Bolt assembly with adjustable single-and-double-ear connecting coaxiality

A bolt assembly, coaxiality technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of poor measurement accuracy, inability to assemble successfully at one time, increase the cost and difficulty of replacement work time, and achieve process cost advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

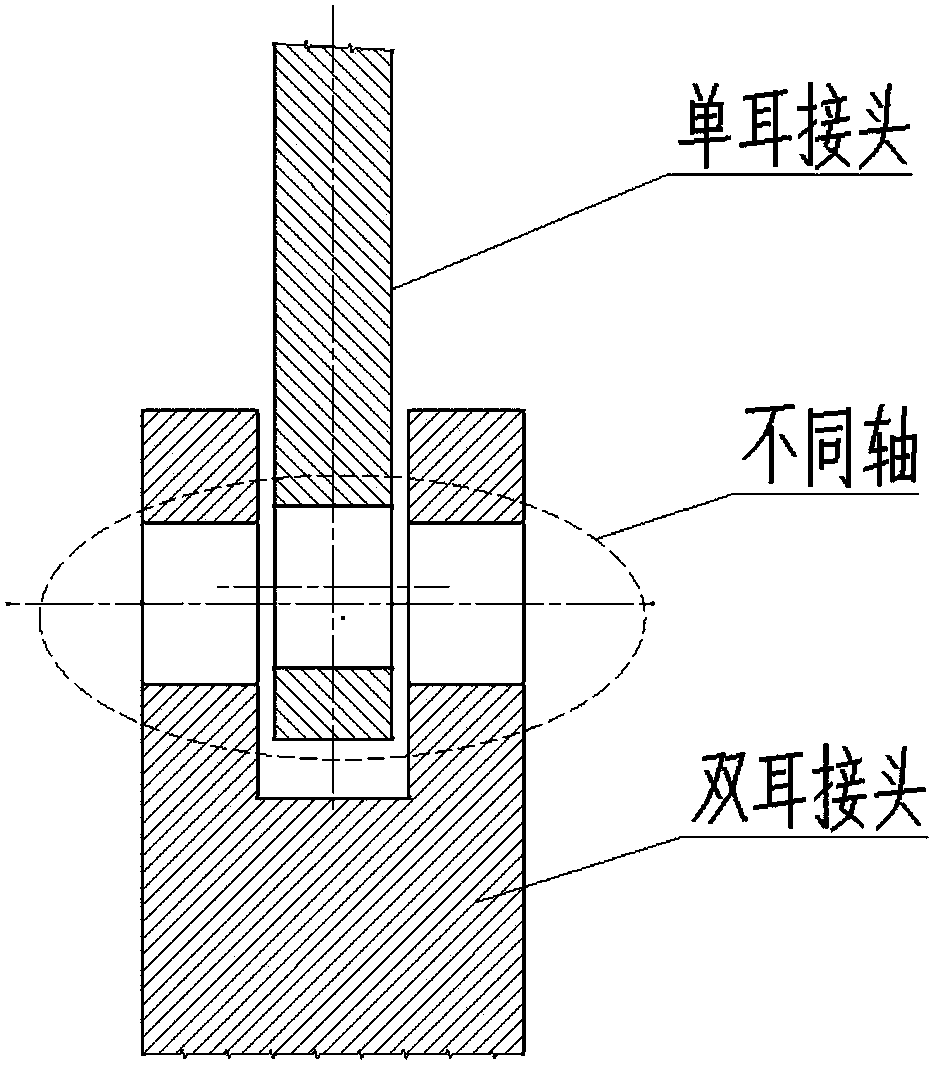

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structural forms introduced in the patent of the present invention will be described in detail below in conjunction with the accompanying drawings.

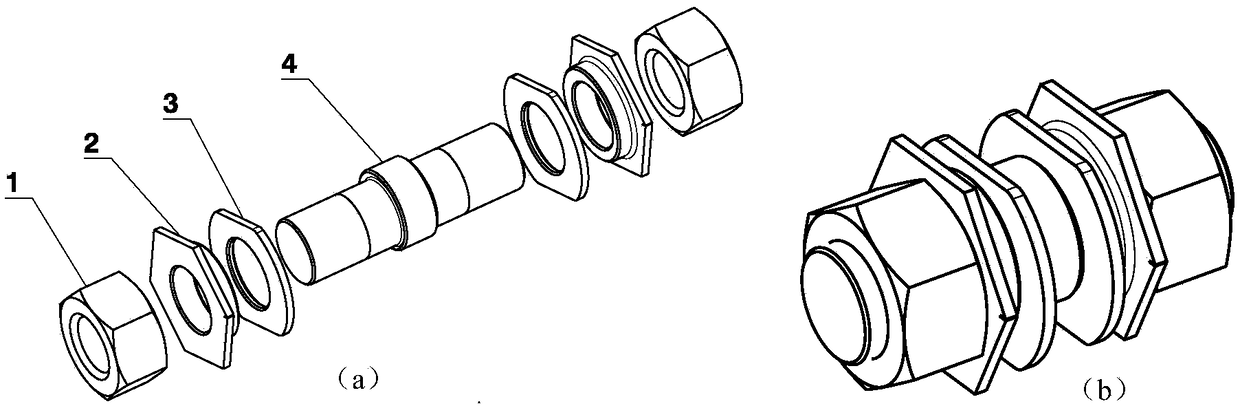

[0019] figure 2 The illustrated embodiment is a diagram of a bolt assembly for adjusting the coaxiality of single and double lug connections proposed by the present invention. There is a twin-screw eccentric pin 4, two gap adjustment washers 3, two eccentric bushings 2 and two nuts 1.

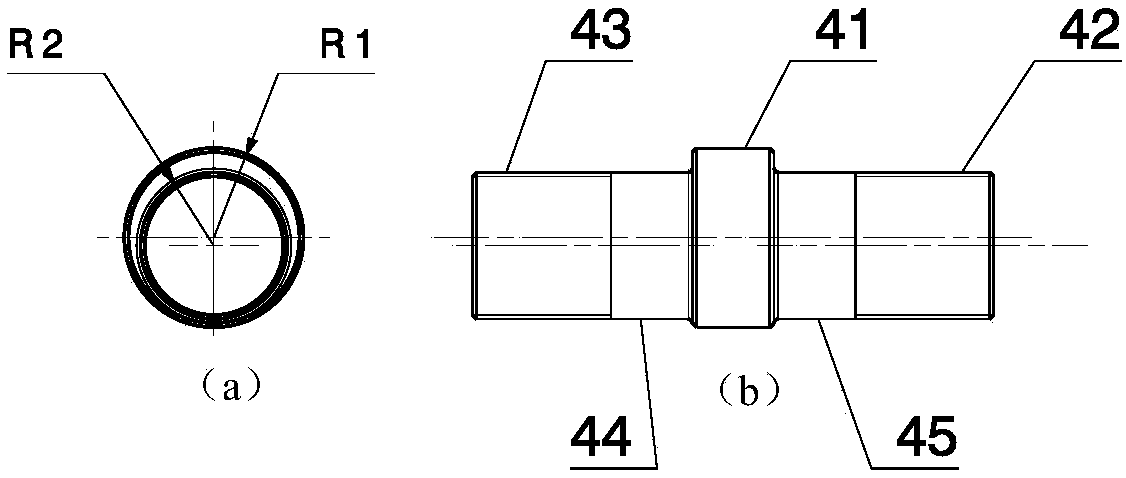

[0020] image 3 The illustrated embodiment is a part diagram of the twin-screw eccentric pin 4 proposed by the present invention. It is divided into five areas: single-ear connection section 41, threaded sections 42 and 43, and double-ear connection sections 44 and 45, wherein threaded sections 42 and 43 are coaxial with double-ear connection sections 44 and 45, and are coaxial with single-ear connection sections. The axis of 41 has certain eccentricity δ1. The outer diameter of the one-ear connection section 41 is larger than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com