Control method of mechanical vacuum pump system based on RH refining process

A mechanical vacuum pump and control method technology, applied in pump control, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of low control efficiency, high energy consumption, weak responsiveness, etc., and achieve high control efficiency and good safety. , responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

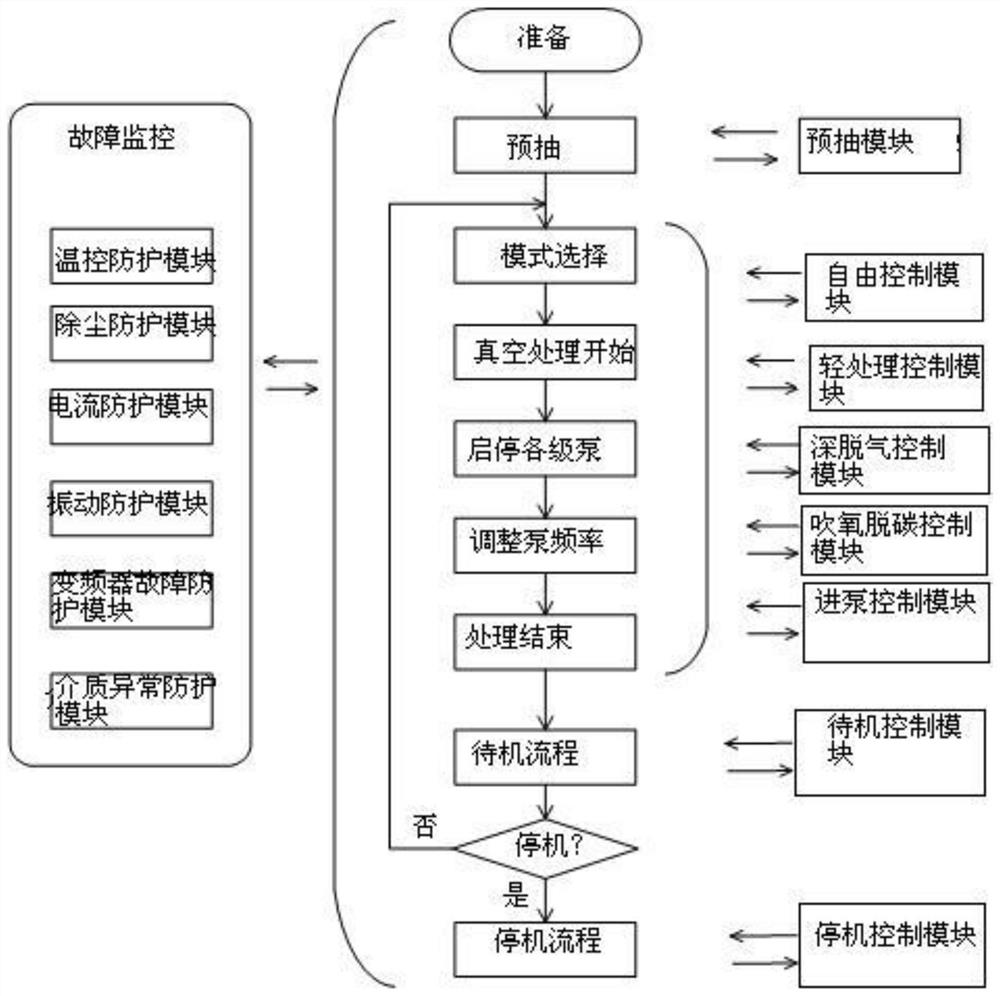

[0030] Such as figure 1 As shown, a control method of a mechanical vacuum pump system based on the RH refining process, the specific steps are as follows:

[0031] 1) Pre-draw after the preparation work is completed;

[0032] 2) After the pre-pumping is finished, select a mode; the control mode includes one or more of free mode, light treatment mode, deep degassing mode, oxygen blowing decarburization mode and pumping mode;

[0033] 3) Select the selected control mode according to the mode, and start the vacuum treatment;

[0034] 4) Start and stop the pumps at all levels and adjust the pump frequency until the treatment is completed;

[0035] 5) Enter the standby process;

[0036] 6) Determine whether to stop according to the shutdown conditions: if it is judged not to stop, then enter the mode selection again, if it judges to stop, then enter the shutdown process to stop;

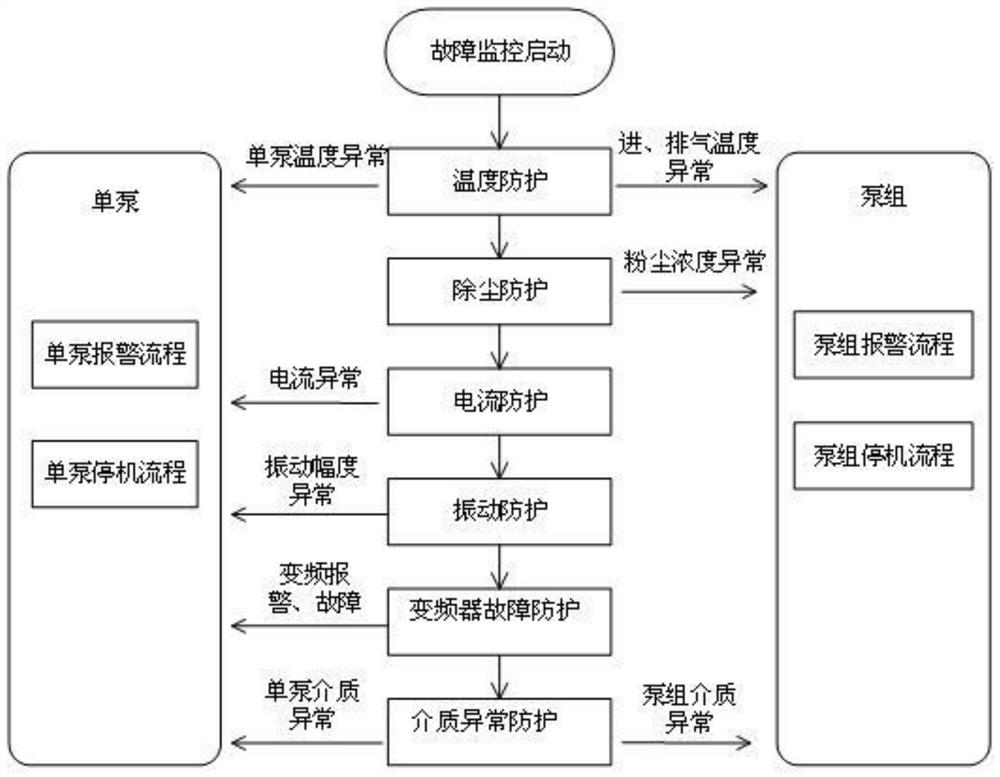

[0037] 7) The steps 1) to 6) all need fault monitoring.

[0038] The invention is applicable to a...

Embodiment 2

[0042] On the basis of Example 1, the specific method of the pre-pumping is as follows: compare the rated pumping time of the pump with the set pre-pumping time, compare the vacuum system pressure of the pump with the set pre-pumping pressure in real time, and if it is greater than the set When the deviation value is reached, the frequency conversion speed regulation and quantity regulation of the multi-stage pump are carried out and the target pressure is reached, and the pre-pumping ends.

[0043] The pre-pumping is carried out through the pre-pumping module, and the target pressure can be reached through the pre-pumping of the pre-pumping module, and the pre-pumping module is an existing intelligent control module for consumption reduction.

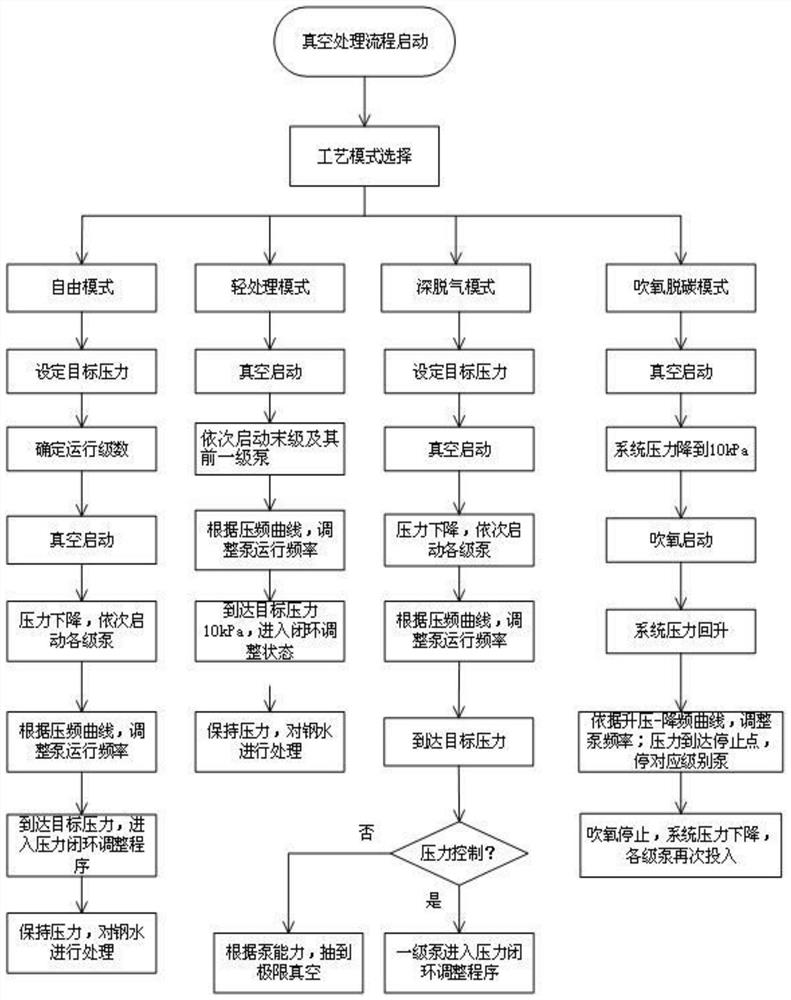

[0044]Such as figure 2 As shown, the specific method of the free mode is: set the target pressure, determine the number of pump operation stages, and start the vacuum. When the target pressure is reached, enter the pressure closed-lo...

Embodiment 3

[0059] On the basis of Example 2, the method of the standby process is: when the vacuum shut-off valve is closed and the vacuum chamber is repressurized, during the process of replacing the molten steel, according to the pump stop conditions, the mechanical vacuum pump is gradually turned off from the front stage to the rear stage , to maintain the low-frequency operation of the final mechanical vacuum pump, to carry out nitrogen cleaning of the dust collector and to remove dust and cool down the pump chamber step by step. When the actual standby time is greater than the set time and the molten steel is replaced, the mechanical vacuum pump is controlled according to the selected control mode. The standby process performs standby processing of the mechanical vacuum pump system through the existing standby control module.

[0060] Further, the method of shutting down the process is as follows: when the vacuum cut-off valve is closed and the vacuum chamber is repressurized, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com