An automated pineapple peeling and piercing robot

A technology for cutting holes and pineapples, which is applied in the fields of vegetable or fruit peeling, food science, application, etc. It can solve the problems of low production efficiency, time-consuming and labor-intensive, and large manpower consumption, so as to achieve high work efficiency, realize adaptive adjustment, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

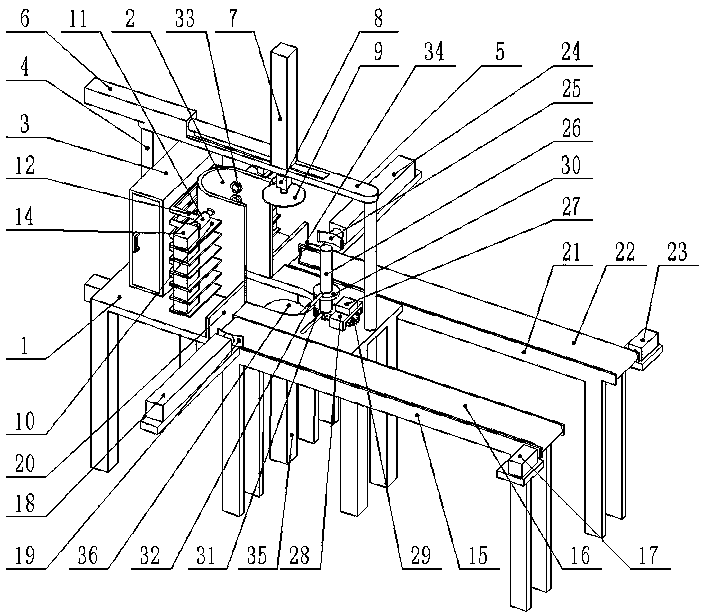

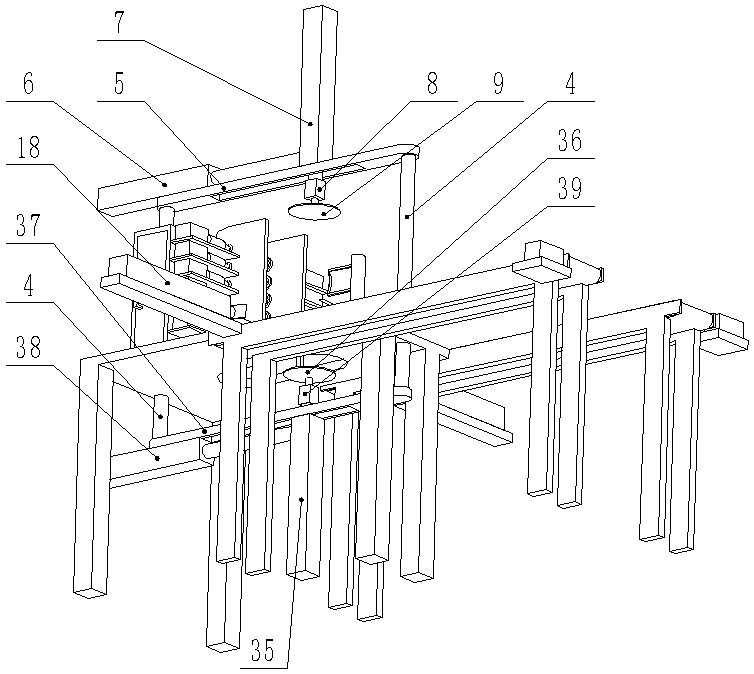

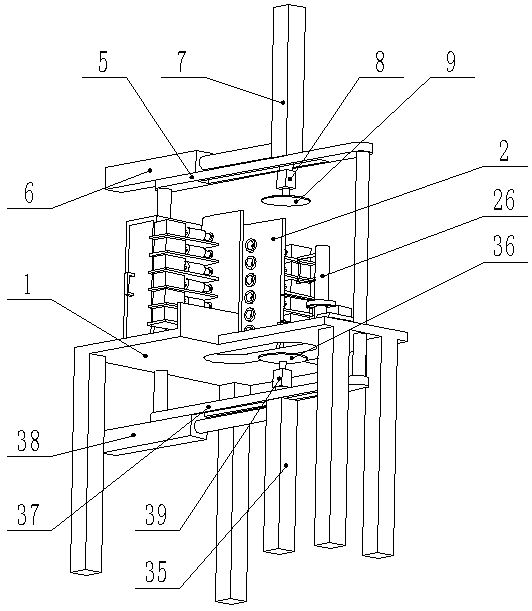

[0021] Example: such as Figure 1 to Figure 10 Shown is a kind of automatic pineapple peeling and peeling robot of the present invention, the main frame 1 top is a flat plate, as an installation platform, and the four corners of the bottom of the flat plate are respectively provided with supporting legs as a support. There is a through hole in the center of the plate, which is convenient for the adjustment of the pineapple's up, down, left, and right positions. The two ends of the through hole are respectively vertically and symmetrically equipped with two uprights 4, and the lower ends of the two uprights 4 pass through the flat plate respectively, and an upper horizontal frame 5 is installed on the top of the upright 4 simultaneously, and a lower horizontal frame 37 is installed on the bottom. On the upper horizontal frame 5 and the lower horizontal frame 37, a chute is provided, and the chute is rectangular. The upper horizontal frame 5 is used to install the upper horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com