High-voltage switch cabinet component assembly working device

A technology for high-voltage switchgear and operating equipment, applied in the direction of switchgear, electrical components, etc., can solve the problems of small working space, low installation efficiency, and high physical exertion, and achieve the effects of convenient positioning, high installation efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

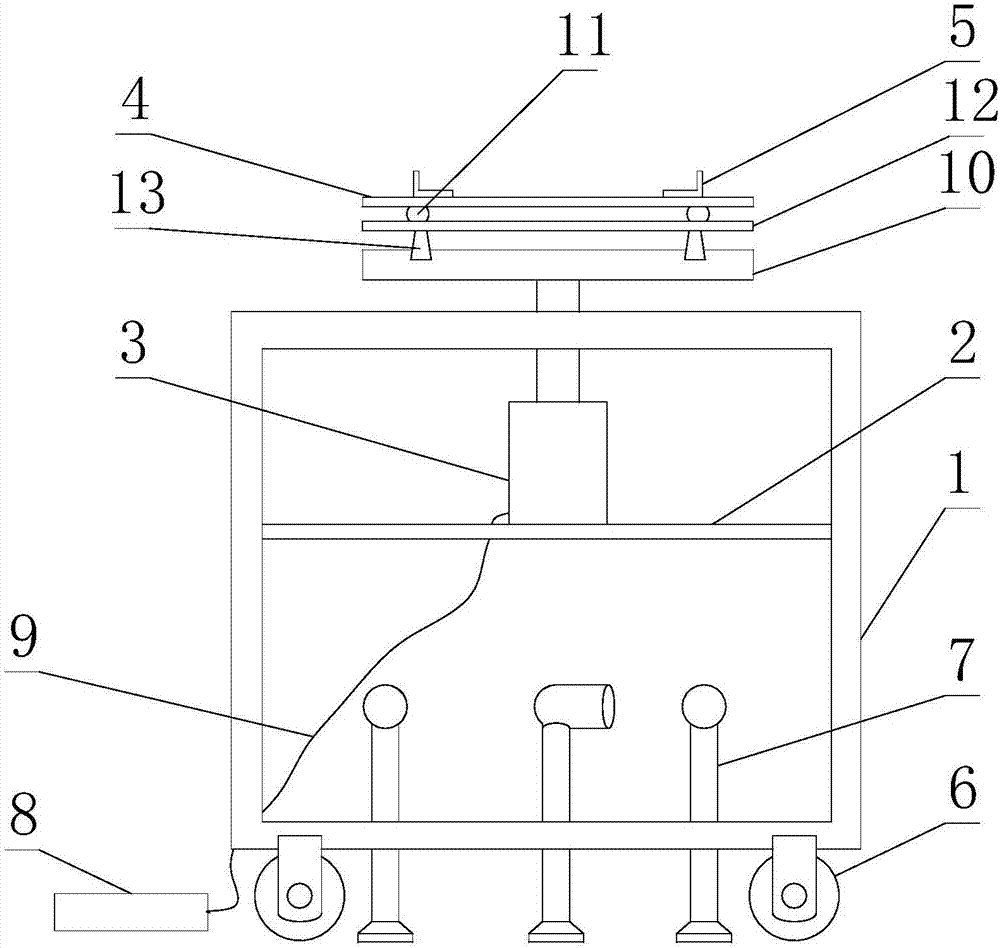

[0032] Such as figure 1As shown, the high-voltage switchgear component assembly operation equipment includes a frame body 1, a jacking device and a pallet 4, and the jacking device is fixed on the frame body 1, and also includes a support plate 10 fixed on the jacking device, The slide rail 13 is arranged between the support plate 10 and the pallet 4, the pallet 4 and the support plate 10 are connected through the slide rail 13, and the slide rail 13 is a linear track.

[0033] Specifically, this operating equipment is used to lift the current transformer to be installed and provide support for the current transformer to be installed. The pallet 4 is used to put the current transformer to be installed, that is, the pallet 4 is on the top Under the action of the lifting device, the corresponding current transformer can be lifted to the installation position. After the position of the current transformer corresponds to the installation position, the corresponding operator can ef...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: As a specific implementation form of the jacking device, the jacking device is a hydraulic cylinder 3, and the frame body 1 is also provided with a mounting seat 2, so The hydraulic cylinder 3 is installed on the mounting seat 2;

[0038] It also includes a foot-operated hydraulic pump 8 and a hose 9, the foot-operated hydraulic pump 8 is connected to the hydraulic cylinder 3 through a hose 9, and the hose 9 is used as a connection between the foot-operated hydraulic pump 8 and the hydraulic cylinder 3 Hydraulic oil lines. In this scheme, the hydraulic cylinder 3 is provided with a pressure medium through the foot-operated hydraulic pump 8. At the same time, since the foot-operated hydraulic pump 8 is connected to the hydraulic cylinder 3 through a hose 9, when the hydraulic cylinder 3 is working, the The foot-operated hydraulic pump 8 is placed on the ground or other platforms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com