Probe of cantilevel probe card

A probe card, horizontal technology, used in the field of probe cards, can solve the problems of easy sticking of probes, reduce the utilization rate of test machines, and shorten the life of probes, so as to reduce the frequency of needle cleaning and improve the test yield. , the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

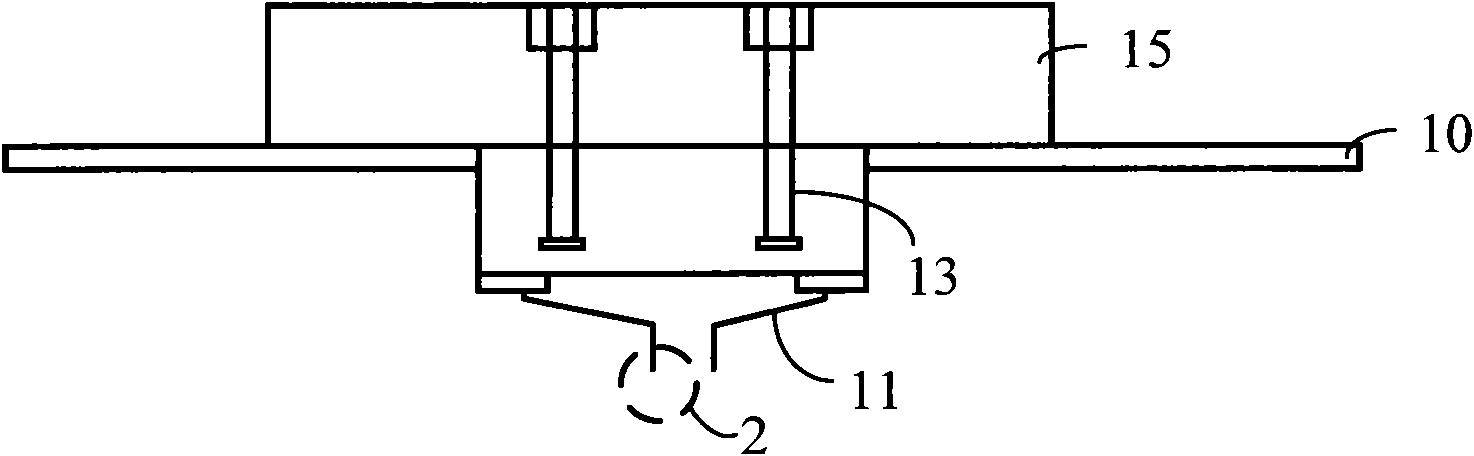

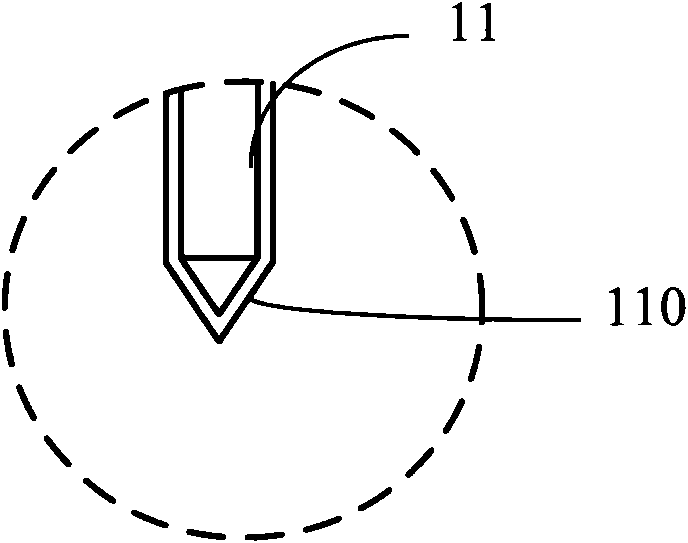

[0015] Specific embodiments are listed below to describe the content of the present invention in detail, and illustrations are used as auxiliary descriptions.

[0016] The invention discloses a horizontal probe card, which includes a plurality of probes and conductive polymer nano-coatings, wherein the probes are made of metal materials and installed on the horizontal probe card, and the conductive polymer nano-coatings are coated on these probes.

[0017] The above-mentioned conductive polymer nano-coating is a conductive polymer material with non-stick properties, such as polypyrrole, polyparaphenylene, polythiophene, polyaniline or the above-mentioned At least one selected composition or its derivatives in the group, and the thickness of the conductive polymer nano-coating film is, for example, 1-20 nanometers, and can be, for example, 1-5 nanometers.

[0018] The above-mentioned probe is made of a metal material, such as nickel, gold, copper, tungsten, rhenium, titanium, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com