Elastic body of weighing sensor

A weighing sensor and elastomer technology, applied in the field of elastomers, can solve the problems of lack of protection for weighing sensors, affect food safety requirements, damage to strain gauges, etc., achieve convenient processing and overload control, meet food safety requirements, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

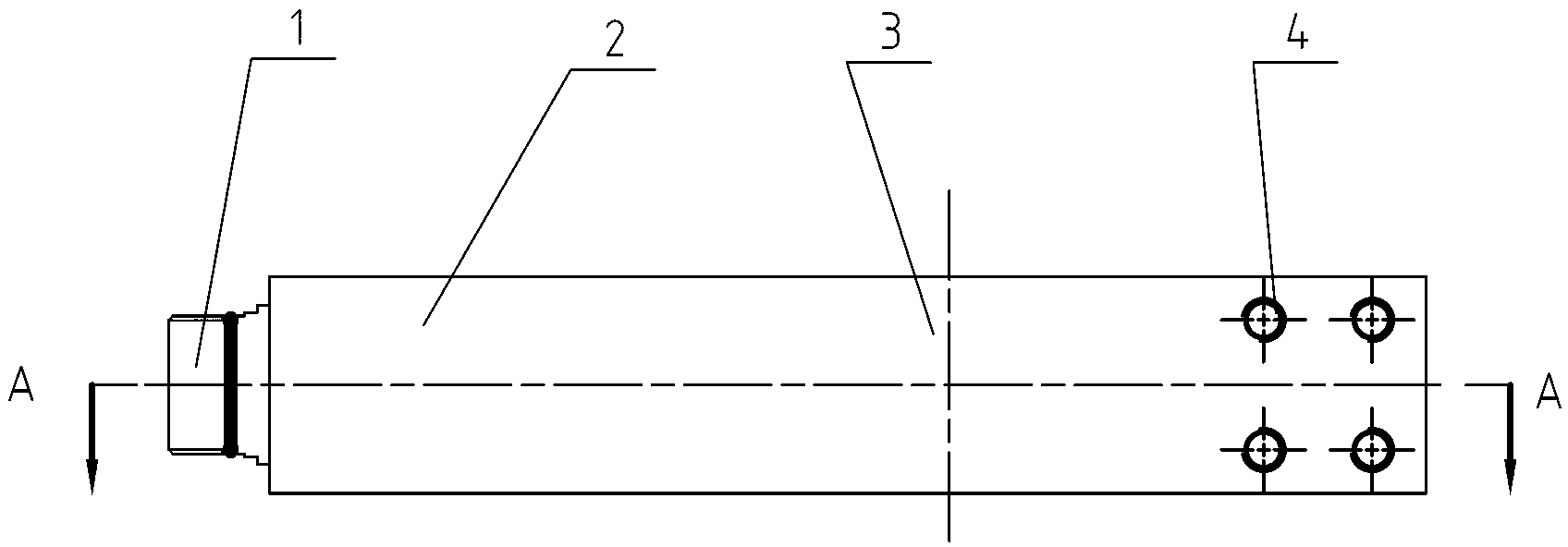

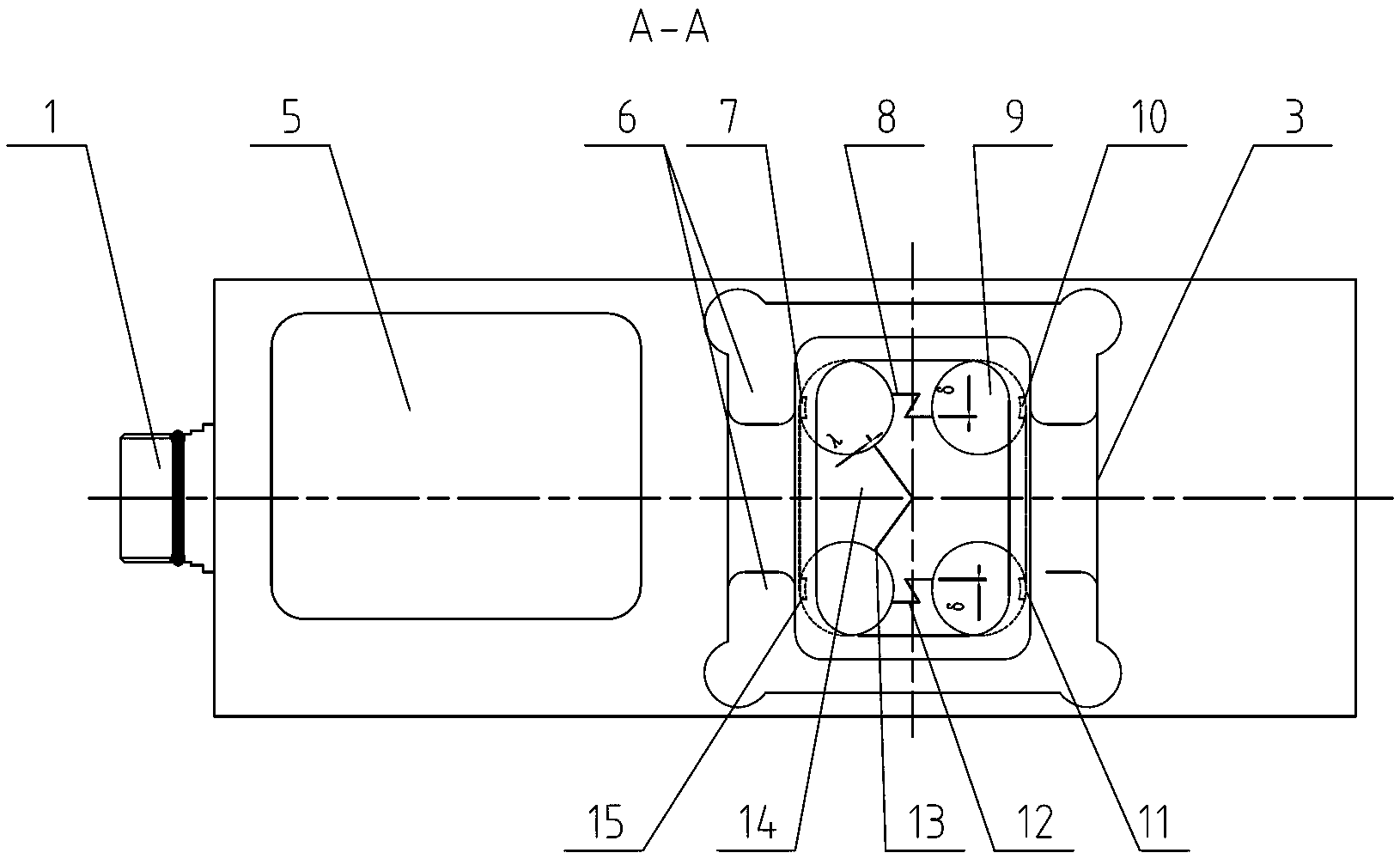

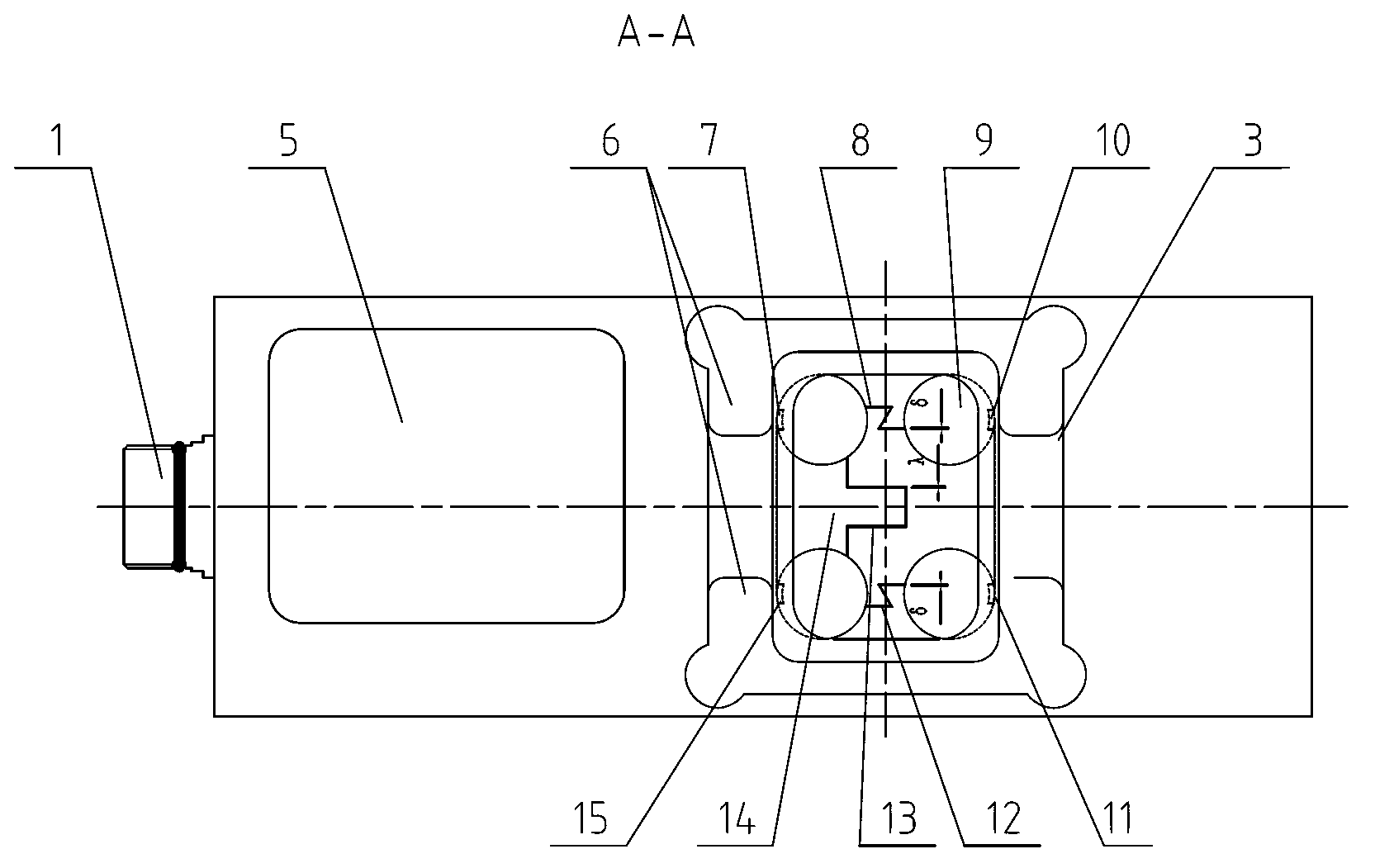

[0017] See Figure 1~4 As shown, the elastic body of the load cell of the present invention includes a fixed part 2 and a strain part 3. The fixed part 2 includes a printed board installation hole 5 arranged on the elastic body, and a printed board is installed in the printed board installation hole 5. The printed board is connected with the cable connector 1, and the electrical signal is output through the cable connector 1. The fixing part 2 also has a threaded hole, and the elastic body is fixed on the base through a fastener. The strain part 3 of the present invention comprises a strain hole 9 on the elastic body and a group of strain gauges fixed in the strain hole 9, a group of strain gauges usually adopts four strain gauges, and each strain gauge is located at the thin wall of the strain hole 9, when When the elastic body is deformed by external force, the strain gauges fixed on the elastic body are also deformed at the same time, causing the resistance value of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com