Patents

Literature

79results about How to "Achieving adaptive adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

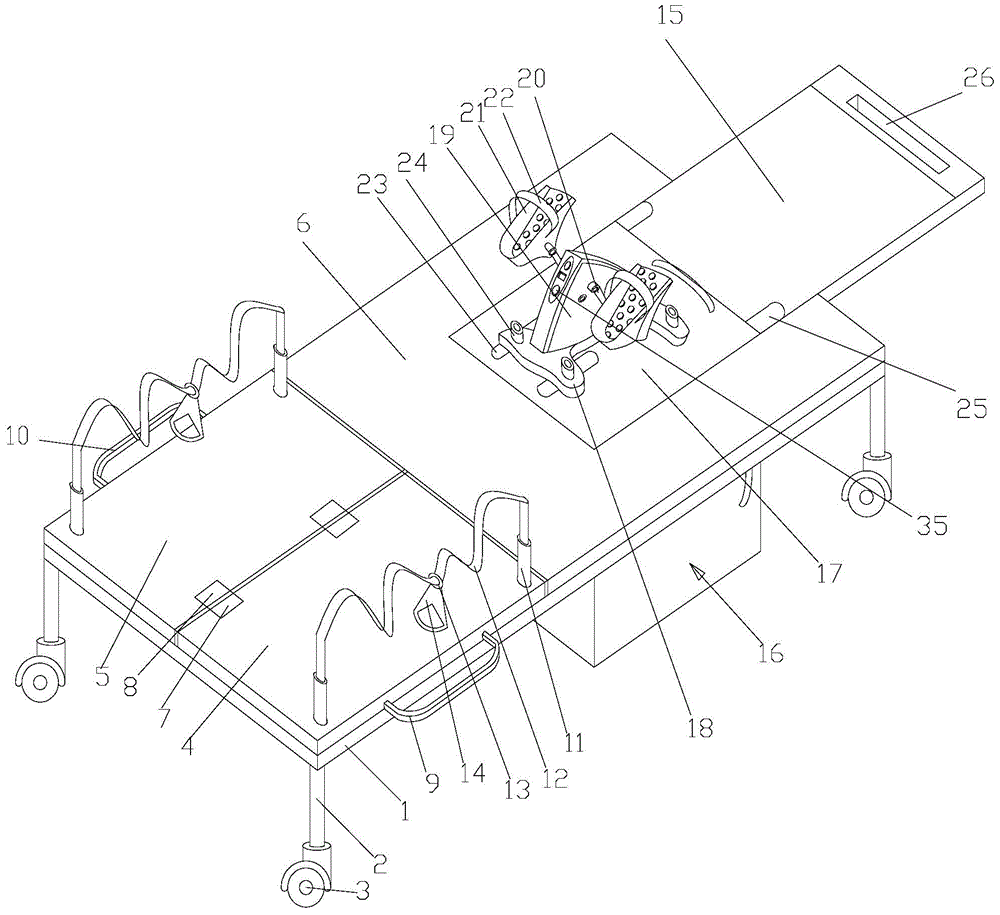

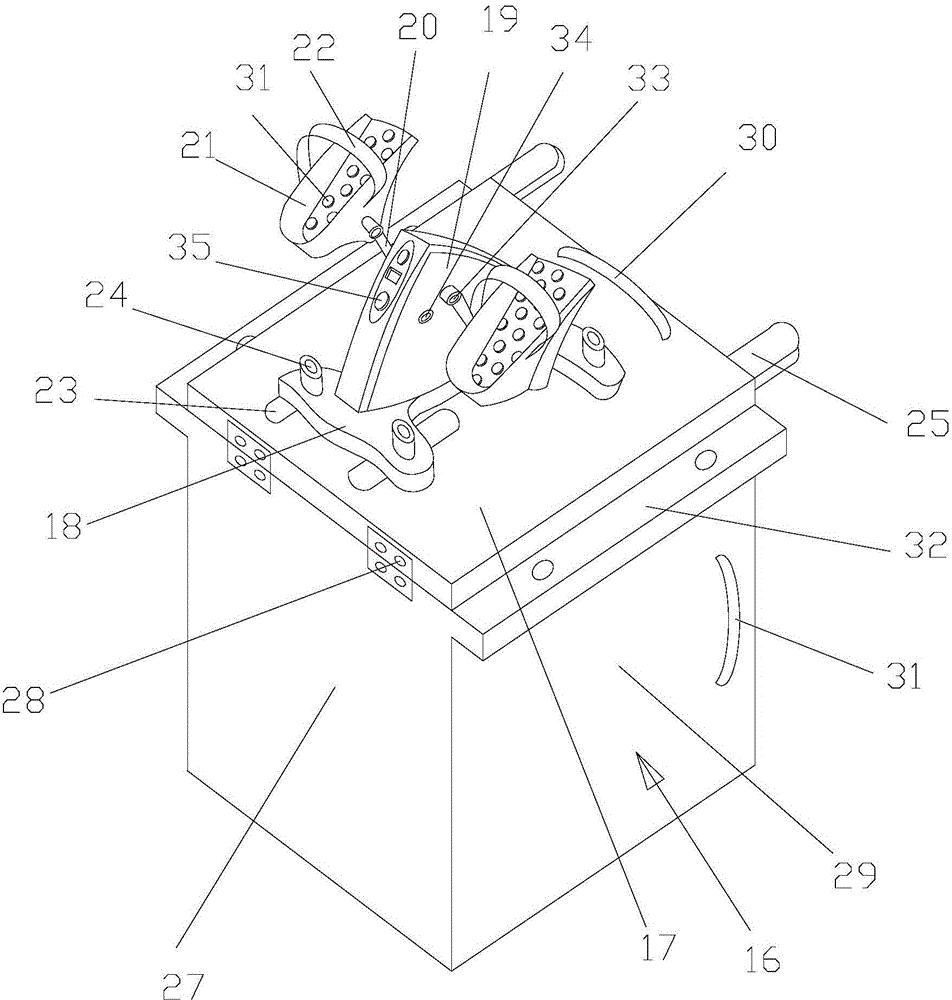

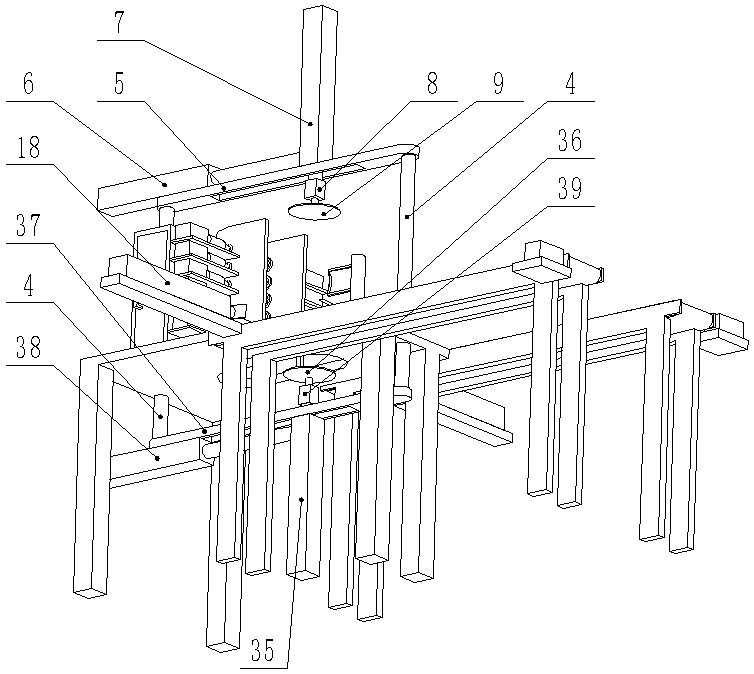

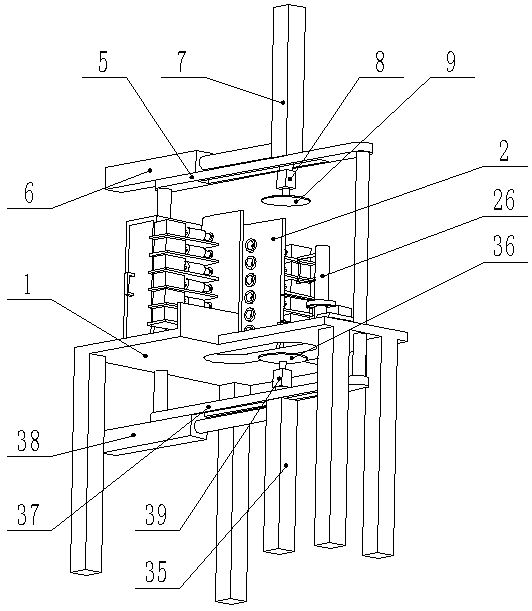

A neurology department nursing bed having active and passive exercise functions

InactiveCN106031688ARealize partial rollover functionConvenient careGymnastic exercisingChiropractic devicesDiseaseFunctional exercises

The invention provides a neurology department nursing bed having active and passive exercise functions. The neurology department nursing bed comprises a bed frame, support legs with universal wheels and a bed plate. The upper portion of the bed plate is a split type waist plate and the lower portion of the bed plate is a leg plate with a groove; the split type waist plate consists of a left turning plate and a right turning plate which can be turned inward; two sides of the split type waist plate are provided with upper limb coordination function exercise devices; the groove in the lower portion of the bed plate is provided with a lower limb active and passive function exercise device; the lower limb active and passive function exercise device consists of a box body fixedly connected to the bed frame and an active and passive pedaling device received in the box body. Compared with the conventional nursing beds, the neurology department nursing bed fulfils a body part side turning function, is equipped with the upper limb coordination function exercise devices and the lower limb active and passive function exercise device and is conducive to the progressive rehabilitation of generalized muscle functions of patients with neurological diseases.

Owner:李丽丽

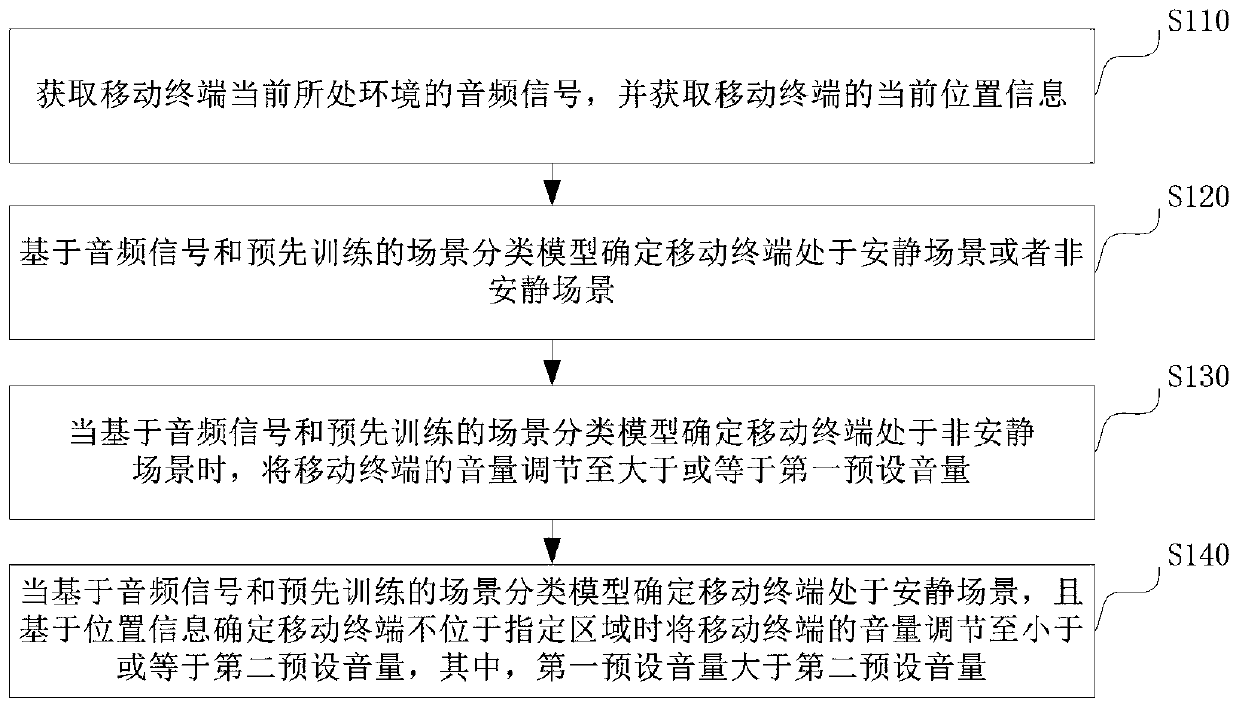

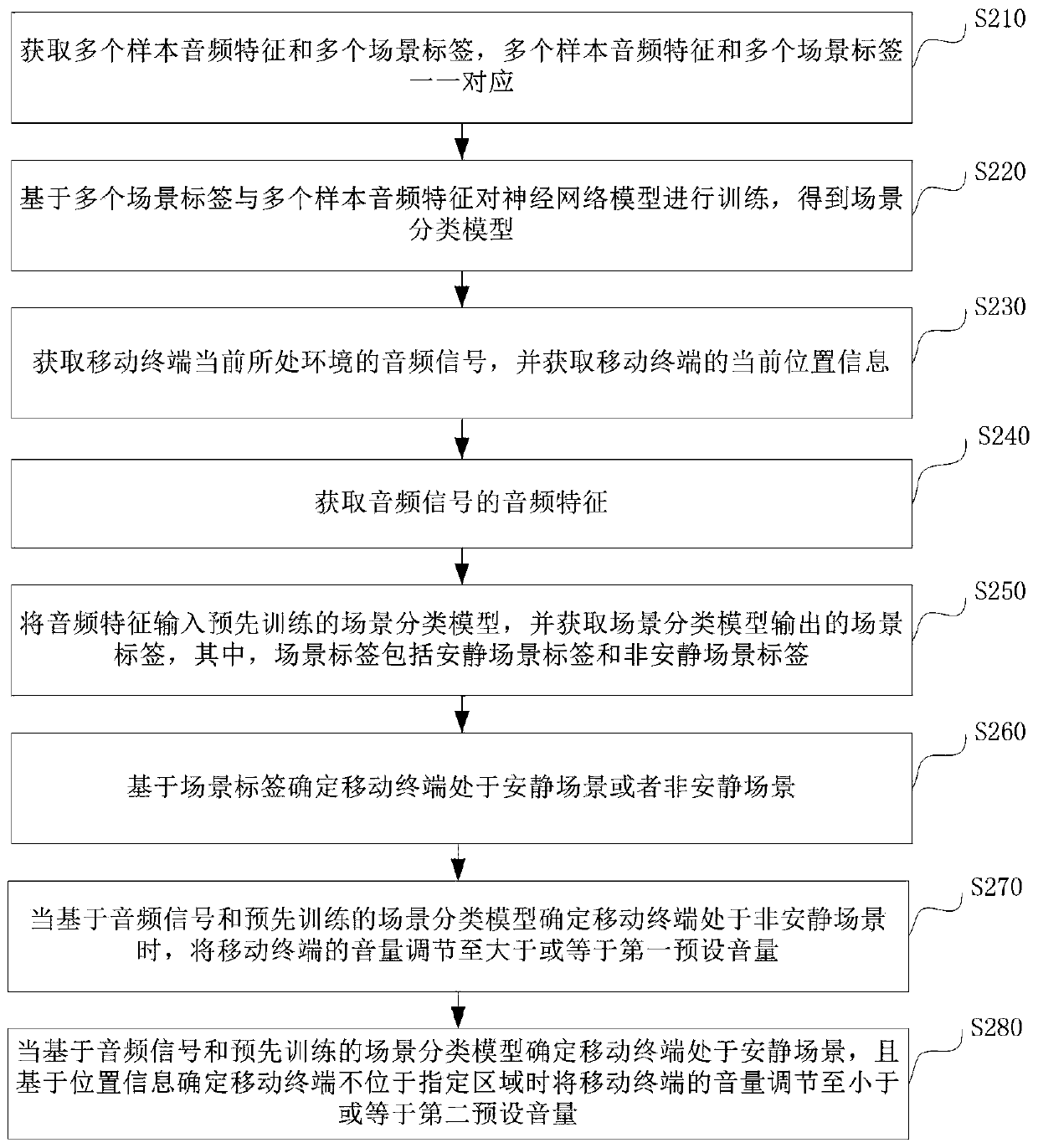

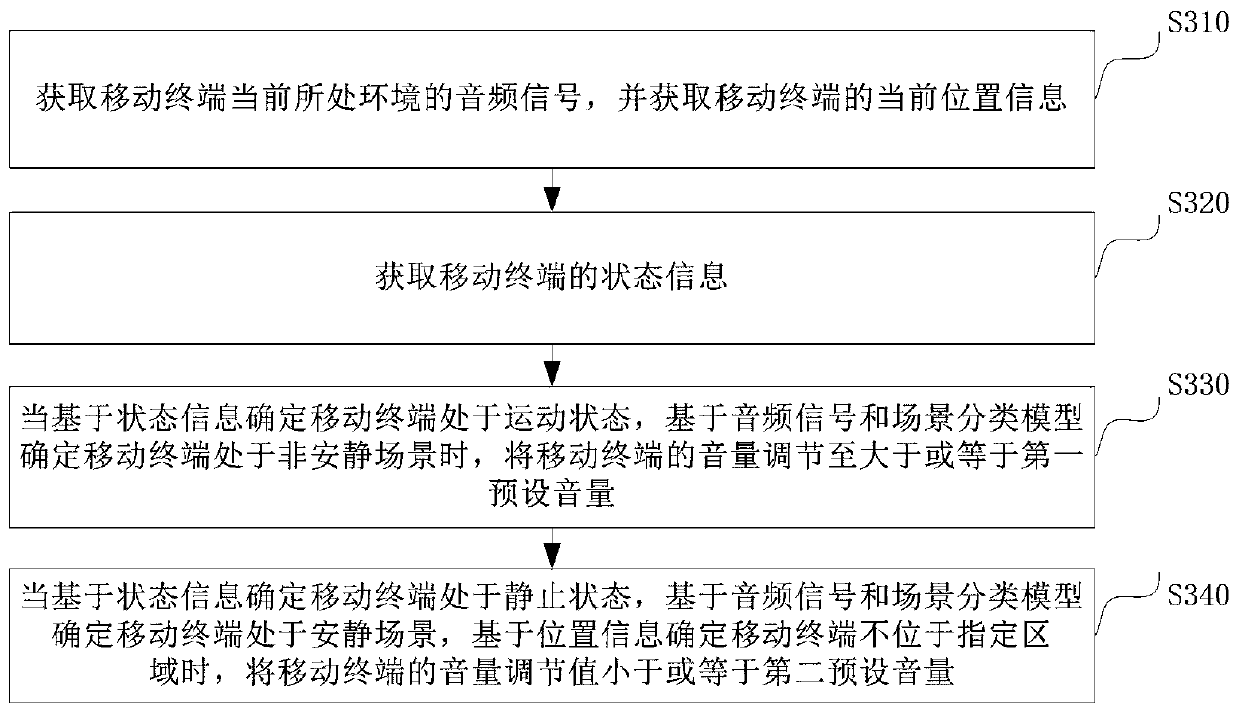

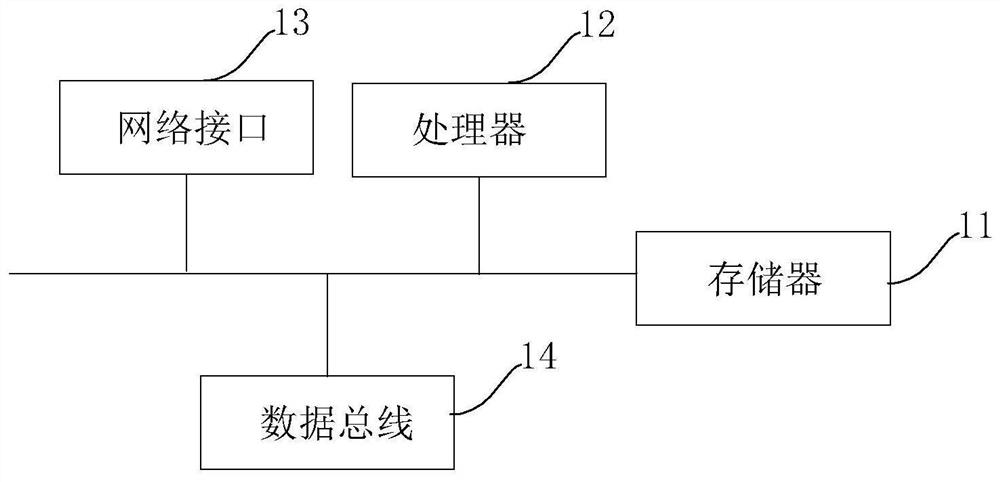

Volume adjustment method and device of mobile terminal, mobile terminal and storage medium

InactiveCN110995933AAffect normal useAchieving adaptive adjustmentDevices with sensorCurrent supply arrangementsEngineeringAudio frequency

The embodiment of the invention discloses a volume adjustment method and device of a mobile terminal, the mobile terminal and a storage medium, and relates to the technical field of mobile terminals.The method is applied to the mobile terminal, and comprises the following steps: acquiring an audio signal of the current environment of the mobile terminal, and acquiring current position informationof the mobile terminal; determining whether the mobile terminal is in a quiet scene or a non-quiet scene based on the audio signal and a pre-trained scene classification model; when it is determinedthat the mobile terminal is in a non-quiet scene based on the audio signal and a pre-trained scene classification model, adjusting the volume of the mobile terminal to be greater than or equal to a first preset volume; and when determining that the mobile terminal is in a quiet scene based on the audio signal and a pre-trained scene classification model and determining that the mobile terminal isnot located in a specified area based on the position information, adjusting the volume of the mobile terminal to be less than or equal to a second preset volume. The volume of the mobile terminal canbe adaptively adjusted according to different scenes.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

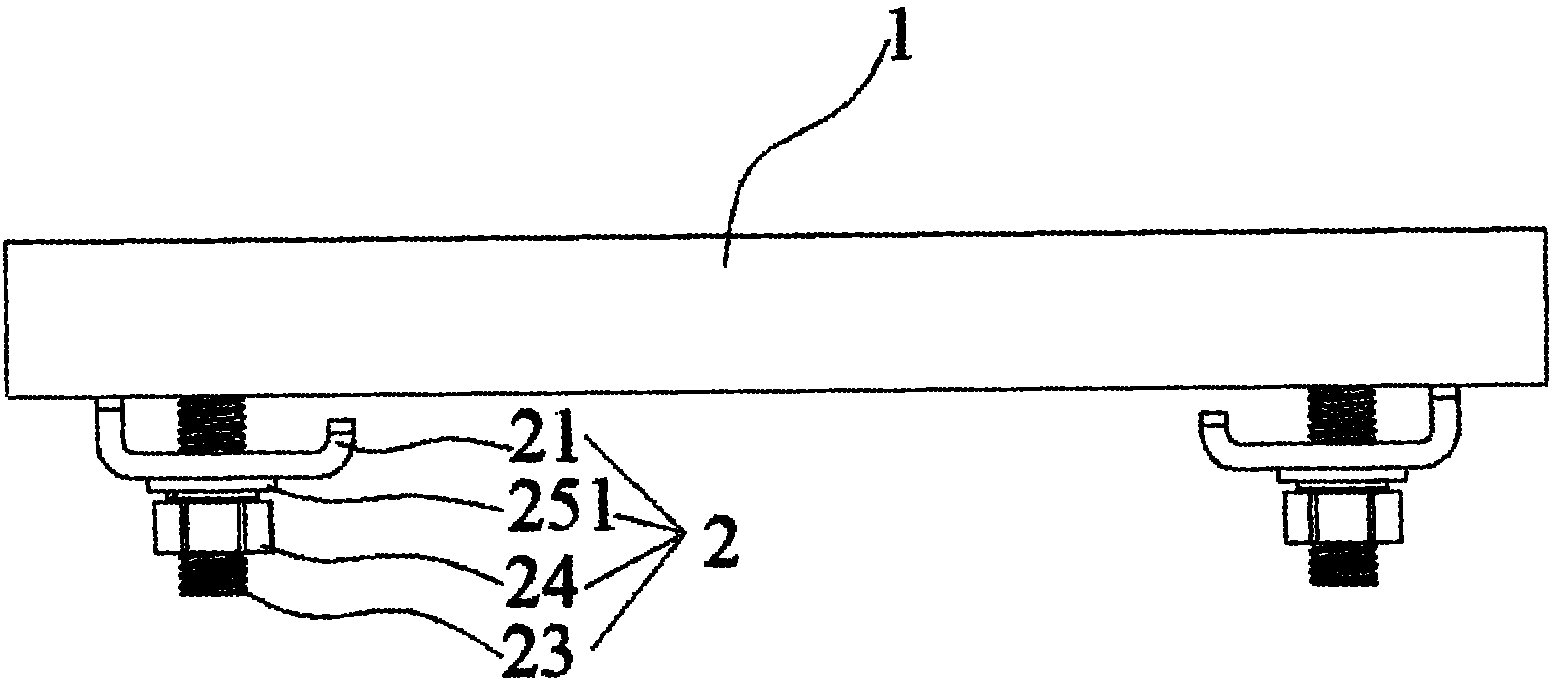

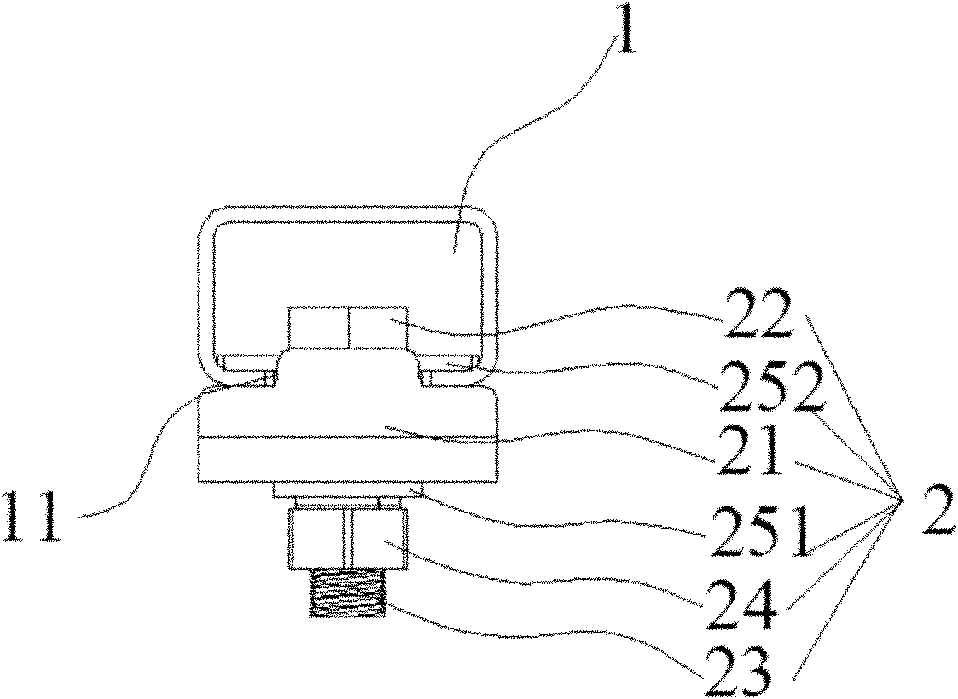

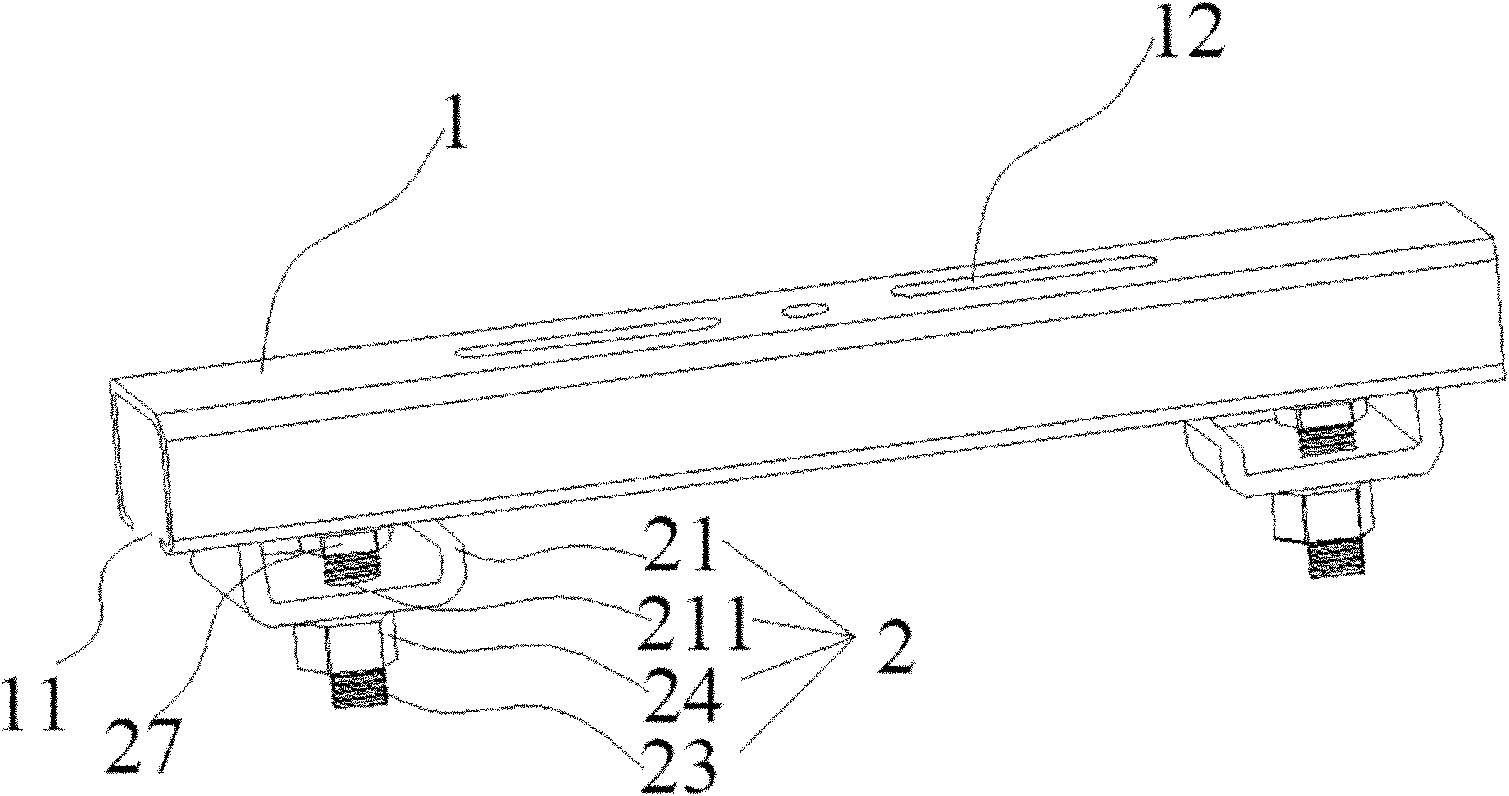

Adjustable type lamp bracket and lamp shell

InactiveCN101975381ASimple structureCompact structureLighting support devicesStructural engineeringLamp shell

The invention discloses an adjustable type lamp bracket and a lamp shell. The adjustable type lamp bracket comprises an installation rod and sliding parts, wherein the installation rod is provided with a sliding groove along an axial direction; the sliding parts are fixed in the sliding groove and arranged in pairs; and the relative positions of the sliding parts and the installation rod and the distance between the two sliding parts are adjustable. The adjustable type lamp bracket effectively realizes the adjustment of the adaptability of lamps with different specifications and different requirements for different positions relative to the installation rod by adjusting the positions of the paired sliding parts positioned on the installation rod and the distance between the sliding parts and effectively realizes the interchangeability of different lamps during fixation by adjusting the positions of the paired sliding parts connected with the lamp shell.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

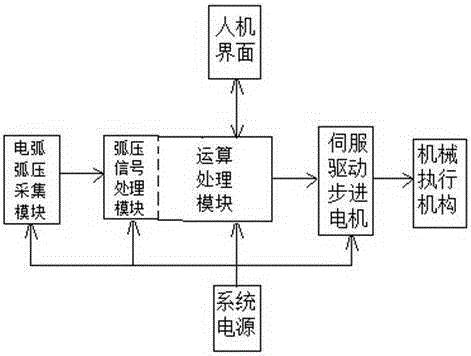

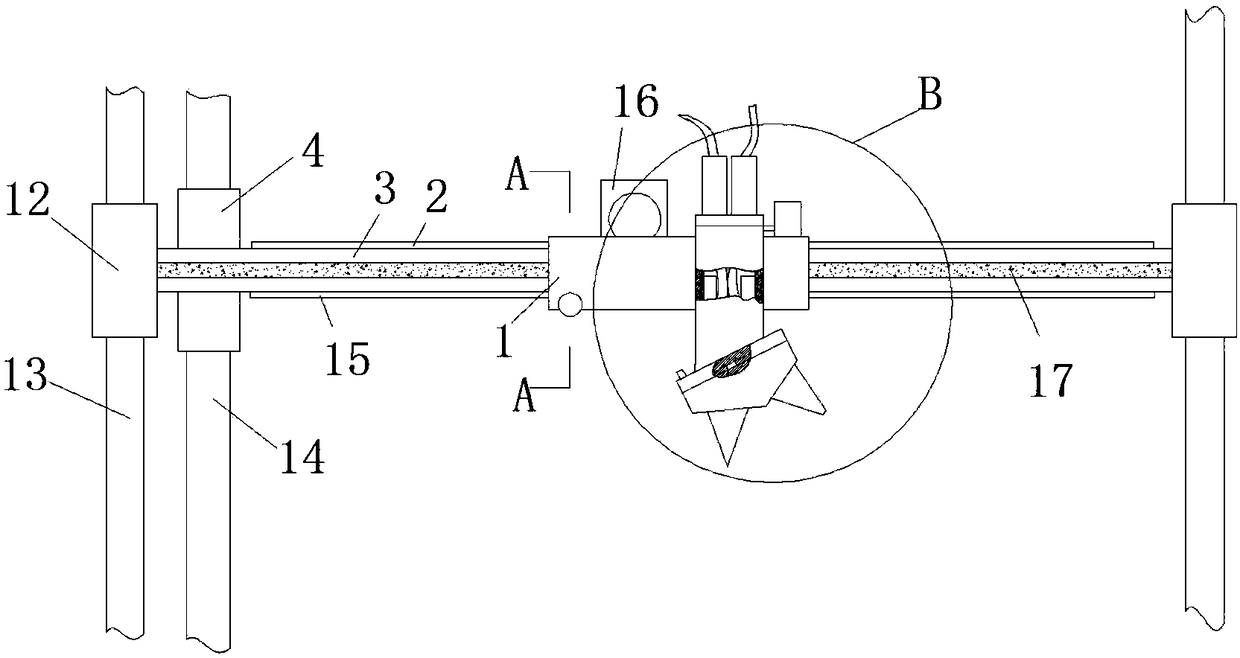

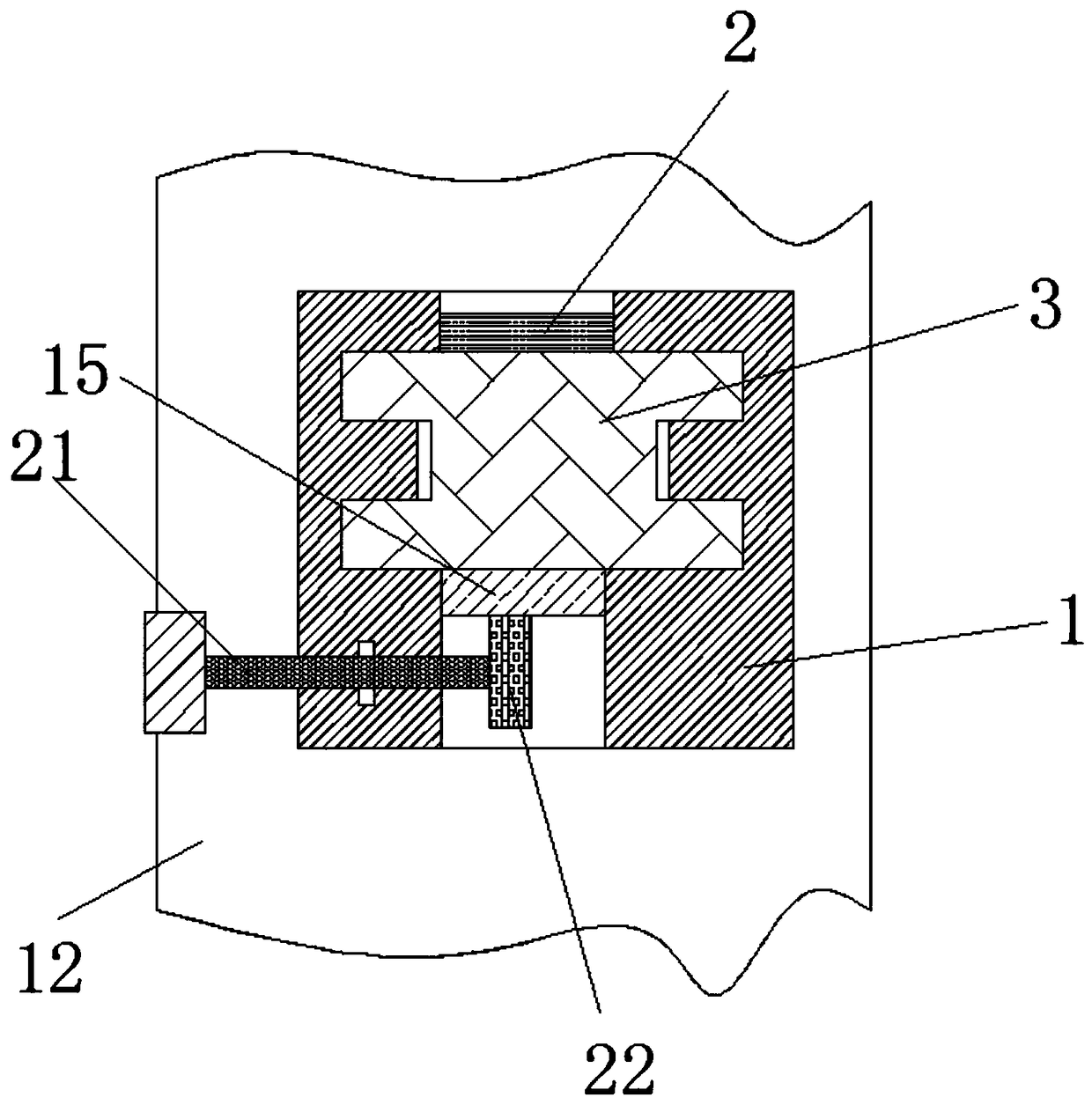

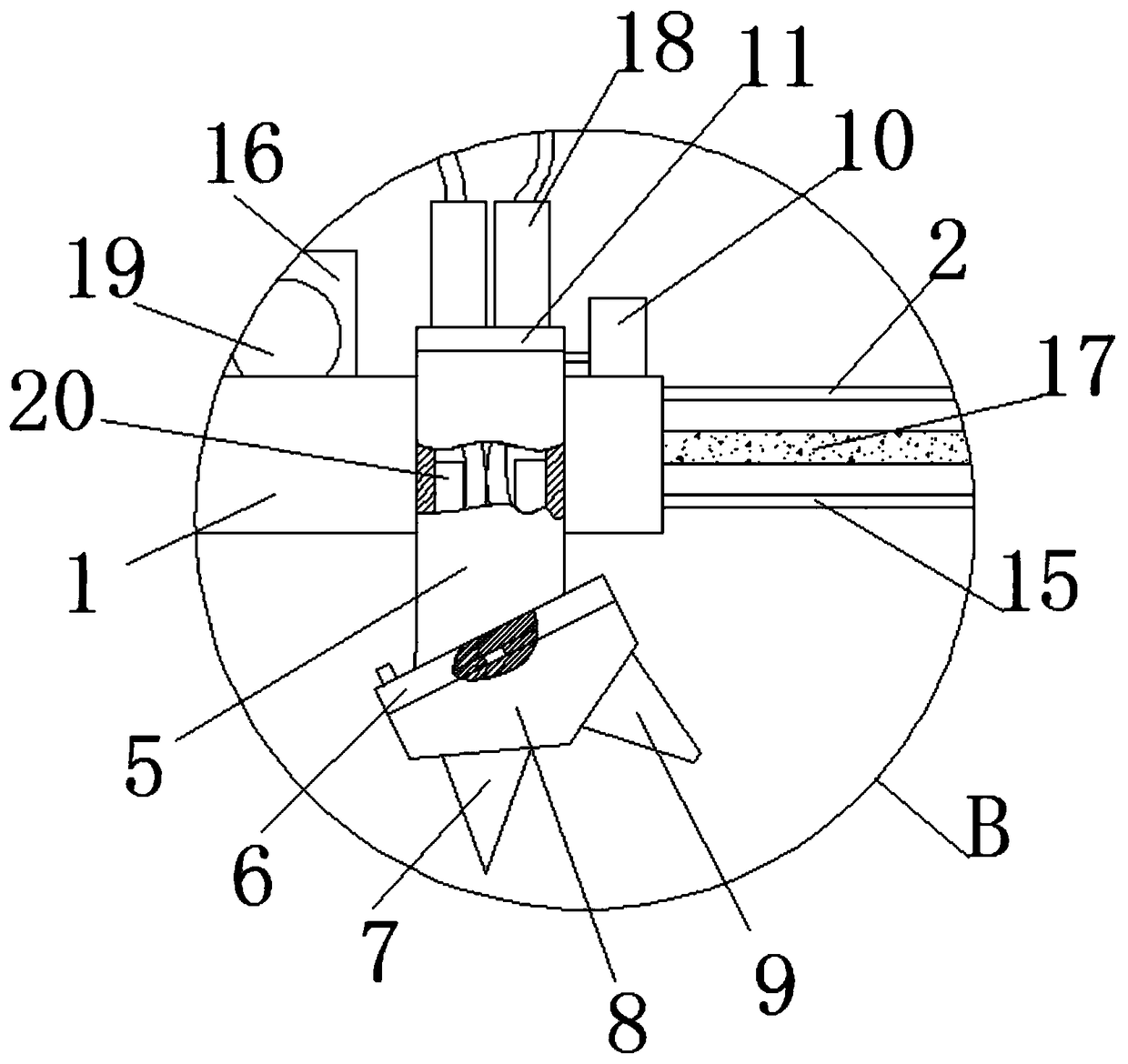

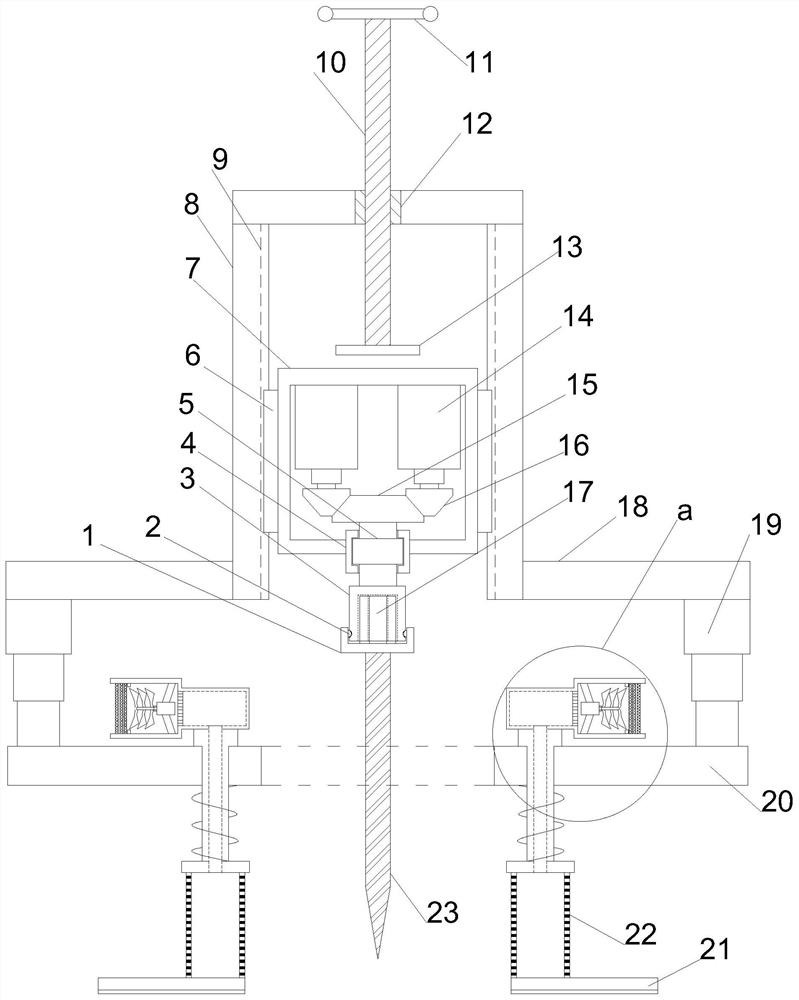

Plasma cutting height adjuster and working method thereof

InactiveCN105290588AAchieving adaptive adjustmentImprove cut qualityPlasma welding apparatusPlasma cuttingVoltage

The invention discloses a plasma cutting height adjuster and a working method thereof. The plasma cutting height adjuster comprises an electric arc voltage collecting module, a cutting gun height adjusting device and a computing module. The signal input end of the computing module is connected with the signal output end of the electric arc voltage collecting module. The signal output end of the computing module is connected with the cutting gun height adjusting device. A set electric arc voltage value corresponding to workpieces of different cutting thicknesses is arranged in the computing module. The computing module is used for driving the cutting gun height adjusting device to act according to the real-time electric arc voltage value collected by the electric arc voltage collecting module, and therefore the height distance between a plasma cutting gun and the workpieces is adjusted, and the real-time electric arc voltage value produced when the plasma cutting gun cuts the workpieces tends to the set electric arc voltage value. The self-adaption adjustment can be conducted on electric arc voltage of the plasma cutting gun by adjusting the height of the plasma cutting gun in the cutting process, and therefore cutting quality and accuracy are improved.

Owner:JIANGSU UNIV OF TECH

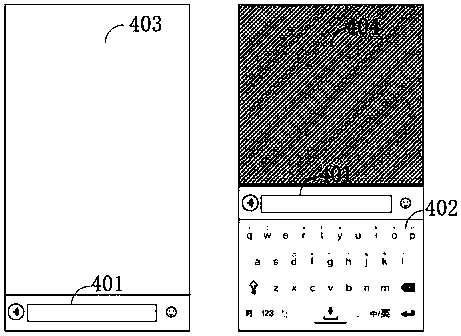

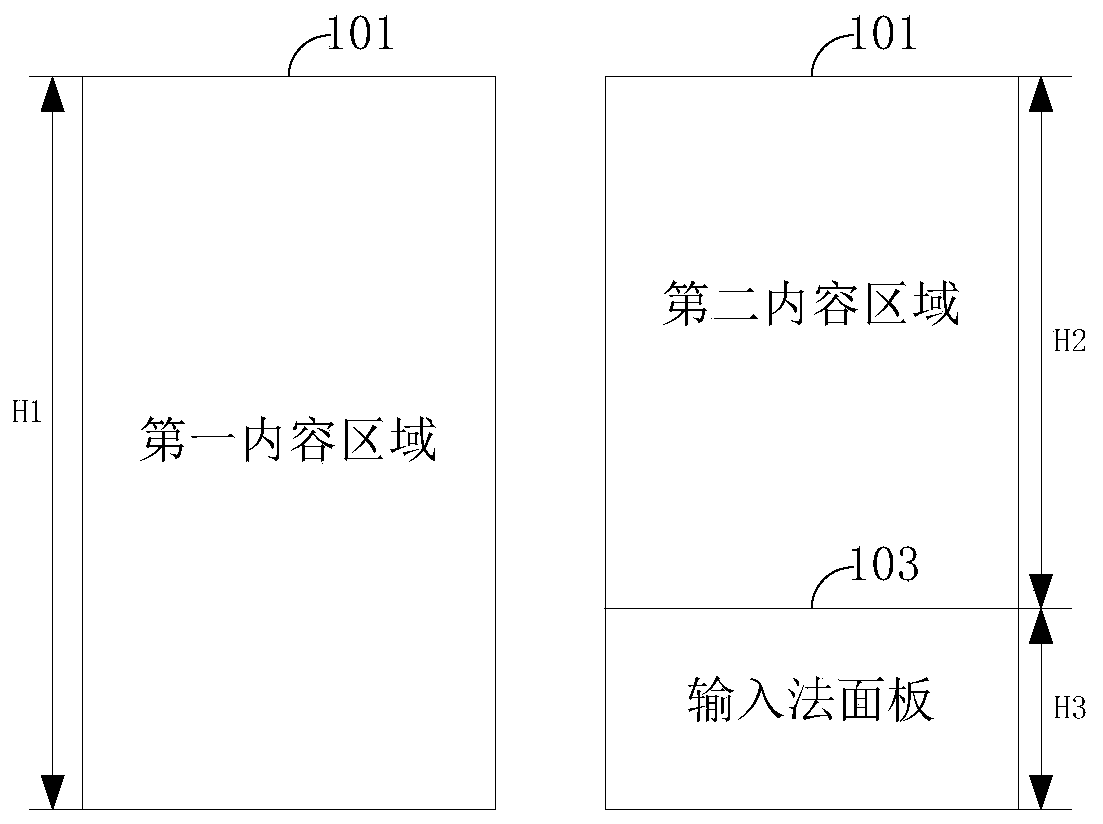

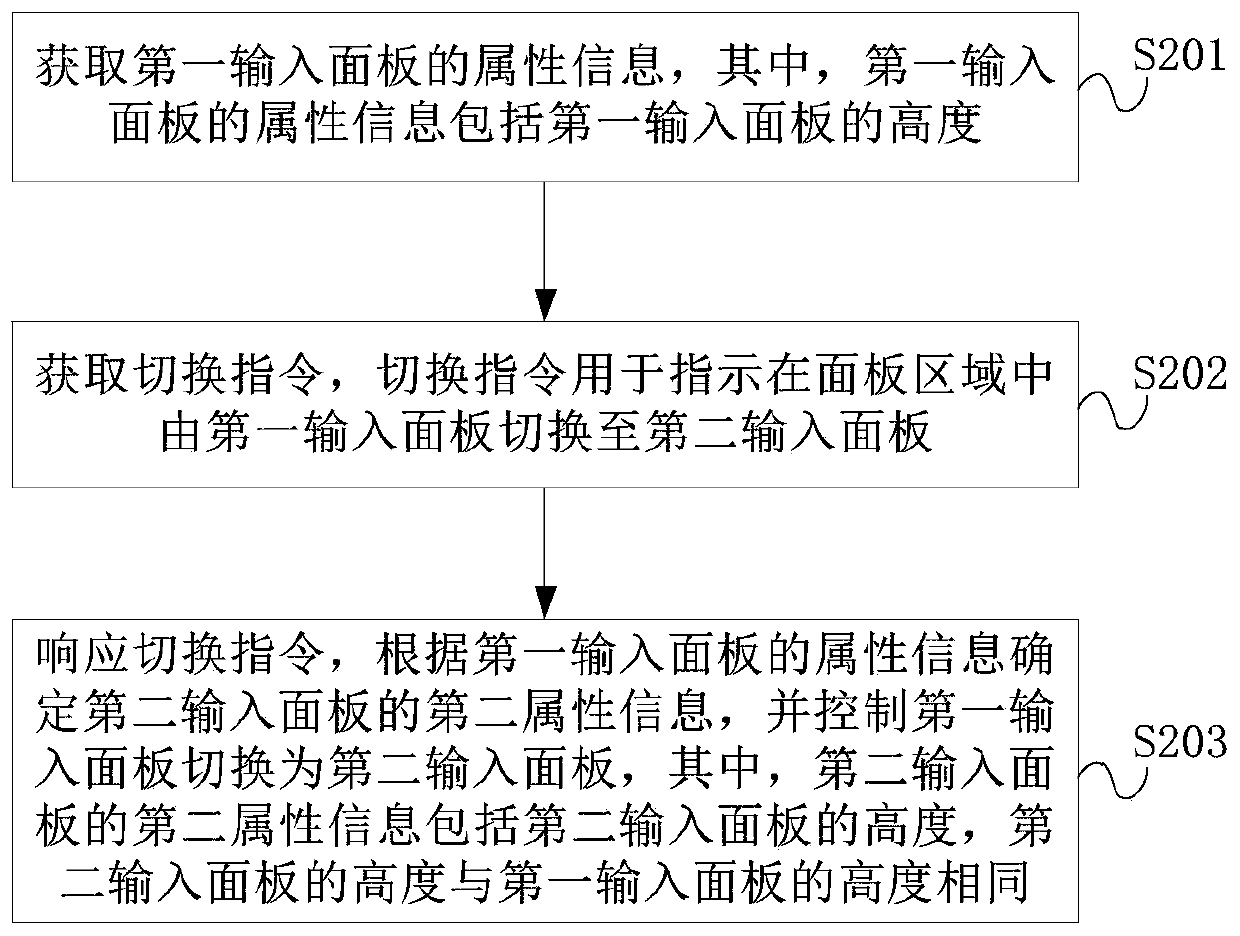

Input panel switching method and device

InactiveCN110058778AAvoid jitterAchieving adaptive adjustmentExecution for user interfacesInput/output processes for data processingComputer engineeringJitter

The embodiment of the invention provides an input panel switching method and device, and the method comprises the steps: obtaining the first attribute information of a first input panel, and enablingthe first attribute information of the first input panel to comprise the height of the first input panel; obtaining a switching instruction, wherein the switching instruction is used for indicating toswitch from the first input panel to the second input panel in the panel area; responsive to switching instructions, according to the first attribute information of the first input panel, determiningsecond attribute information of the second input panel, controlling the first input panel to be switched into the second input panel, wherein the second attribute information of the second input panel comprises the height of the second input panel, and the height of the second input panel is the same as that of the first input panel. According to the embodiment, the first attribute information ofthe first input panel is acquired, and the height of the second input panel is set to be the same as that of the first input panel, so that switching of the input panels is realized, and jitter in the switching process of the input panels is avoided.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

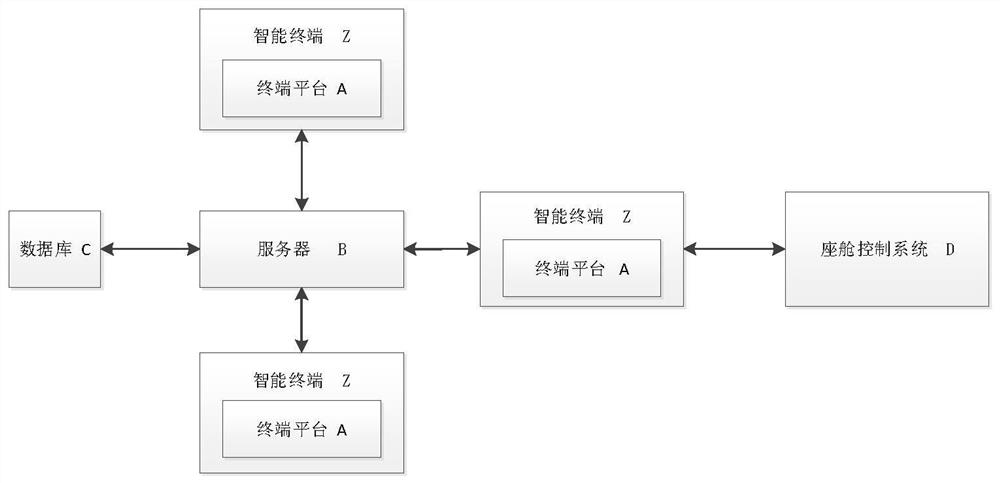

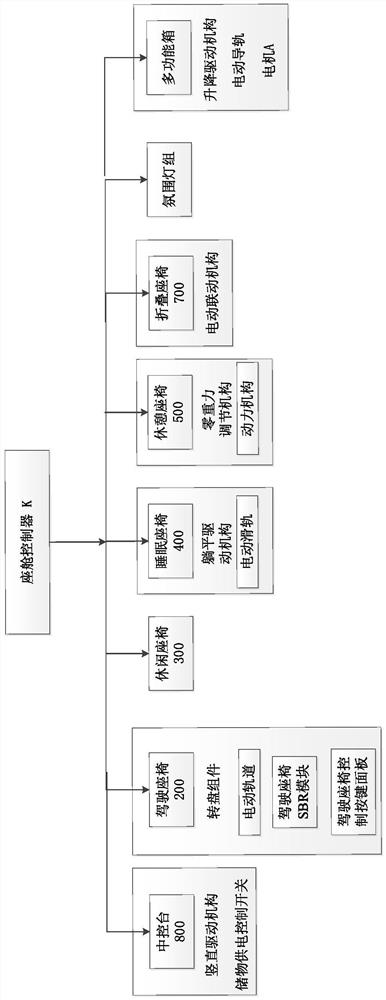

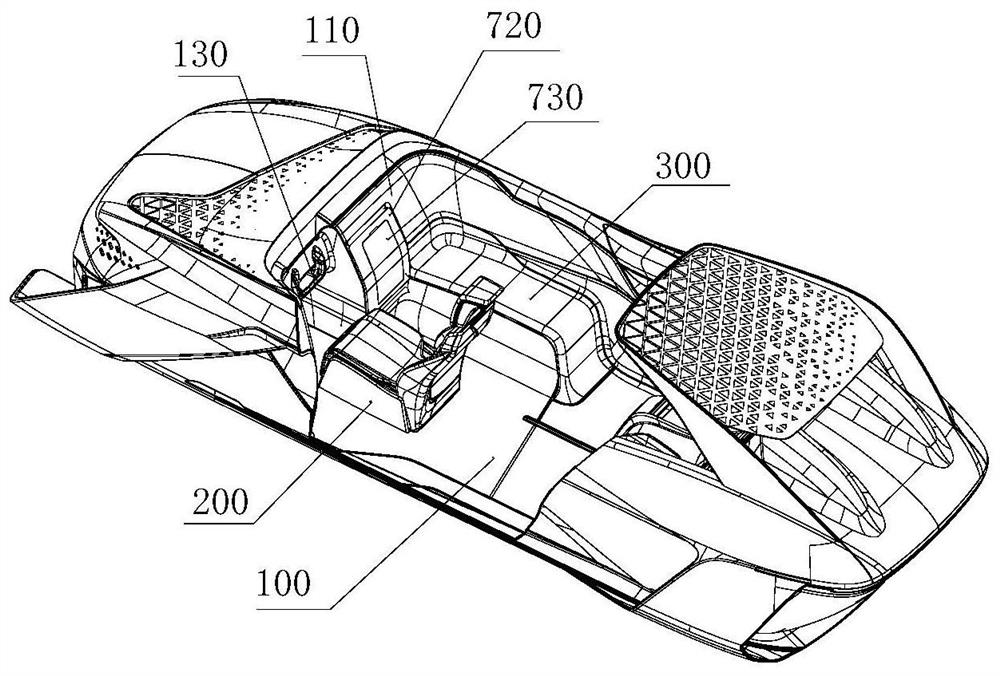

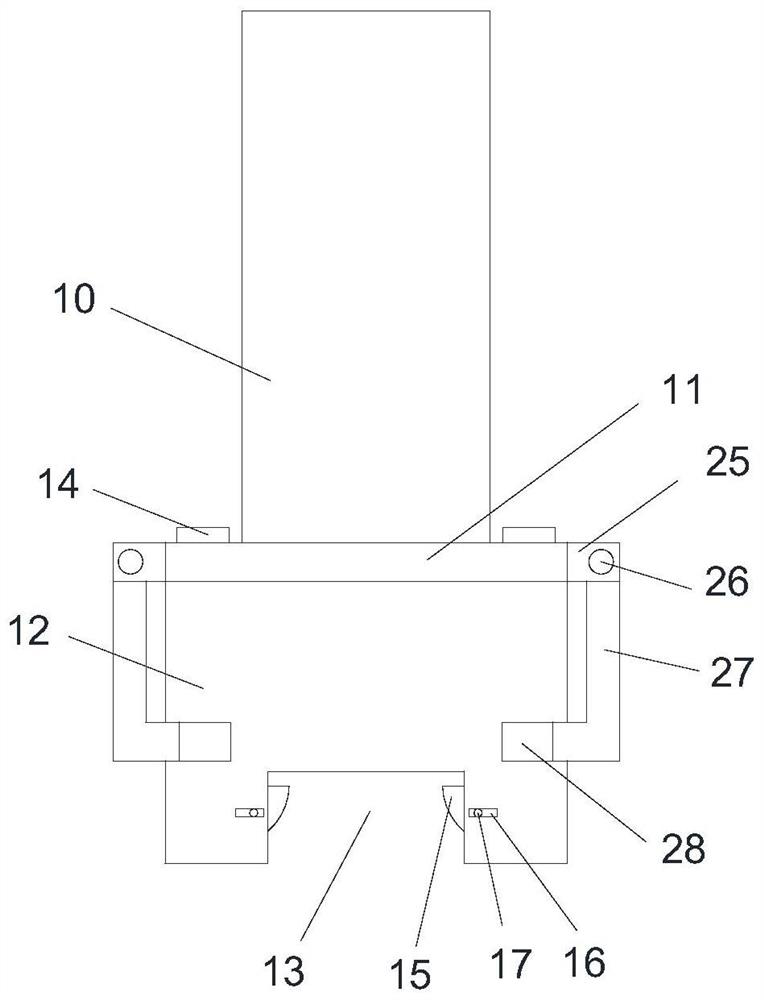

Terminal control platform based on multi-scene adaptation mode automobile cabin control system

ActiveCN111959354AMeet the needs of different time periodsMeet different needsMovable seatsProgramme control in sequence/logic controllersControl systemHuman–computer interaction

The invention discloses a terminal control platform based on a multi-scene adaptation mode automobile cabin control system. The platform comprises a terminal platform arranged on an intelligent terminal, the terminal platform is connected with a server, and the server is connected with a database for storing default page data of all virtual cabins; the terminal platform is provided with a user entry page group and a virtual cabin control page group; the user entry page group is used for carrying out user login, acquiring an associated automobile model and corresponding virtual cabin page data,and establishing a connection relationship between the intelligent terminal and the cabin control system; the virtual cabin control page group is used for displaying virtual cabin default page data,acquiring position and attitude data of all components of a cabin of the currently associated automobile, and performing adaptive adjustment to enable the interior of the cabin to be consistent with aplatform picture; and the virtual cabin control page group is used for changing a cabin scene mode and a position posture. And adaptive adjustment of the scene mode and the component attitude position in the cabin is realized, and intelligence is high.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

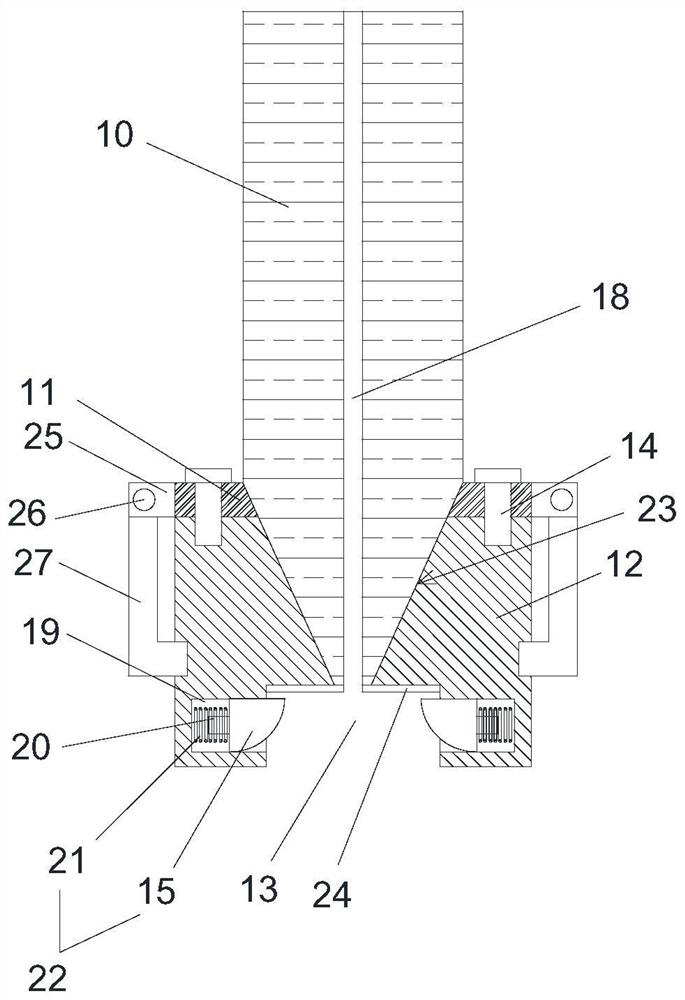

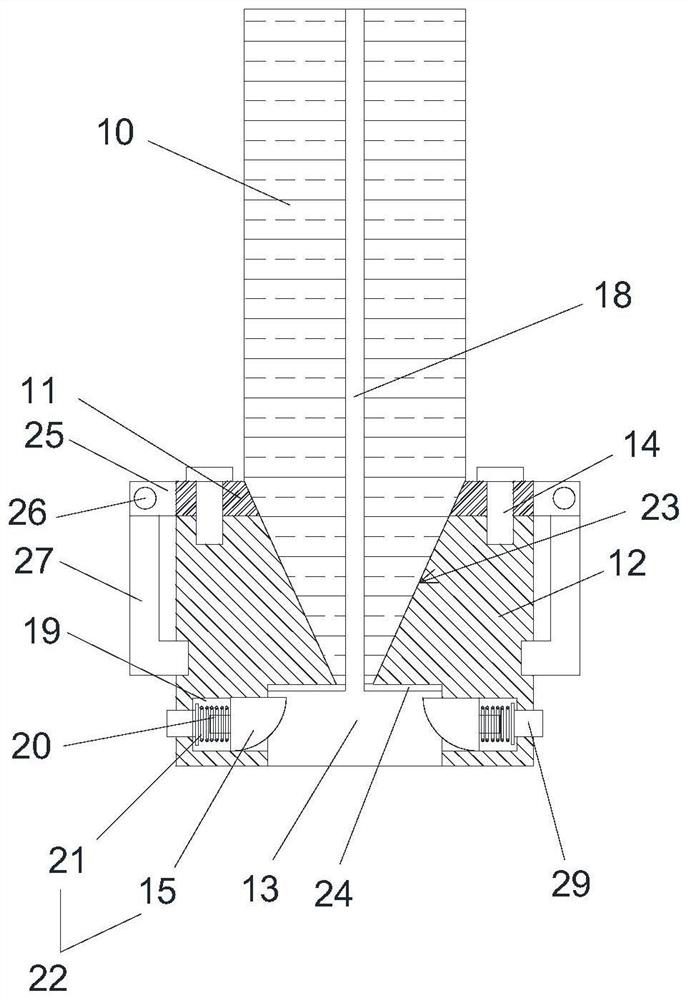

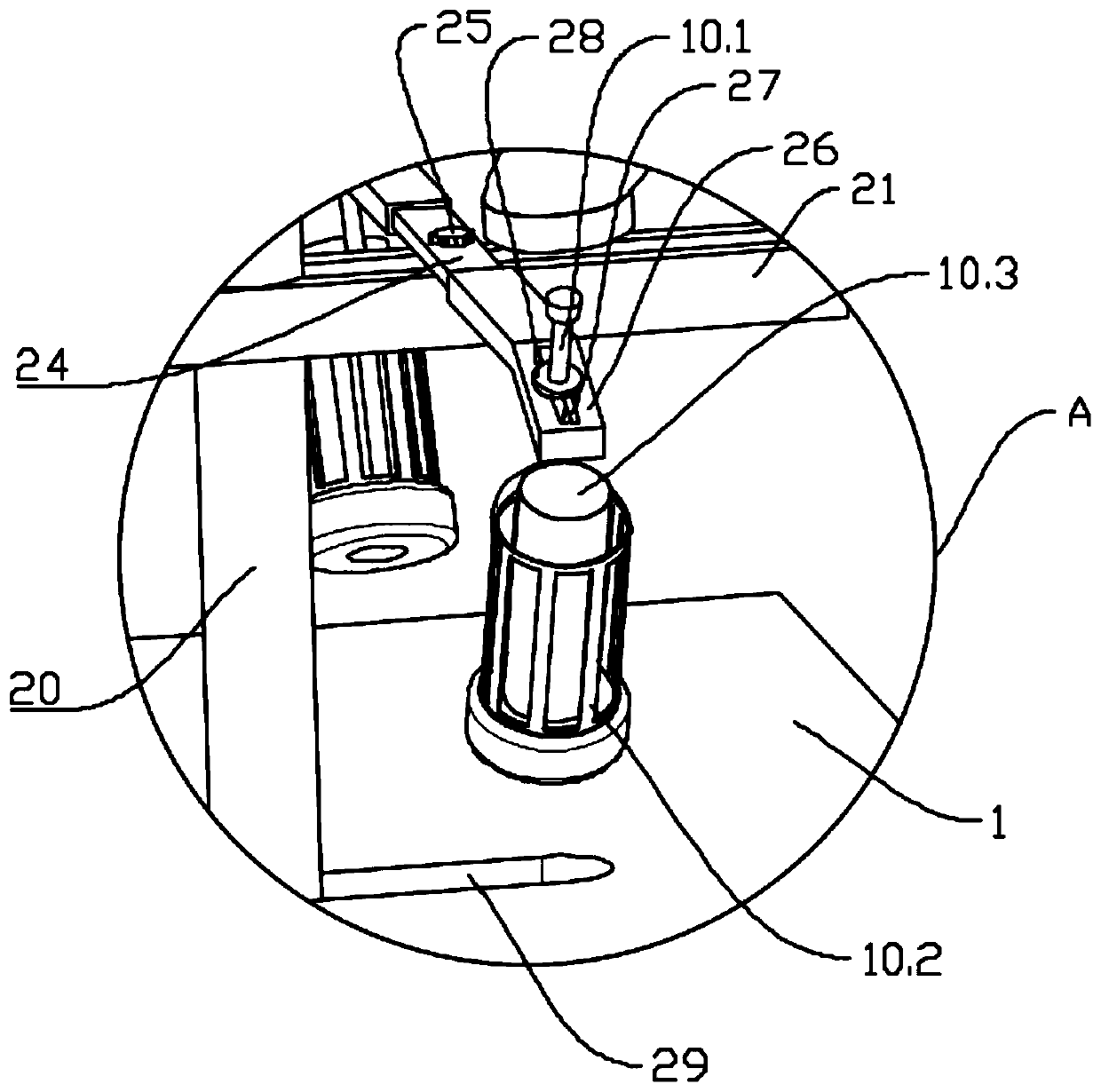

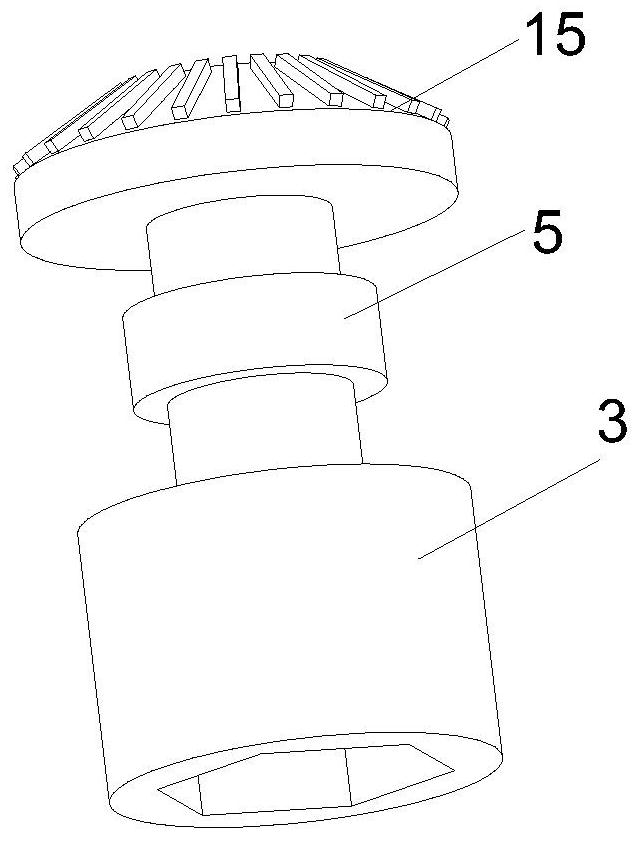

High-precision adjustable chip diode suction pen structure

ActiveCN114464565ASolve stuck or crushedReduce maintenance equipmentSemiconductor/solid-state device manufacturingPhysicsDiode

The invention provides a high-precision adjustable chip diode suction pen structure which comprises a suction pen body, a conical suction nozzle is formed in the bottom of the suction pen body, and a vacuum air cavity is coaxially formed in the suction pen body. The position, close to the suction nozzle, of the suction pen body is sleeved with a limiting sleeve, and the lower portion of the limiting sleeve is connected with an anti-deviation block through a bolt. An anti-deviation receding cavity is formed in the center of the bottom of the anti-deviation block. The bottom of the suction nozzle penetrates through the anti-deviation block, and the vacuum air cavity is communicated with the anti-deviation receding cavity. Auxiliary clamping structures are arranged on the two opposite sides, located on the deviation preventing receding cavity, of the deviation preventing block. The auxiliary clamping structure comprises fan-shaped blocks arranged on the two opposite sides of the deviation prevention receding cavity correspondingly and buffer springs connected with the fan-shaped blocks. The two opposite side walls of the deviation prevention receding cavity are each provided with a displacement receding groove for containing the corresponding fan-shaped block and the corresponding buffer spring. The clamping device has the beneficial effects that the size of the clamping space can be automatically adjusted by being matched with a product, and the situation of clamping or crushing damage is effectively avoided.

Owner:先之科半导体科技(东莞)有限公司

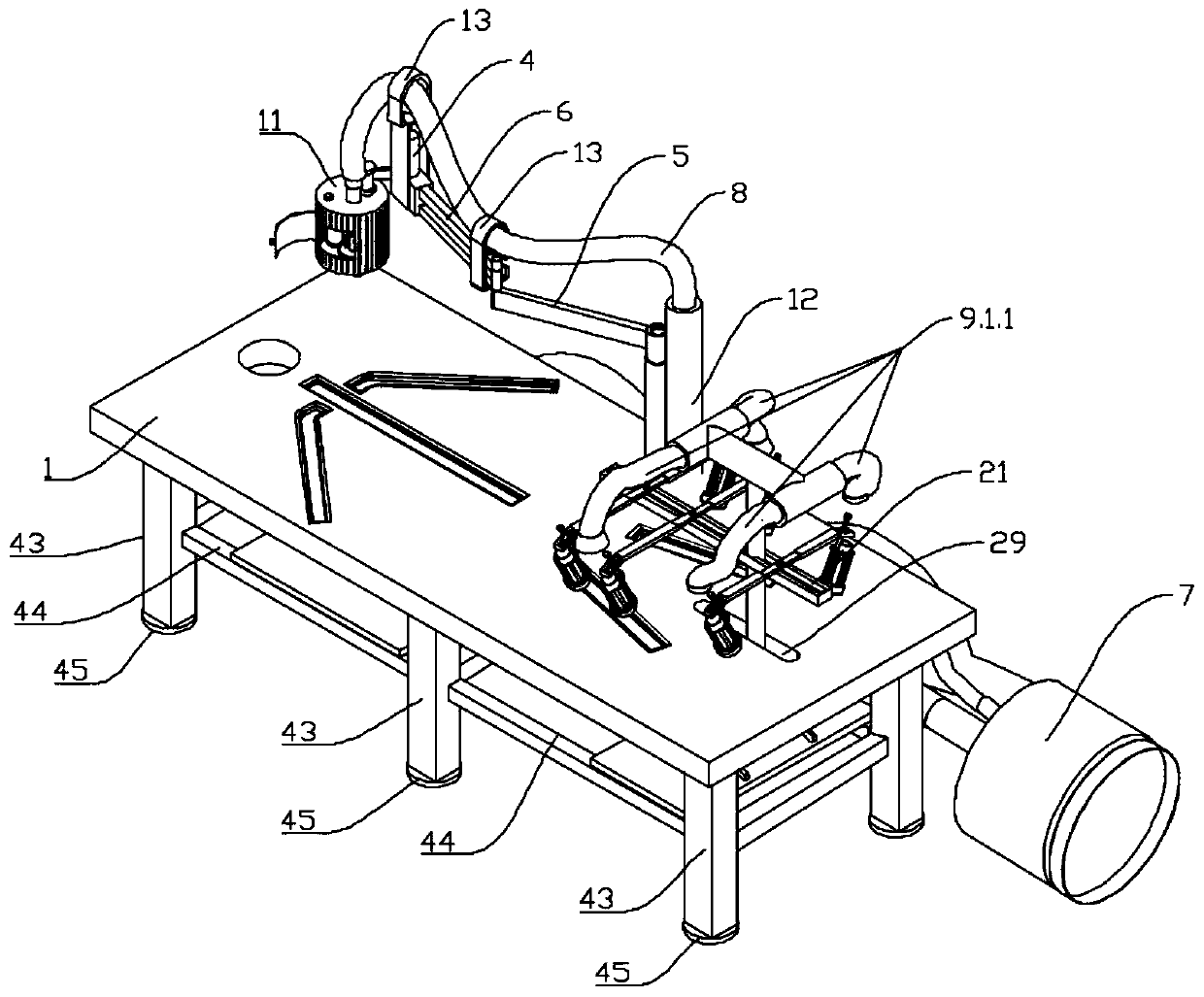

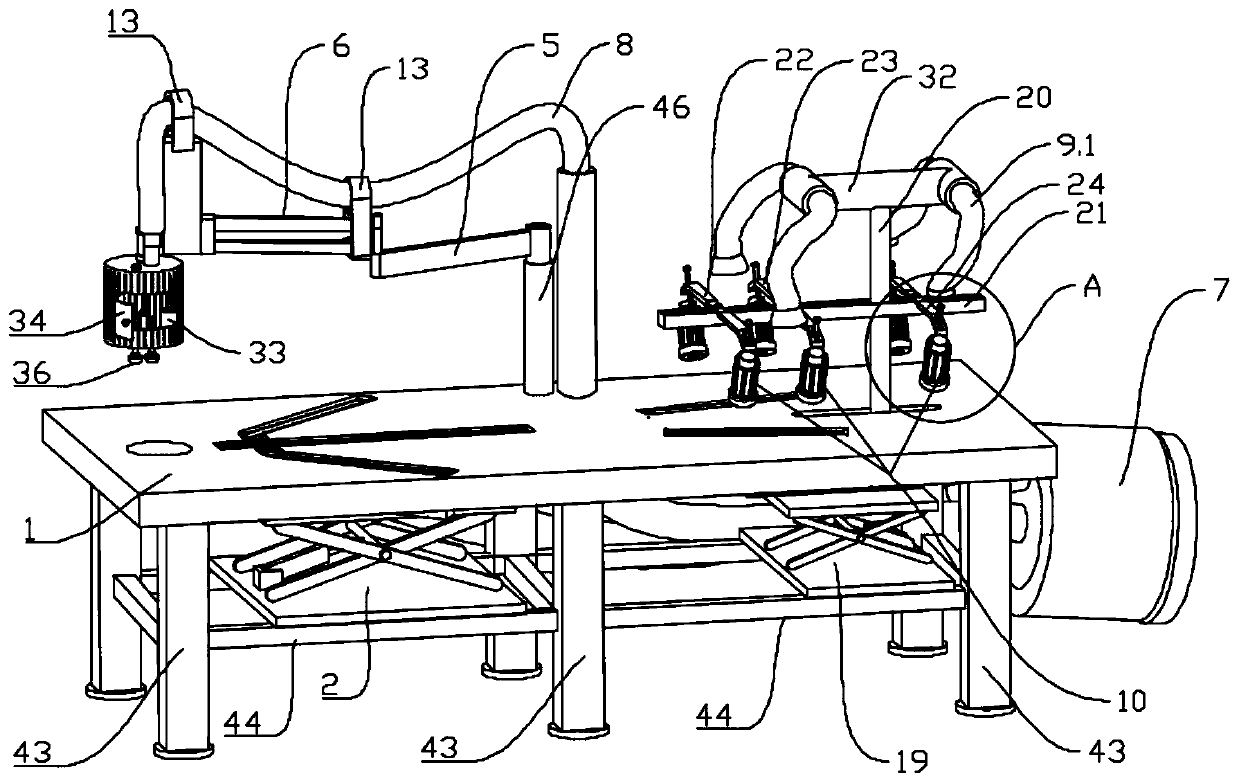

AiWuBing moxa-moxibustion machine

PendingCN110787054ASolve the problem that simultaneous moxibustion at different acupoints cannot be achieved at the same timeWith anti-scald functionDevices for heating/cooling reflex pointsPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of moxa-moxibustion devices, and discloses an AiWuBing moxa-moxibustion machine. The AiWuBing moxa-moxibustion machine comprises a back moxa-moxibustion mechanism, a front moxa-moxibustion mechanism and an air exhaust mechanism for exhausting smoke, wherein the back moxa-moxibustion mechanism comprises a bed body, a plurality of lifting channels adaptedto the body shape of a human body are arranged on the bed body, back moxa-moxibustion boxes are arranged in the lifting channels, and a first lifting device for driving the back moxibustion boxes todo up-and-down movements along the lifting channels is arranged below the bed body; the AiWuBing moxa-moxibustion machine provided by the invention can achieve moxa-moxibustion on multiple acupuncturepoints of a human body simultaneously, the moxa-moxibustion temperature can be adjusted according to needs in the process of moxa-moxibustion, with a burn-preventing function, adaptive adjustment canbe performed according to body shapes of different people, with a higher adaptability, and smoke produced in the using process can be discharged outdoors due to the arrangement of the air exhaust mechanism.

Owner:程方明

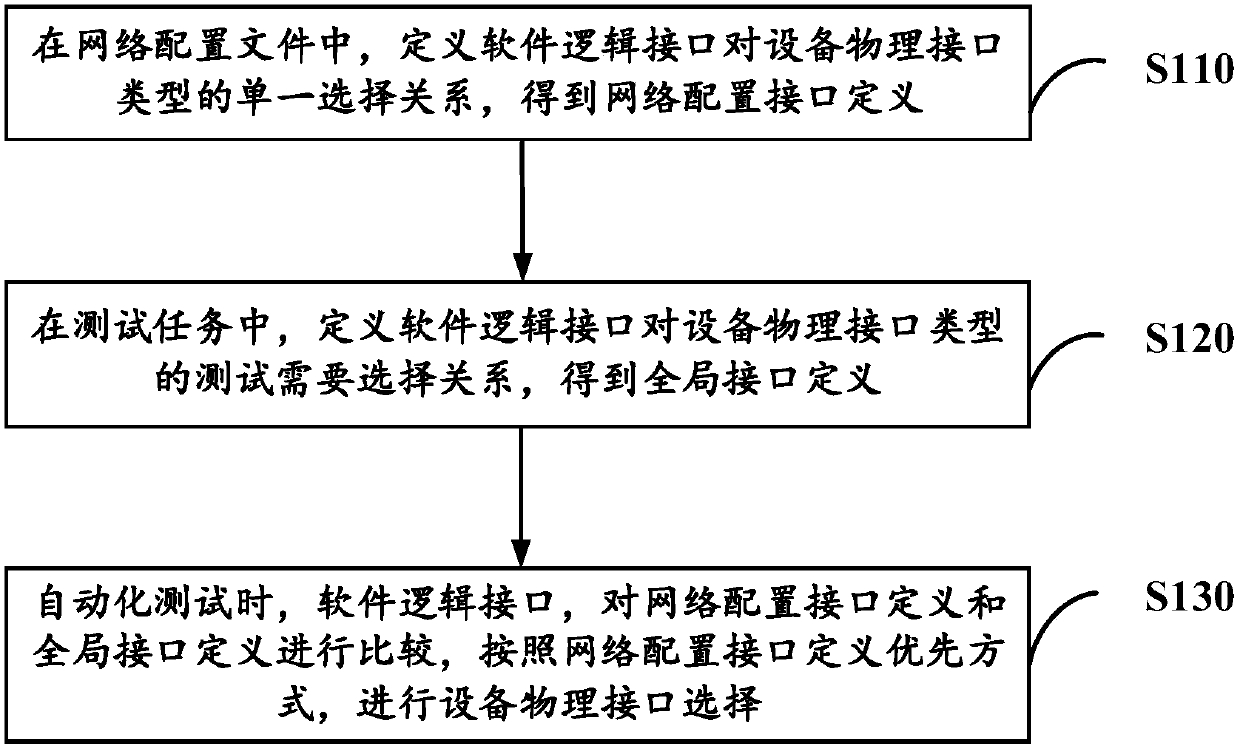

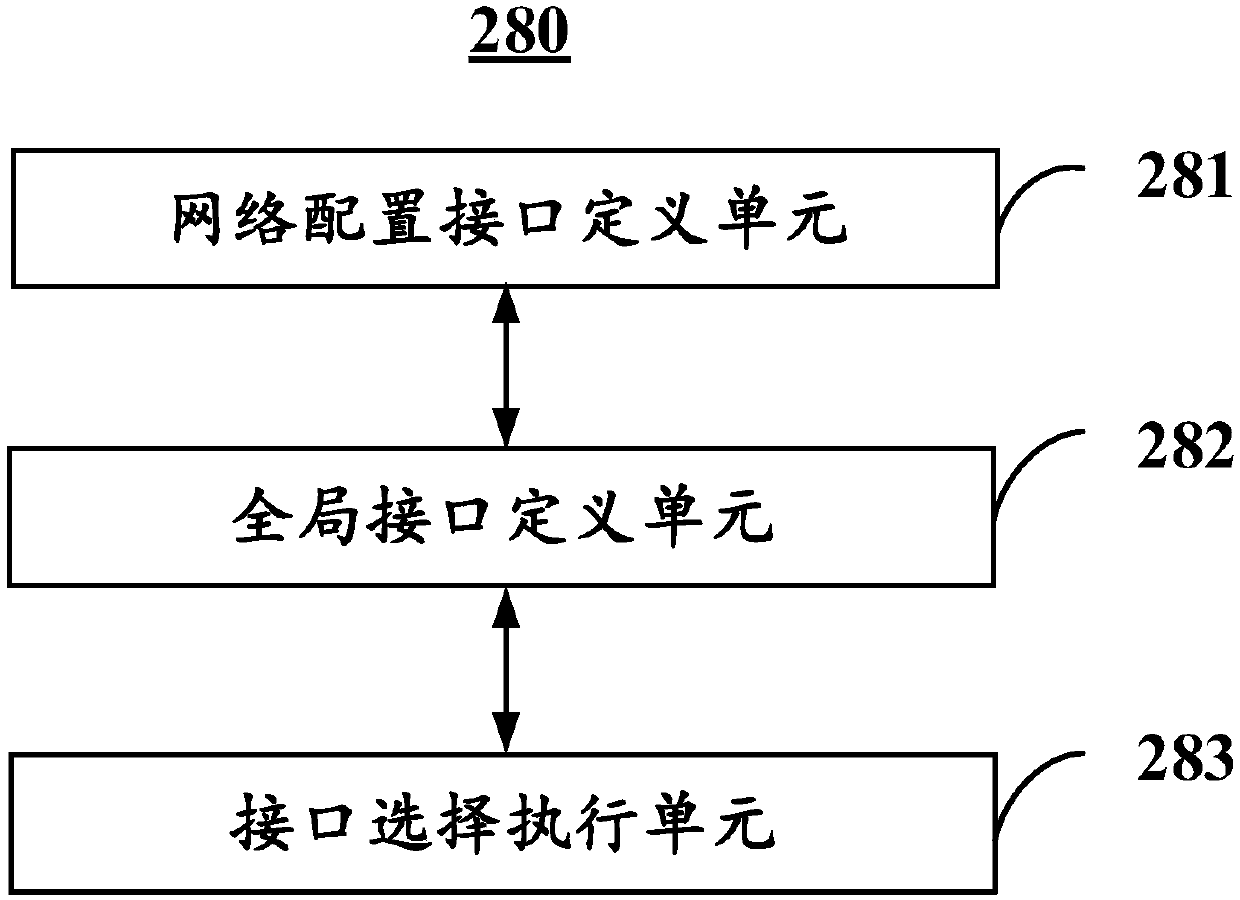

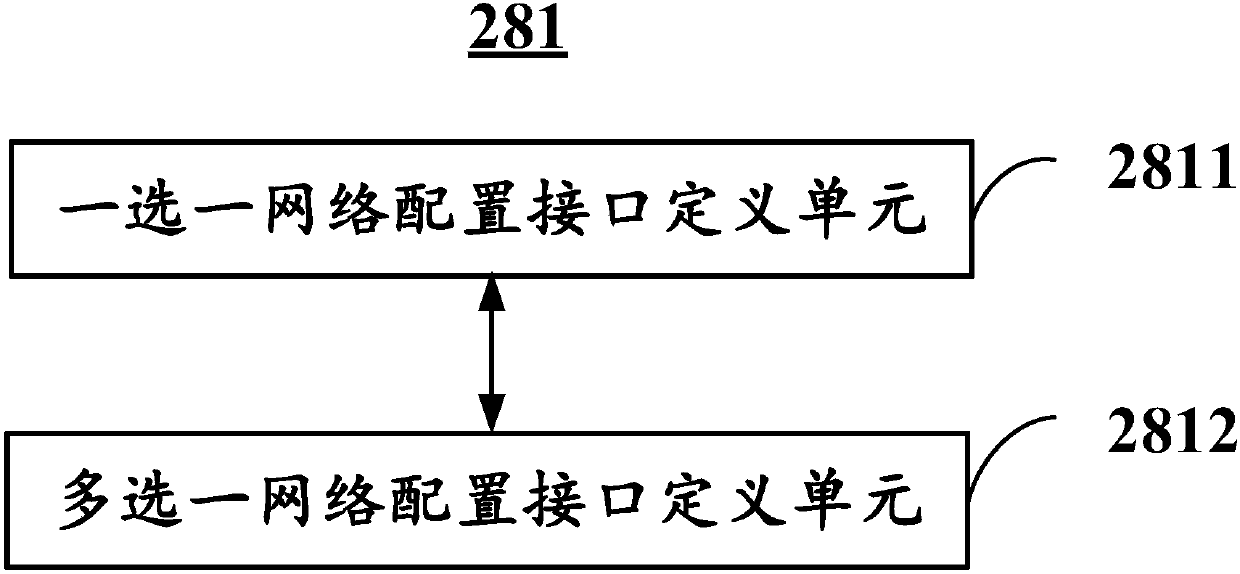

Interface selection method and device, testing console and testing system

ActiveCN107786382AAchieving adaptive adjustmentImprove the efficiency of definition adjustmentData switching networksAutomatic testingInterface selection

The embodiment of the invention provides an interface selection method and device, a testing console and a testing system. The interface selection method comprises the following steps: defining a single selection relation on an equipment physical interface type by a software logic interface in a network configuration file, thereby obtaining a network configuration interface definition; defining atesting need selection relation on the equipment physical interface type by the software logic interface in a testing task, thereby obtaining an overall interface definition; comparing the network configuration interface definition with the overall interface definition by the software logic interface in the automatic testing, and performing the equipment physical interface selection according to the network configuration interface definition priority mode. The interface selection method provided by the embodiment of the invention has high network equipment automatic testing efficiency.

Owner:MAIPU COMM TECH CO LTD

Adjustable nozzle for 3D printer

InactiveCN108437464AAchieving adaptive adjustmentIncrease supply3D object support structuresApplying layer means3d printEngineering

The invention discloses an adjustable nozzle for a 3D printer, comprising a moving block; a horizontal guide rail is slidably nested in the moving block through a slider; each of the front and rear ofthe horizontal guide rail is provided with a slide groove matching with the slider; a first rack is fixedly connected to the upper surface of the horizontal guide rail; a second rack is fixedly connected to the lower surface of the horizontal guide rail; each of the upper and lower surfaces of the horizontal guide rail is provided with a rectangular through hole; a melting mechanism is fixedly connected to the front of the moving block and includes a first barrel, a heating element is fixed to the inner wall of the first barrel, a circular plate is fixedly connected to the upper surface of the first barrel, and the upper surface of the circular plate is provided with two through holes. The adjustable nozzle is convenient to operate, and can be adaptively adjusted according to the shape orsize of a target model, so that printing efficiency is improved, printing time is shortened, the quality of 3D printed products is improved, product yield is increased, and long-term development of enterprises is benefited.

Owner:马鞍山小古精密机电科技有限公司

PCBA (printed circuit board assembly) performance test equipment and test method

ActiveCN112904178AAchieving adaptive adjustmentFacilitates bending impact testingElectronic circuit testingMeasurement instrument housingTest executionPower apparatus

Owner:深圳市宇昊森达科技有限公司

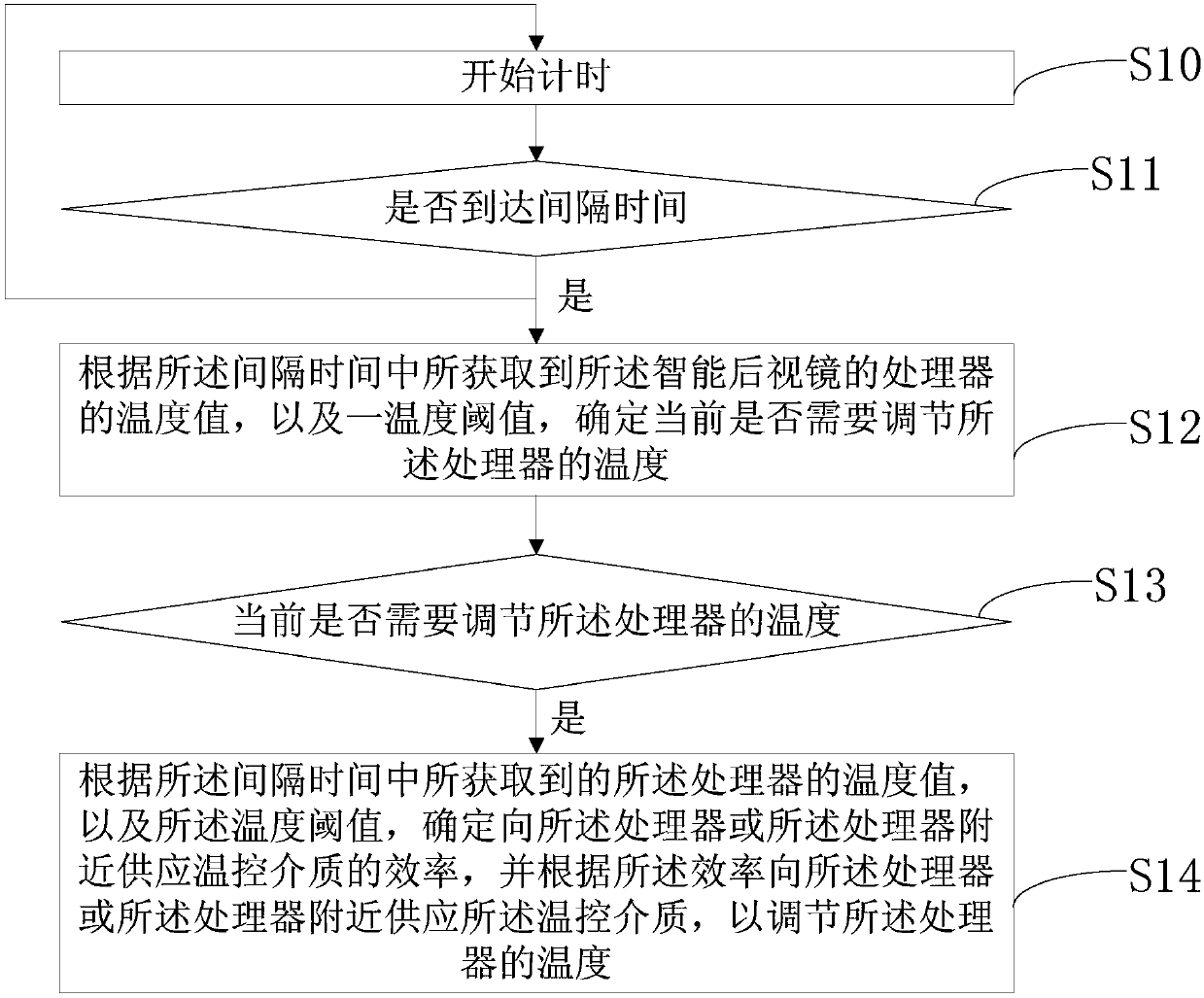

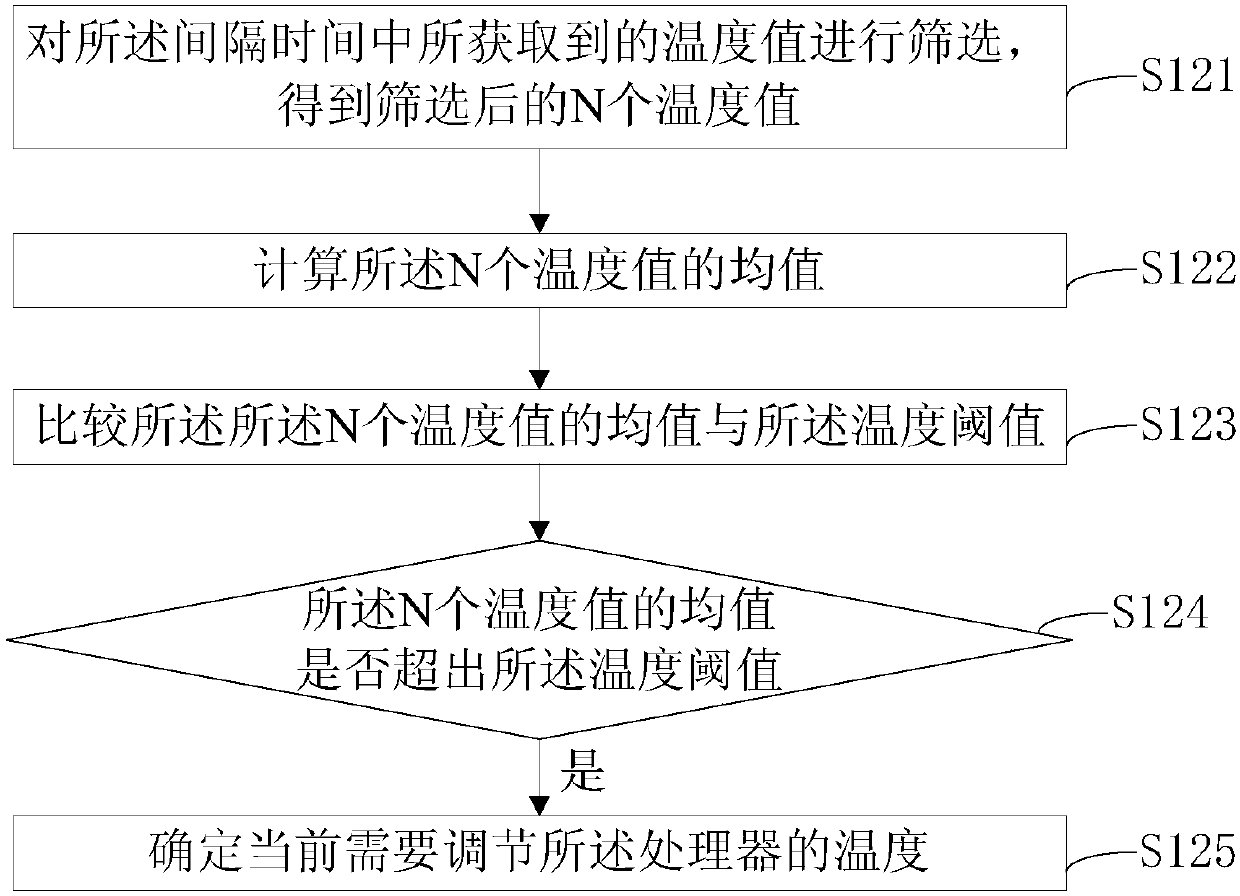

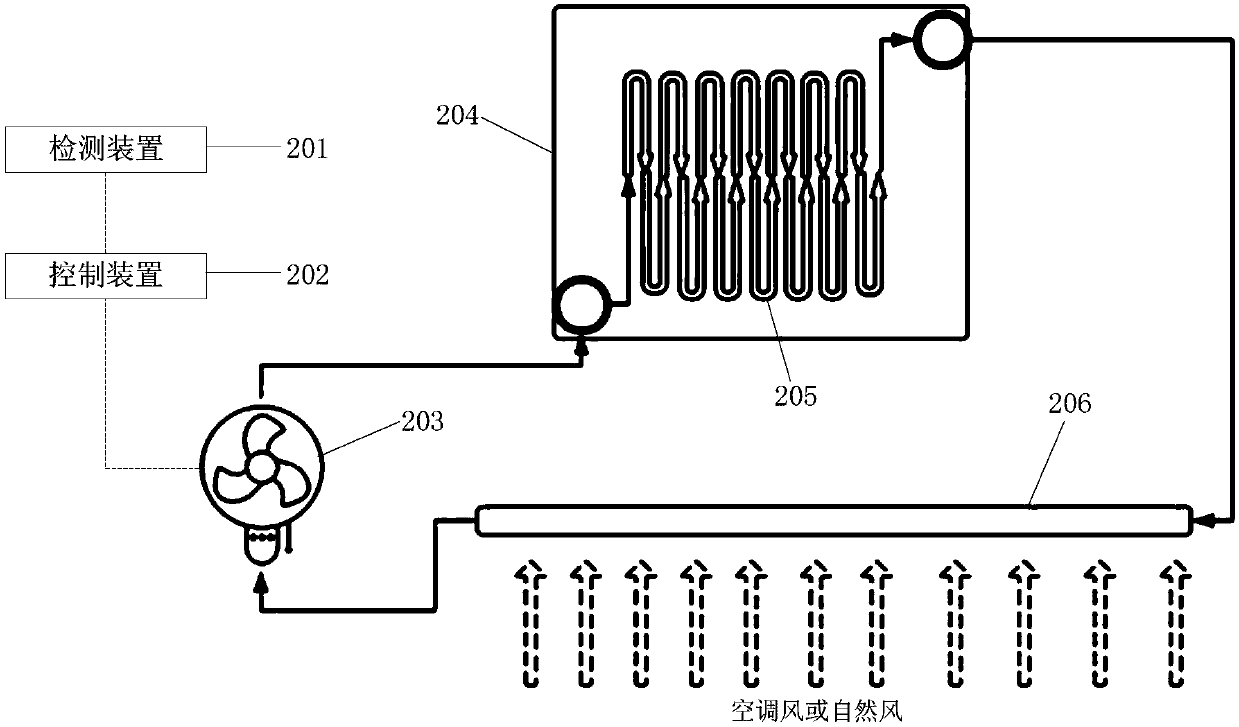

Temperature control method, device and system of intelligent rearview mirror

InactiveCN108407722AAchieving adaptive adjustmentMeet needsTemperatue controlOptical viewingTemperature controlComputer science

The invention provides a temperature control method, device and system of an intelligent rearview mirror. The method comprises the steps that the temperature value of a processor of the intelligent rearview mirror and a temperature threshold are obtained at each preset interval according to the interval time, and whether the current temperature of the processor needs to be adjusted or not is determined; and if the temperature of the processor is currently required to be adjusted, the temperature value of the processor and the temperature threshold are obtained in the interval time, the efficiency of supplying a temperature-controlled medium to or near the processor is determined, and the temperature-controlled medium is supplied to the processor or nearby to adjust the temperature of the processor according to the efficiency. The temperature control method, device and system of the intelligent rearview mirror avoid the influence of too high temperature or too low temperature on the processor and other electronic devices.

Owner:ZEBRED NETWORK TECH CO LTD

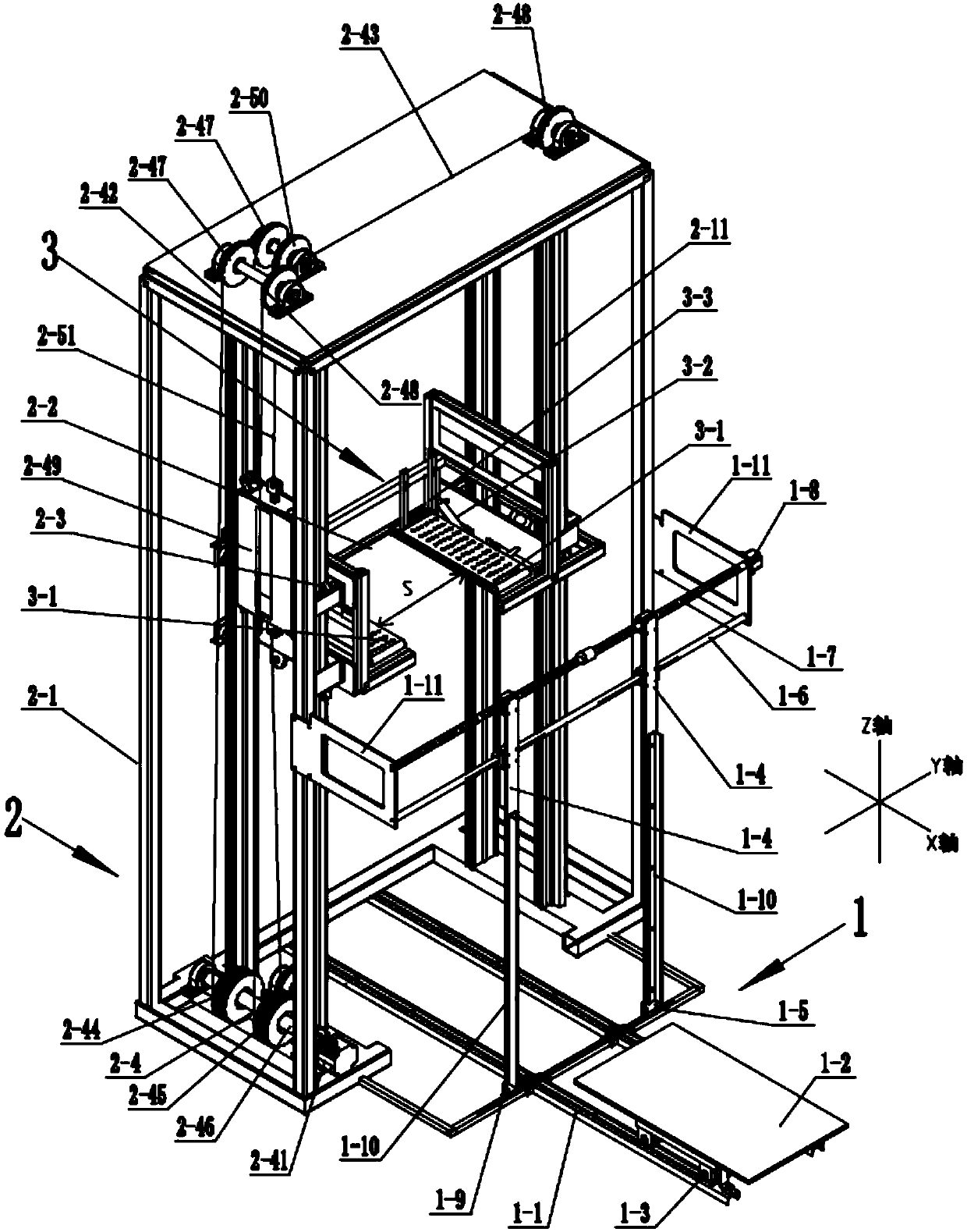

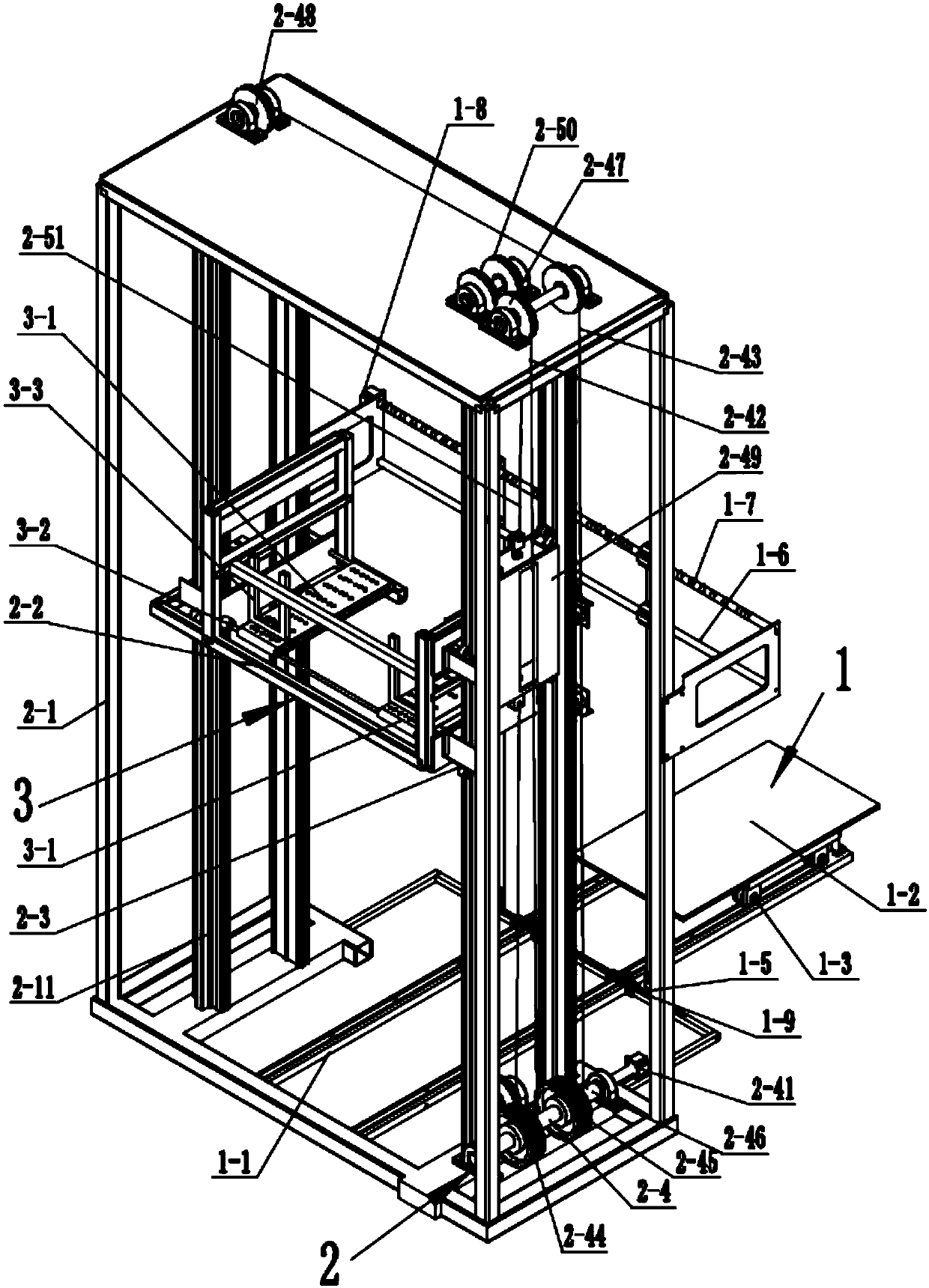

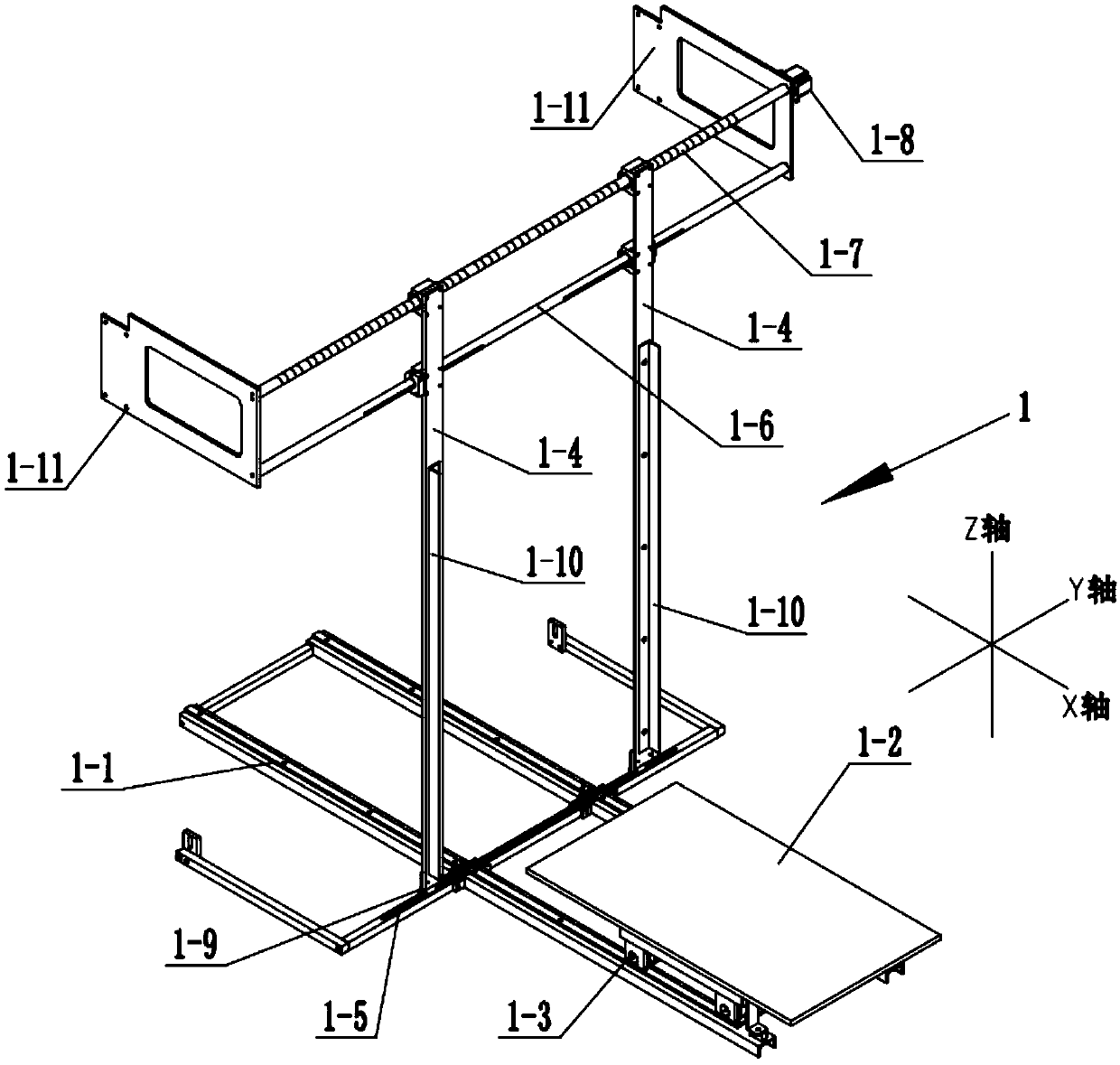

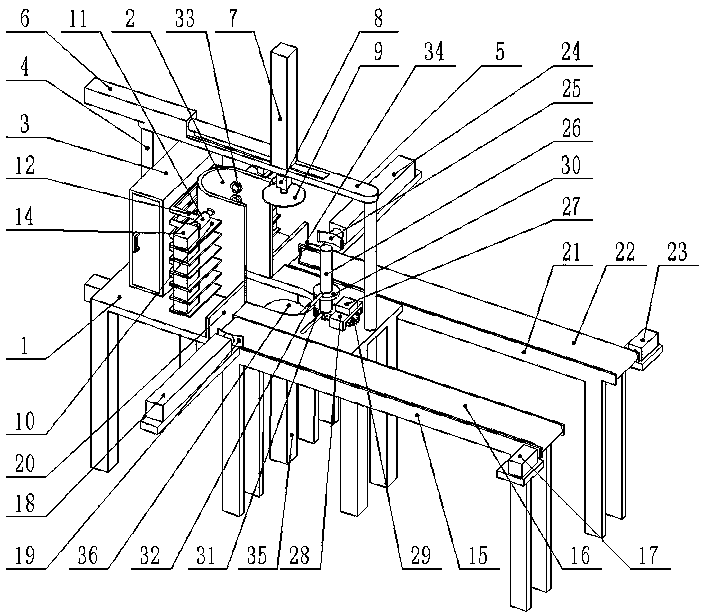

Paper pre-stacking, lifting and feeding all-in-one machine and printing machine

ActiveCN109607261AReduce manufacturing costImprove work efficiencyArticle feedersArticle separationFeed drivePulp and paper industry

The invention discloses a paper pre-stacking, lifting and feeding all-in-one machine. The paper pre-stacking, lifting and feeding all-in-one machine is characterized by comprising a paper pre-stackingdevice (1), a paper lifting device (2) and a paper feeding device (3); the paper pre-stacking device (1) comprises an X-direction guide rail (1-1), a paper supporting vehicle plate (1-2), wheels (1-3), two Z-direction beams (1-4), a Y-direction guide groove (1-5), a Y-direction guide rod (1-6), a Y-direction screw rod (1-7) and a first motor (1-8); the paper lifting device (2) comprises a fixingframe (2-1), a lifting seat (2-2), a guiding assembly (2-3) and a lifting driving assembly (2-4); one end of the X-direction guide rail (1-1) is located below the lifting seat (2-2); and the paper feeding device (3) comprises two air suction belts (3-1), a paper feeding driving assembly (3-2) and two bottom paper gauges. By means of the paper pre-stacking, lifting and feeding all-in-one machine, paper pre-stacking, paper lifting and paper feeding work can be sequentially achieved, automatic production is achieved, and the work efficiency is high. In addition, the invention further discloses aprinting machine.

Owner:重庆仨睿包装印务有限公司

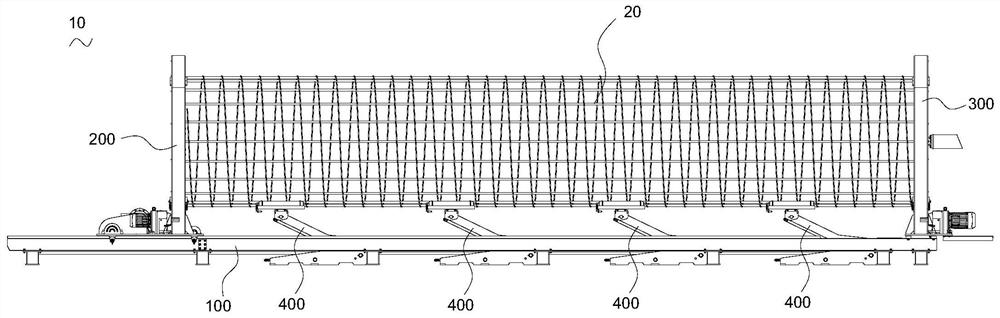

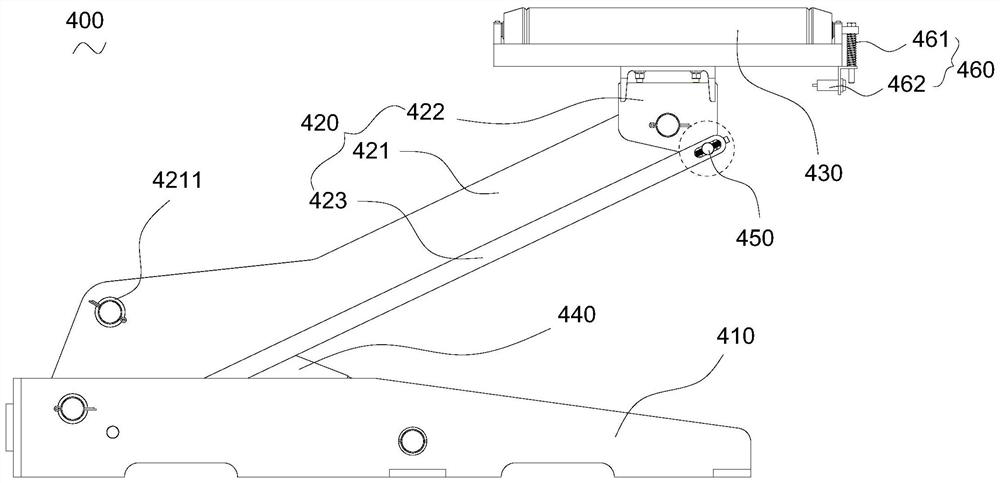

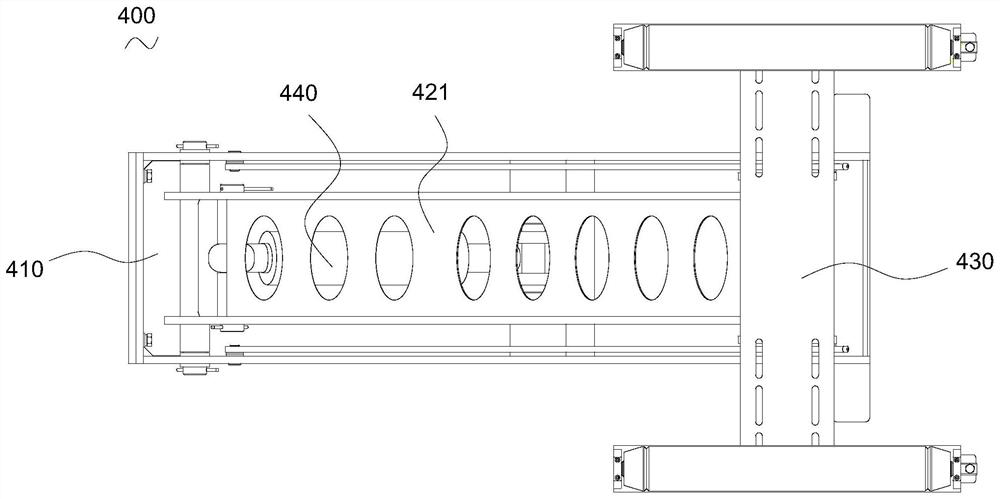

Reinforcement cage supporting device and reinforcement cage seam welder

ActiveCN111889859AGuaranteed support effectImprove adaptabilityWire networkWelding with roller electrodesClassical mechanicsEngineering

Owner:湖南艮通智能装备有限公司

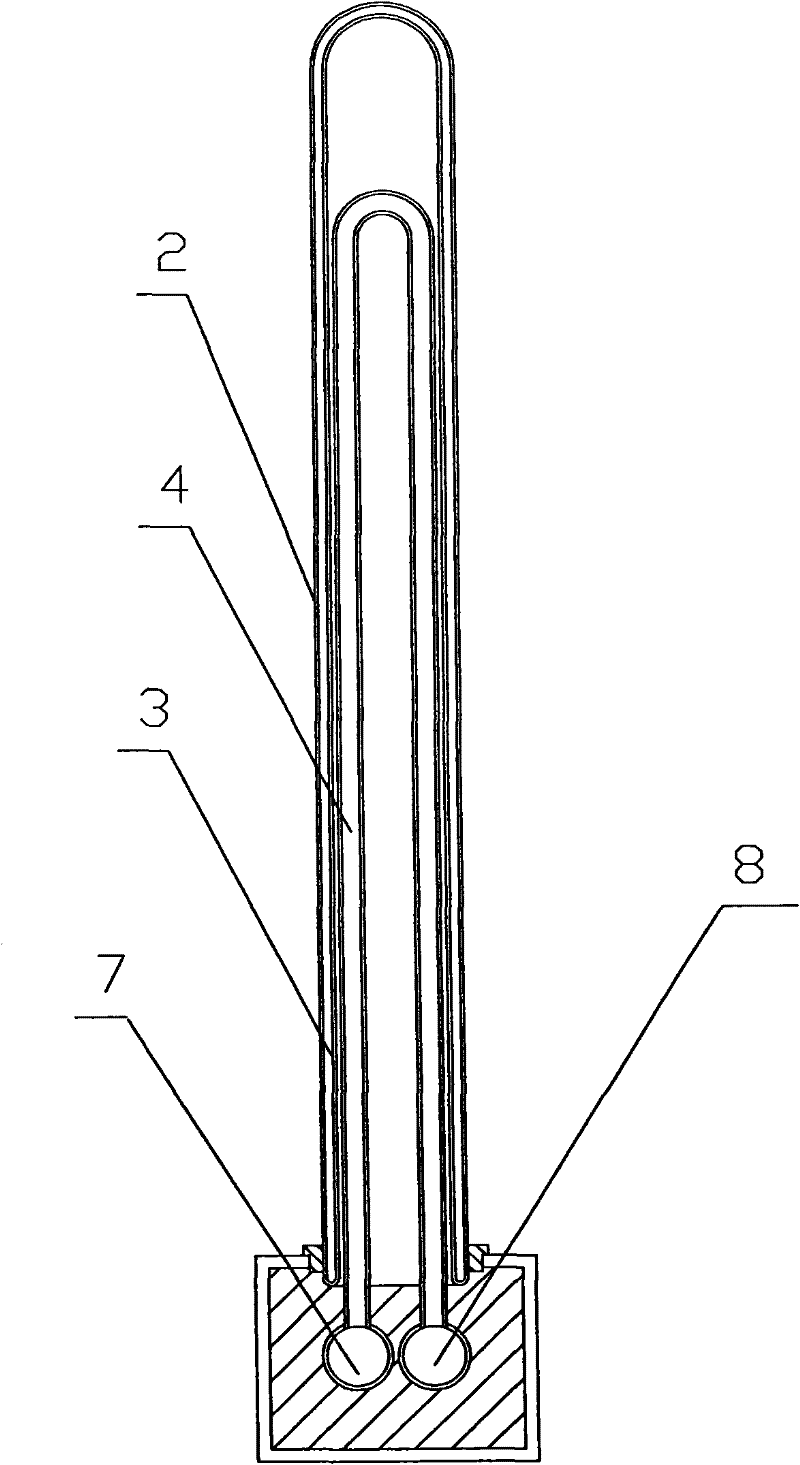

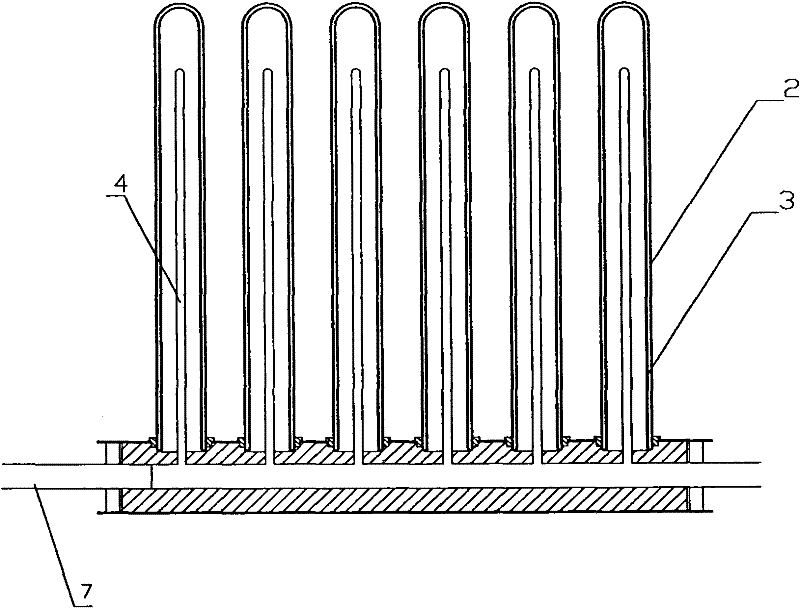

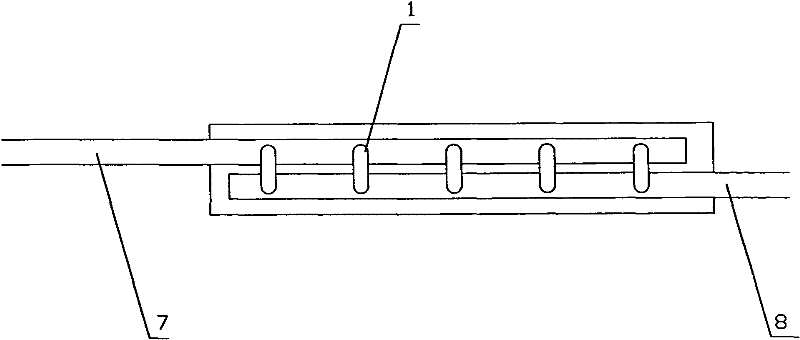

Solar energy heat-collection system utilizing vacuum tube matrix

InactiveCN102444999AGuarantee a reasonable matchAppropriate drag loss along the waySolar heating energySolar heat devicesCollection systemEngineering

The invention discloses a solar energy heat-collection system utilizing a vacuum tube matrix, which comprises a water inlet main pipe and a water outlet main pipe both for medium circulation, and w solar energy vacuum tube units connected in parallel, wherein, each solar energy vacuum tube unit is respectively arranged between the water inlet main pipe and the water outlet main pipe and consists of N solar energy vacuum tube groups connected in series, a medium delivery pump and a temperature sensor; and each solar energy vacuum tube group is composed of M solar energy vacuum tubes of which the internal U-shaped metal pipes are connected in parallel, and is connected with the adjacent solar energy vacuum tube groups through the water inlet main pipe and the water outlet main pipe. The solar energy heat-collection system provided by the invention, which can collect heat with high efficiency and low cost, is suitable for the fields of industrial production, city heating, heat power generation and the like.

Owner:卓卫民

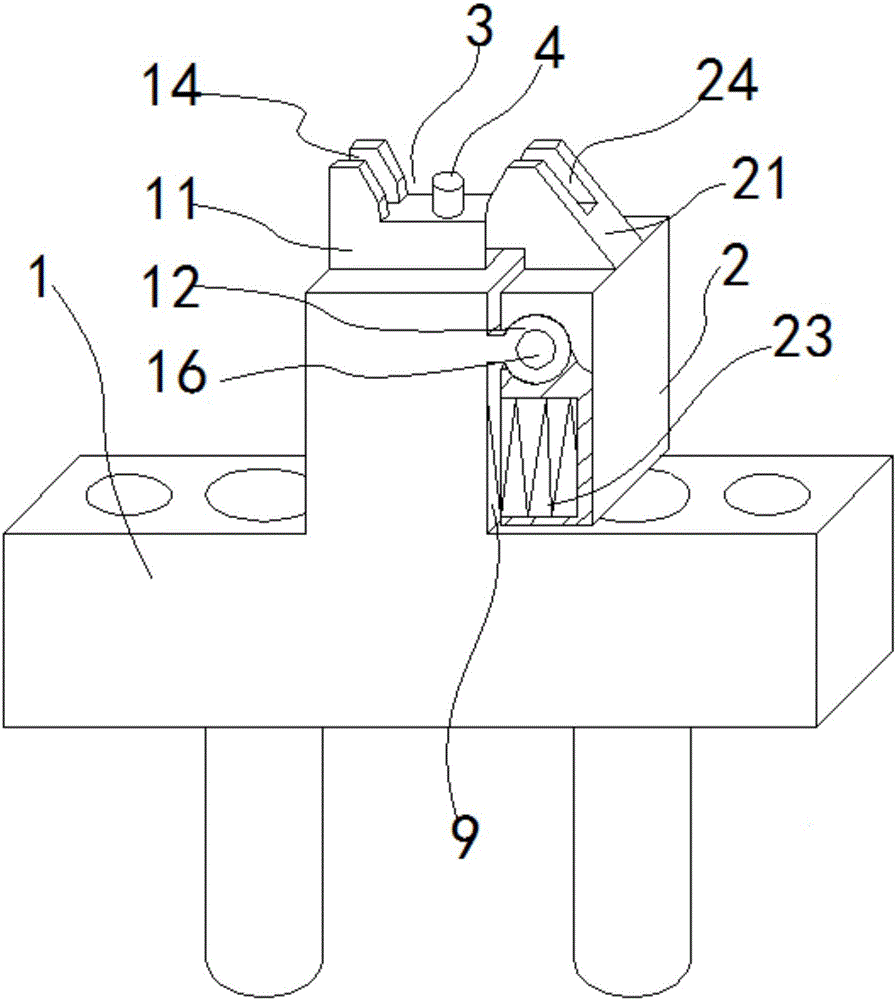

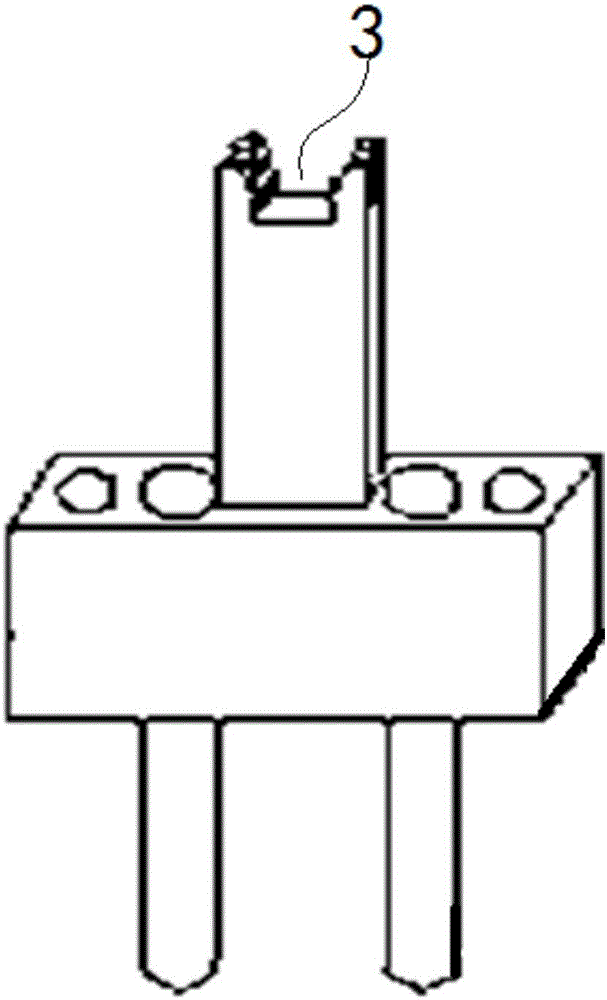

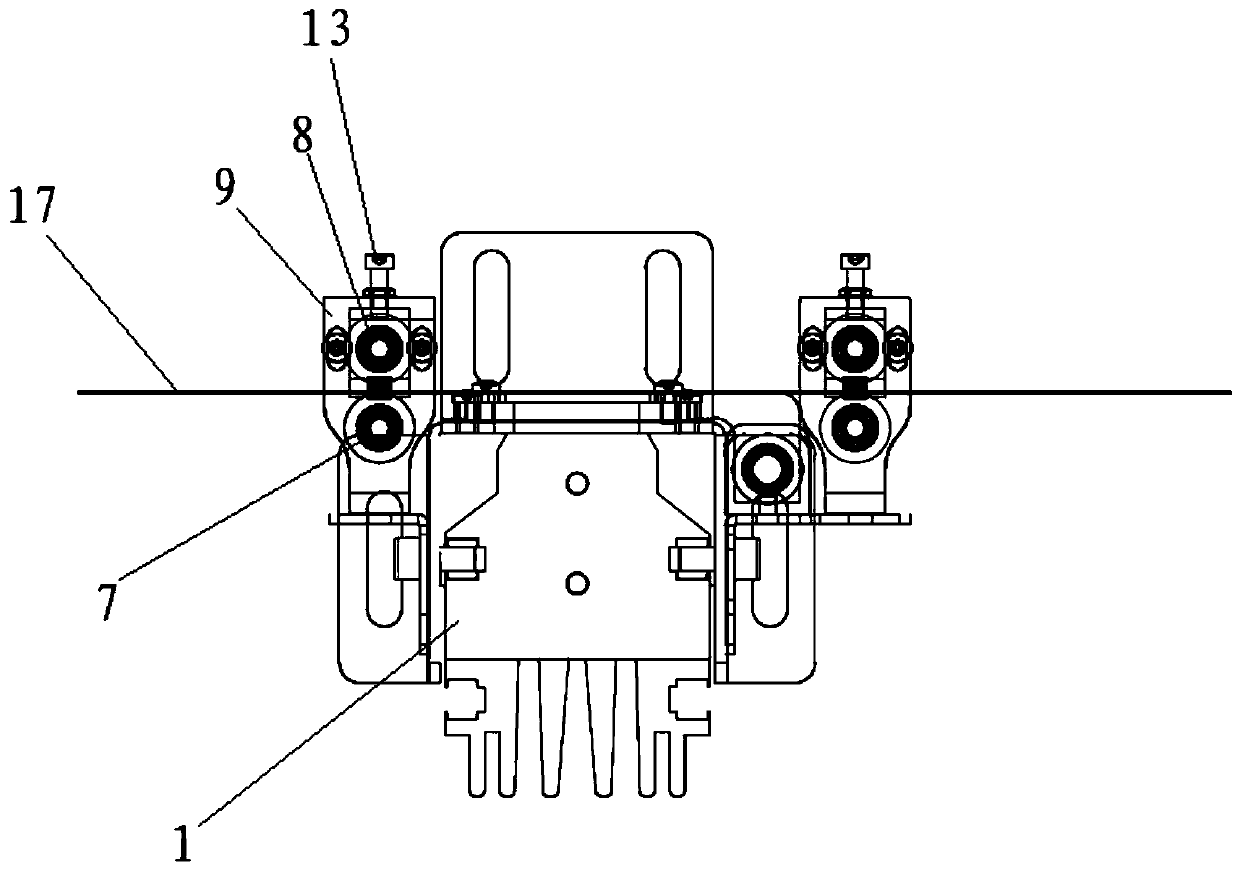

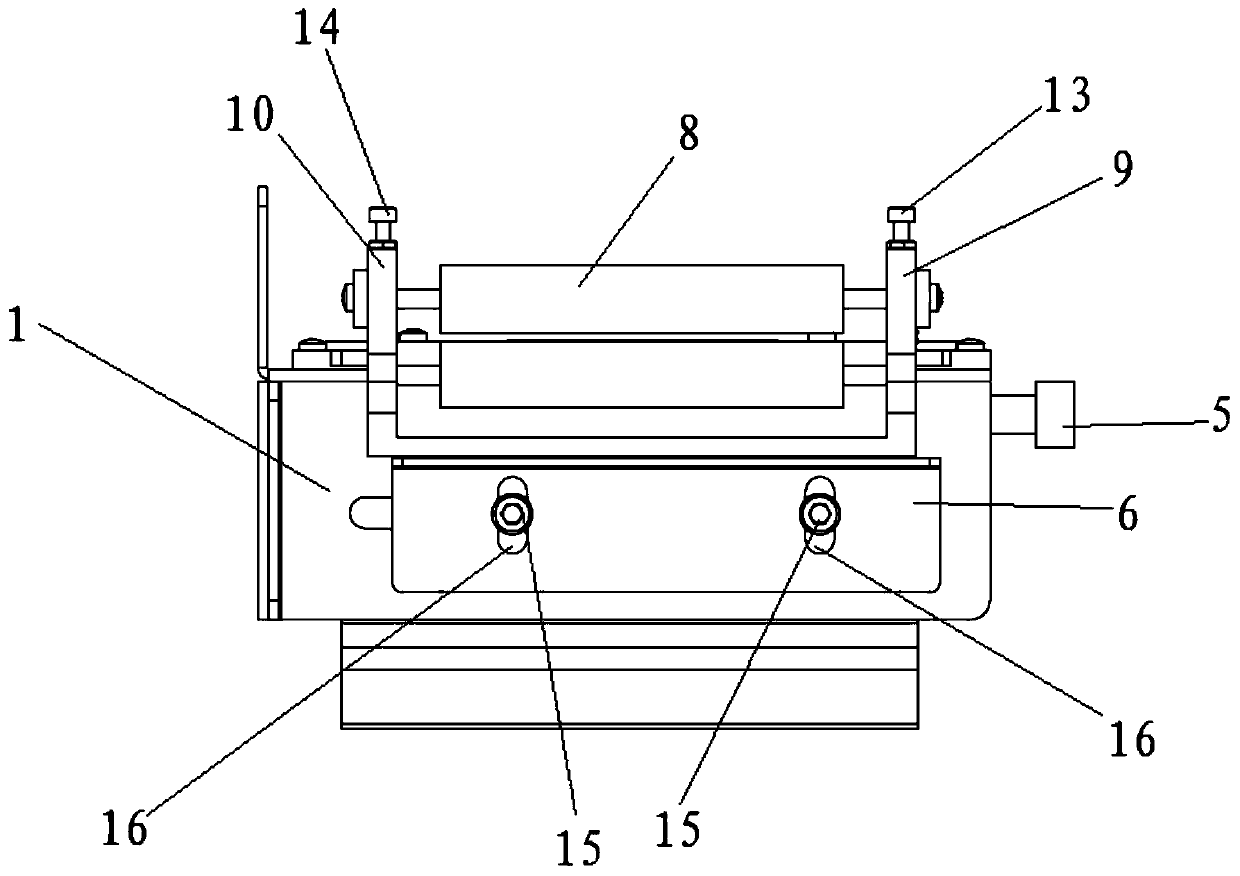

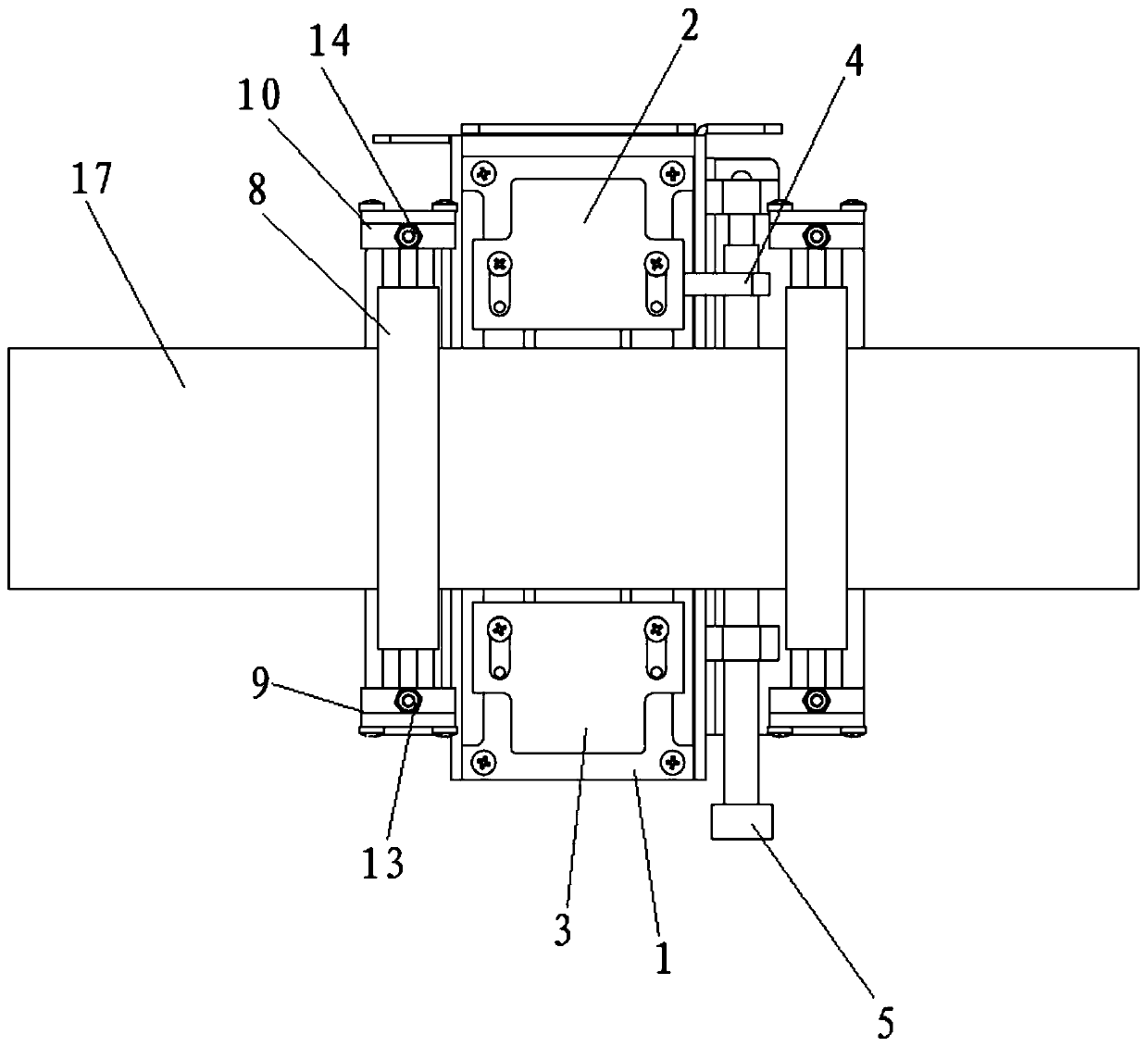

SOT26 test clamp with adjustable test groove and operation method thereof

ActiveCN106356314AImprove test yieldImprove yieldSemiconductor/solid-state device testing/measurementControl theoryMechanical engineering

The invention discloses a SOT26 test clamp with an adjustable test groove and an operation method thereof and belongs to the technical field of chip test. The SOT26 test clamp with the adjustable test groove provided by the invention comprises a fixed clamp and a moveable clamp, wherein the fixed clamp and the moveable clamp are connected through mutually matched rotating devices; the width adjustment of a clamp rim between the fixed clamp and the moveable clamp can be realized through the rotation of the moveable clamp relative to the fixed clamp; the clamp rim of the test clamp can be adaptively adjusted according to the size of SOT26. The operation method for the test clamp provided by the invention comprises the steps of pressing in SOT26, testing and pushing out; a spring is utilized to control the opening and closing of the moveable clamp, so that the left and right shifting caused by the size of SOT26 can be made up and the yield of once test can be increased; a jacking rod is additionally arranged; under the synergic effect of the moveable clamp and the jacking rod, the purposes of accurately positioning SOT26 in a test process, preventing the material overlapping and increasing the test yield can be achieved; equivalently, the capacity is promoted, so that the effect of double benefit can be achieved.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

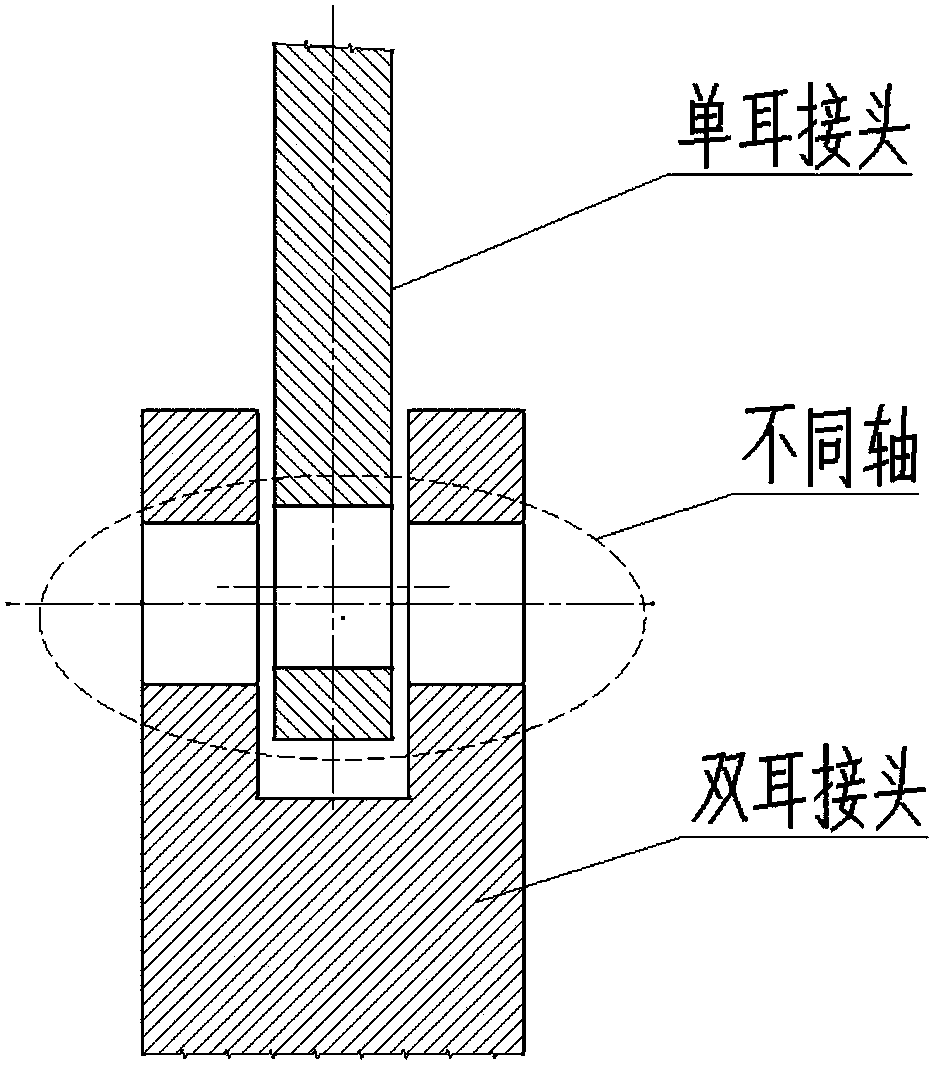

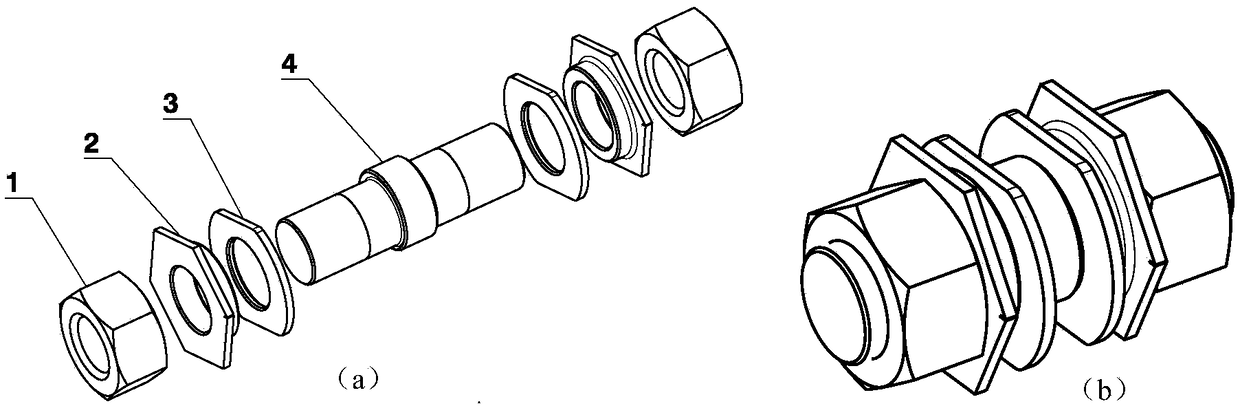

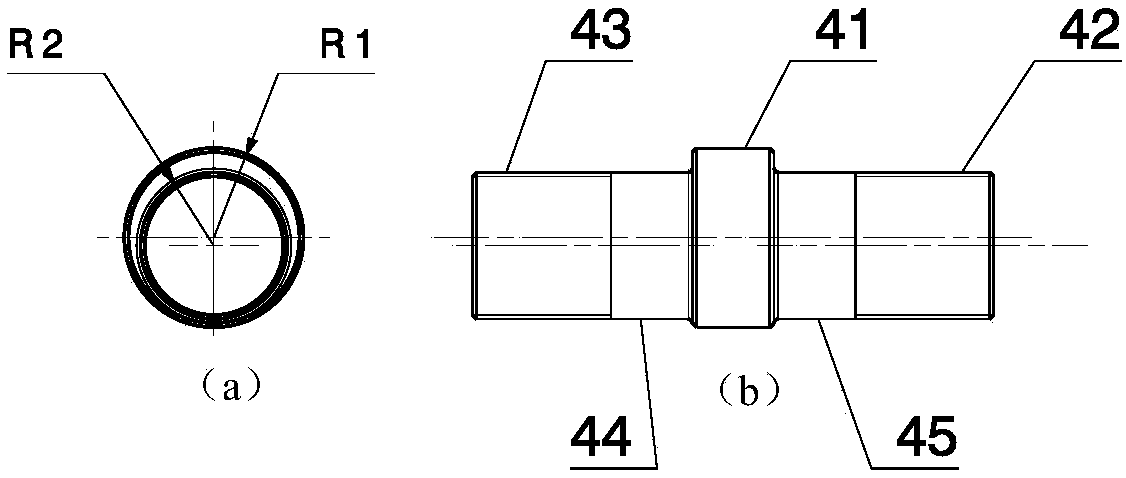

Bolt assembly with adjustable single-and-double-ear connecting coaxiality

InactiveCN108253004AAchieve regulationAchieving adaptive adjustmentWashersScrewsEngineeringMechanical engineering

The invention aims at providing a bolt assembly with adjustable single-and-double-ear connecting coaxiality. The bolt assembly is characterized by comprising a twin-screw eccentric pin, two clearanceadjusting gaskets, two eccentric linings and two nuts. The double-screw eccentric pin is composed of a single-ear polished rod connecting shaft in the middle and bolt rods at the two ends. By means ofthe bolt assembly, connection assembly can be conveniently and rapidly achieved through adjustment of the assembly when hole heart deviation is generated in the connection process of a single-ear connector and a double-ear connector.

Owner:CHENGDU AIRCRAFT DESIGN INST OF AVIATION IND CORP OF CHINA

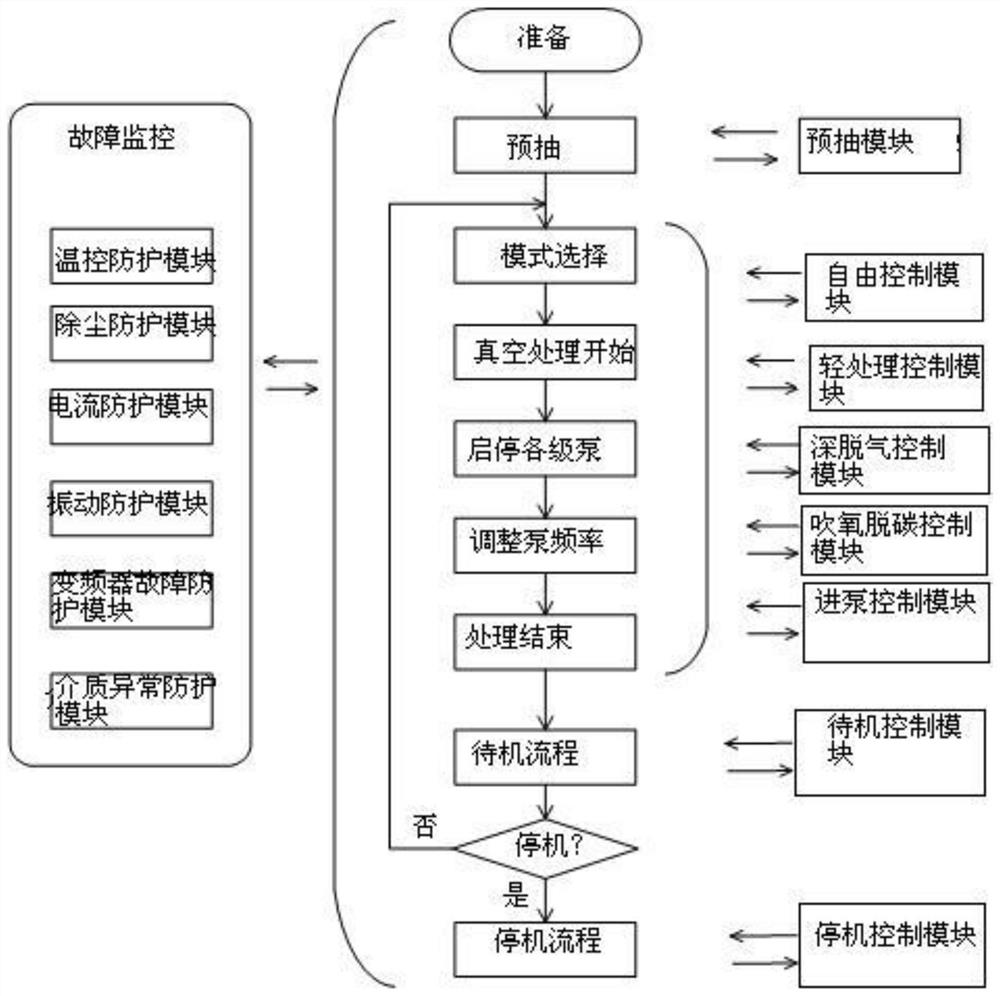

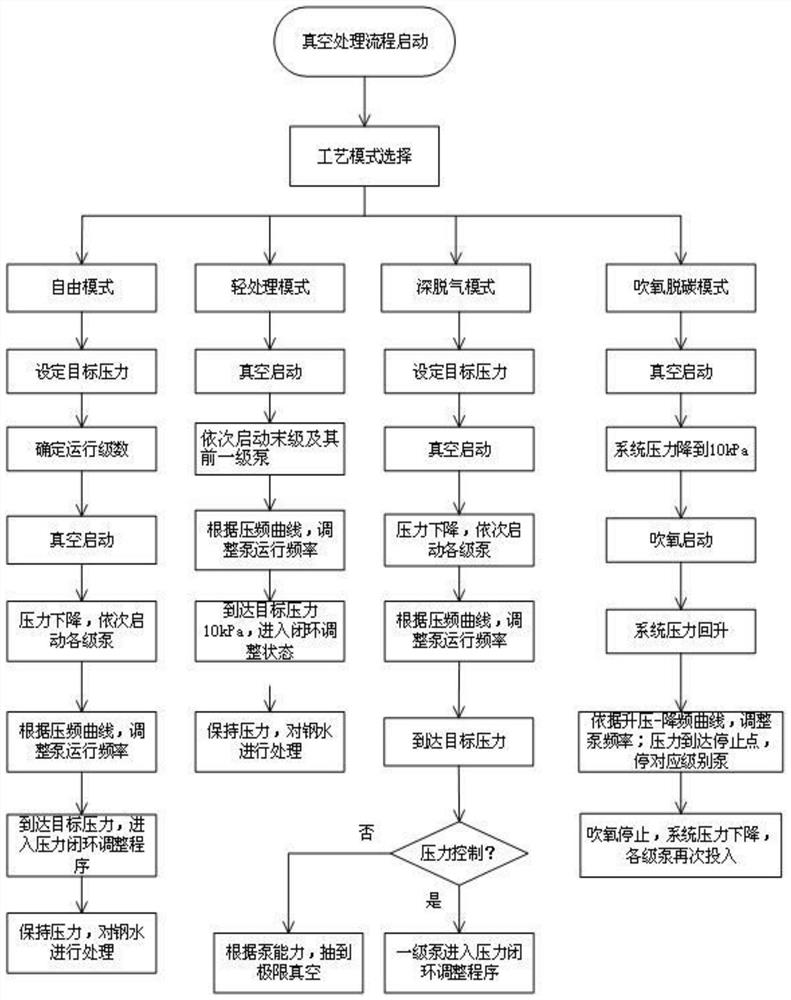

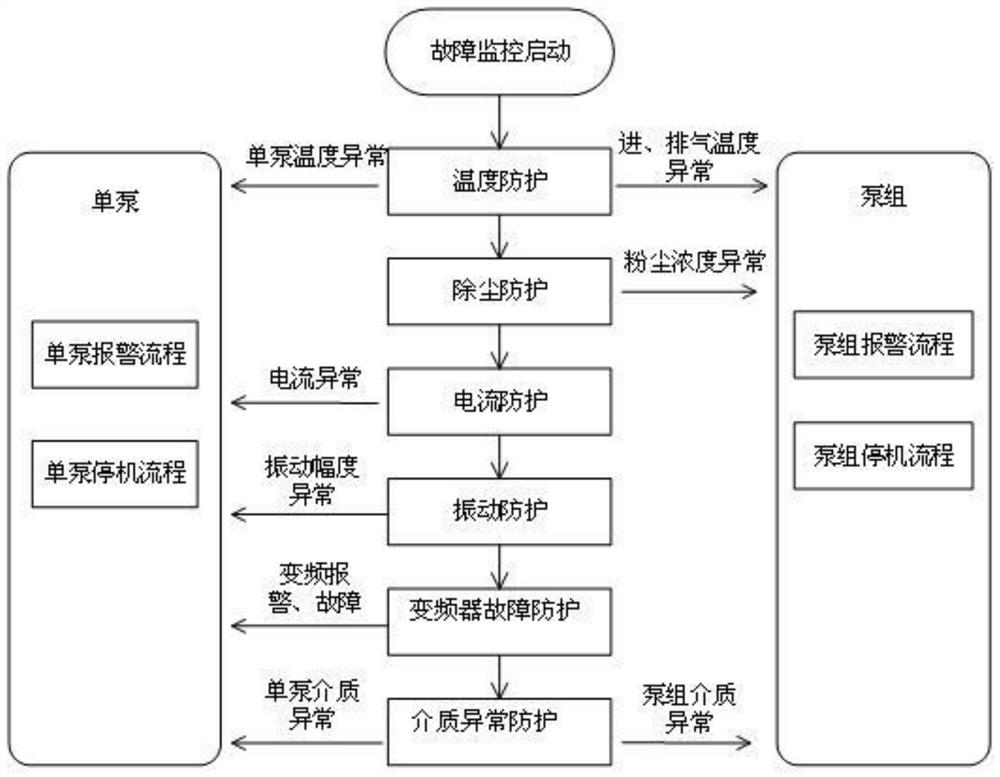

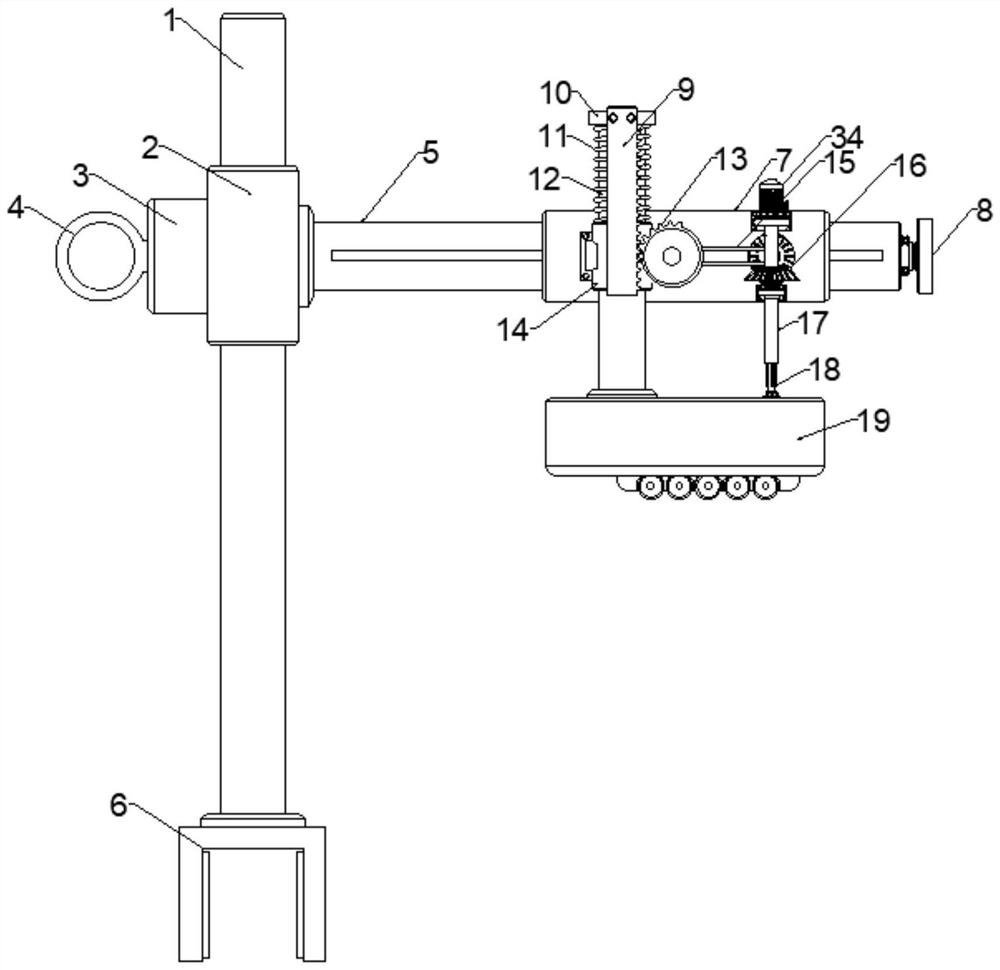

Control method of mechanical vacuum pump system based on RH refining process

ActiveCN111878374AResponsiveImprove control efficiencyPump testingPump controlAutomatic controlProcess engineering

The invention belongs to the technical field of automatic control over molten steel external refining equipment, and particularly provides a control method of a mechanical vacuum pump system based onan RH refining process. The control method comprises the following specific steps of conducting pre-pumping after preparation work is finished; after pre-pumping is finished, conducting mode selection; starting vacuum treatment according to a control mode selected by mode selection; starting and stopping each stage of pump and adjusting the pump frequency until the treatment is finished; enteringa standby process; and judging whether shutdown is needed or not according to a shutdown condition, if it is judged that shutdown is not needed, entering mode selection again, and if it is judged thatshutdown is needed, entering the shutdown process to achieve shutdown. The steps all need fault monitoring, the problems that an existing RH refining process is poor in responsiveness to changes, lowin control efficiency, high in energy consumption, poor in safety and not intelligent are solved; mechanical pump system adaptability adjustment conducted due to influences of an RH refining processmethod and molten steel waste gas amount changes on the air exhaust capacity of the mechanical vacuum pumps is achieved; and meanwhile, the protection function of long-term stable operation of the mechanical vacuum pumps is achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Auxiliary massage device for pediatric digestion treatment

PendingCN112870045AAchieving adaptive adjustmentInnovative designRoller massageSuction-kneading massageMassagePhysical therapy

The invention relates to an auxiliary massage device for pediatric digestion treatment. The auxiliary massage device for pediatric digestion treatment comprises a mounting rack and a movable sleeve sleeving the mounting rack, and the movable sleeve is matched with a plurality of clamping grooves formed in the mounting rack through a clamping pin assembly mounted on the movable sleeve. A cylindrical piece of a hollow structure is fixed to the side, away from the clamping pin assembly, of the movable sleeve, the cylindrical piece is sleeved with a sliding sleeve, and the sliding sleeve is connected with a horizontal adjusting mechanism installed on the inner side of the cylindrical piece. The auxiliary massage device for pediatric digestive treatment further comprises a mounting base, a connecting column is fixed to the mounting base, and the connecting column is inserted into a bearing sleeve fixed to the sliding sleeve and is in sliding fit with the bearing sleeve. A massage assembly is arranged on the mounting seat, the mounting assembly is connected with a reciprocating driving assembly mounted on the mounting seat, and the reciprocating driving assembly is connected with the driving mechanism.

Owner:SHENZHEN CHILDRENS HOSPITAL

Double-roller-shaft light blocking device

PendingCN110255256AAchieving adaptive adjustmentAvoid uneven windingMaterial analysis by optical meansWebs handlingEngineeringPaper sheet

Owner:武汉市海维鑫科技有限公司

Convenient wall perforating device for building construction

PendingCN113071008AProtection securityReduce dustWorking accessoriesStone-like material working toolsPunchingArchitectural engineering

The invention relates to the field of building construction, in particular to a convenient wall perforating device for building construction. The convenient wall perforating device comprises a supporting mounting plate, wherein a displacement mounting plate is arranged on one side of the supporting mounting plate in a right opposite manner, a supporting mounting cylinder is vertically arranged on the other side of the supporting mounting plate, an operation mounting hole is formed in the position, right opposite to the supporting mounting cylinder, of the displacement mounting plate, electric control telescopic columns are vertically arranged at the four corners of the supporting mounting plate, the other ends of the electric control telescopic columns are fixed to the displacement mounting plate, a limiting bearing sleeve is arranged on the side, right facing the displacement mounting cylinder, of a guide mounting cylinder, stable punching operation of the device is achieved through a guide displacement moving structure, under telescopic displacement adjustment, adaptive adjustment of drilling at different depths is achieved, operation vibration is weakened through elastic reset, the safety of a drill bit is protected, dust at an operation station is greatly reduced through active flow guide, and the view field and the health of operators are guaranteed.

Owner:JIANGSU SUZHONG CONSTR GROUP

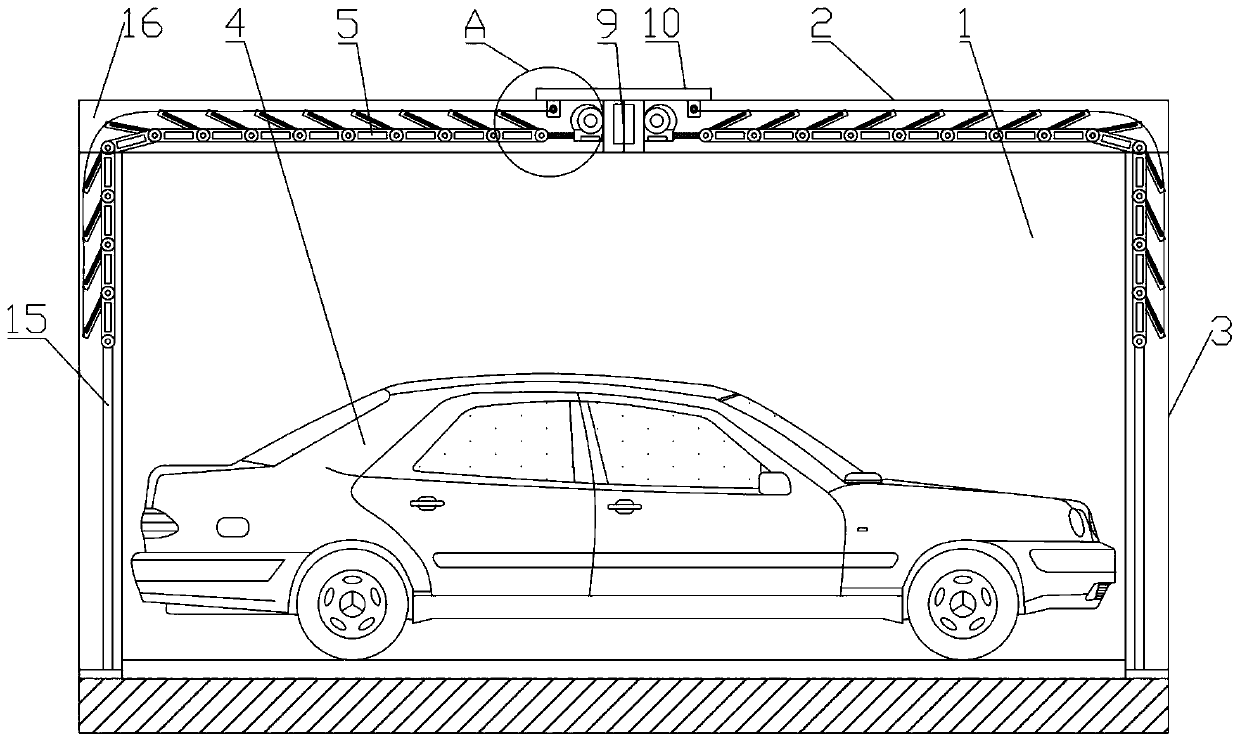

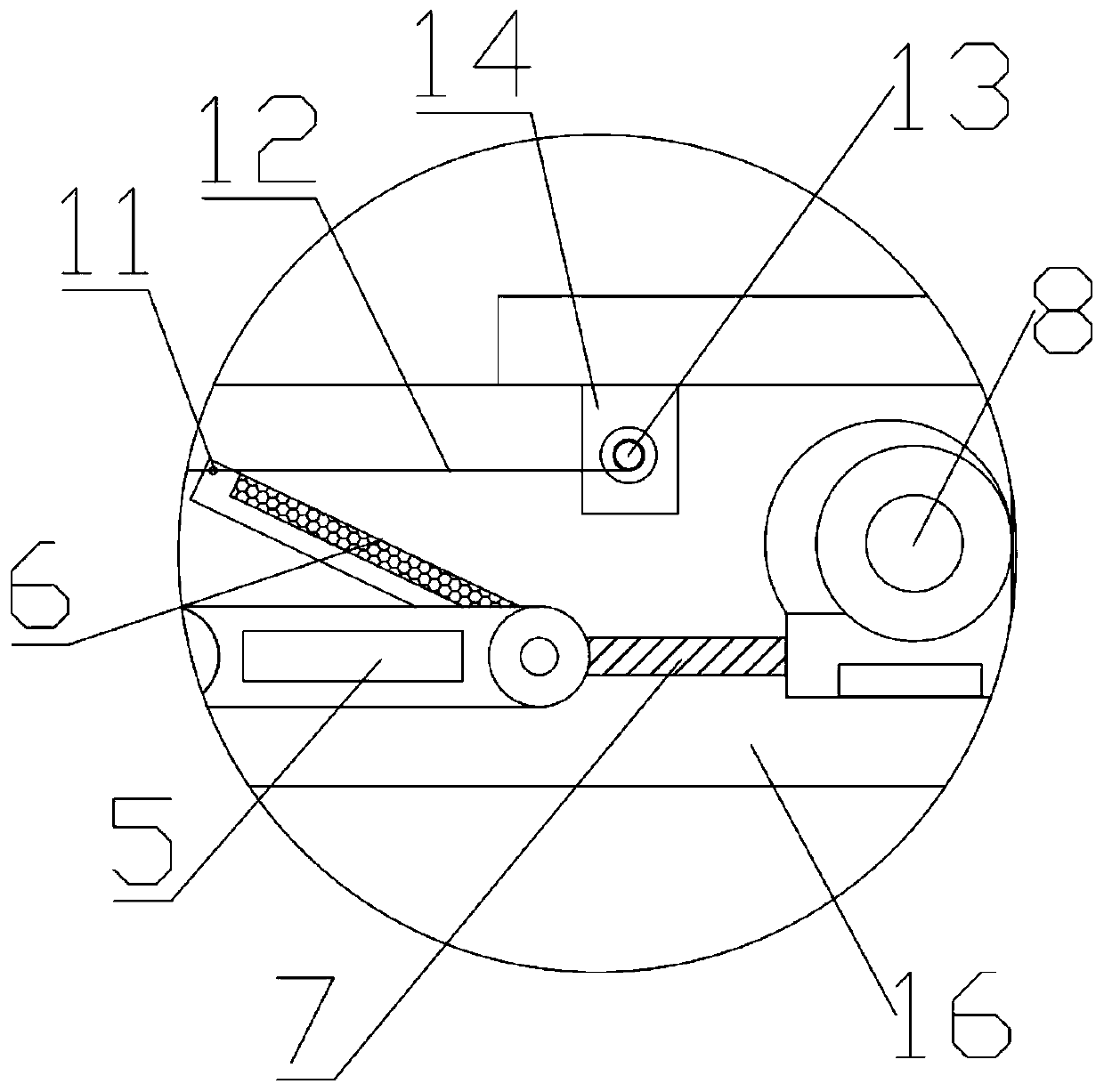

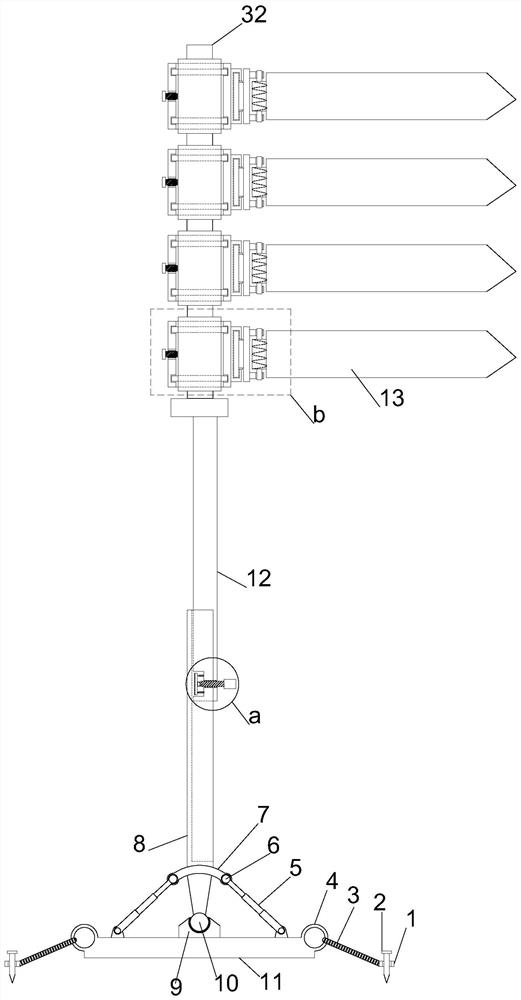

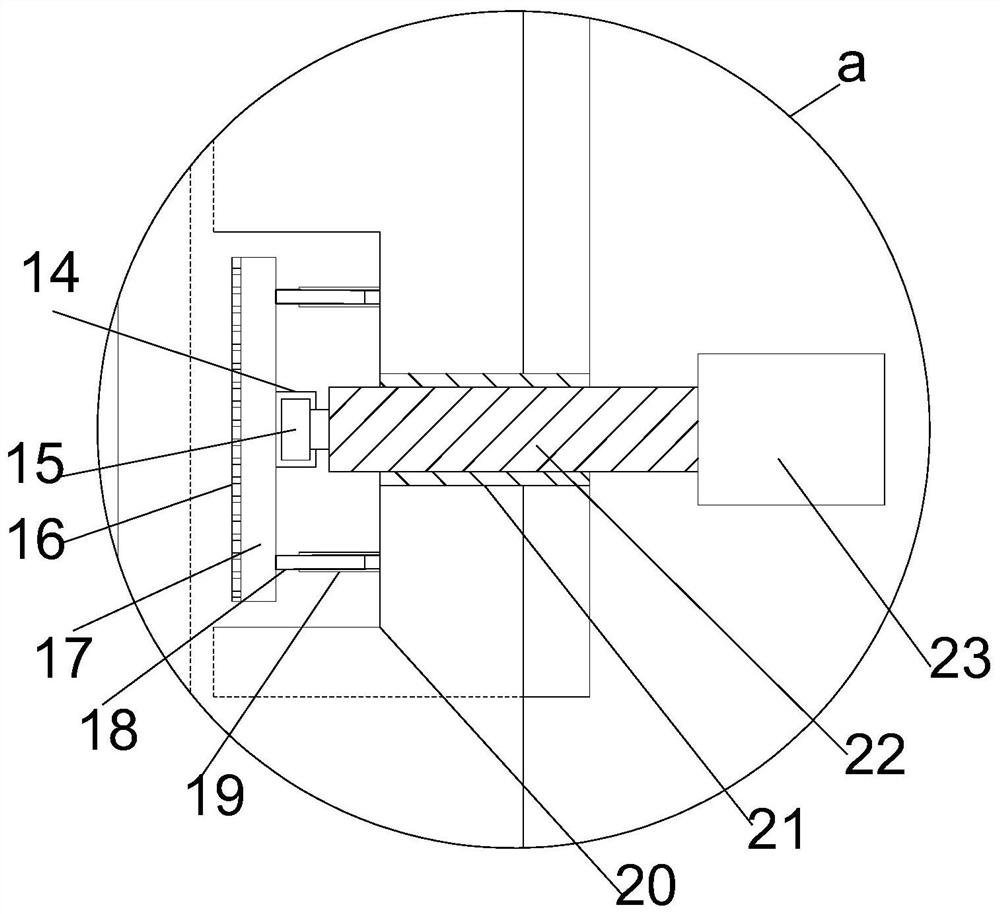

Solar panel folding and unfolding device for stereo garage

PendingCN110661483AImprove power conversionAchieving adaptive adjustmentPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringSolar battery

The invention discloses a solar panel folding and unfolding device for a stereo garage. The solar panel folding and unfolding device comprises a top plate frame arranged at the top of the garage and stand columns arranged at four corners of the garage, wherein the top plate frame is internally provided with an accommodating cavity, and a fixing base is arranged at the center of the accommodating cavity; two sides of the fixing base are provided with winders; the accommodating cavity is internally provided with a plurality of strip-shaped chain plates which are hinged front and back, and each chain plate is provided with a solar cell panel with one end being hinged and the other end being movable. According to the invention, the application area of the solar cell panel in the stereo garagecan be greatly increased, and the solar cell panel can be automatically folded and unfolded; and the sun-proof and wind-proof effects in the garage are further improved.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

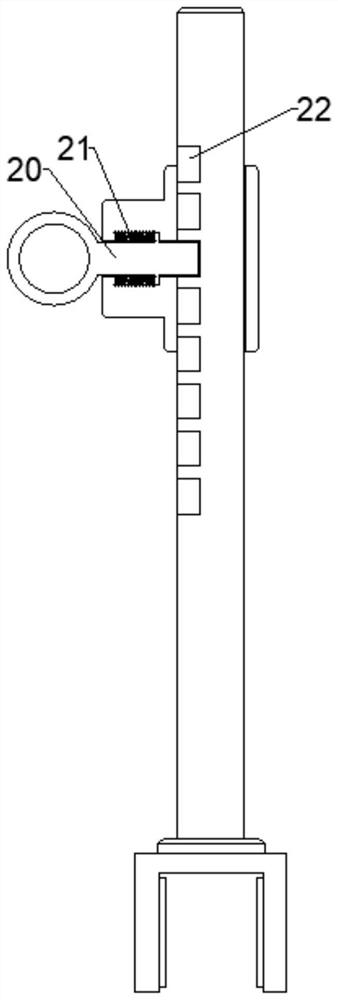

Guide device for urban and rural planning

InactiveCN111968495AQuick changeProtection securitySignsStructural engineeringMechanical engineering

The invention relates to the field of guide equipment, and particularly relates to a guide device for urban and rural planning. The device comprises a support mounting plate which is horizontally arranged, wherein a swinging ball shaft sleeve is vertically arranged in the middle of the upper end of the support mounting plate; a swinging ball shaft is arranged in a mode of being matched with the swinging ball shaft sleeve; a swinging mounting plate is arranged at the upper end of the swinging ball shaft; a limiting guide cylinder is vertically arranged in the middle of the upper end of the swinging mounting plate; a limiting guide column is arranged in a mode of being matched with the limiting guide cylinder; a fixed mounting groove is formed in the inner side of the lower half section of the limiting guide column; a supporting mounting column is vertically arranged at the upper end of the limiting guide column through a limiting plate; the device is kept in a vertical state all the time after being installed by matching a stable mounting structure with swing adjustment, adaptive adjustment of the height of the device is achieved through limiting, guiding, adjusting and fixing, rapid replacement of a guide board is achieved through interchangeable combined installation, the safety of the guide board is protected through reset rotation, the guide angle can be simply adjusted, andthe guide effect of the device is remarkably improved.

Owner:HENAN UNIV OF URBAN CONSTR

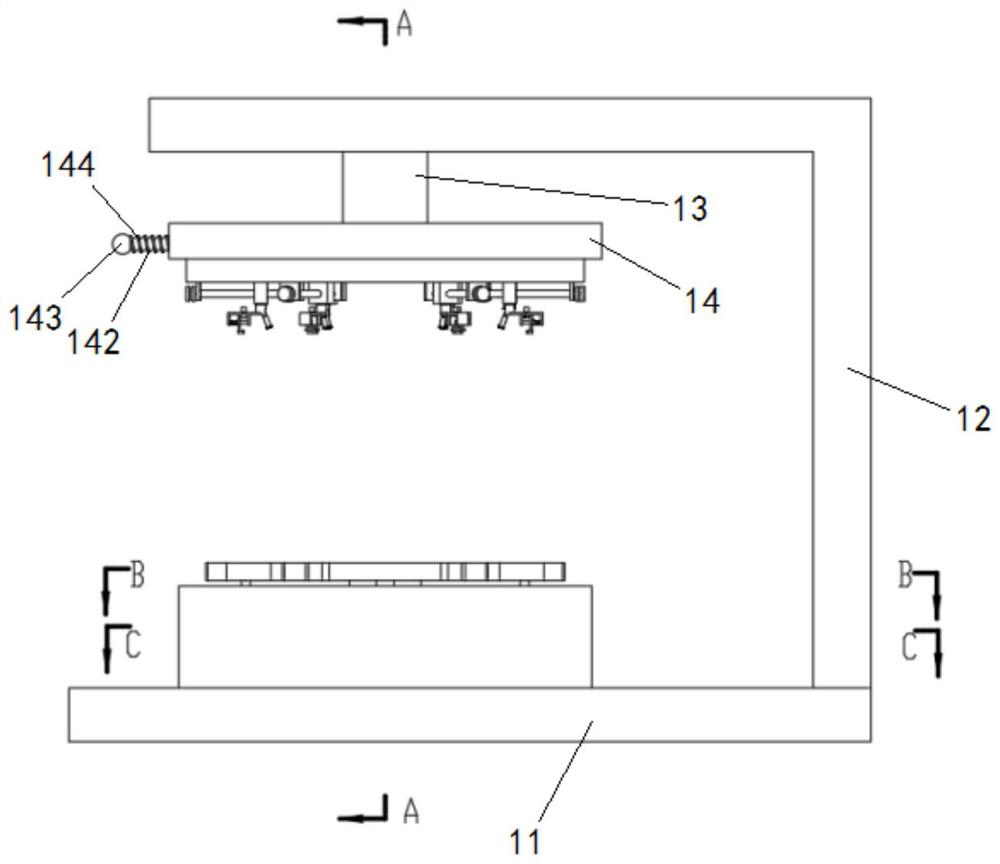

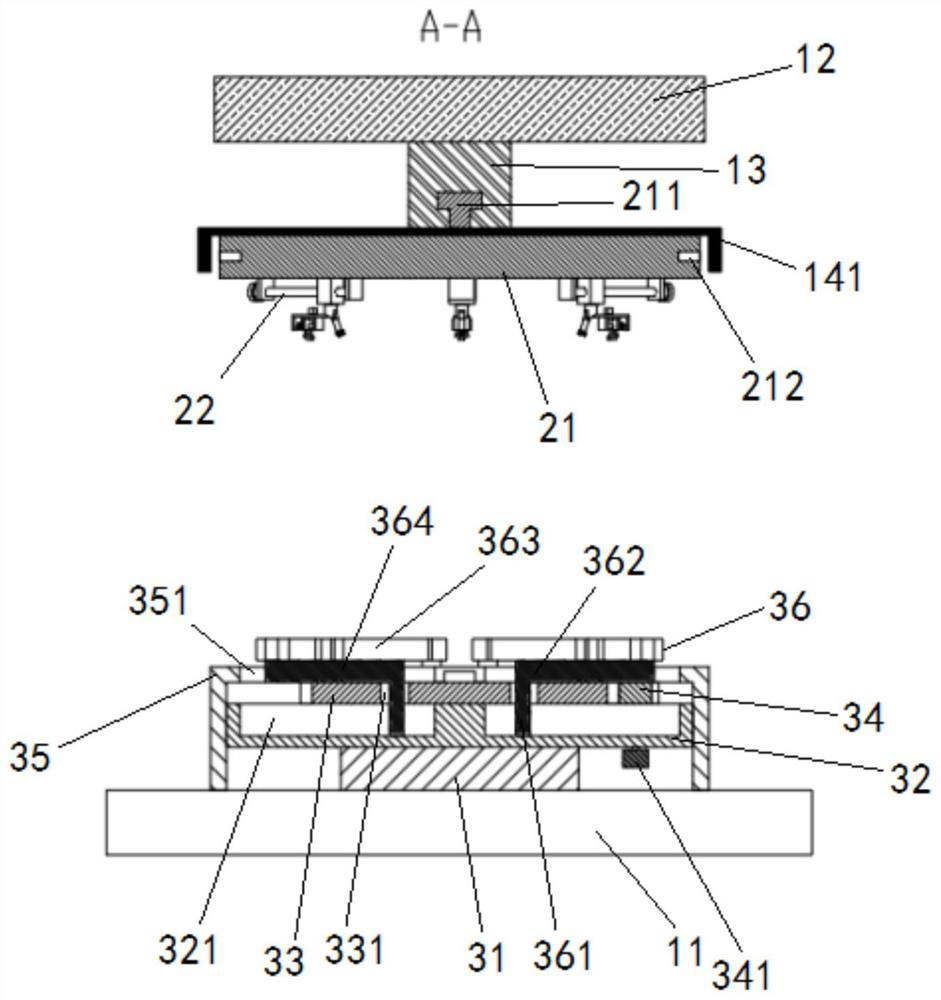

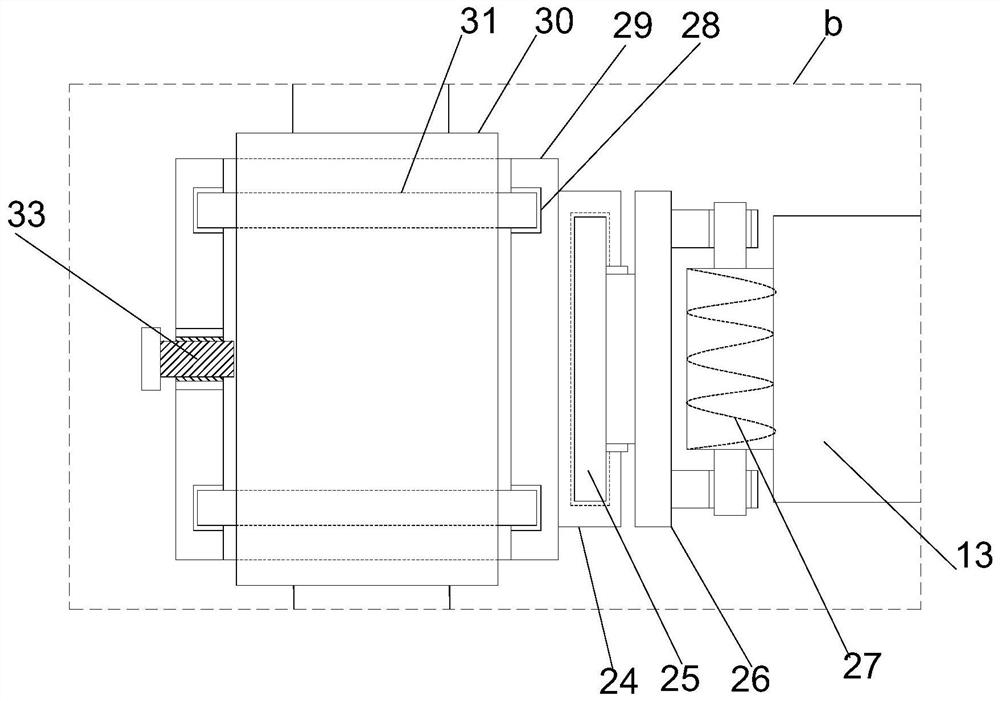

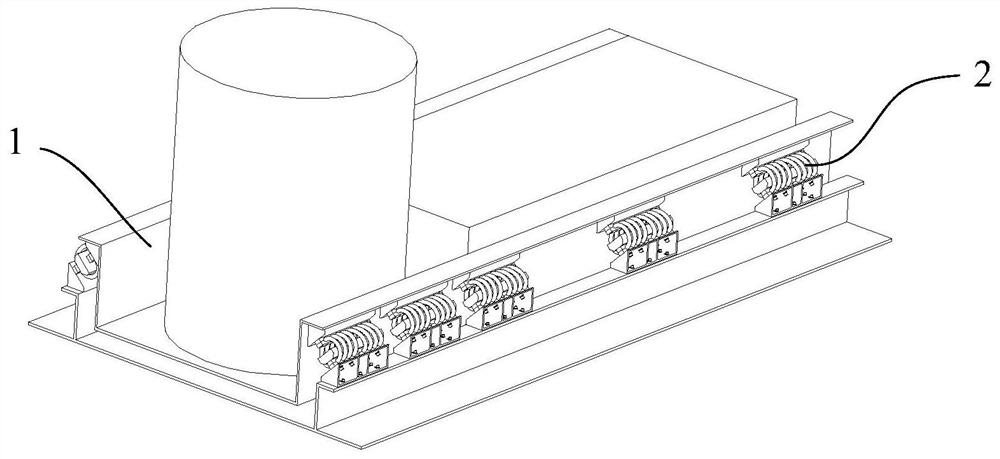

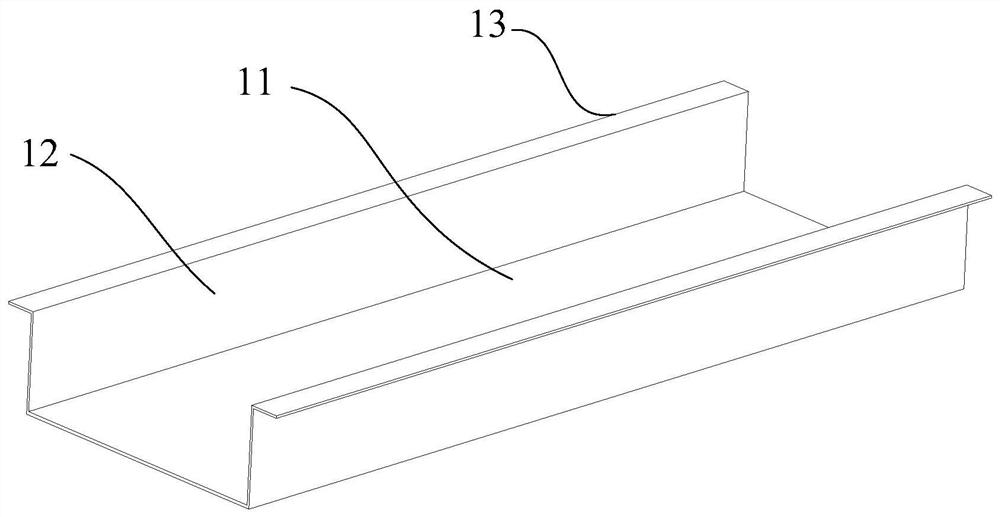

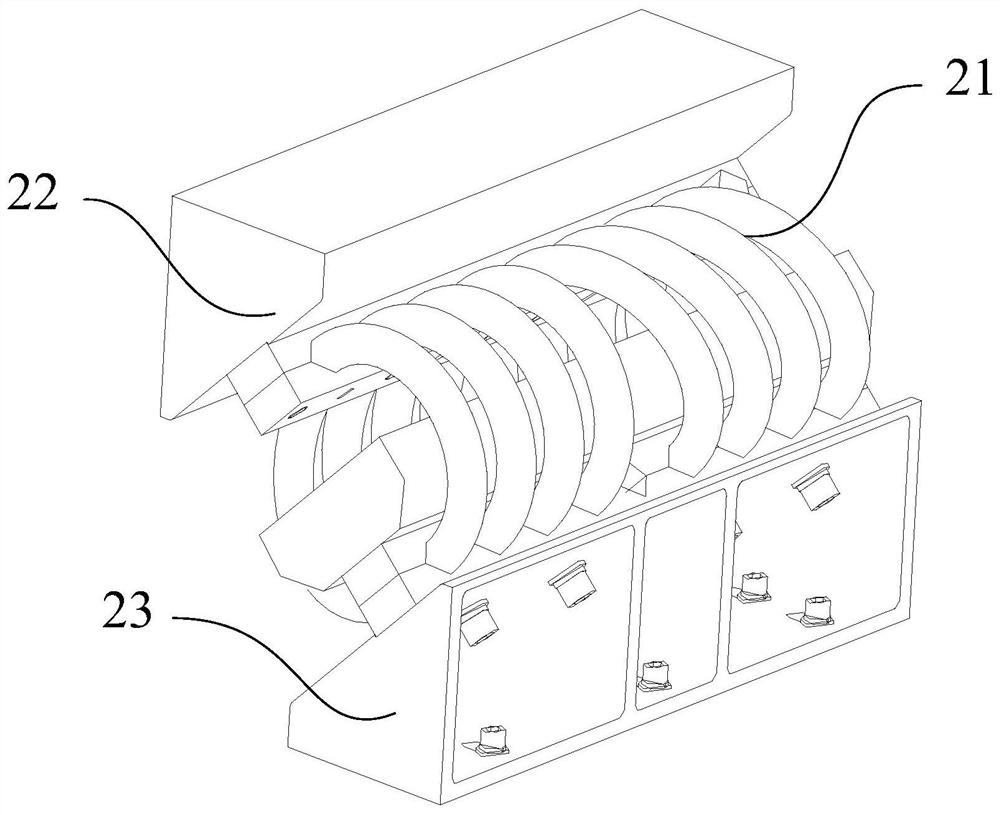

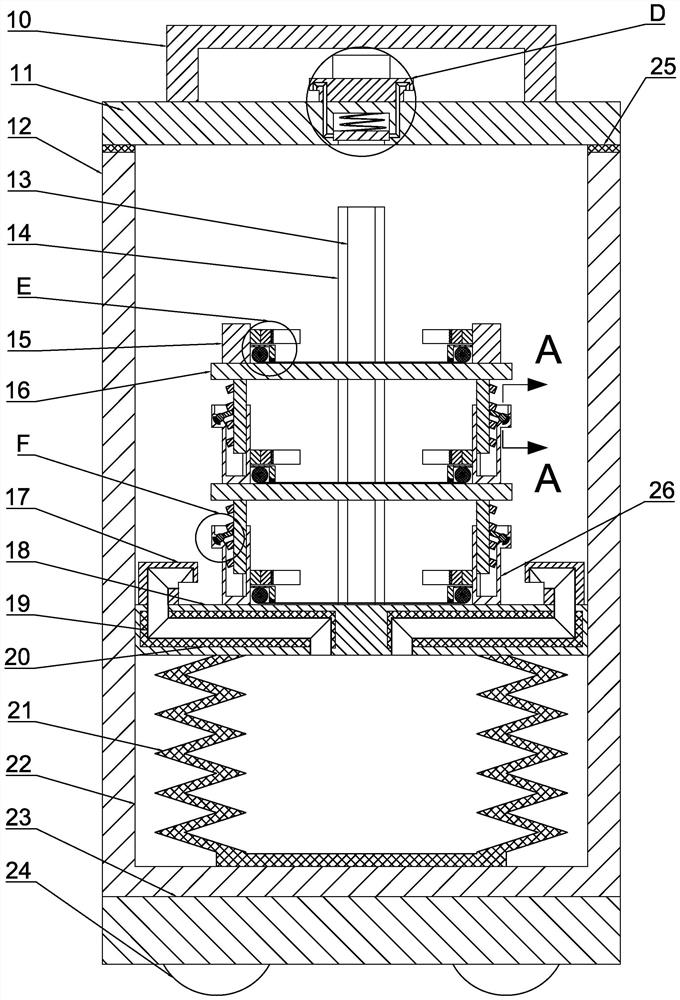

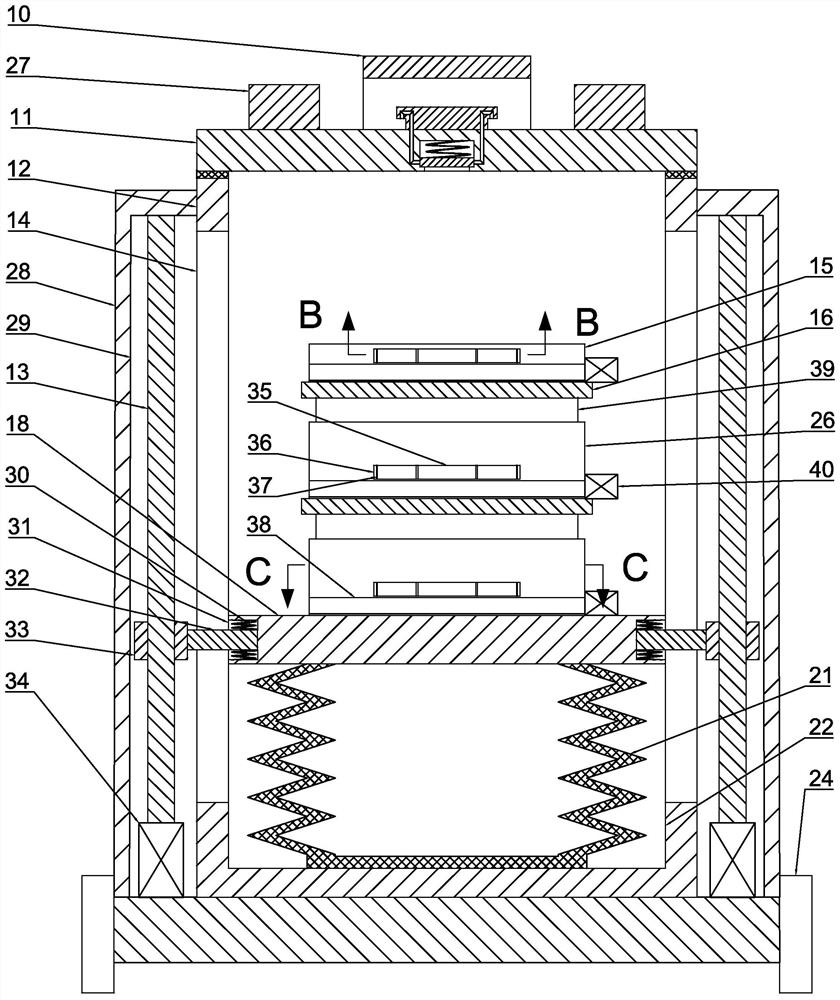

Ship-borne optical platform passive vibration isolation system and design method thereof

InactiveCN113404810AReduce vibration transmissionReduce measurementVibration suppression adjustmentsEngineeringOptical table

The invention relates to a ship-borne optical platform passive vibration isolation system and a design method thereof. The ship-borne optical platform passive vibration isolation system comprises an optical platform and a vibration isolation device, wherein the optical platform is horizontally arranged, the optical platform is used for placing or installing optical equipment, the vibration isolation device is arranged at the lower end of the optical platform, and the rigid center of the vibration isolation device is close to the common mass center of the optical platform and the optical equipment on the surface of the optical platform. The ship-borne optical platform passive vibration isolation system is simple in structure, can bear mechanical environments such as swinging, inclination and vibration of ships caused by oceans or lakes, and meets the requirements of high precision and tracking of optical equipment.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

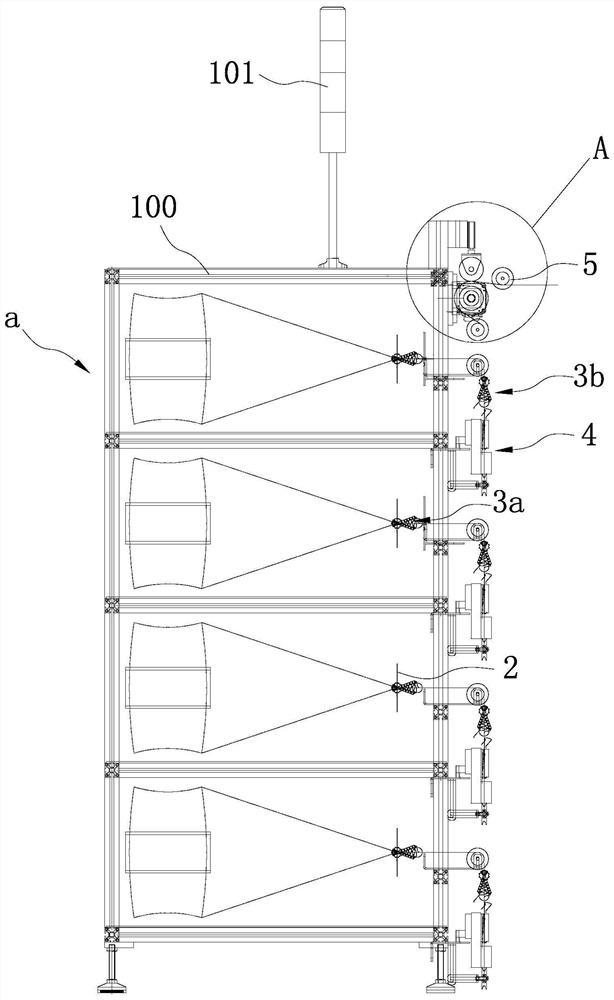

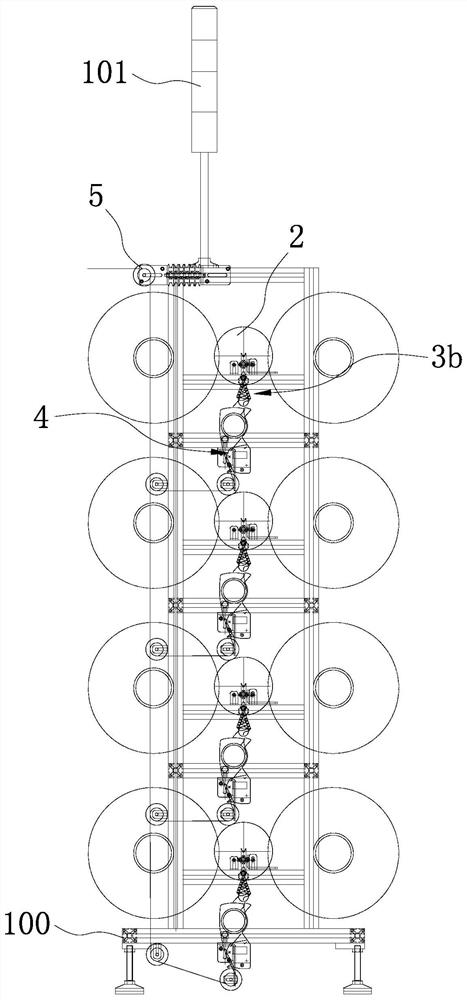

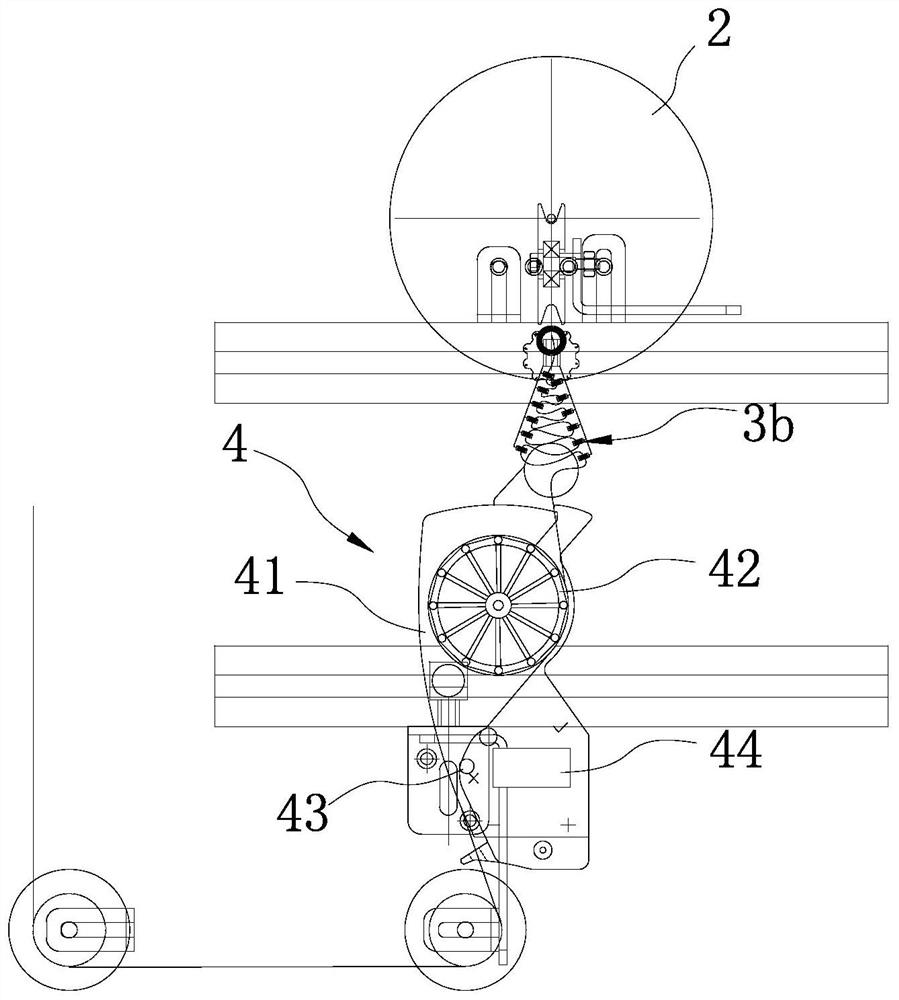

Full-automatic datamation constant-tension tailing-free automatic roll changing and unwinding control system

The invention relates to the field of elastic material conveying equipment, in particular to a full-automatic datamation constant-tension tailing-free automatic roll changing and unwinding control system which comprises a rack, a plurality of feeding stations are arranged on the rack in a stacked mode, and each feeding station is provided with two symmetrically-arranged material hanging frames used for containing material rolls. In the feeding process of rubber bands, each feeding station is sequentially provided with a yarn baffle, a first-stage buffer mechanism, a second-stage buffer mechanism, a datamation elastic force control mechanism and a plurality of guide wheels used for guiding all parts, wherein a yarn outlet guide wheel set used for collecting the rubber bands conveyed on all the feeding stations is arranged at the portion, located at the conveying rear end of the datamation elastic force control mechanism, of the rack. Each yarn baffle is arranged on the symmetrical center line of the corresponding two material hanging frames, a ceramic hole for the rubber bands to penetrate through is formed in the center of each yarn baffle, and when material rolls are arranged on the material hanging frames, the axial centers of the material rolls are arranged right opposite to the ceramic holes. According to the full-automatic datamation constant-tension tailing-free automatic roll changing and unwinding control system, the problem that the tension cannot be kept constant when an existing elastic piece is fed and unwound is solved.

Owner:大途科技(泉州)有限公司

High-voltage switch cabinet component assembly working device

InactiveCN107257097APrecise positioningReduce labor intensitySwitchgearEngineeringMechanical engineering

A high-voltage switch cabinet component assembly working device disclosed by the present invention comprises a rack body, a jacking device and a supporting bench, and the jacking device is fixed to the rack body. The high-voltage switch cabinet component assembly working device also comprises a supporting plate fixed on the jacking device and a sliding rail arranged between the supporting plate and the supporting bench, the supporting bench and the supporting plate are connected via the sliding rail, and the sliding rail is a linear rail. The working device enables a current transformer to be positioned at an installation position conveniently.

Owner:绵阳行之智汇知识产权服务有限公司

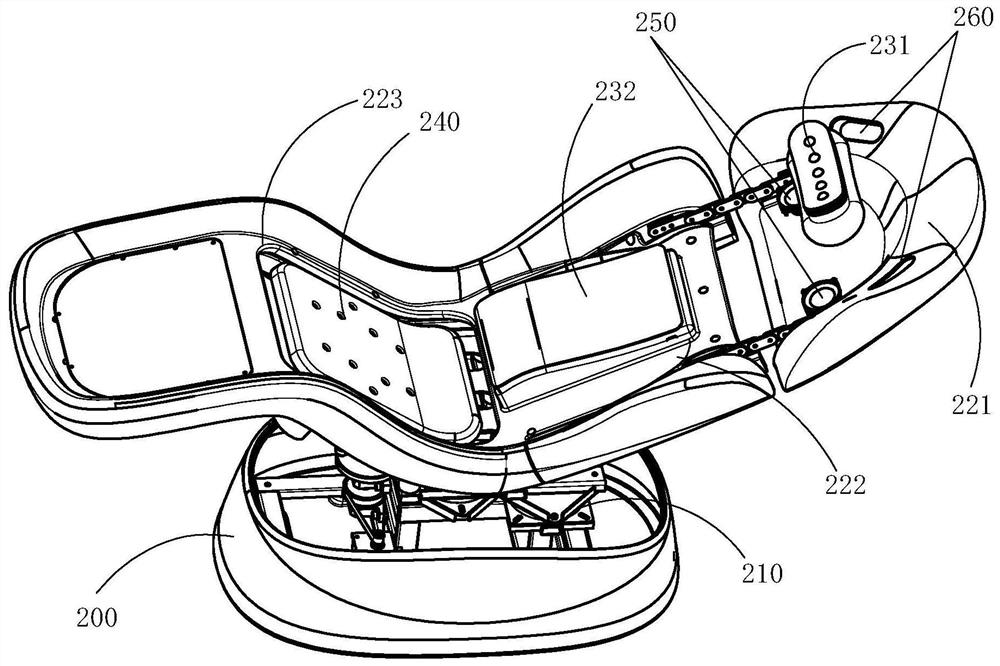

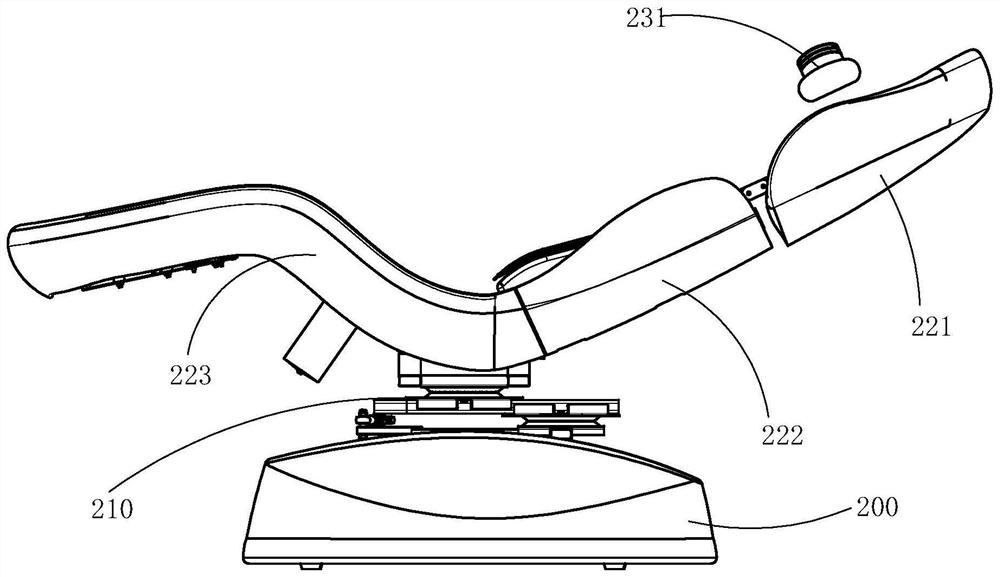

Novel sleep disorder rehabilitation physiotherapy robot control method and robot

PendingCN113908004ARelieve physical fatigueImprove sleepDiagnosticsChiropractic devicesHuman bodyData control

The invention relates to the technical field of physiotherapy equipment, and discloses a novel sleep disorder rehabilitation physiotherapy robot control method and a robot. The method is applied to the robot and comprises the steps that: a massage mode is entered; in the massage mode, human body state data of a user lying on the robot are detected; the robot is controlled to conduct massage operation on the user in combination with the human body state data; after the robot enters the massage mode, when the working duration of the robot meets a preset duration condition, the robot is switched to the swing mode; and in the swing mode, the robot is controlled to conduct swing operation. Therefore, body relaxing and conditioning and sleep promoting actions supplement each other; closed-loop feedback adjustment of massage operation is carried out in combination with the monitored human body state; the sleep time of the user can be easily prolonged; and the sleep aiding effect is better.

Owner:TEINYO (ZHONGSHAN) ROBOT CO LTD

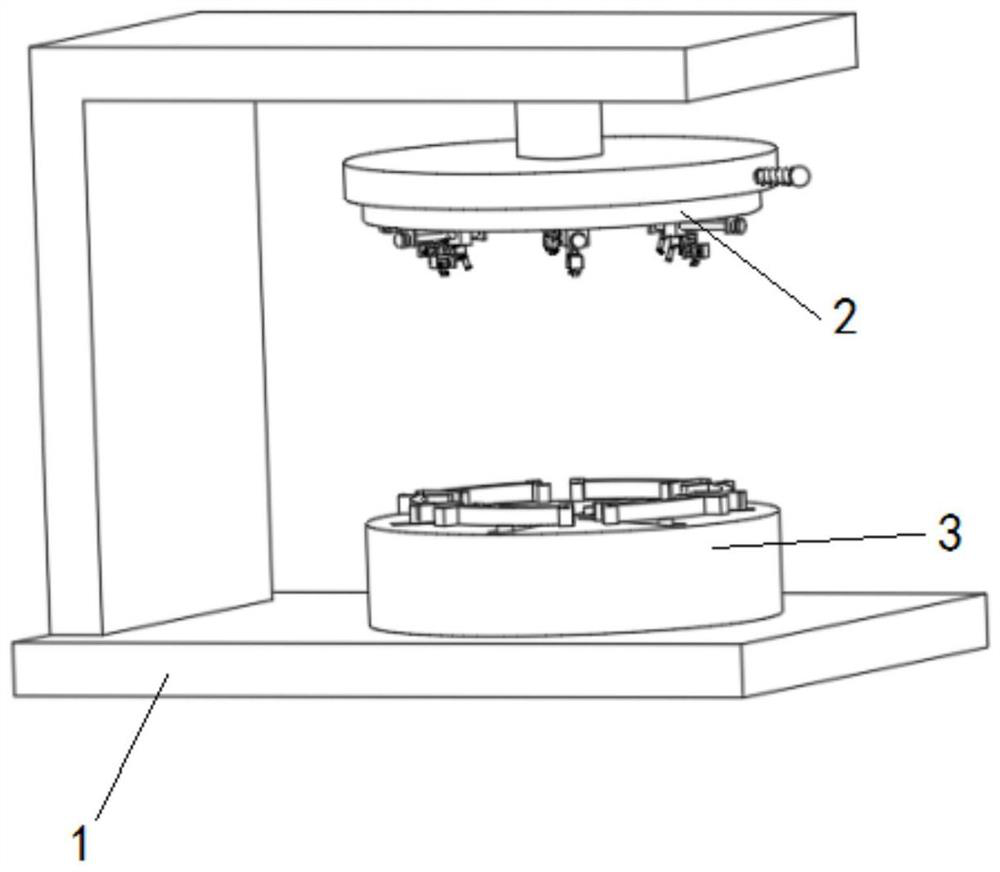

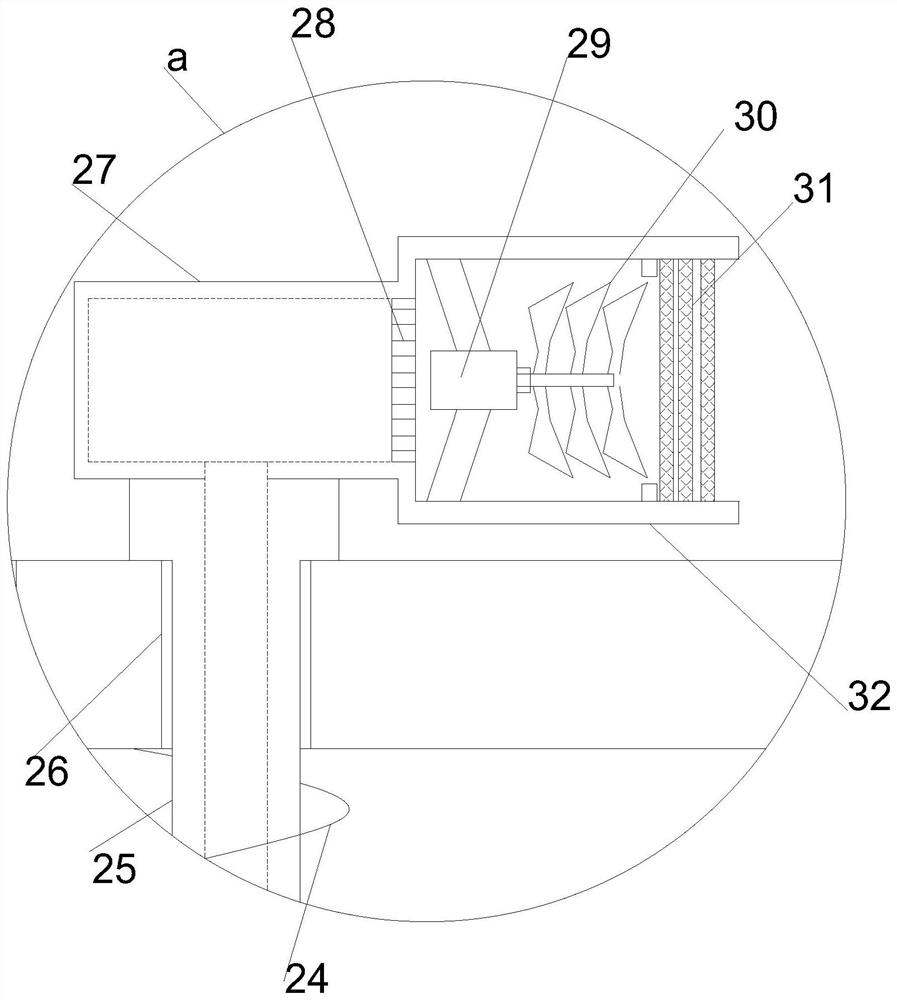

An automated pineapple peeling and piercing robot

ActiveCN106666768BRealize the function of automatic peeling and peelingAchieving adaptive adjustmentVegetable peelingCylinder blockControl theory

The invention discloses a robot for automatically peeling a pineapple and peeling holes of the pineapple. The robot comprises a main frame, a material sending conveyor belt and a material discharging conveyor belt, two vertical columns, an upper horizontal frame, a lower horizontal frame, an upper horizontal electric cylinder, a lower horizontal electric cylinder, an upper vertical electric cylinder, a lower vertical electric cylinder, a U-shaped hole-peeling frame, a hole-peeling collecting box, a material sending electric cylinder and a material discharging electric cylinder, wherein the cylinder body of the upper horizontal electric cylinder is arranged on the upper horizontal frame; the cylinder body of the upper vertical electric cylinder is slidably arranged in a sliding groove of the upper horizontal frame, and the end part of a piston rod of the upper vertical electric cylinder is further provided with an upper rotating motor; the cylinder body of the lower horizontal electric cylinder is arranged on the lower horizontal frame; the cylinder body of the lower vertical electric cylinder is slidably arranged in a sliding groove of the lower horizontal frame, and the vertical electric cylinder slides in the sliding groove of the lower horizontal frame under the drive of the lower horizontal electric cylinder. According to the robot for automatically peeling the pineapple and peeling holes of the pineapple, by arranging a peeling system and a hole peeling system, the functions of automatically peeling the pineapple and peeling holes of the pineapple are achieved; by arranging adjusting mechanisms in the vertical direction and the horizontal direction, the dimension adjusting of different pineapples is achieved; the structure is reasonable and the work efficiency is high.

Owner:山东中聚电器有限公司

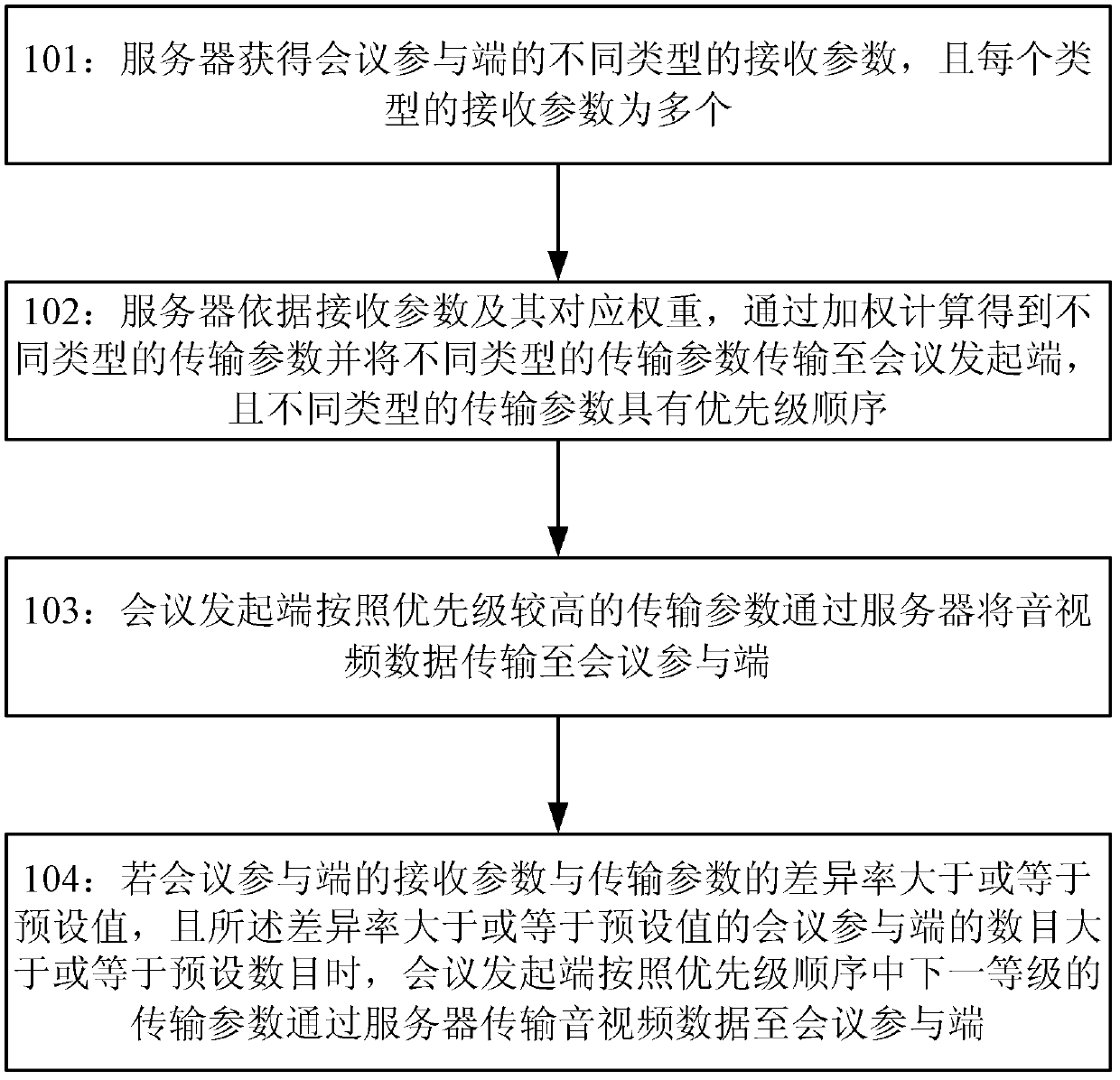

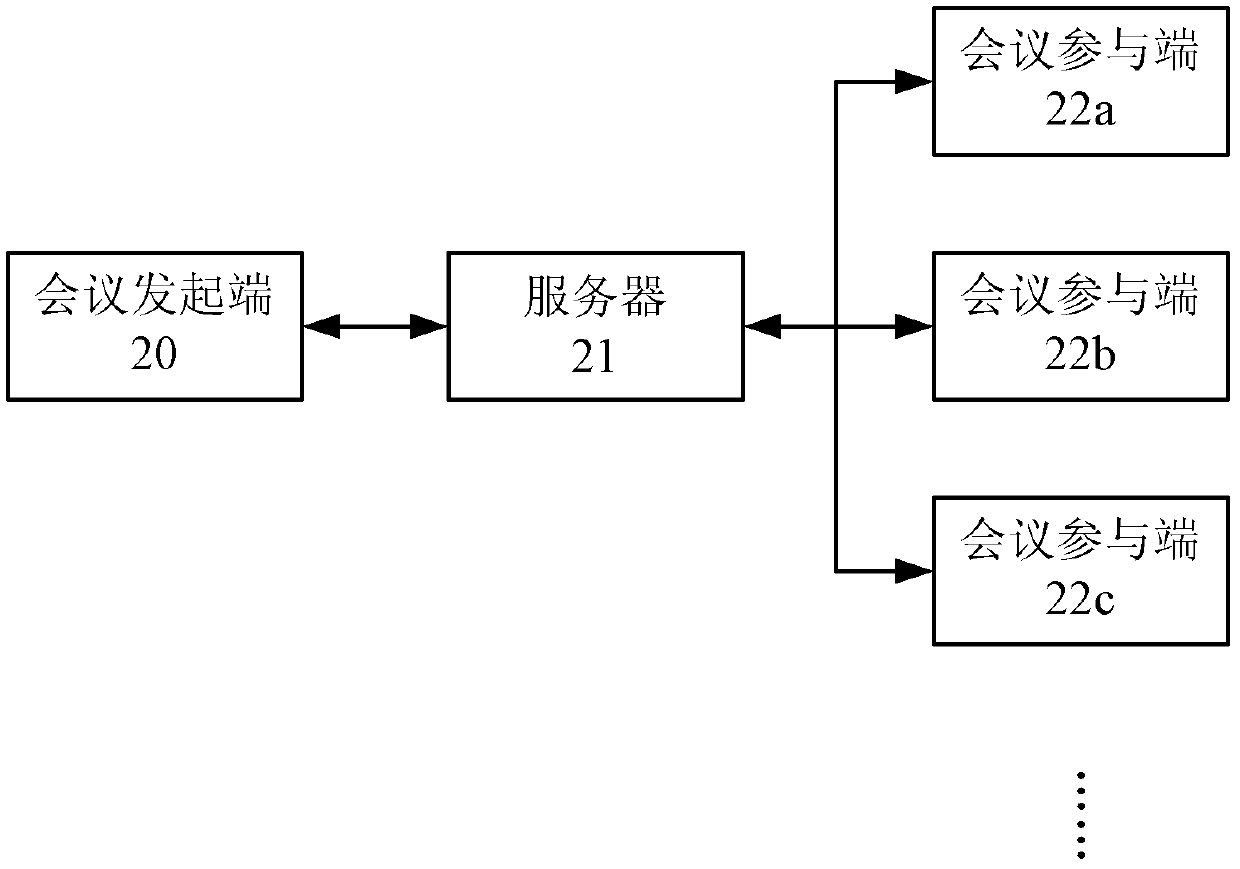

Audio and video transmission control method of network conference and system thereof

InactiveCN102364937BMeet needsAchieving adaptive adjustmentTelevision conference systemsTwo-way working systemsVideo transmissionData transmission

The invention provides an audio and video transmission control method of a network conference and a system thereof. The method comprises the following steps that: a server acquires different types of receiving parameters of a conference participant and a number of the each type of the receiving parameters is more than one; the server calculates through weighting so as to obtain the different types of the transmission parameters according to the receiving parameters and corresponding weight and the different types of the transmission parameters possess a priority order; the conference initiator transmits audio and video data to the conference participant through the server and according to the transmission parameter with a higher priority; when a variance ratio of the receiving parameters of the conference participant to the transmission parameters is larger than or equal to a preset value and the number of the conference participant whose variance ratio is larger than or equal to the preset value is greater than or equal to a preset number, the conference initiator transmits the audio and video data to the conference participant through the server and according to the transmissionparameters with a next lever in the priority order.

Owner:SUZHOU GOLD HEAD INTELLIGENT SYST ENG CO LTD

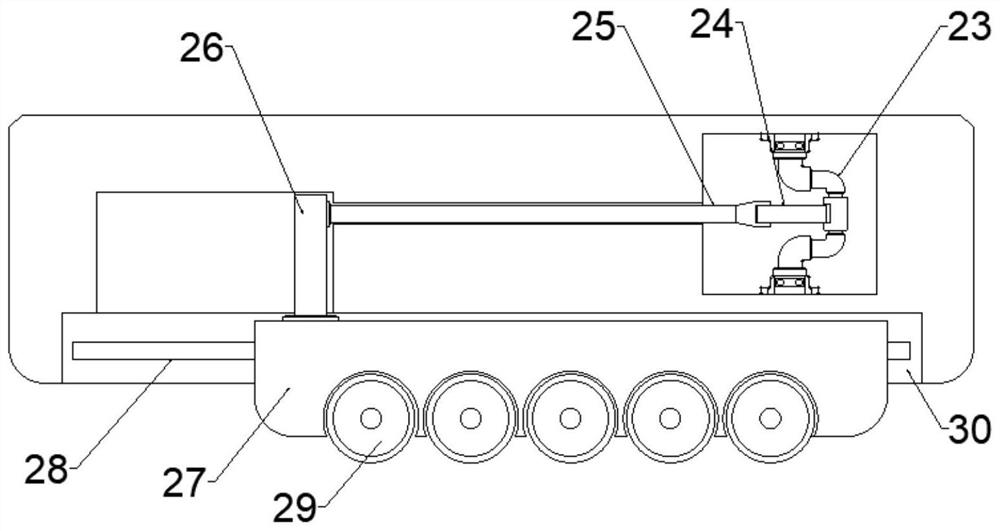

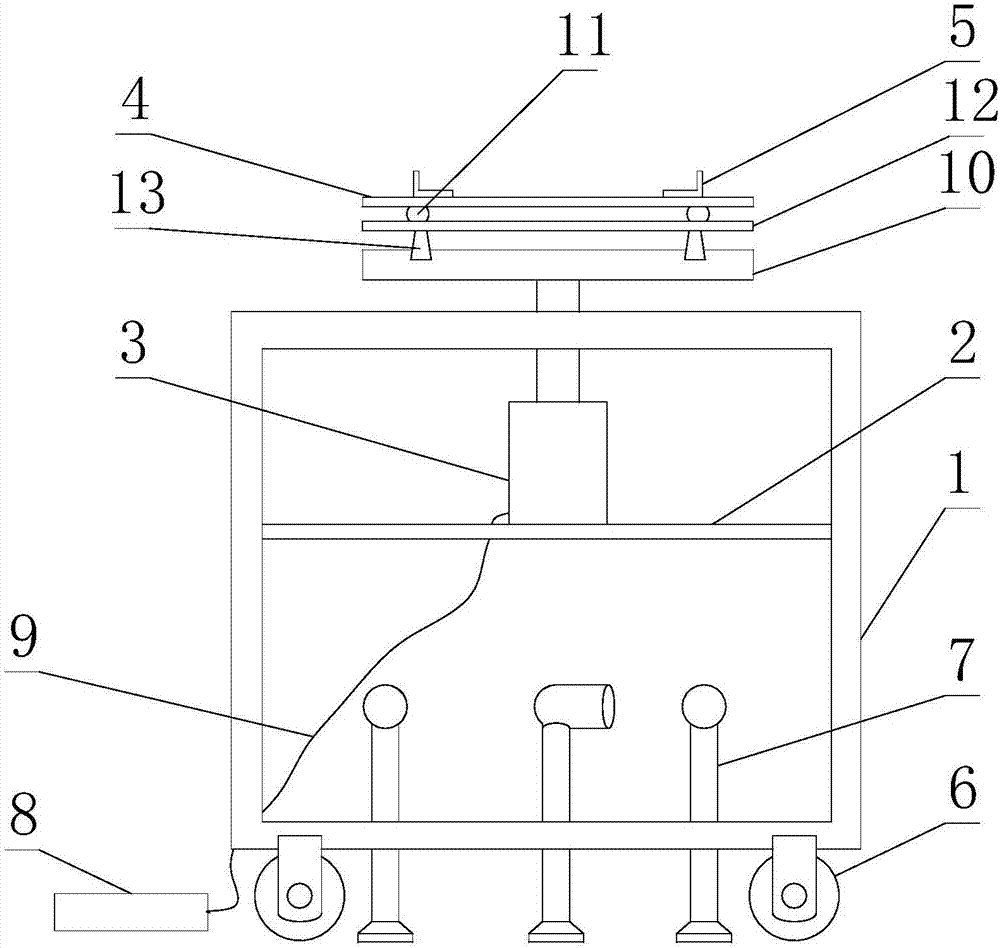

Movable energy-saving serving trolley and using method thereof

InactiveCN114128990AWith shock absorption functionAvoid enteringServing tablesFeetHeat conservationMechanical engineering

The invention belongs to the field of movable energy-saving equipment, and particularly relates to a movable energy-saving serving trolley and a using method thereof. The method is matched with the movable energy-saving meal delivery trolley and the using method thereof, the method is carried out in cooperation with the movable energy-saving meal delivery trolley, the movable energy-saving meal delivery trolley comprises a main machine shell, a main machine cavity is formed in the main machine shell, a damping and heat storage mechanism is arranged in the main machine cavity, and a controllable meal frame mechanism is arranged on the damping and heat storage mechanism. The meal frame mechanism is provided with a tableware clamping damping mechanism, a cleaning mechanism is arranged on the meal frame mechanism, outer machine shells are symmetrically and fixedly arranged outside the main machine shell, outer machine cavities are formed in the outer machine shells, a meal taking damping mechanism is arranged in each outer machine cavity, and a sealing cover mechanism capable of being taken down is arranged on the upper portion of the main machine shell. According to the movable energy-saving meal delivery trolley and the using method thereof, the heat preservation effect is good, the excellent and efficient damping effect is achieved, heat loss caused by meal taking can be prevented, and the cleaning capacity effect is achieved.

Owner:宁波市燕翔环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com