SOT26 test clamp with adjustable test groove and operation method thereof

A SOT26, adjustable technology, applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problem of SOT26 pin left and right deviation, so as to improve the average yield rate of testing, increase production capacity, and improve yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

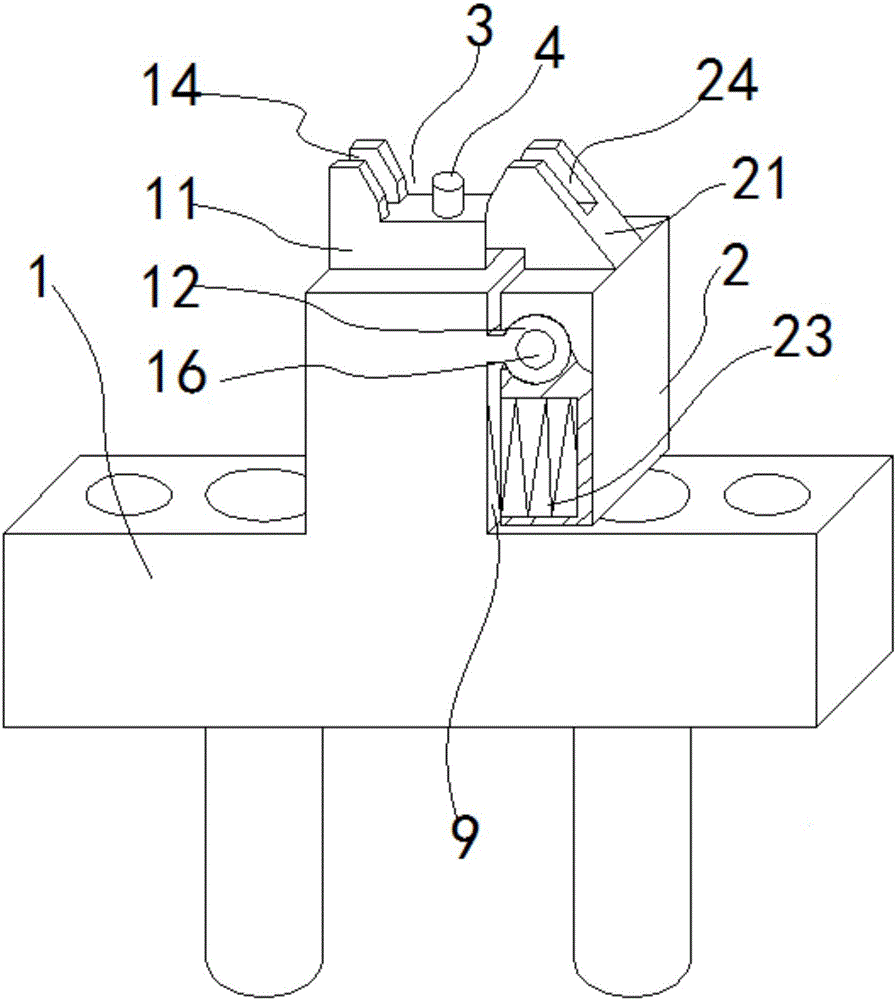

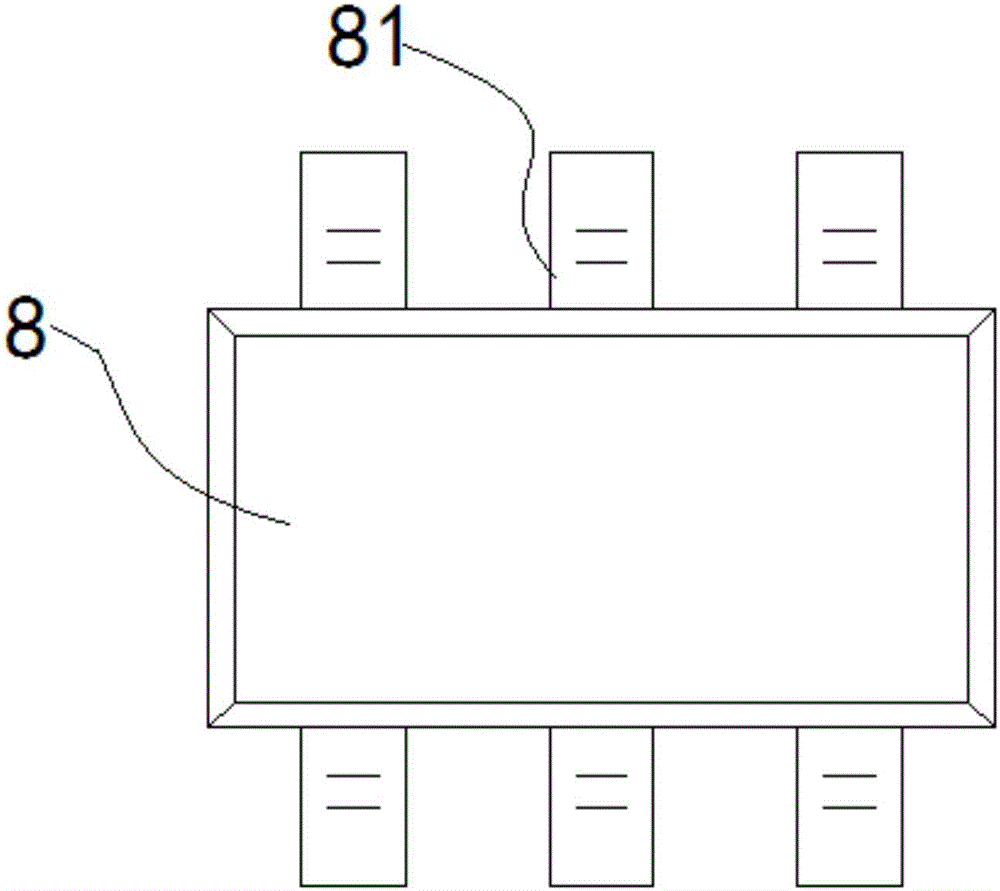

[0050] The test groove adjustable SOT26 test clip of this embodiment includes a fixed clip 1 and a movable clip 2; the fixed clip 1 and the movable clip 2 are connected by a rotating device that cooperates with each other, such as Figure 5 , 7 As shown, the rotating device is a convex semi-cylinder 12 and a concave semi-cylindrical 22 respectively arranged on the respective sides facing the fixed clip 1 and the movable clip 2 and cooperatingly arranged; On the convex semi-cylindrical 12, the concave semi-cylindrical 22 rotates around the convex semi-cylindrical 12. It is realized that the jaw of the test clip can be adaptively adjusted according to the size of the SOT26, thereby achieving the purpose of improving the average yield rate of the SOT26 test. Due to the small overall size of SOT26, there is no need to realize a large width adjustment, as long as a small gap is reserved between the fixed clip 1 and the movable clip 2, the required width adjustment of the jaw 3 can...

Embodiment 2

[0052] The test groove adjustable SOT26 test clip of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are as follows: figure 1 As shown, the fixed clamp 1 is in the shape of an inverted "T"; the movable clamp 2 is hung on one side of the middle boss of the fixed clamp 1, and an "L"-shaped rotation gap 9 is left between the fixed clamp 1 and the fixed clamp 1. , the gap is "L"-shaped, which realizes the small-angle rotation of the concave semi-cylinder 22 with the convex semi-cylindrical 12 as the axis. Such as Figure 6 As shown, the lower half of the movable clamp 2, the lower part of the concave half cylinder 22 is provided with a horizontal spring chamber 25, and a horizontal jaw width adjustment spring 23 is built in. After the SOT26 test is completed, the width of the jaw 3 can be reset, and the clamping force of the jaw 3 to the SOT26 can be realized during the test, so as to ensure the stability of the position dur...

Embodiment 3

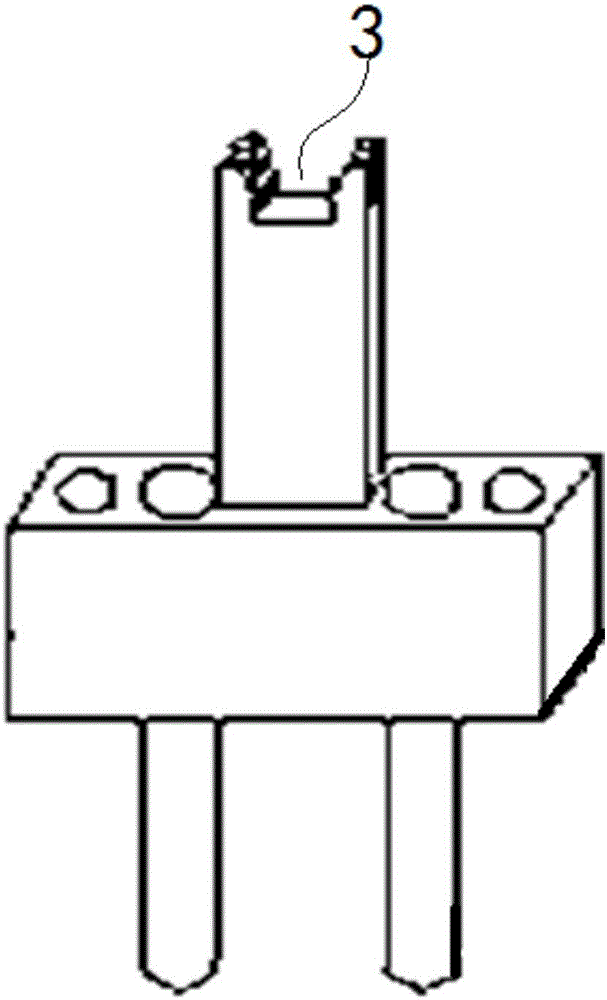

[0054] The test groove adjustable SOT26 test clip of this embodiment has the same basic structure as that of Embodiment 2, the differences and improvements are as follows: Figure 5 As shown, a vertical ejector rod chamber 15 is arranged inside the boss of the middle part of the fixing clip 1, and the ejector rod spring and the ejector rod 4 connected to each other are built in from bottom to top; as Figure 10 As shown, the ejector rod 4 is in a "convex" shape, the top end passes through the upper surface of the fixing clip 1, near the middle of the jaw 3, and the bottom is the ejector rod seat 41 connected to the ejector rod spring, so as to ensure that the SOT26 product is not tested after the test is completed. It will be stuck in the test clip, thereby reducing the probability of overlapping alarms on the auxiliary plate. The upper surface of the fixed clip 1 is provided with a fixed clip finger 11, and the upper surface of the movable clip 2 is provided with a movable cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com