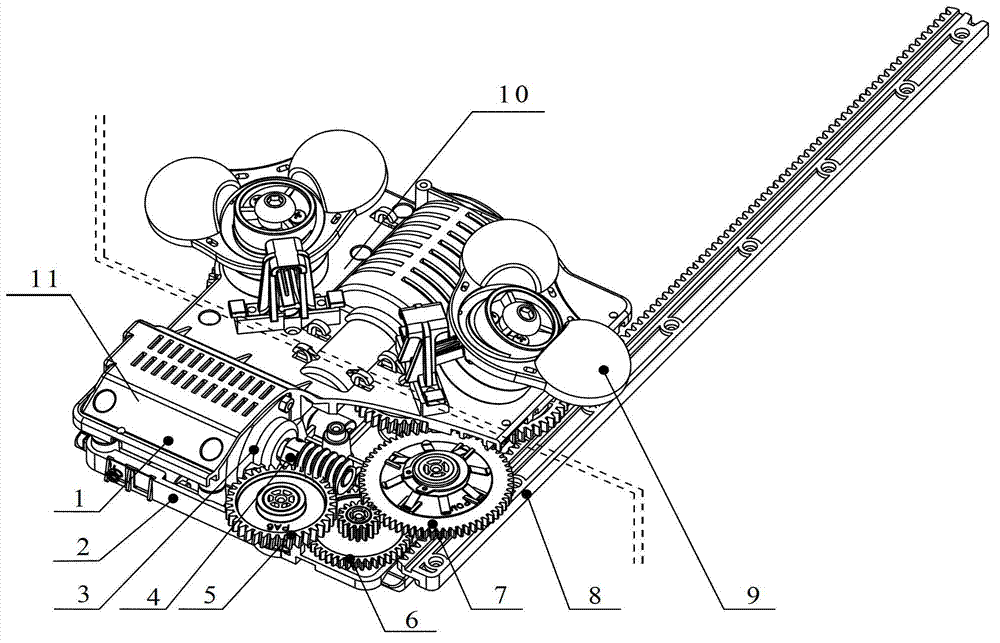

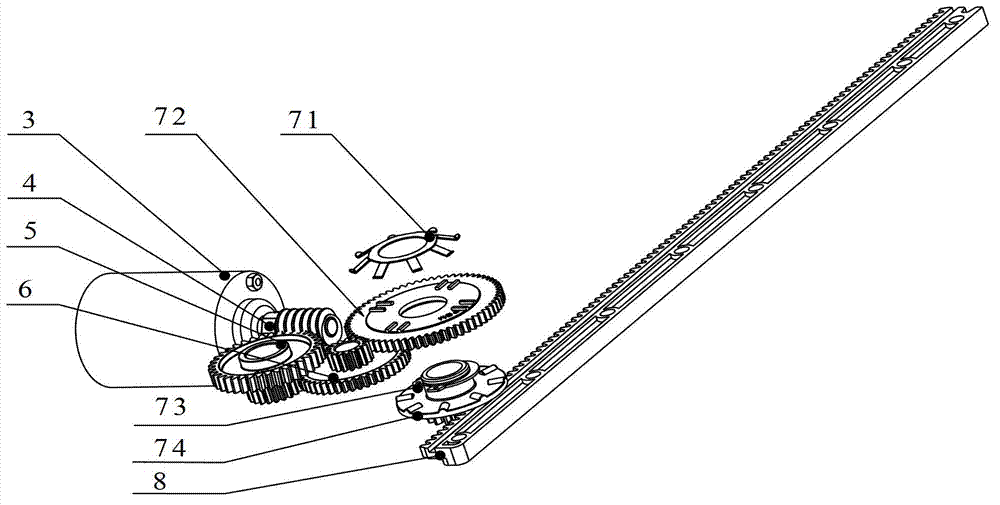

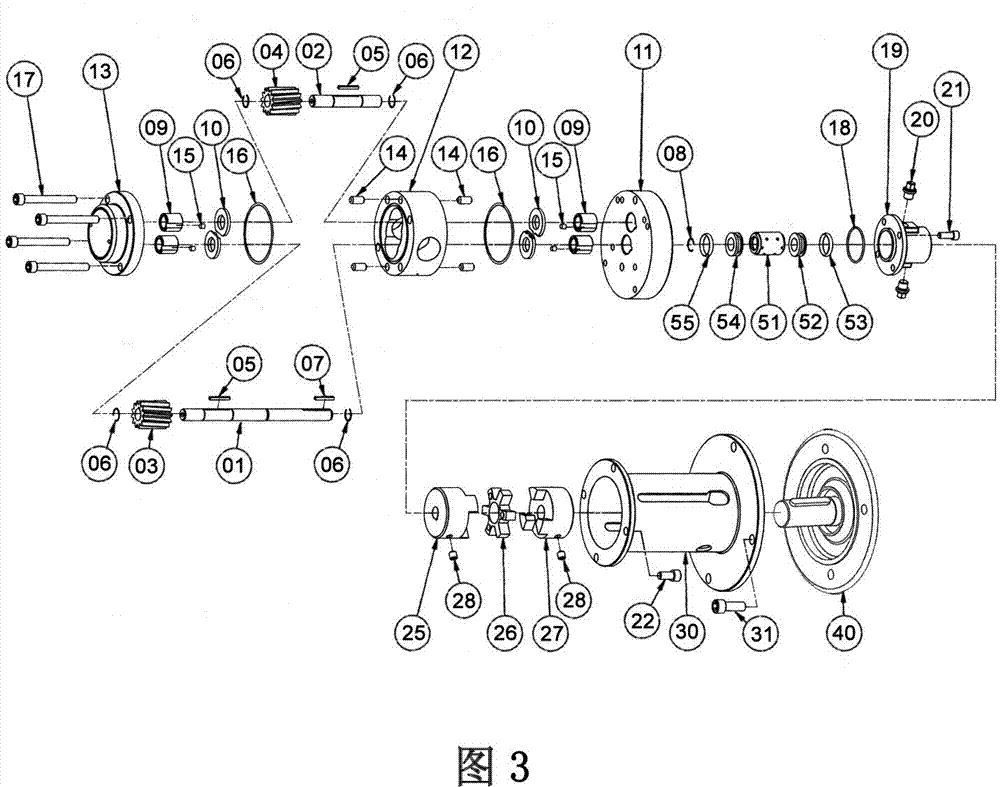

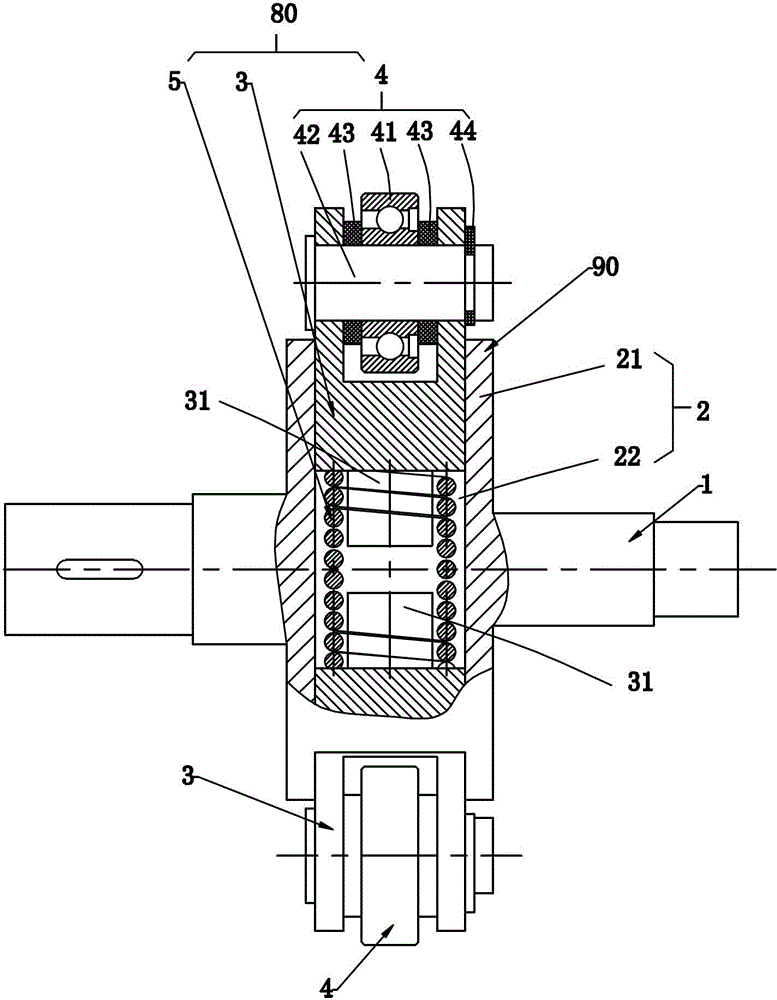

Machine core overload protection device used on massager

ActiveCN102813594AEliminate potential safety hazardsExtended service lifeDevices for pressing relfex pointsSuction-kneading massageClutchEngineering

The invention belongs to the technical field of a massage chair and particularly relates to a machine core overload protection device used on a massager. The device comprises a traveling driven gear wheel and a traveling meshing pinion; the traveling driven gear wheel is sleeved on an extension shaft of the traveling meshing pinion and then a belleville spring is also sleeved on the extension shaft; the traveling driven gear wheel is squeezed by the belleville spring, so that radial grooves arranged on the lower end face of the traveling driven gear wheel are matched with radial convex semicylinders arranged on the upper end face of the traveling meshing pinion; and finally, the belleville spring and the traveling driven gear wheel are subjected to axial limiting by an axial elastic check ring. Under the overload condition, the traveling meshing pinion and the traveling driven gear wheel on an overload clutch device are in coaxial departure connection, so that a machine core traveling transmission device of the massager drives the traveling driven gear wheel on the overload clutch device to idle, and thus, the protection effect on a rack and a machine core of the massager is achieved and the overload protection effect and the protection mechanism are improved.

Owner:SHANGHAI RONGTAI FITNESS TECH DEV CO LTD

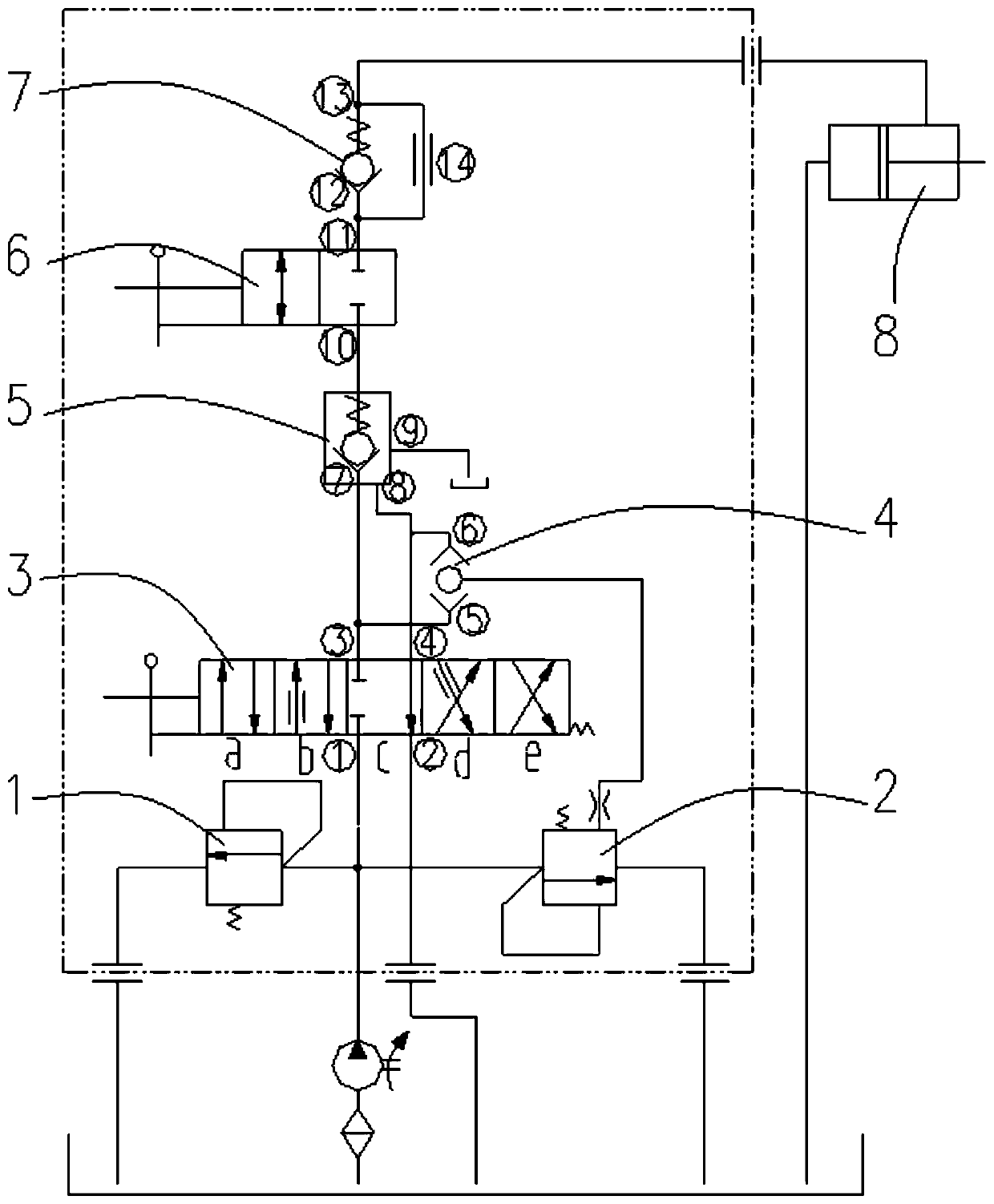

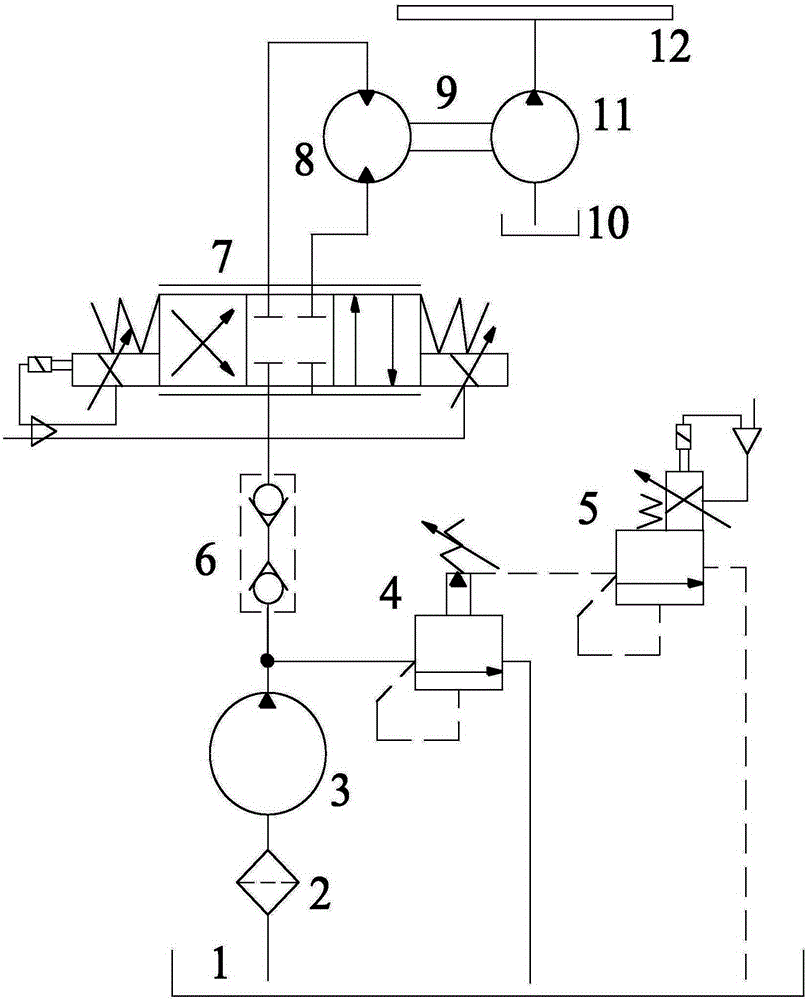

Multifunctional valve used for controlling seedling table of rice transplanter to rise and fall

PendingCN109779996AAct as overload protectionDouble protectionServomotor componentsFluid-pressure actuator componentsFuel tankEngineering

The invention belongs to the technical field of rice transplanters, and particularly relates to a multifunctional valve used for controlling a seedling table of a rice transplanter to rise and fall. The multifunctional valve used for controlling the seedling table of the rice transplanter to rise and fall comprises a reversing valve, a shuttle valve, a hydraulic-control one-way valve, a stop valve, a one-way throttling valve and a lifting oil cylinder, wherein the reversing valve, the shuttle valve, the hydraulic-control one-way valve, the stop valve, the one-way throttling valve and the lifting oil cylinder are connected in sequence. The reversing valve is a five-position and four-way reversing valve. A first oil outlet of the reversing valve communicates with a first oil port of the shuttle valve and a main oil path of the hydraulic-control one-way valve. A second oil outlet of the reversing valve communicates with a second oil port of the shuttle valve and an auxiliary oil port of the hydraulic-control one-way valve. An unloading valve is connected to an oil outlet of the shuttle valve. A throttling pressure-relief hole communicating with the auxiliary oil port of the hydraulic-control one-way valve is formed in the hydraulic-control one-way valve and is connected with an oil tank. The reversing valve has a rising position, a throttling rising position, a middle position, athrottling falling position and a falling position. An oil outlet of the one-way throttling valve communicates with a cavity of the lifting oil cylinder, and the other cavity of the lifting oil cylinder communicates with the oil tank. The reversing motion of the reversing valve controls the lifting oil cylinder to rise and fall.

Owner:江苏沃得高新农业装备有限公司

Peripheral transmission concentration mud scraper

The invention discloses a peripheral transmission concentration mud scraper which comprises a pond body, a center rotating support, a main beam, a transmission device and a scraper plate, wherein the pond body is of a half-straddle type structure, a center upright and a water inlet pipe are arranged in the middle of the pond body, the water inlet pipe and the center upright are arranged in parallel, the center rotating support is arranged at the upper end of the center upright, one end of the main bam is connected with the center rotating support, the transmission device is arranged at the other end of the main beam, the transmission device is connected with a hinged scraping arm, the bottom of the hinged scraping arm is connected with the scraping plate, and vertical gird bars are arranged on the scraping plate. The peripheral transmission concentration mud scraper is simple in structure; water enters from the center and is discharged from the periphery, and mud is discharged from the bottom of the center, the vertical grids mainly play roles in slow carding and coagulating, so that the sludge compactness is improved. By adopting the hinged scraping arm, the effect of overload protection is played, the operation cost is effectively lowered; a truss girder is light in mass and good in rigidity; the scraper plate is arranged spirally, so that the mud scraping effect is relatively good.

Owner:CHANGZHOU LIWEI KNIFE

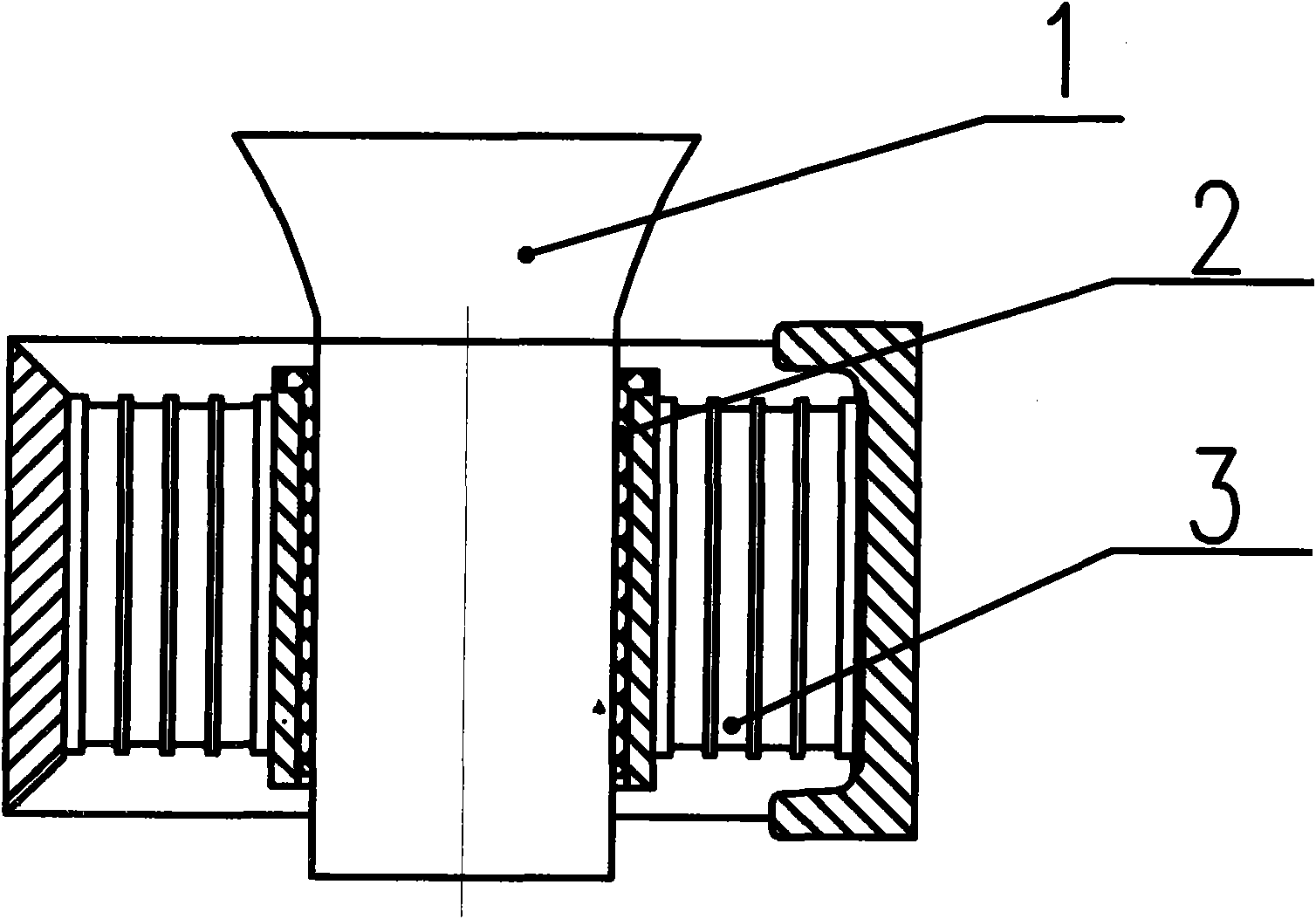

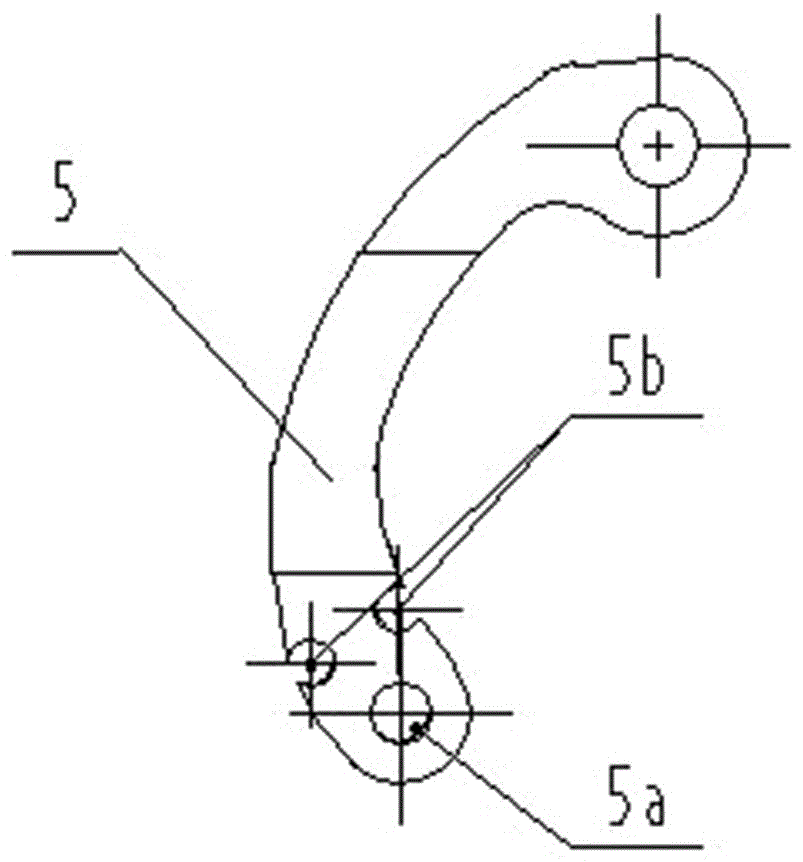

Automobile air-conditioner fixed torque driver

InactiveCN106763268AWith overload protection functionQuick breakSlip couplingStress concentrationAutomobile air conditioning

The invention relates to an automobile air-conditioner fixed torque driver which comprises a belt wheel (1) and a spline disc (6). A set of leaf springs (5) are arranged. One end of each leaf spring is connected to one end face of the belt wheel through a bolt (2), and the other end of each leaf spring is connected to the spline disc through a rivet (7). The opposite edges of each leaf spring are provided with opposite split pin holes respectively. Outer side positioning pins (3) and inner side positioning pins (4) correspondingly matched with the split pin holes are arranged on the spline disc. The automobile air-conditioner fixed torque driver has the advantages that the portion between the two split positioning pin holes in the leaf springs is the stress concentration position; when a compressor is overloaded continuously, the stress concentration position is most likely to be snapped, the compressor overload protection effect is achieved, and the rated torque of the automobile air-conditioner fixed torque driver can be determined by determining a tension value during snapping. When the compressor is overloaded instantaneously, the inner and outer side positioning pins are extruded and retracted, large instant elasticity is fed back to the leaf spring, and it has been ensured that the leaf springs can continue to be in use normally after being overloaded instantaneously.

Owner:ANHUI HAOFANG ELECTROMECHANICS

Elastic body of weighing sensor

ActiveCN103256971AAffect normal useGood ability to resist side loadWeighing apparatus detailsElastomerEngineering

The invention relates to an elastic body of a weighing sensor. The elastic body comprises a fixed part and a strain part. The fixed part comprises a printing plate mounting hole formed in the elastic body. The strain part comprises a strain hole formed in the elastic body and a set of strain pieces fixed in the strain hole. A cross-shaped overload beam is arranged in the strain hole. An upper overload gap on an upper groove opening of a vertical beam of the overload beam is used for balancing an output signal during overloading of a first strain piece and a second strain piece on two sides of the upper groove opening. A lower overload gap on a lower groove opening of the vertical beam of the overload beam is used for balancing an output signal during overloading of a third strain piece and a fourth strain piece on two sides of the lower groove opening. The upper overload gap delta 1 of the upper groove opening is identical to the lower overload gap delta 2 of the lower groove opening. A middle groove opening is formed in a horizontal beam of the overload beam. A middle overload gap lambada of the middle groove opening is used for overload protection. The elastic body of the weighing sensor is compact in structure, an overload part is arranged in the elastic body, good side-loading-resistant capacity and good overload protection performance are achieved, controlling and machining are convenient, and service life can be prolonged.

Owner:METTLER TOLEDO CHANGZHOU PRECISION INSTR +2

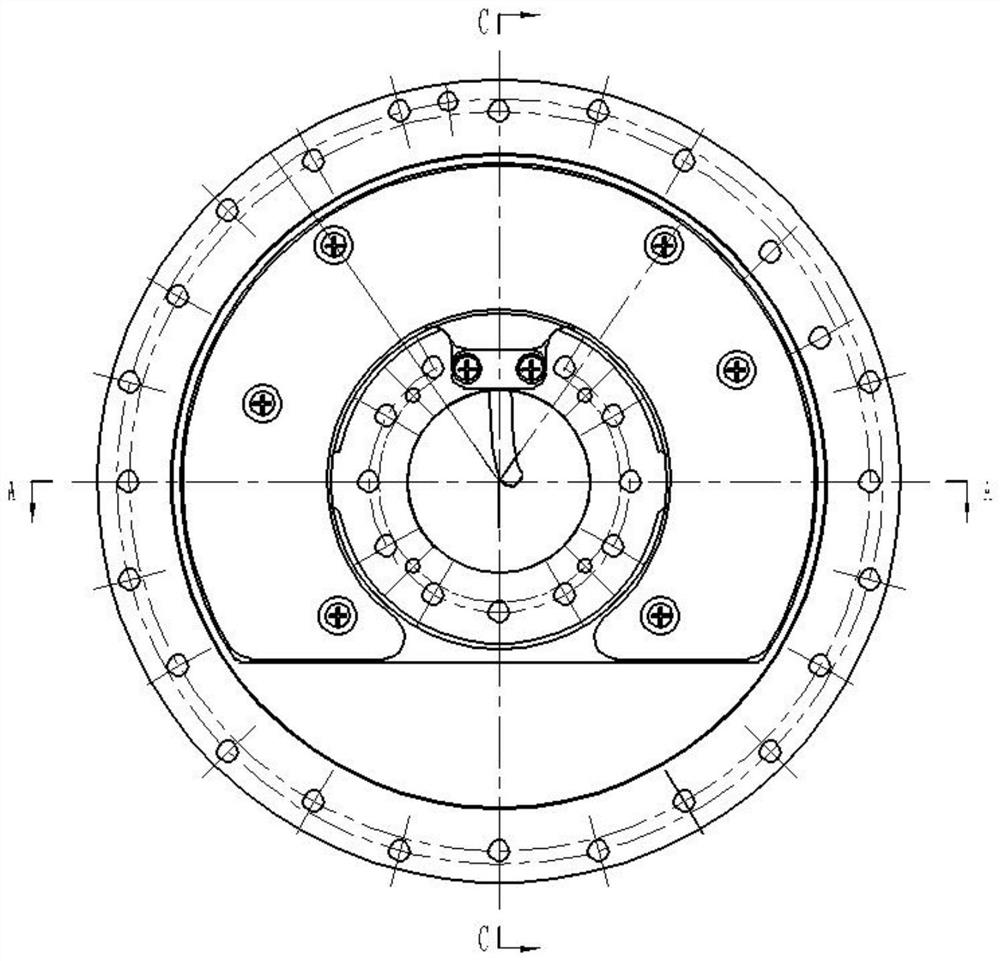

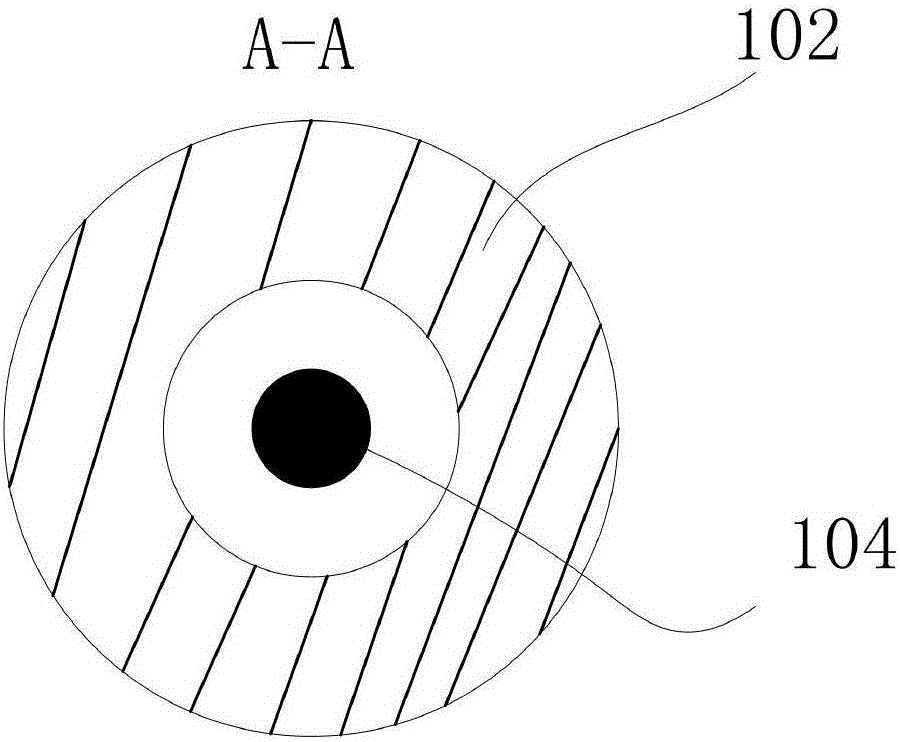

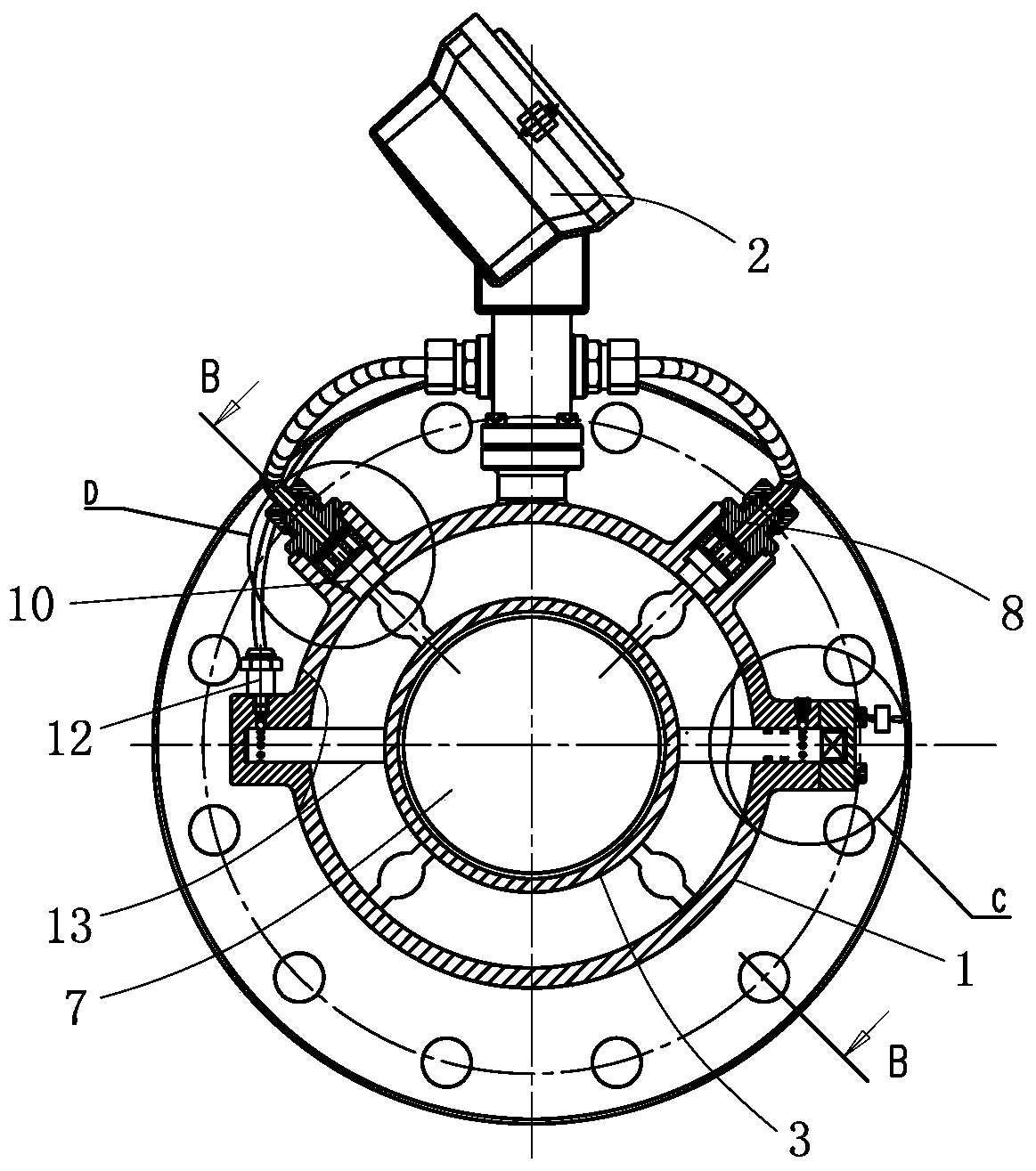

Anti-overload torque sensor based on film sputtering

InactiveCN112611489AImprove stabilityStrong precisionWork measurementTorque measurementSputteringElastomer

The invention discloses an anti-overload torque sensor based on film sputtering. The anti-overload torque sensor comprises an output cable, a circuit board, a cushion column, a shell, an elastic body, a strain beam and film strain gauges, wherein the elastic body is an annular plate, the annular plate is sequentially divided into an inner edge section, an installation ring section and an outer edge section from inside to outside, the installation ring section is provided with an integrally formed rectangular bulge serving as the strain beam, the shell is coaxially mounted on the installation ring section of the elastic body, the circuit board is located in the annular cavity of the shell and installed on the installation annular section of the elastic body through the cushion column, one end of the output cable is welded on the circuit board, the other end of the output cable is connected with an external electric connector, and the strain resistors of the two film strain gauges are sputtered on the strain beam of the elastic body through a sputter coating technology. According to the invention, a sensitive film is prepared by adopting a sputter coating process, and an anti-torque limiting structure is arranged, so that when a torque load exceeds a set threshold value, the anti-torque limiting structure can play a role in overload protection of the elastic beam.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

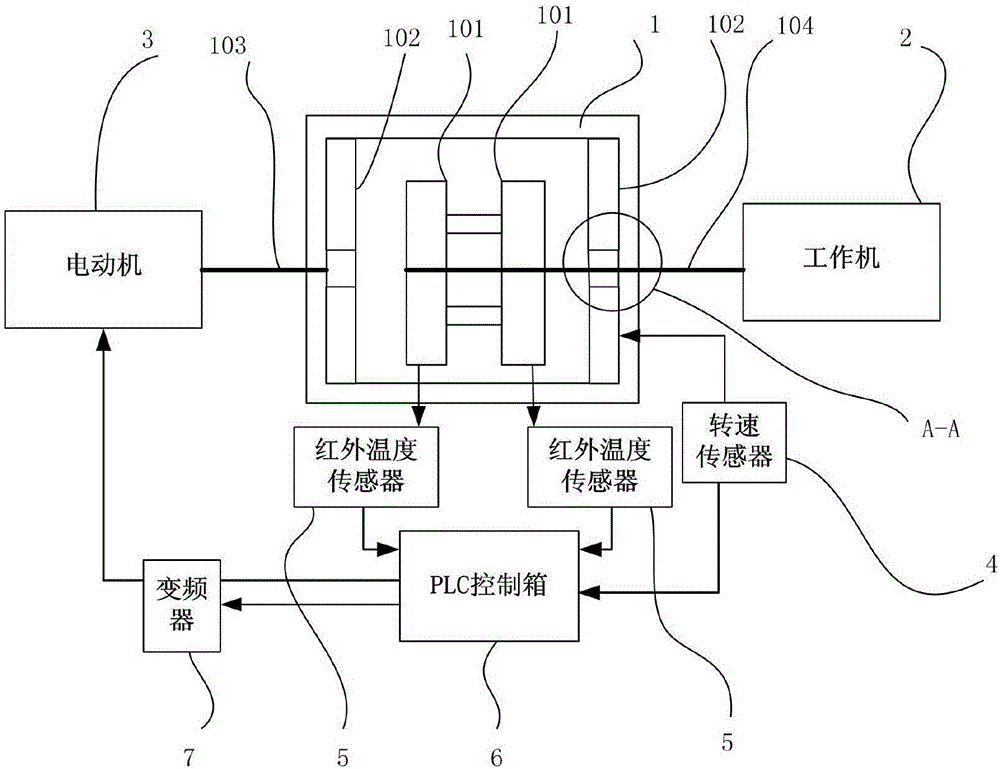

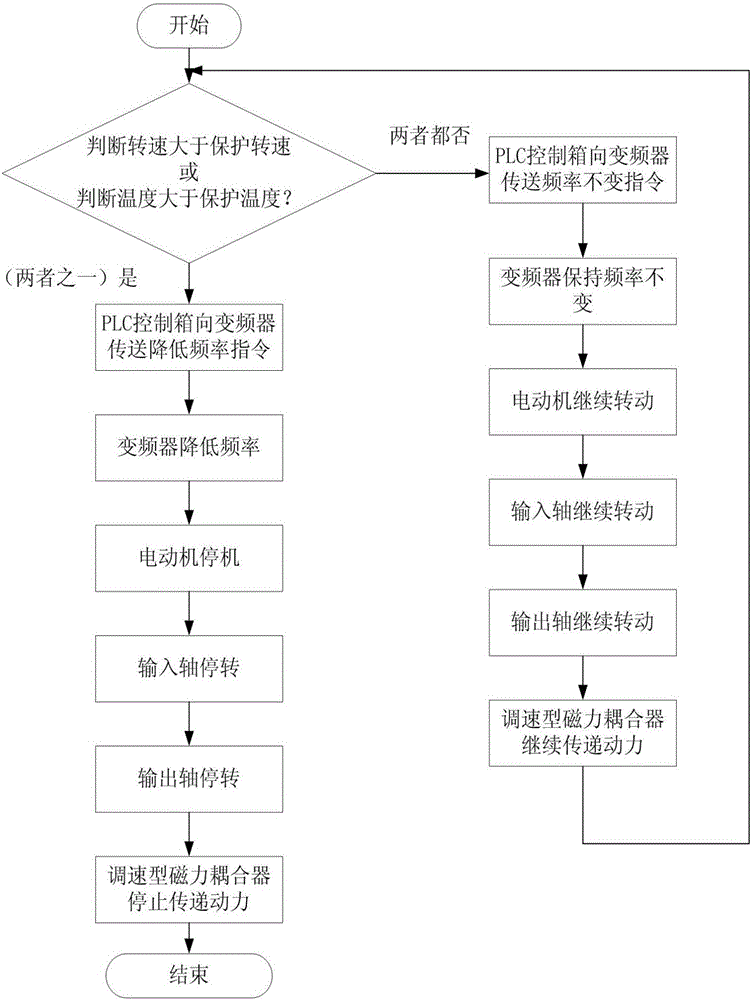

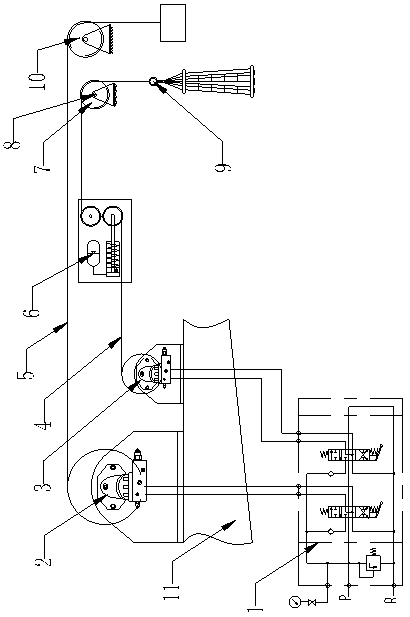

Overload protecting device and method for speed regulation type magnetic coupling

InactiveCN106786388AAvoid slipping and slippingIncrease temperatureAC motor controlEmergency protective circuit arrangementsFrequency changerPermanent magnet rotor

The invention relates to an overload protecting device for a speed regulation type magnetic coupling. The overload protecting device comprises a speed regulation type magnetic coupling, a working machine, an electric motor, a rotation speed sensor, an infrared temperature sensor, a PLC control box and a frequency converter. If the rotation speed of a copper rotor sent by the rotation speed sensor to the PLC control box exceeds a preset protection rotation speed, the PLC control box sends a frequency reducing instruction to the frequency converter, otherwise, the PLC control box sends a frequency invariant instruction; if the temperature of a permanent magnet rotor sent by the temperature sensor to the PLC control box exceeds a preset protection temperature, the PLC control box sends a frequency reducing instruction to the frequency converter, otherwise, the PLC control box sends a frequency invariant instruction; if the electric motor receives a halt instruction, the rotation speed of an input shaft is zero, and then the rotation speed of an output shaft is zero, namely the power is not transferred by the speed regulation type magnetic coupling; otherwise, the electric motor receives a continuous operation instruction, and the speed regulation type magnetic coupling continues to provide powder.

Owner:ANHUI UNIV OF SCI & TECH

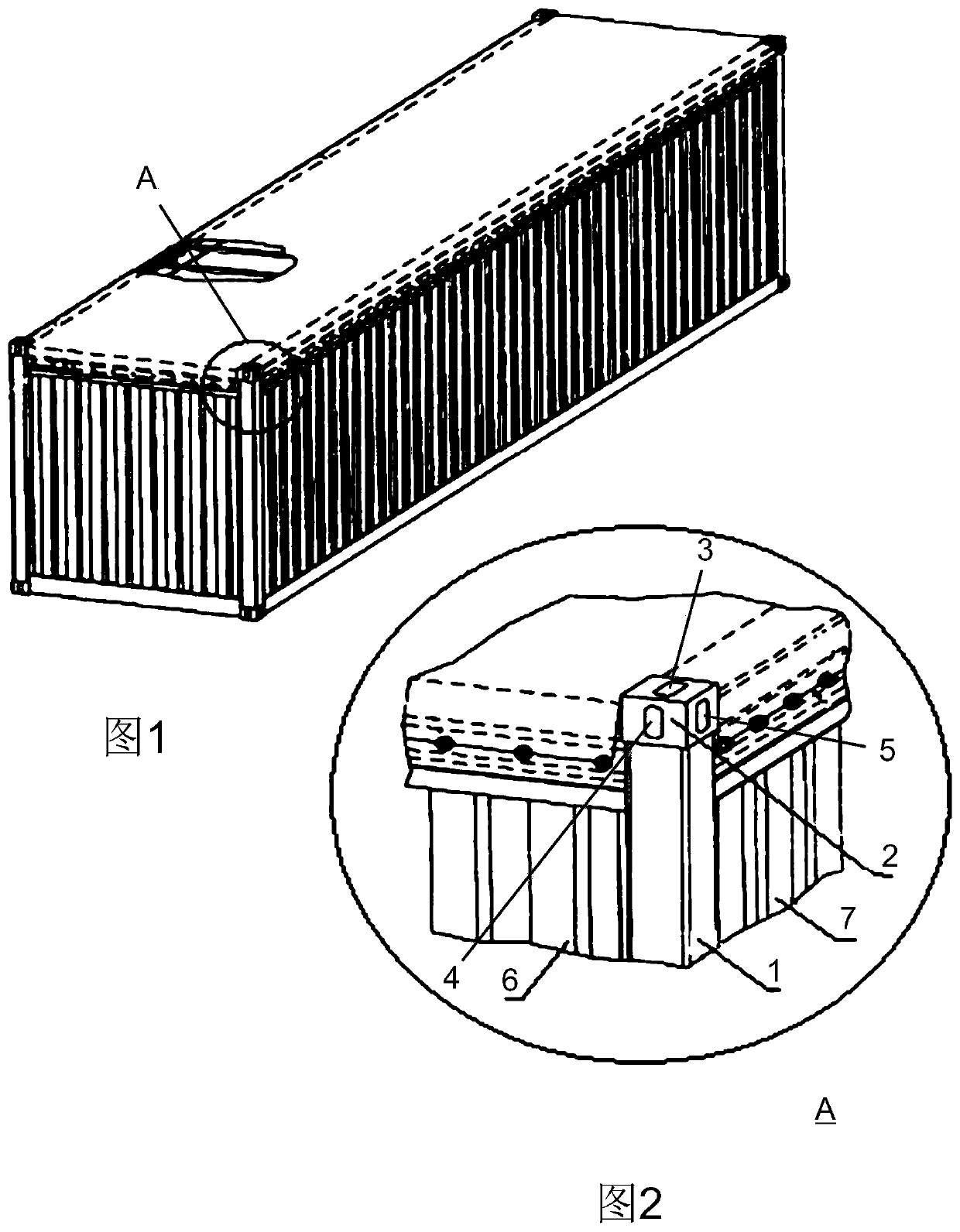

Safety protection system and safety protection method for preventing container truck from being hoisted

PendingCN110255382AHigh precisionHigh center of gravity calculation accuracySafety gearEngineeringTruck

The invention discloses a safety protection system and a safety protection method for preventing a container truck from being hoisted. The safety protection system comprises torsion locks on a container truck carriage, a truck scale used for weighing the container truck, and a lifting appliance used for lifting containers, force sensors are arranged on the torsion locks, the lifting appliance is provided with a plurality of rotating pin force sensors, and the system further comprises a controller used for receiving data of the force sensors, the rotating pin force sensors and the truck scale and used for comparing the data. According to the safety protection system and safety protection method, the problem of potential safety hazards caused by manual operation errors is solved.

Owner:SHANGHAI ZHENHUA HEAVY IND

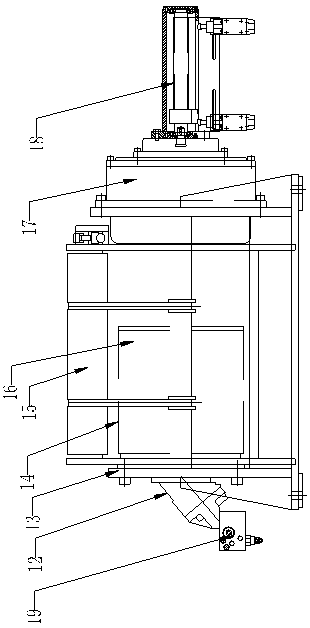

Elevator with supporting rod type safety device

The invention provides an elevator with a supporting rod type safety device. The elevator is characterized by comprising a first winch, wherein a first motor is connected with the first winch by a first belt; one end of a first traction cable is arranged on a second frame; the other end of the first traction cable is arranged on the first winch by a movable pulley; the movable pulley is connected with an elevating box by a steel wire rope; the elevating box is respectively connected with slide blocks on slide rails on two sides of the elevating box by two supporting rods; a second winch is arranged below the slide rails; one end of a second traction cable is arranged on the second winch; the other end of the second traction cable is respectively connected with the two slide blocks by two supporting rods; and a second motor is connected with the second winch by a second belt. The elevator with the supporting rod type safety device, provided by the invention, has the advantages of simple structure, low cost, lower requirement on motor load capacity and overload protective effect; shortcomings in the prior art are overcome; and dropping and overrunning accidents of the elevating box can be prevented.

Owner:DONGHUA UNIV

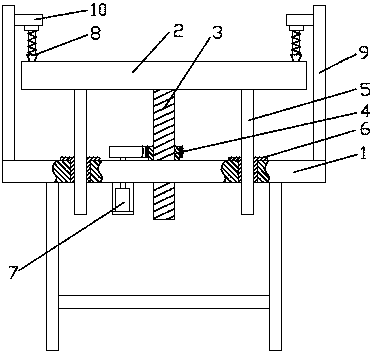

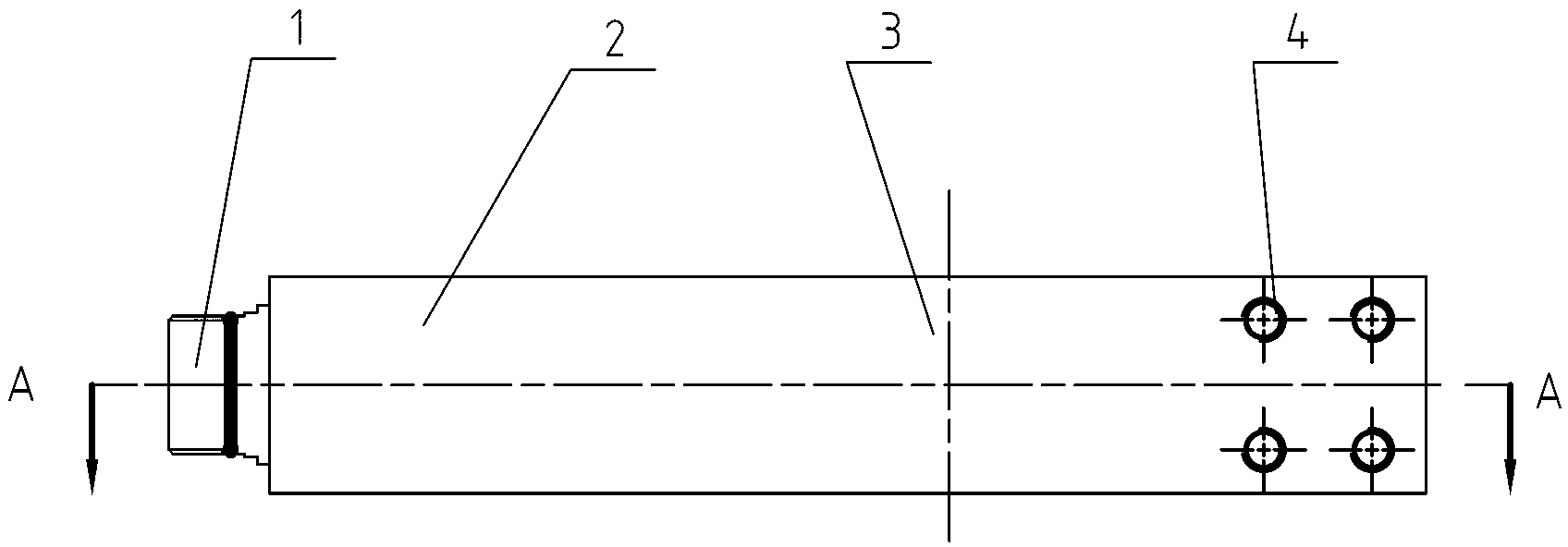

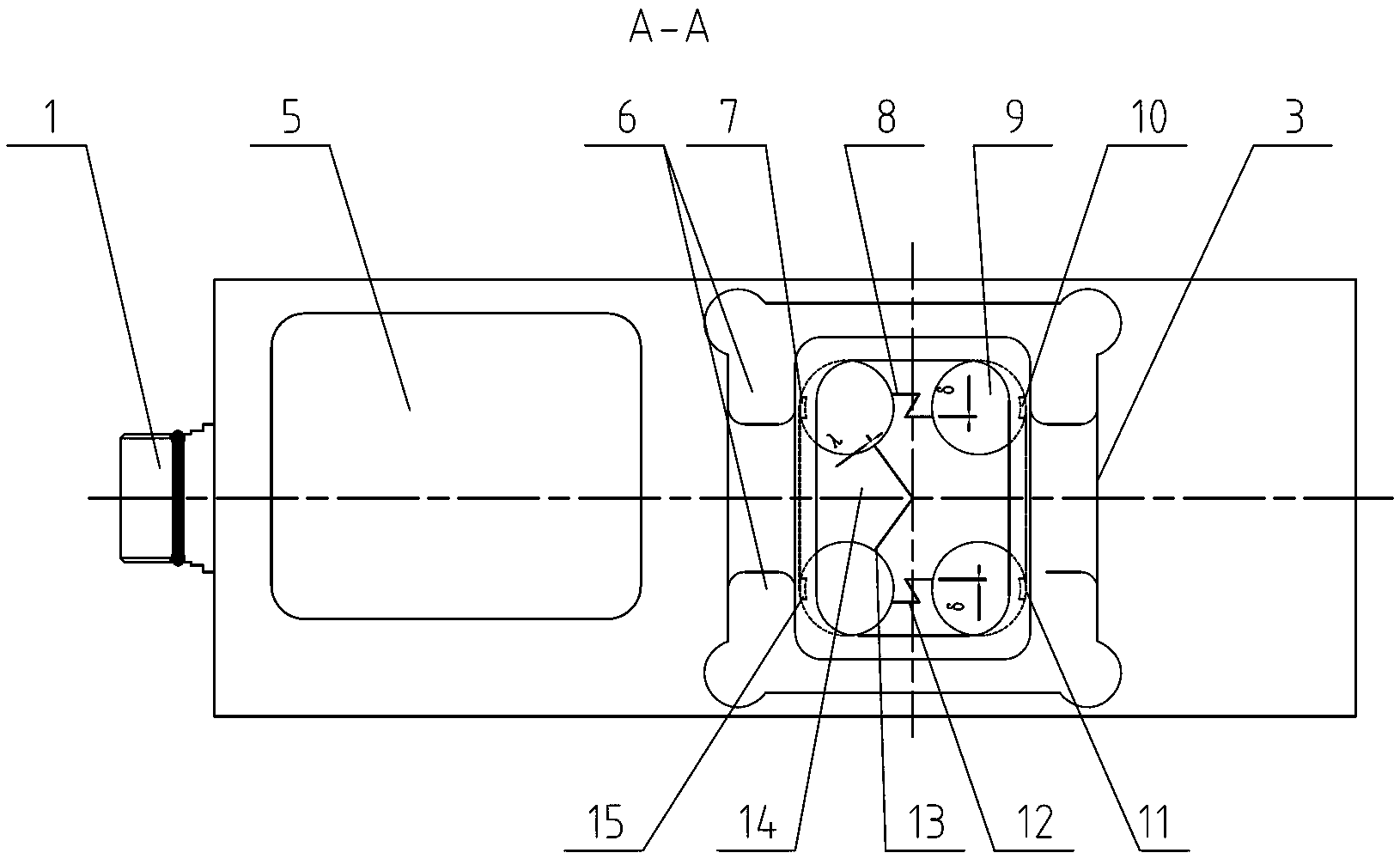

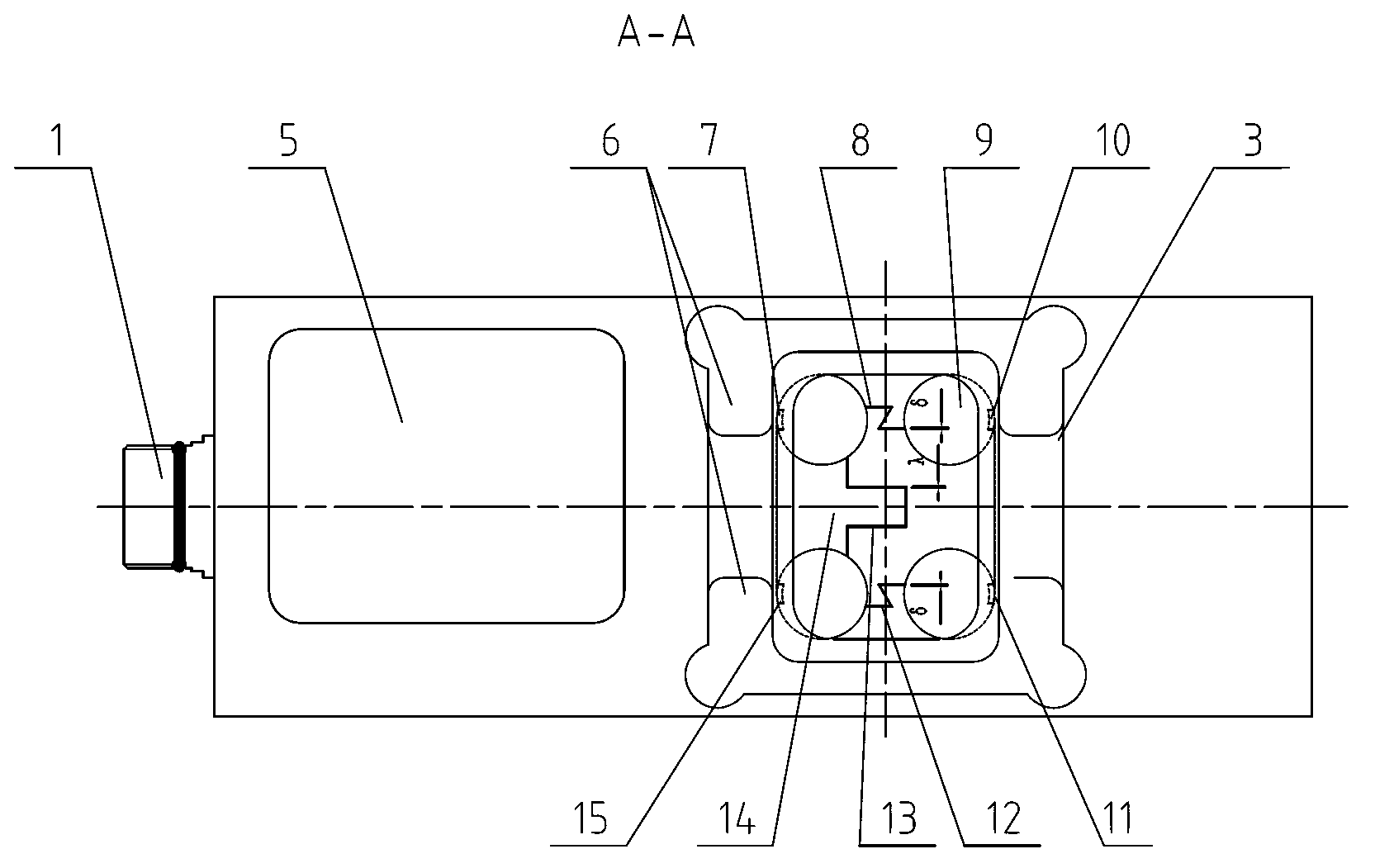

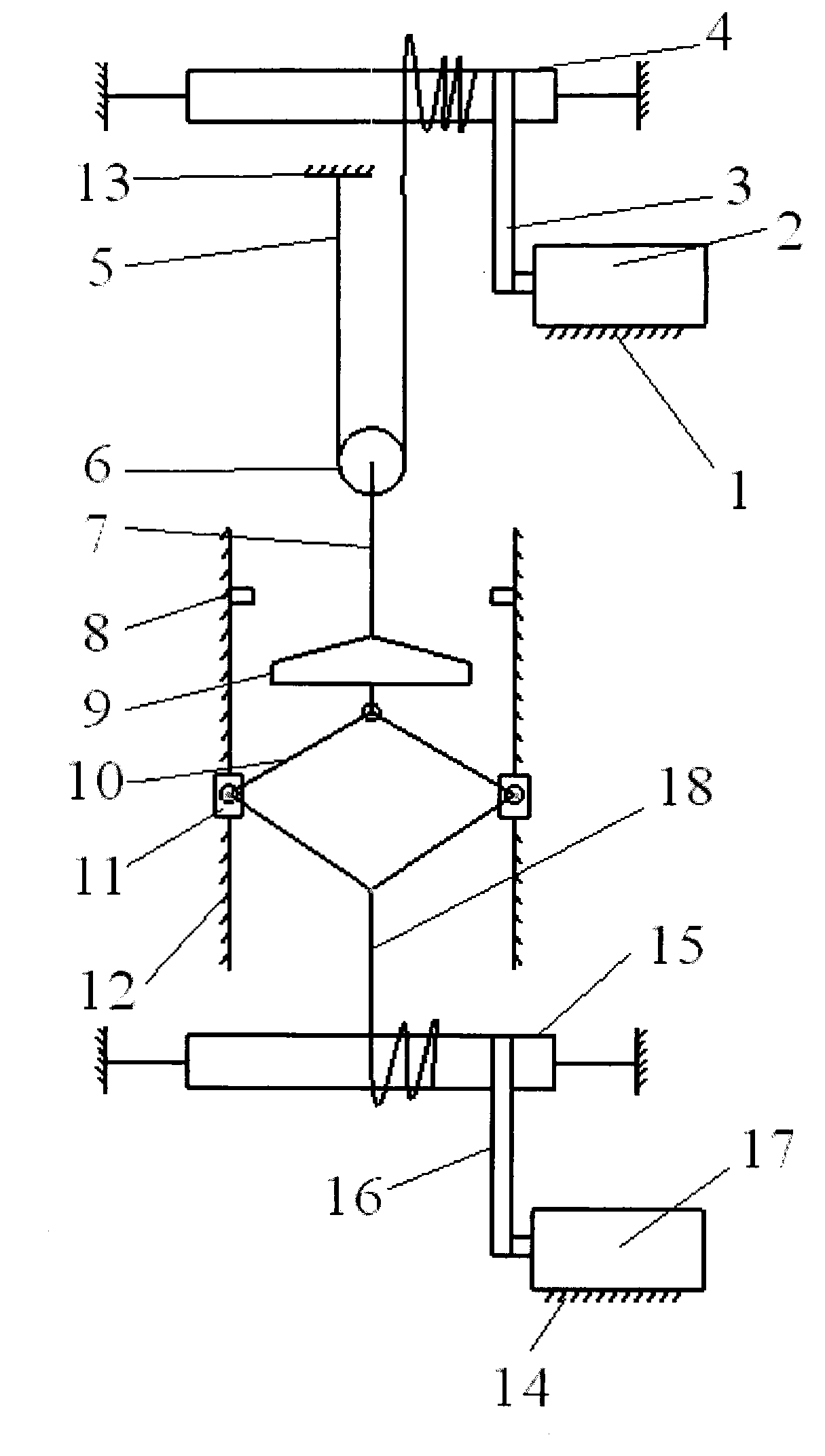

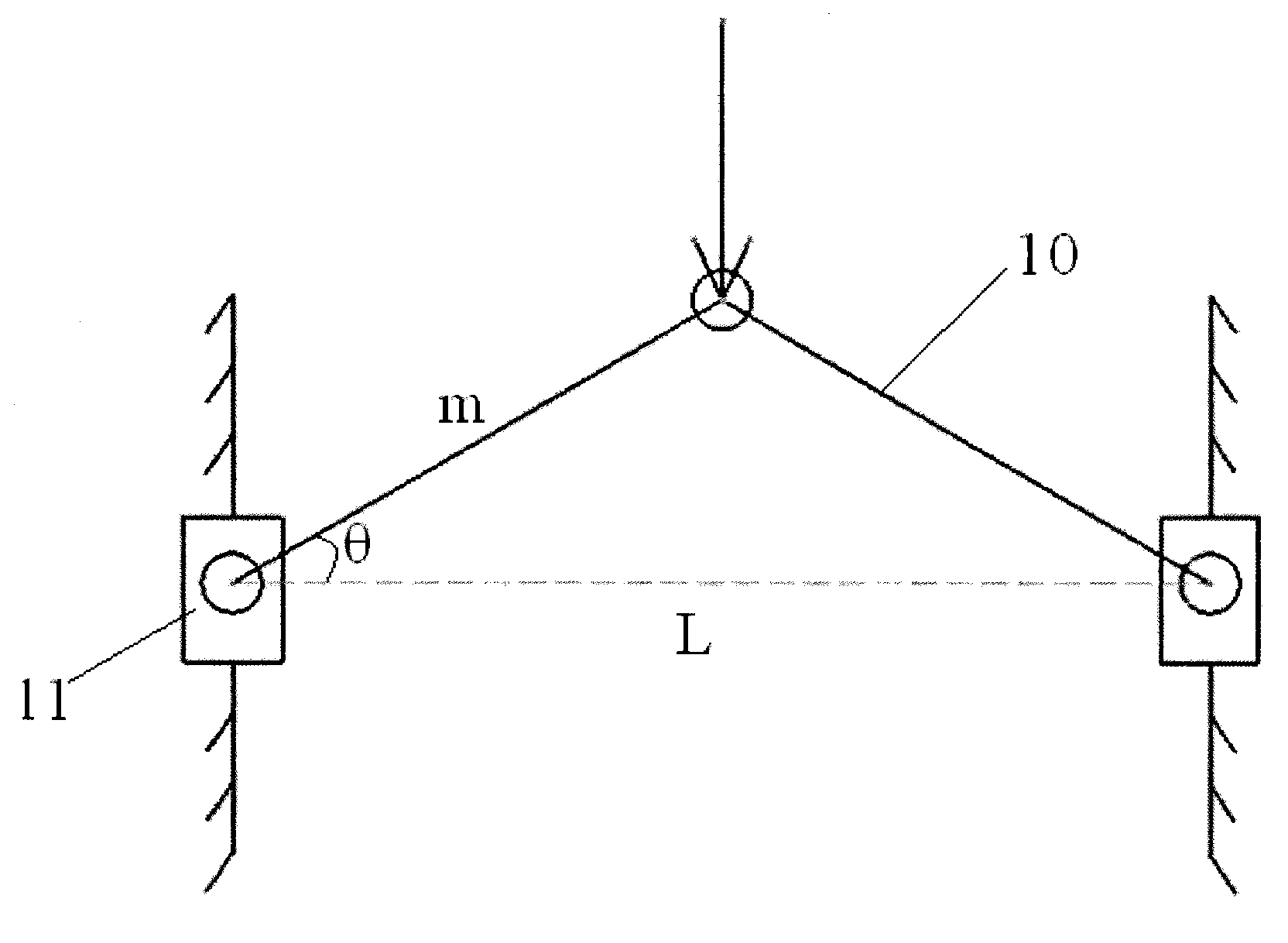

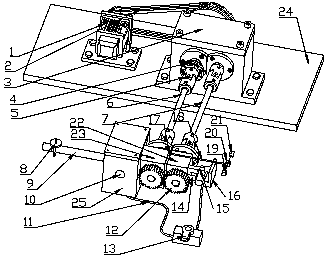

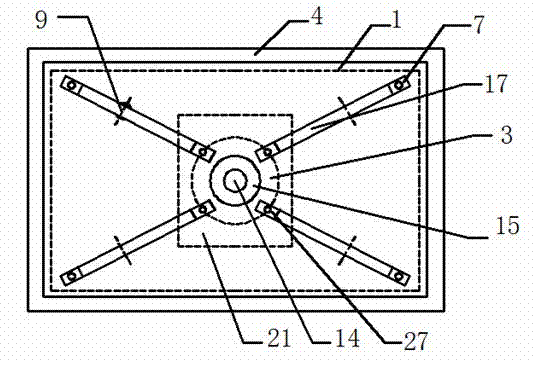

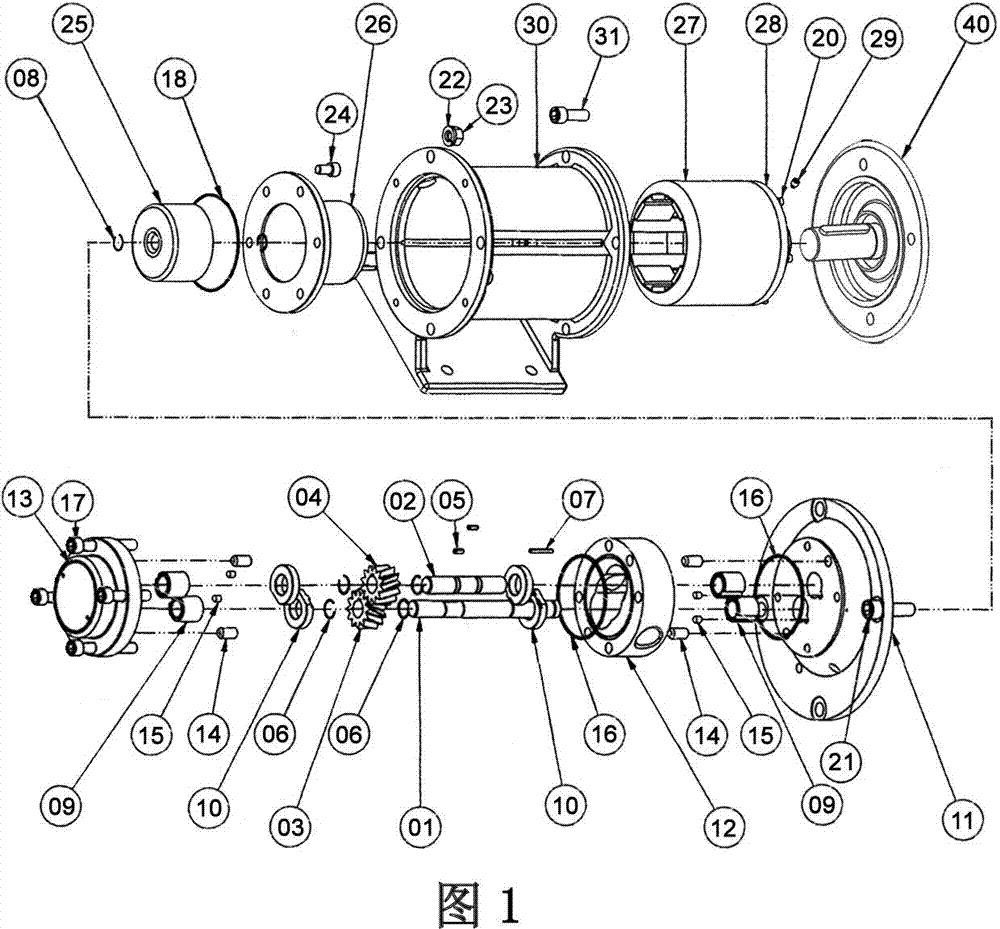

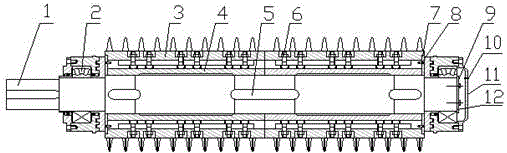

Plastic gear wear life testing machine for single support self-compensation loading system

InactiveCN109084979AAchieve variable speedAct as overload protectionMachine gearing/transmission testingInvestigating abrasion/wear resistanceSingle supportIndirect test

The invention discloses a plastic gear wear life testing machine for a single support self-compensation loading system. The machine is on the basis of an indirect test principle of a ''discontinuous phase method'', and uses an adjustable composite load loading system. A test gear pivot box is supported by a simple hinge, so as to realize the combination loading of a torque and a bending moment ina dynamic meshing simulation process of a test gear. According to the plastic gear wear life testing machine for the single support self-compensation loading system, the dynamic measurement of gear tooth wear can be completed, and the self-compensation loading function of the testing machine in a gear transmission process can be achieved.

Owner:UNIV OF JINAN

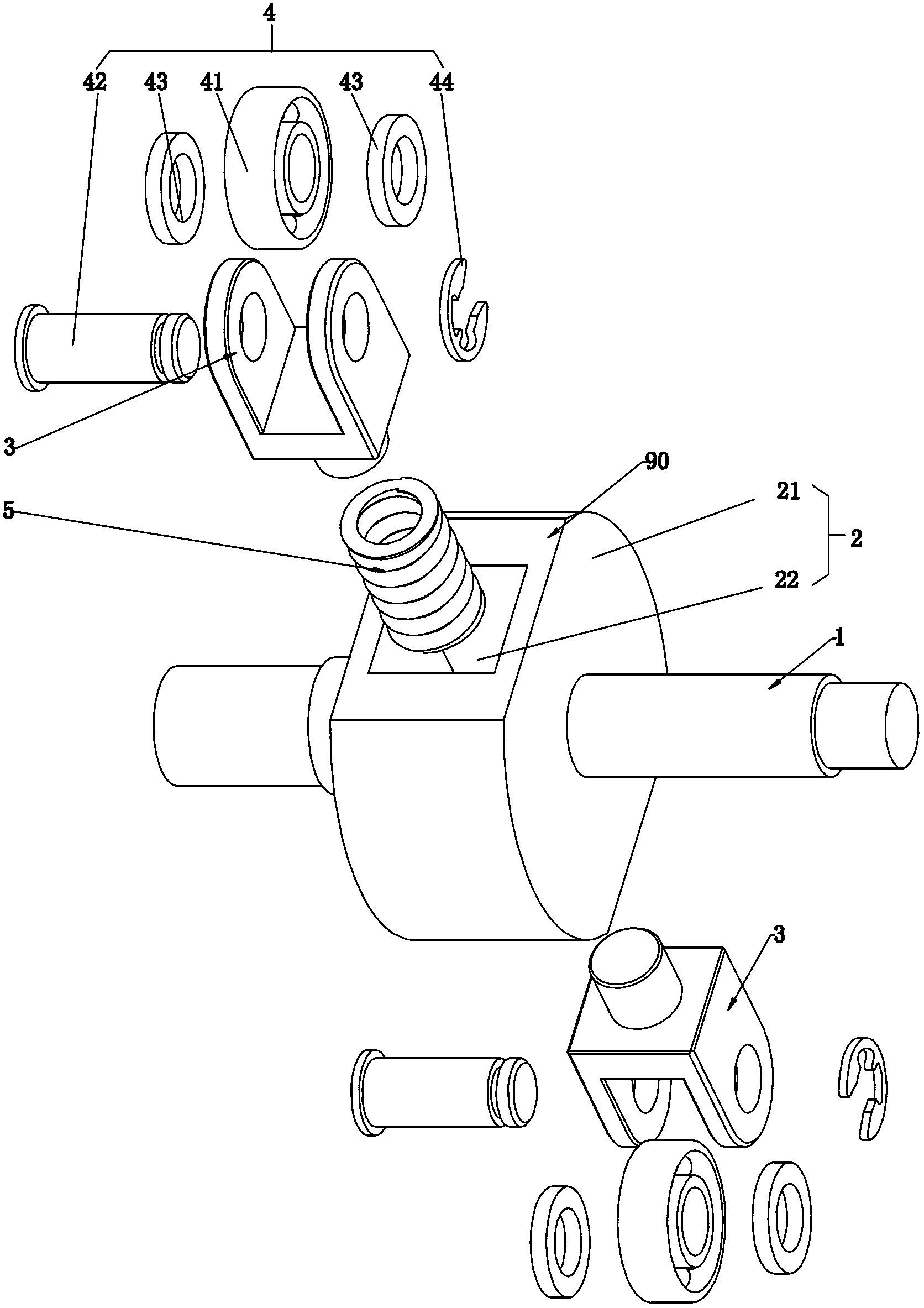

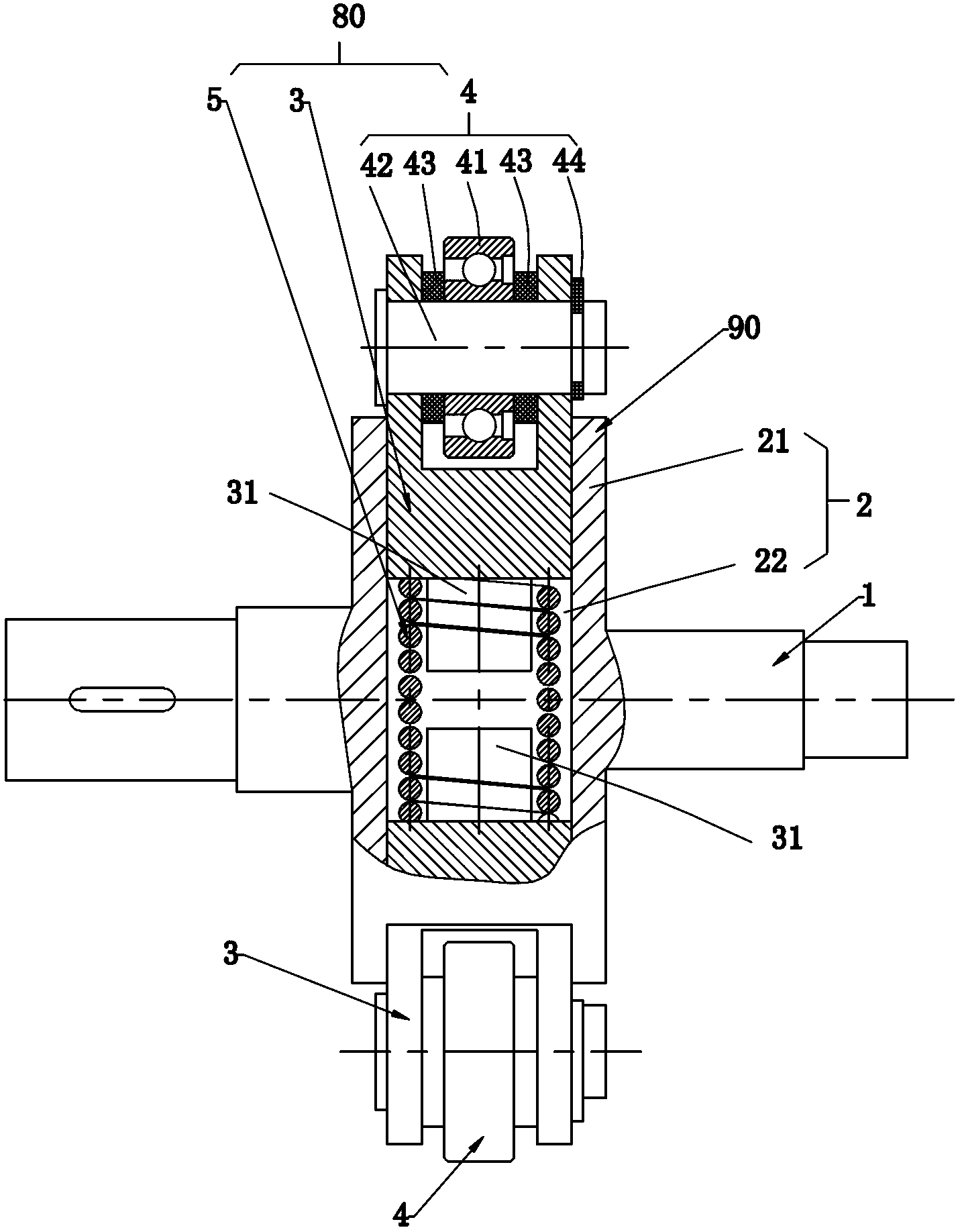

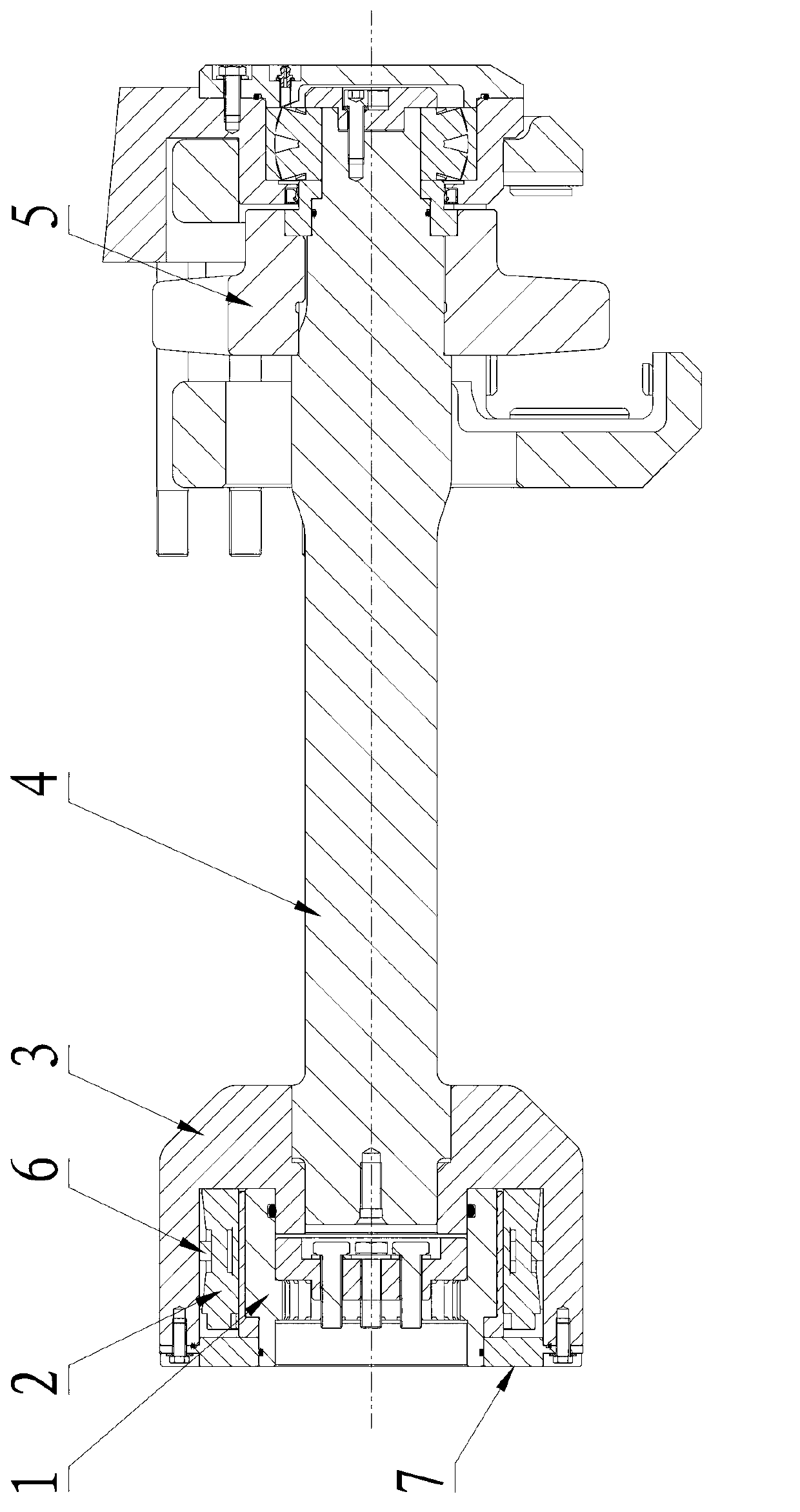

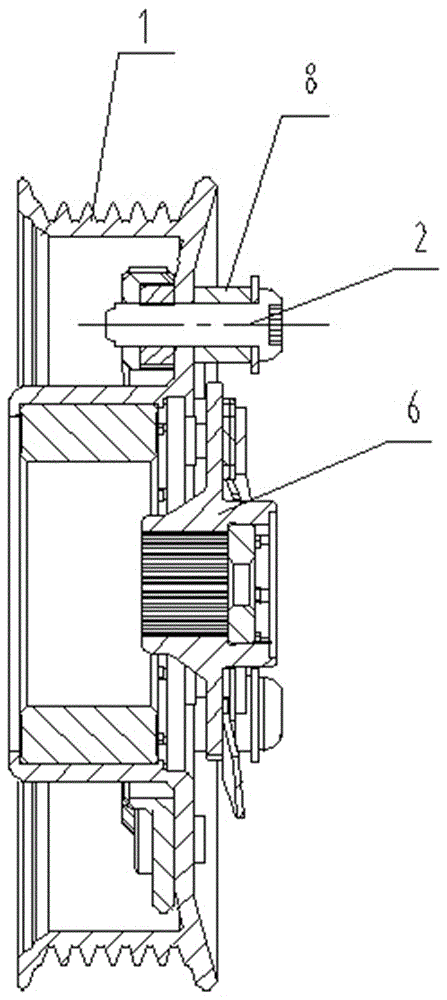

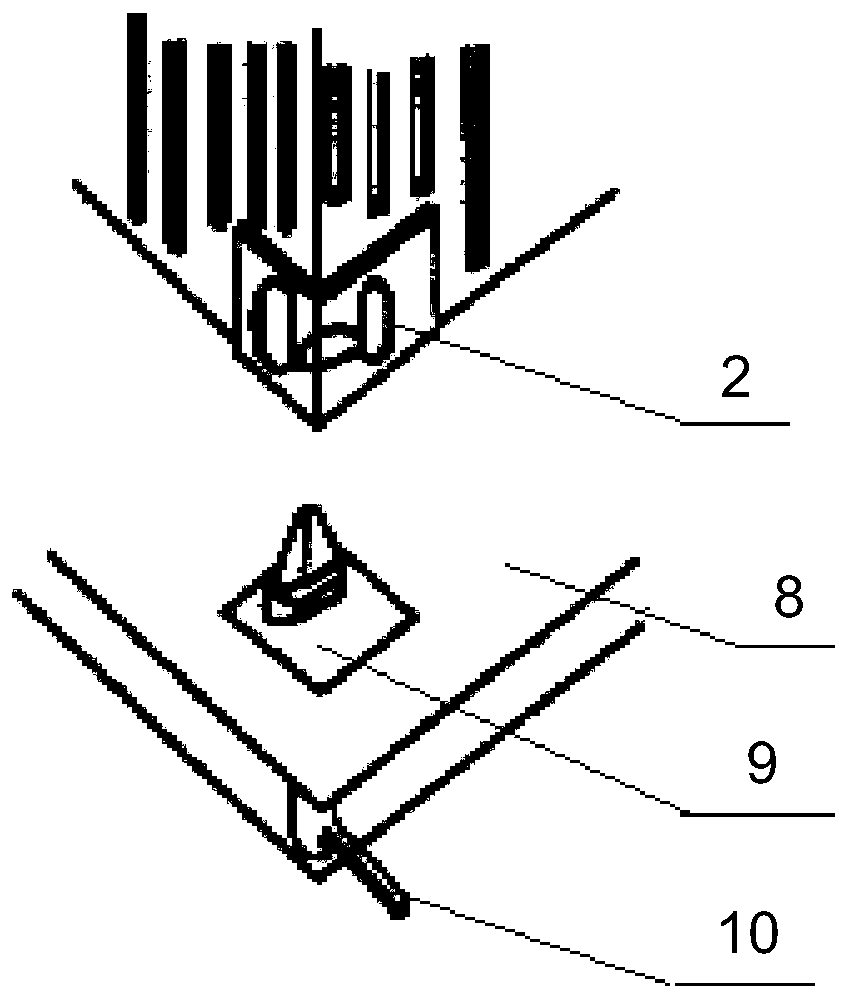

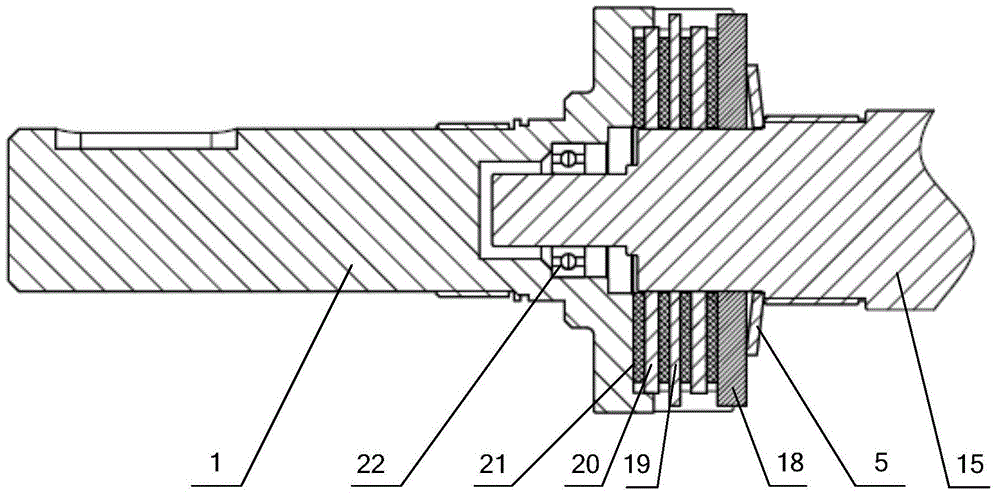

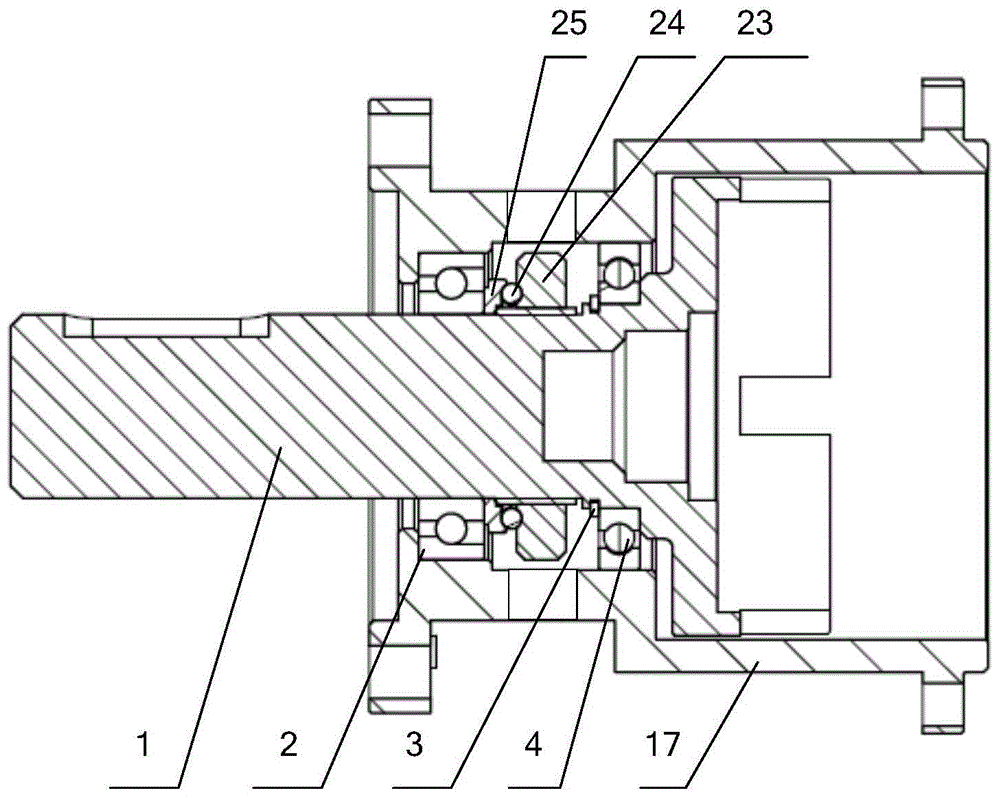

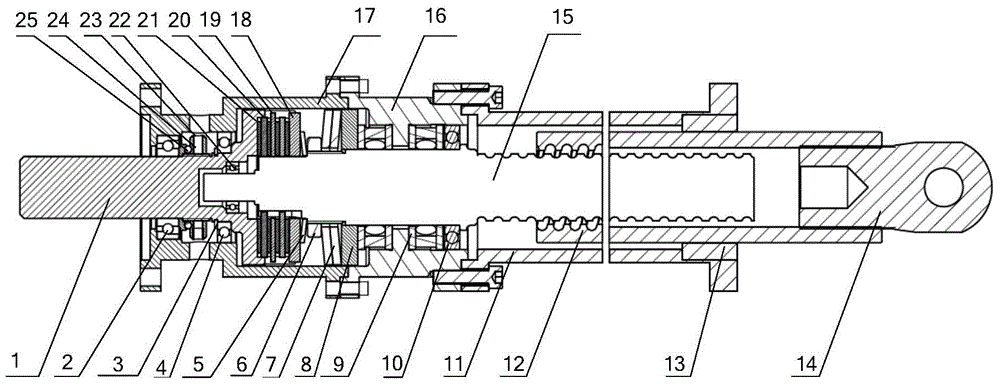

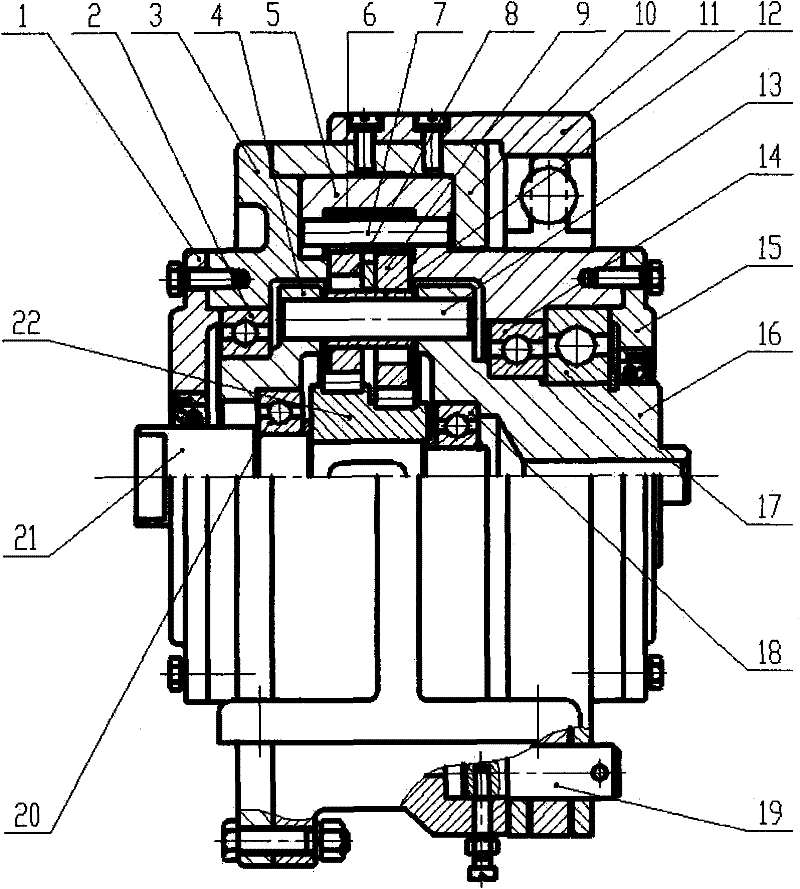

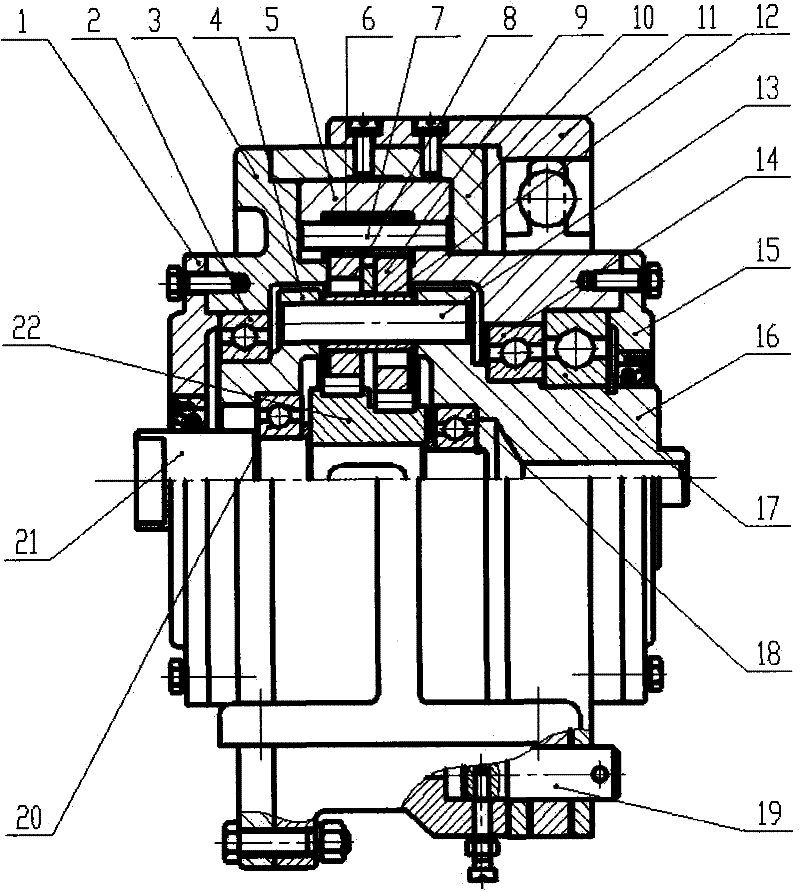

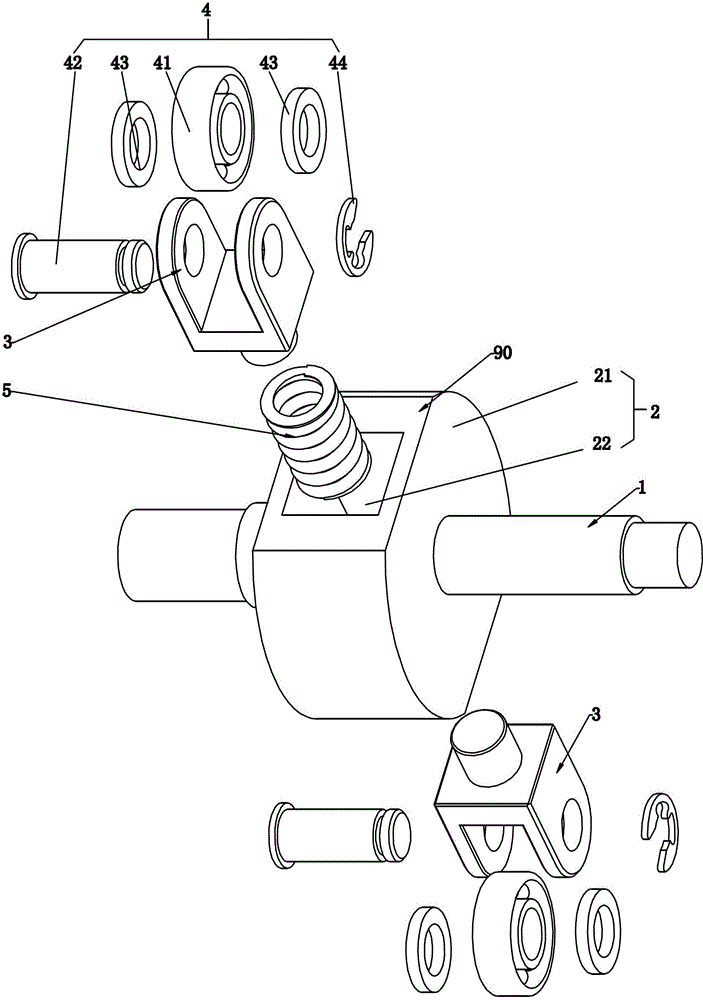

Axial tension safe clutch for large load

InactiveCN104632933ADisengagement process safetyAct as overload protectionAutomatic clutchesClutchEngineering

The invention provides an axial tension safe clutch for large load. The axial tension safe clutch for the large load comprises a shell, an input shaft, a lead screw, a friction engaging and disengaging mechanism, a reset pre-tightening adjusting mechanism and a lead screw nut matched with the lead screw, wherein the input shaft and the lead screw penetrate through the shell to be arranged in a rotating mode, the friction engaging and disengaging mechanism is used for transmission between the input shaft and the lead screw, and the reset pre-tightening adjusting mechanism is arranged on the input shaft. The friction engaging and disengaging mechanism comprises an input friction disc axially fixed to the input shaft, an output friction disc axially fixed to the lead screw, and a reset spring arranged between the lead screw and the output friction disc. The reset pre-tightening adjusting mechanism comprises a reset locking nut fixed at the axial position and is arranged on the input shaft through threaded connection. When the driving tension load of the input shaft or the lead screw is smaller than the corresponding separation load, the input friction disc and the output friction disc rotate synchronously under the effect of the pre-tightening force. When the driving tension load of the input shaft or the lead screw is not smaller than the corresponding separation load, the input friction disc and the output friction disc slip.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

Brake axle load integrated-type axle load measuring device

InactiveCN103048079AIncrease the effective areaPrecise positioningApparatus for force/torque/work measurementSteel ballEngineering

The invention discloses a brake axle load integrated-type axle load measuring device, which comprises a roller-type brake force testing platform, a pressure plate, a pull rod, a force measuring sensor, a working air cylinder, first connecting pieces, a second connecting piece and four working levers which stay on the same horizontal plane, wherein the pressure plate is fixedly connected with a push rod of the working air cylinder sequentially through the pull rod and the force measuring sensor, a first end of each working lever is connected with the pressure plate respectively through own first connecting piece, and a second end of each working lever is connected with a stander of the testing platform respectively through the second connecting piece; two of the four working levers are overlapped with a first straight line, the other two working levers are overlapped with a second straight line, the orthographic projection of a joined point of the first straight line and the second straight line on a working panel of the testing platform is overlapped with a geometric center of the working panel, and two working levers staying on the same straight line are symmetrically distributed by adopting the joined point as the center; and each first connecting piece comprises a first lower spherical seat and a first steel ball, and each second connecting piece comprises a second upper spherical seat, a second steel ball and a second lower spherical seat.

Owner:ZHEJIANG UNIV

Novel high-pressure chemical industry gear pump

ActiveCN104500389AGuaranteed working lifeSmooth pumping operationRotary piston pumpsRotary/oscillating piston combinationsChemical industryMagnetic tension force

The invention relates to a pump and particularly relates to a novel high-pressure chemical industry gear pump which is used for conveying various chemical media, corrosive and dangerous chemicals, or oil or water or toxic and harmful liquids or inflammable and detonable liquids and has high pressure resistance, high temperature resistance, corrosion resistance, acid and alkali resistance and abrasion resistance. According to the novel high-pressure chemical industry gear pump, a pair of unique helical gears capable of resisting high-pressure pumping and a wear-resisting plate with a pressure relief groove are designed and adopted; by virtue of innovatively designing the structure, improving the processing process, reasonably selecting metal and nonmetal combined materials, and adopting short-axis coupling and magnetic driving mode of a self-alignment structure or a mechanical seal mode of a coupling with an elastomer to connect driving between the pump and a motor, working conditions with high pressure, high pressure difference and various viscosity are met, various harsh chemical media are efficiently delivered, the defect or blank of the prior is overcome, zero leakage and no pulse are really realized, the leakage problem of an existing shaft seal is solved, and extensive application in various industries such as petroleum and chemical industry is met.

Owner:何祥军

A double-proportioning-valve-controlled liquid fertilizer application system capable of timely amount changing

InactiveCN105393689AImprove efficiencyFast fertilizerLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserHydraulic motorCoupling

The objective of the invention is to provide a double-proportioning-valve-controlled liquid fertilizer application system capable of timely amount changing. The system comprises a hydraulic fuel tank, a liquid injection pipe, a liquid injection pump, a hydraulic motor and an electric-hydraulic proportional direction valve. The hydraulic pump is connected to the hydraulic fuel tank. A filter is disposed between the hydraulic pump and the hydraulic fuel tank. The electric-hydraulic proportional direction valve comprises a fuel inlet, a fuel return port, a first fuel outlet and a second fuel outlet. The hydraulic pump is connected to the fuel inlet of the electric-hydraulic proportional direction valve through a pipe. A quick coupling is mounted on the pipe. The fuel return port of the electric-hydraulic proportional direction valve is communicated with the hydraulic fuel tank. The first fuel outlet and the second fuel outlet of the electric-hydraulic proportional direction valve are respectively communicated with the inlet and the outlet of the hydraulic motor. The output shaft of the hydraulic motor is connected to a fuel injection pump through a coupling. The fuel injection pump is separately communicated with a liquid fertilizer tank and the liquid injection pipe. The system achieves timely-amount-changing fertilization of liquid fertilizers according to different actual agricultural production requirements, achieves an objective of accurate control, increases the using efficiency of the liquid fertilizers, promotes rapid production of desired fertilizer effects, and reduces loss.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

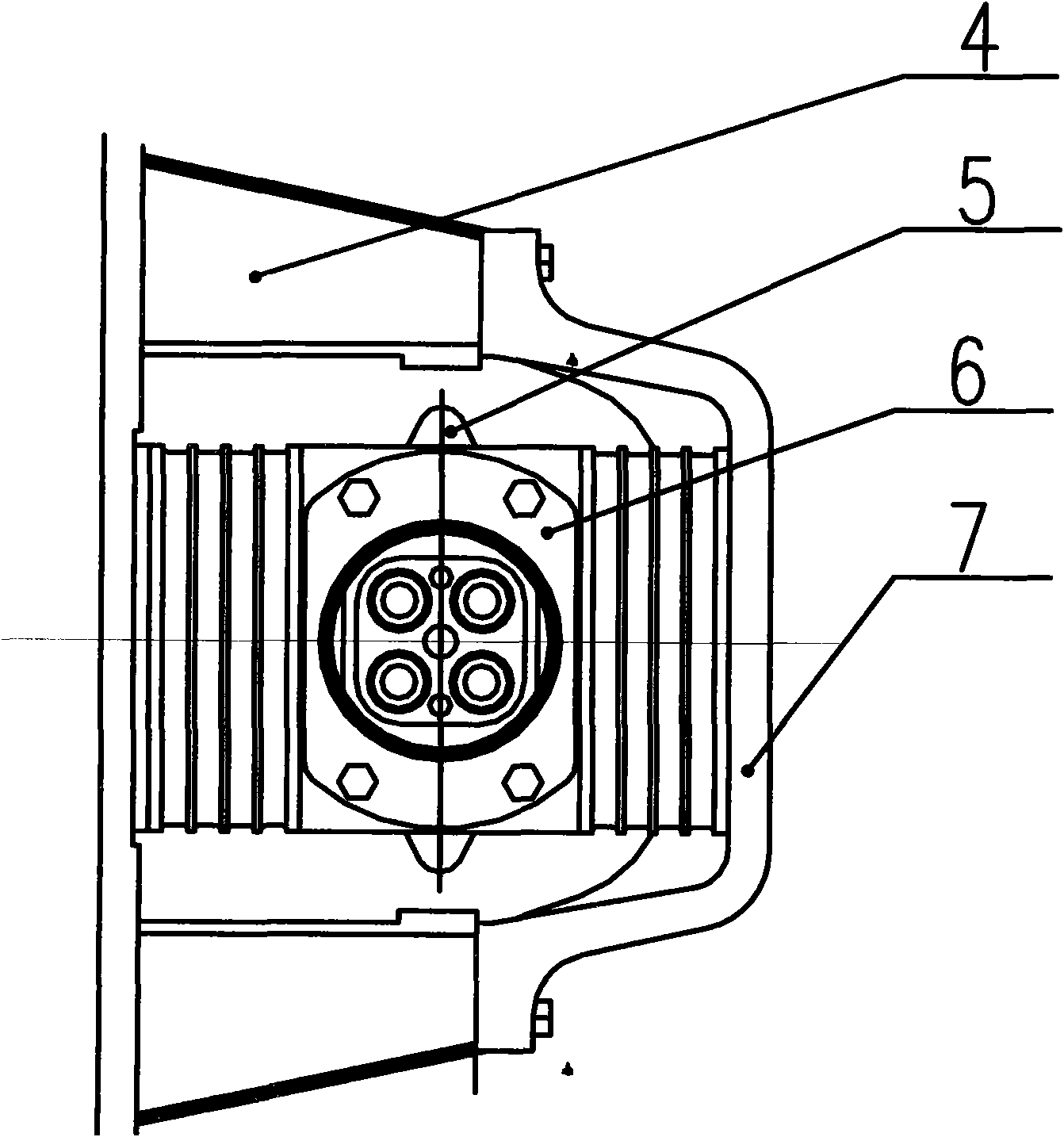

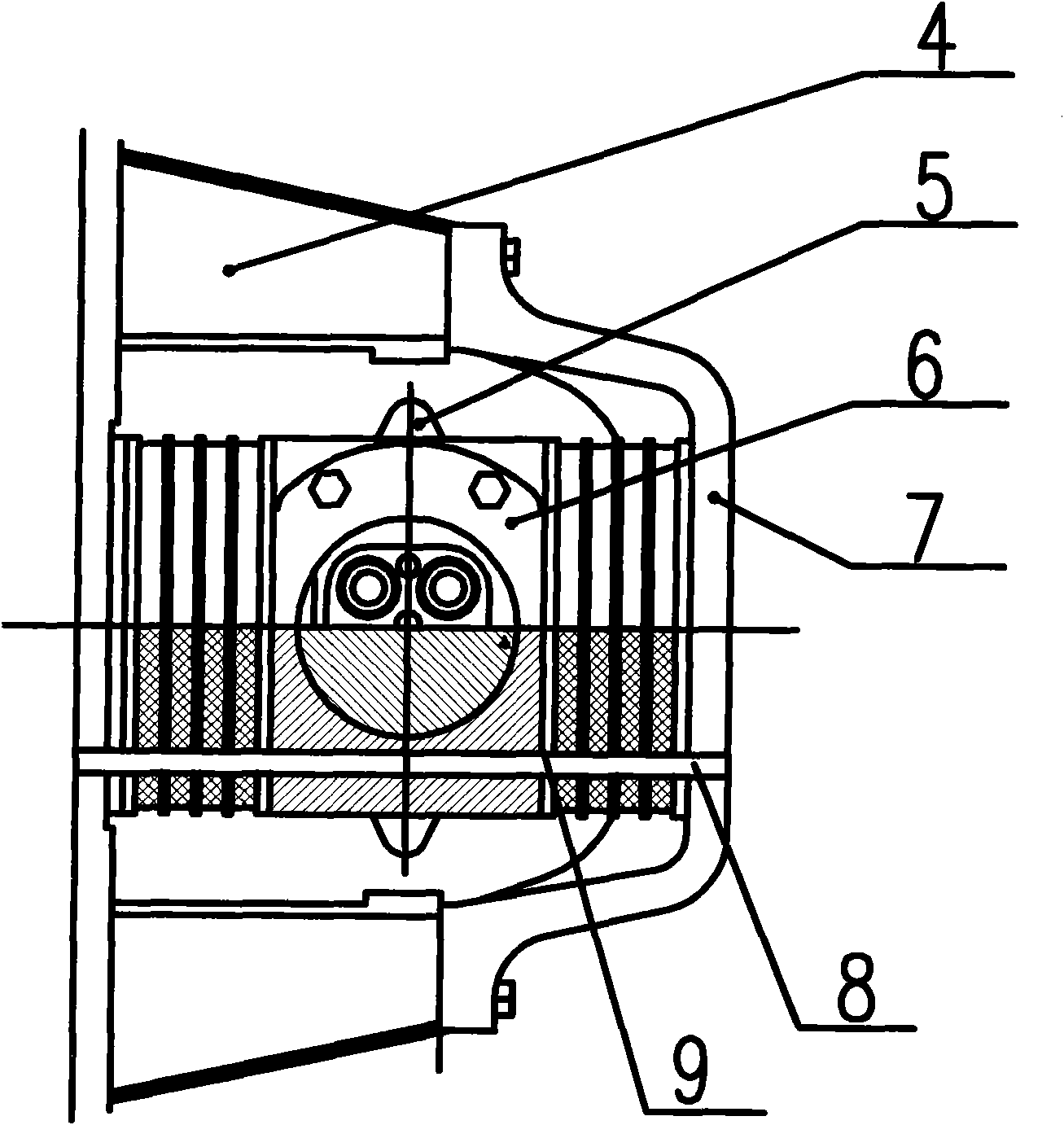

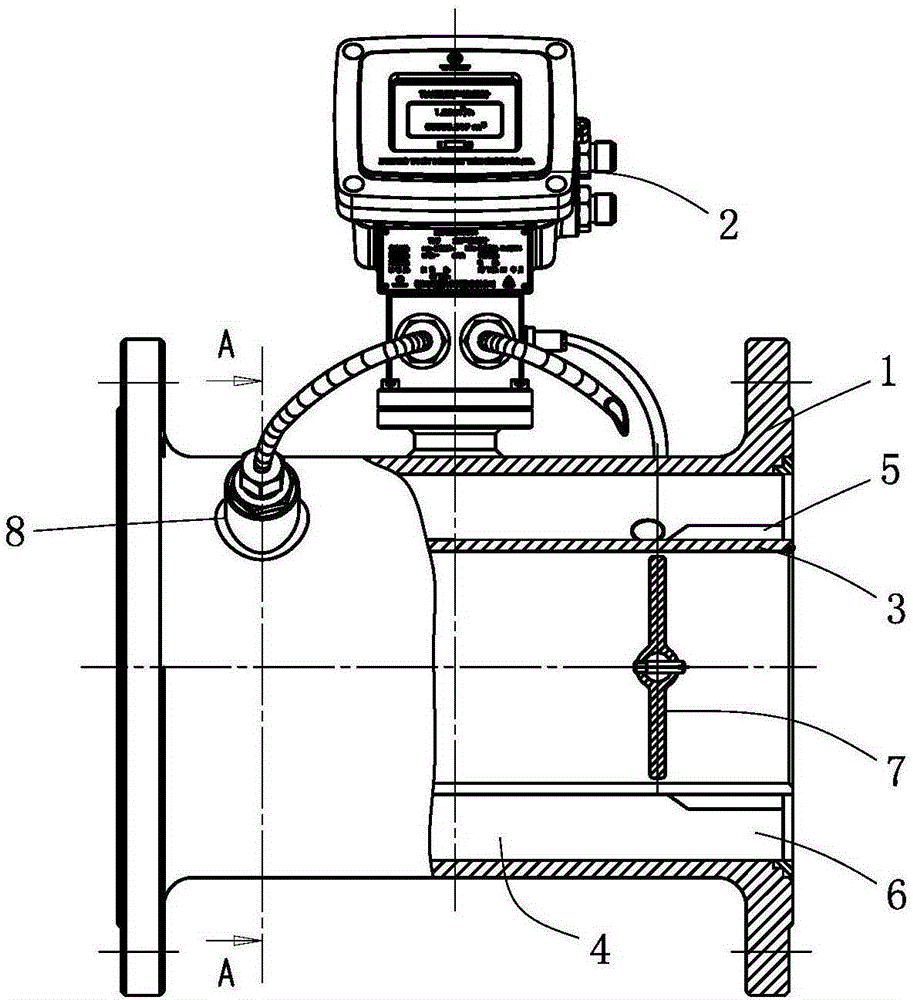

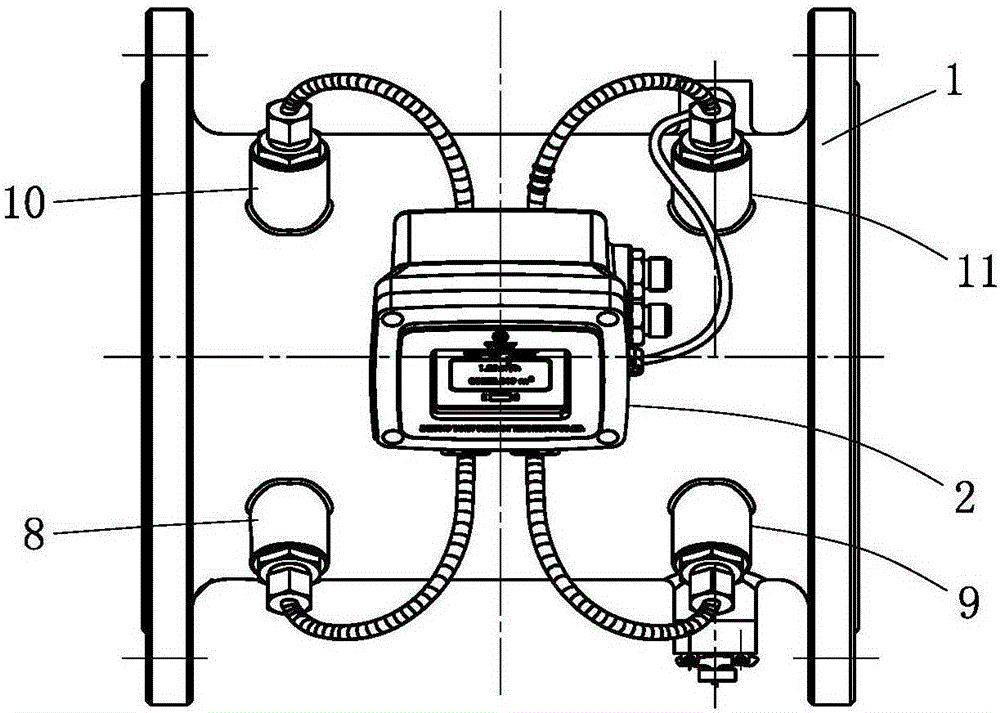

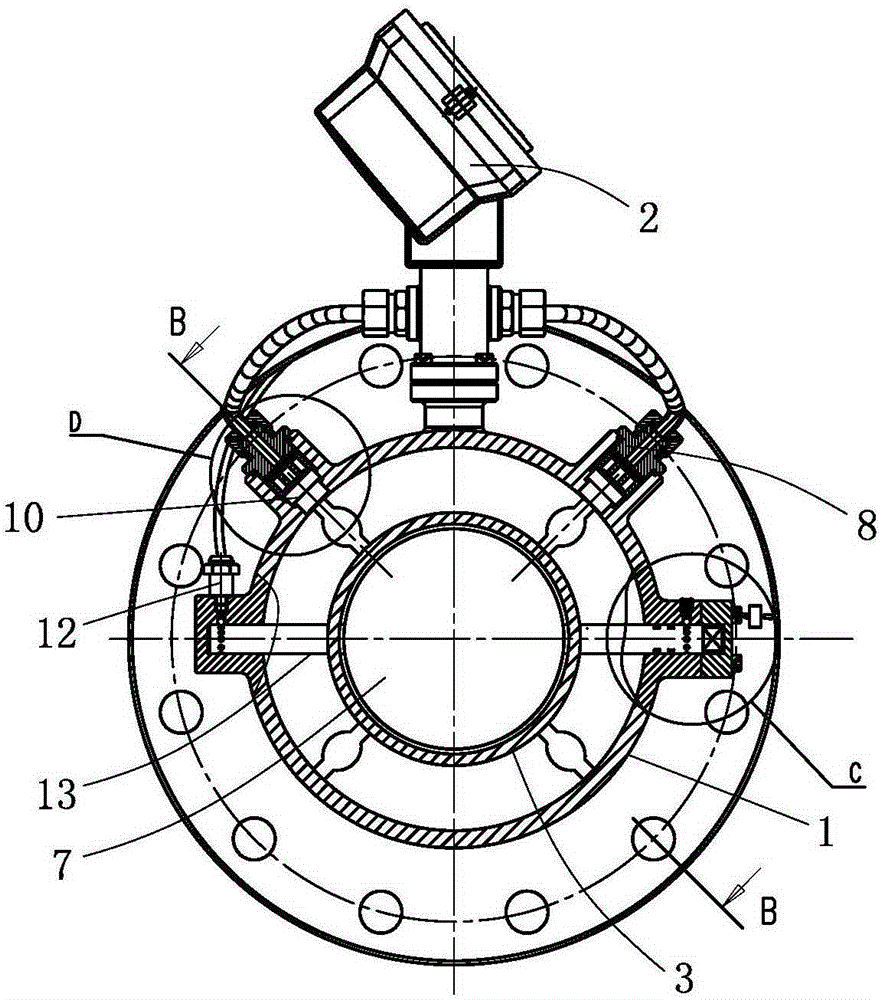

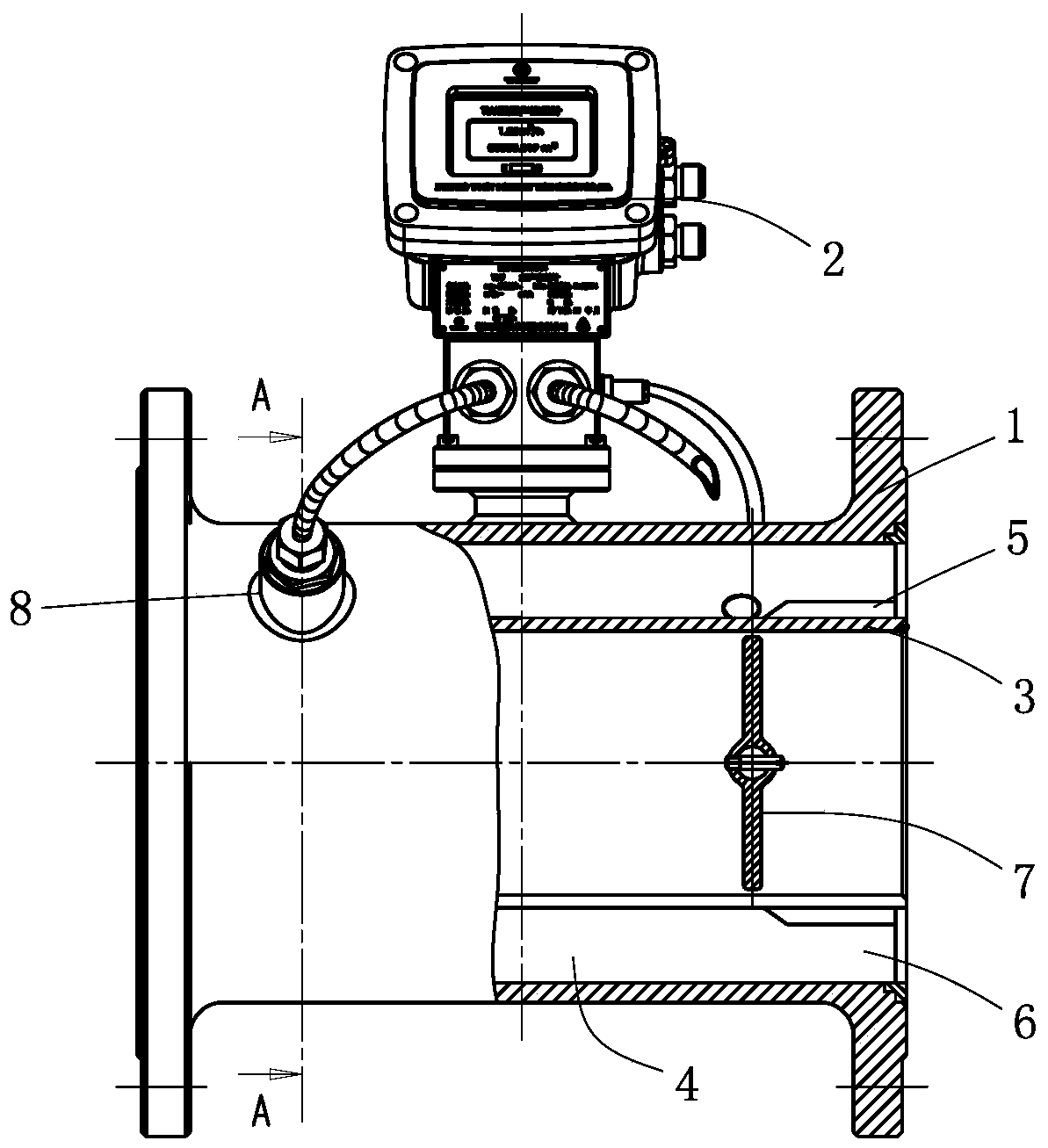

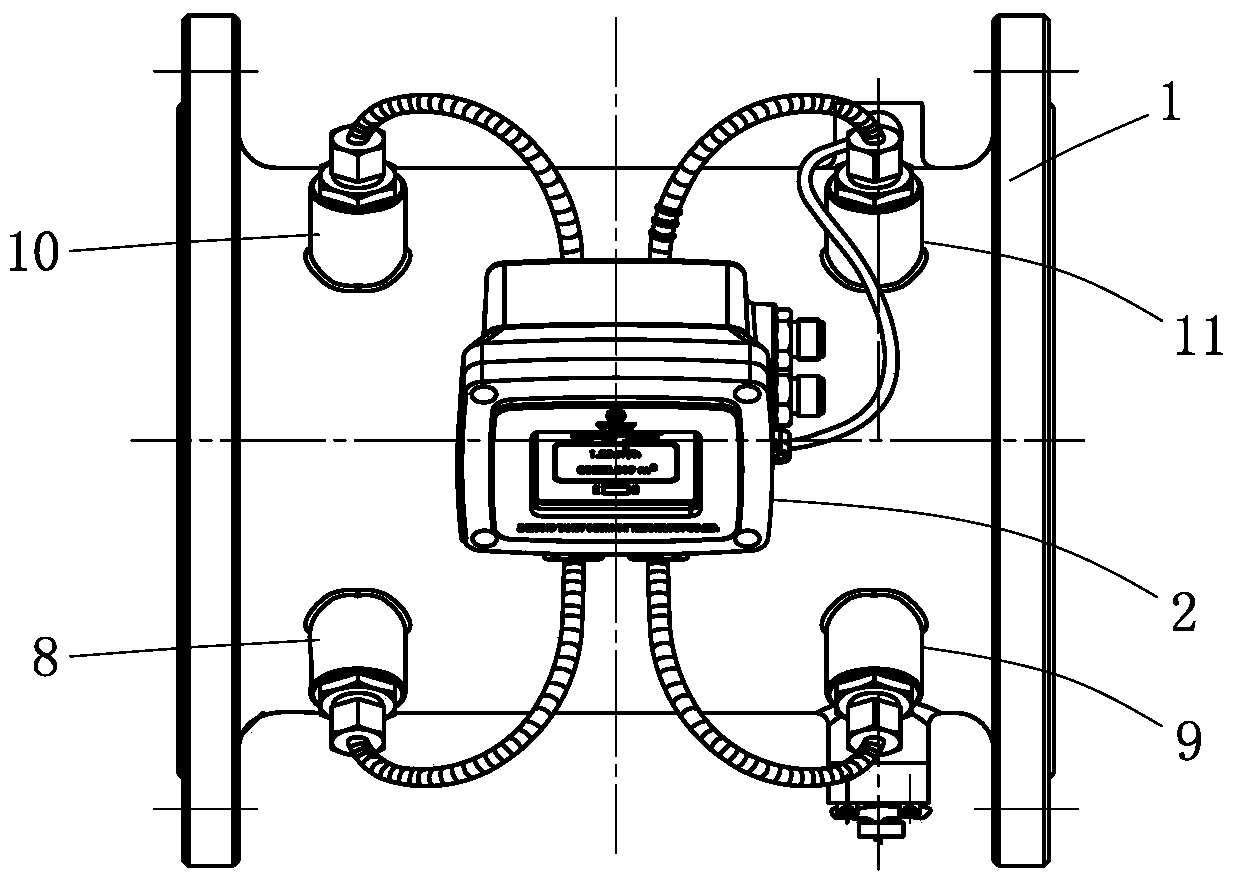

Ultrasonic flowmeter

ActiveCN105181044AHigh measurement accuracyImprove rectification effectVolume/mass flow measurementEngineeringMeasurement precision

The invention discloses an ultrasonic flowmeter which belongs to the technical field of fluid flow measuring equipment. The flowmeter comprises an outer housing. A flowmeter head is arranged outside the outer housing. The inner part of the outer housing is coaxially provided with an inner housing. A flow gap is arranged between the outer housing and the inner housing. Two ends of the flow gap are respectively provided with a first reflector plate and a second reflector plate. The first reflector plate and the second reflector plate are respectively provided with flow channels which extend axially, wherein the number of the flow channels on the first reflector plate is same with that of the flow channels on the second reflector plate. The flow channels on the first reflector and the second reflector which are arranged oppositely are coaxially arranged. The end of the first reflector plate is provided with a first reflection oblique surface which is conically arranged. The end of the second reflector plate is provided with a second reflection oblique surface which is conically arranged. A first probe and a second probe are separately arranged on the outer housing. The first probe and the second probe are connected with the flowmeter head. The ultrasonic flowmeter overcomes technical problems of low measurement precision and no wide enough measurement range in a time-difference-method ultrasonic flowmeter. The ultrasonic flowmeter provided by the invention can be widely applied in measurement for the flow speed of the fluid.

Owner:ZHEJIANG TIANXIN INSTR TECH CO LTD

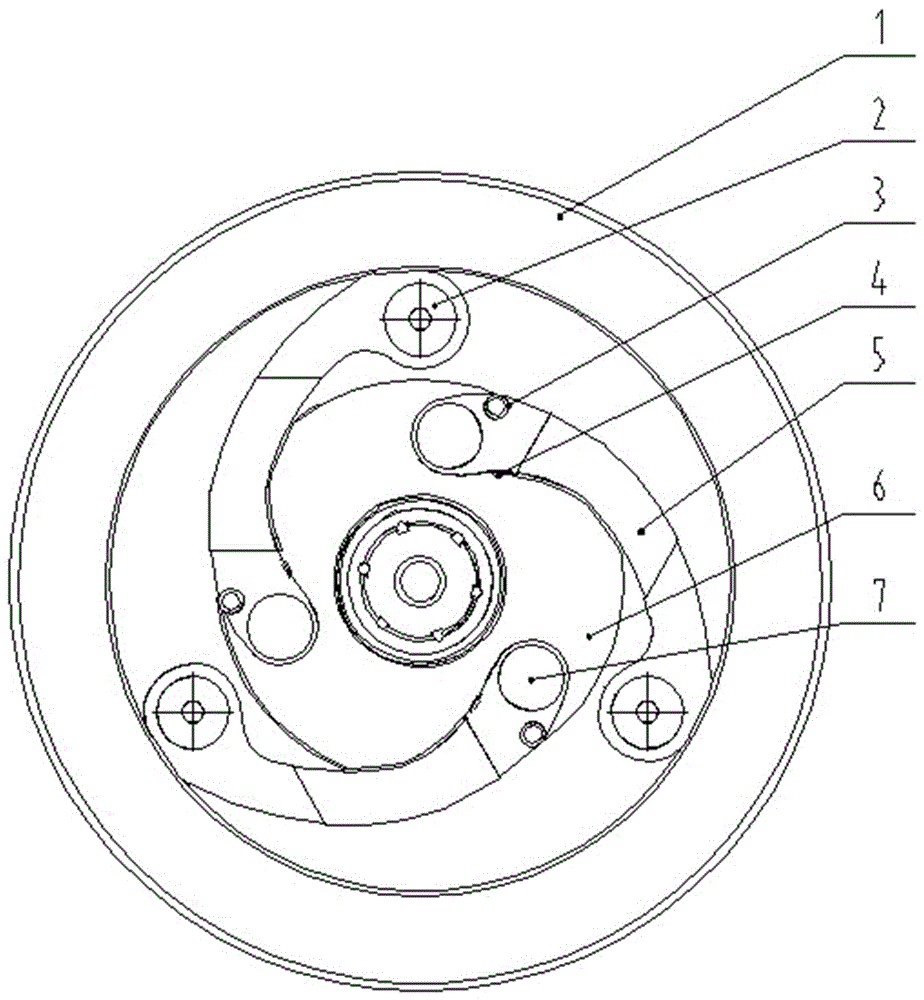

Cycloid planetary speed reducer of rapid point machine

The cycloid planetary speed reducer of a rapid point machine of the invention belongs to the technical field of mechanical drive technique, mainly comprising a uniform tray, a pin gear shell, a left cycloid gear, a right cycloid gear, pins, an input shaft, an output shaft, steady bearings and a dual-eccentric bearing. The uniform tray is supported on the end cap of the shell through the bearing, and the output shaft is supported by two ends of two bearings with different external diameters. The right end of the input shaft is supported on the inner surface of the centre bore of the output shaft, and the left end of the input shaft is supported on the inner surface of the centre bore of the uniform tray. When the input shaft rotates, the left cycloid gear and the right cycloid gear with 180 degrees phase difference take planetary motion through the dual-eccentric bearing. The uniform tray is used to equalize the bearing force of each pin, and the supporting of the output shaft is changed from the cantilever to the two ends to significantly enhance the strength and the rigidity of the entire output mechanism. The direct fixing of the pin gear shell and the shell is changed to cylindrical surface movable fit to play the function of overload protection. The invention has the characteristics of small size, light weight, large bearing capacity, steady transmission, high transmissionefficiency and long service life.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for reducing drive eccentric errors of harmonic gear and automatic aligning wave generator

The embodiment of the invention discloses a method for reducing drive eccentric errors of a harmonic gear and an automatic aligning wave generator. The automatic aligning wave generator comprises a turn plate driven by an input shaft and an elastic floating mechanism provided with two rollers. The elastic floating mechanism is flexibly arranged inside the turn plate in a sliding manner in the long axis direction of the automatic aligning wave generator. The elastic floating mechanism comprises two roller brackets symmetrically distributed relatively to the centre of the turn plate and an elastic element arranged between the roller brackets; the elastic element elastically resists against the two roller brackets, and the two rollers are respectively arranged on the two roller brackets, elastically resist against an inner circle of a flexible gear under the action of the elastic element and force the flexible gear to form an ellipse from a round shape, so that gear teeth of the flexible gear are tightly meshed with gear teeth of a rigid gear. The automatic aligning wave generator can reduce the eccentric errors caused by processing and assembling of parts, can remove the gear backlash between the gear teeth of the flexible gear and the gear teeth of the rigid gear and play an overload protection role.

Owner:深圳市东汇精密机电有限公司

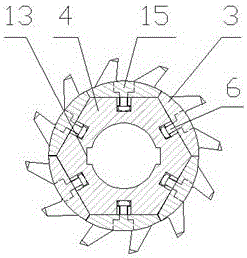

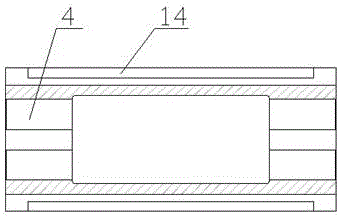

Gear tooth type crusher tooth roller

The invention relates to a toothed roller of a gear-toothed crusher, comprising a main shaft, a self-aligning roller bearing, a tooth plate, and a hexagonal cylinder. Connect the transmission, the tooth plate is fastened to the hexagonal cylinder with bolts through T-shaped slots; a signal generator is installed on the shaft end retaining ring at one end of the main shaft, and a signal receiver is installed on the blind cover outside the spherical roller bearing , when the main shaft rotates, the signal generator and the main shaft rotate together, while the signal receiver on the cover is relatively stationary relative to the main shaft, and the rotational speed of the main shaft is measured. The present invention changes the tooth roller structure of the gear-tooth crusher into a split type, which is convenient for replacement and maintenance, has a simple and reasonable structure, and reduces manufacturing costs; at the same time, it has a safety detection device, which plays the role of overload protection and enhances the safety and reliability of work. .

Owner:SHANGHAI UNIV

Manned system of ship crane

The invention discloses a manned system of a ship crane. An independent manned winch is mounted on the rear portion of a cargo winch on a crane jib. The manned winch is composed of a wall frame, a winding drum, a manned lifting cage, a hydraulic motor, a speed reducer, a winding drum brake and a valve set. The winding drum is fixed to the jib through the wall frame. The speed reducer is arranged in the winding drum. The speed reducer is provided with a wet hydraulic normal close brake and is connected with the hydraulic motor. The valve set is mounted on the hydraulic motor. A manned steel wire rope is wound on the winding drum and is connected with the manned lifting cage through a lifting hook. The winding drum brake is mounted on the winding drum and is provided with a lifting hook ascending and descending limiting device. The requirements for safety and reliability of the manned winch of the manned system are higher than those of the cargo winch, the winding drum brake is additionally arranged on the basis of integrating the brake on the speed reducer, dual brake is formed, the two brakes are controlled by the same oil way and act at the same time, and the design redundancy rate of the safety and reliability of the manned winch is fully guaranteed.

Owner:中船绿洲镇江船舶辅机有限公司

An ultrasonic flow meter

ActiveCN105181044BHigh measurement accuracyImprove rectification effectVolume/mass flow measurementEngineeringMeasurement precision

The invention discloses an ultrasonic flowmeter which belongs to the technical field of fluid flow measuring equipment. The flowmeter comprises an outer housing. A flowmeter head is arranged outside the outer housing. The inner part of the outer housing is coaxially provided with an inner housing. A flow gap is arranged between the outer housing and the inner housing. Two ends of the flow gap are respectively provided with a first reflector plate and a second reflector plate. The first reflector plate and the second reflector plate are respectively provided with flow channels which extend axially, wherein the number of the flow channels on the first reflector plate is same with that of the flow channels on the second reflector plate. The flow channels on the first reflector and the second reflector which are arranged oppositely are coaxially arranged. The end of the first reflector plate is provided with a first reflection oblique surface which is conically arranged. The end of the second reflector plate is provided with a second reflection oblique surface which is conically arranged. A first probe and a second probe are separately arranged on the outer housing. The first probe and the second probe are connected with the flowmeter head. The ultrasonic flowmeter overcomes technical problems of low measurement precision and no wide enough measurement range in a time-difference-method ultrasonic flowmeter. The ultrasonic flowmeter provided by the invention can be widely applied in measurement for the flow speed of the fluid.

Owner:ZHEJIANG TIANXIN INSTR TECH CO LTD

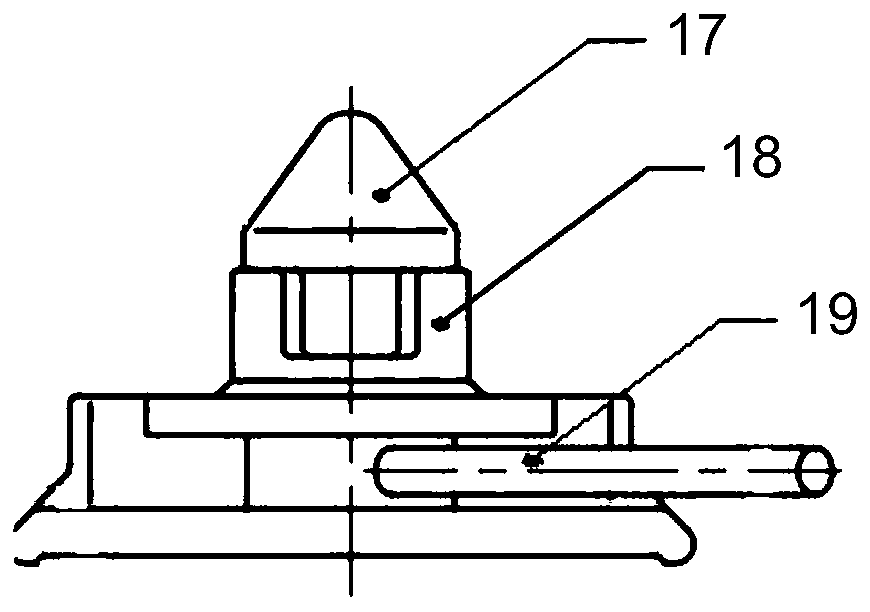

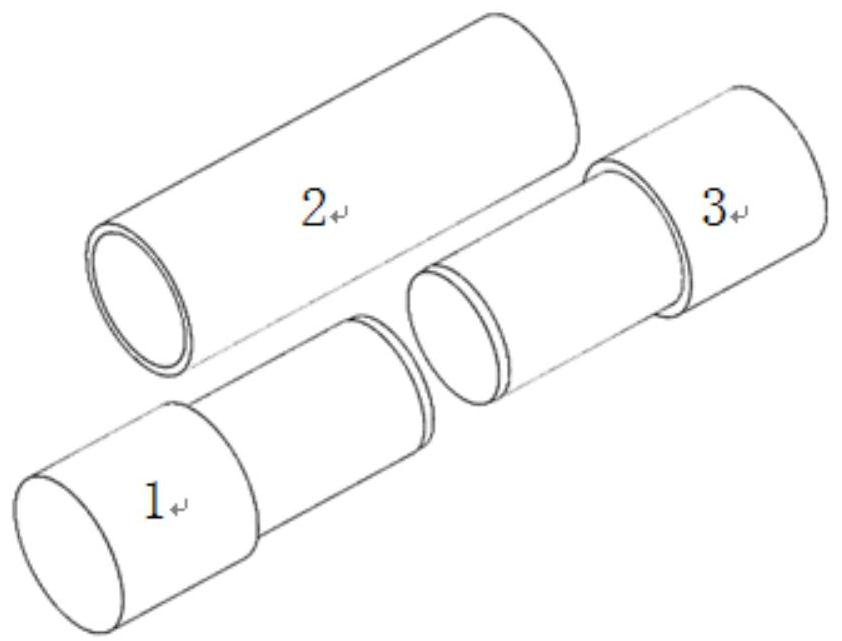

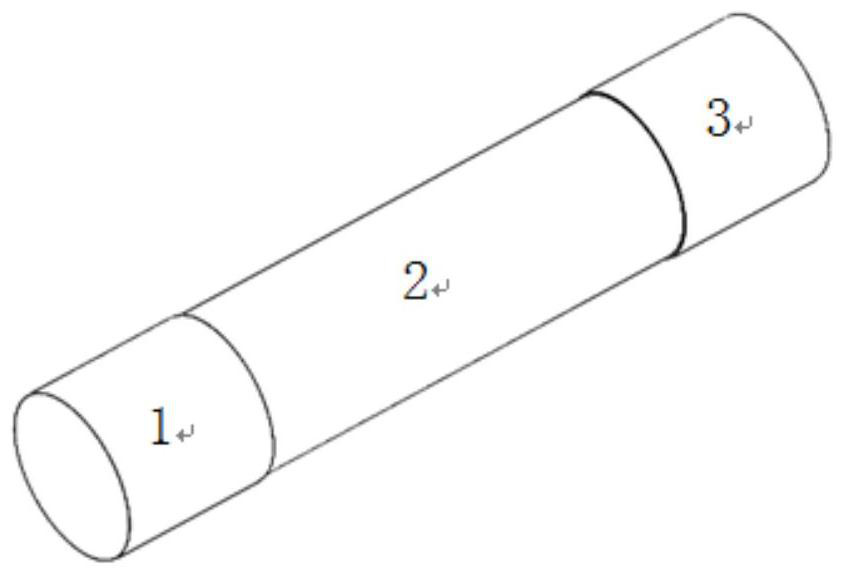

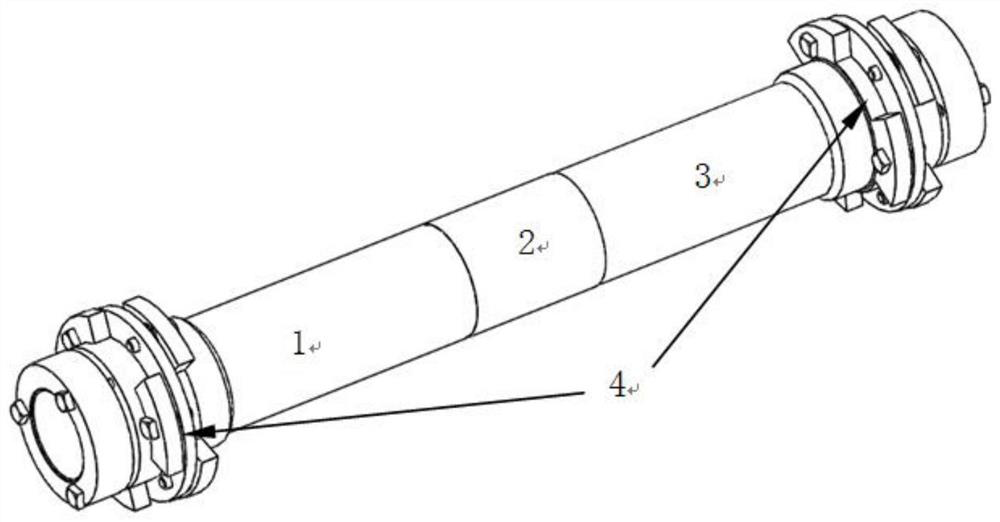

A Torque Overload Protection Method for Transmission Shaft Based on Carbon Fiber Composite Materials

ActiveCN110242682BReduce transmission efficiencyLarge structure sizeAutomatic clutchesFiberFriction torque

The invention relates to a transmission shaft torque overload protection method based on a carbon fiber composite. The method is achieved through failure of the interference connection of a metal material transmission shaft and a carbon fiber composite shaft pipe. When the torque transmitted by the transmission shaft is within the rated torque range, friction torque generated by interference connection of the metal shaft and the carbon fiber composite shaft pipe is larger than the transmission torque, and torque can be normally transmitted; when the transmission torque is larger than the rated torque, slippage is generated between the metal shaft and the carbon fiber composite shaft pipe, interference connection fails, the torque cannot be transmitted, and overload protection is achieved; a carbon fiber composite base body has certain elasticity and wear resistance, when overloads fail, the connection interface is quite small in wear, when overload torque is eliminated, the transmission state can be immediately recovered, compared with the prior art, the method is integrated with the transmission shaft, other structures are not increased, and the structure and the size of an existing shaft do not need to be changed.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com