Adapter plate needle die mechanism

A technology of adapter board and needle mold, which is applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve the problems of long test time, low efficiency, and easy misoperation, so as to improve test efficiency and test yield, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

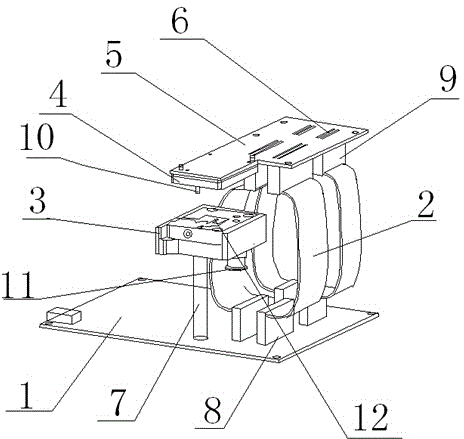

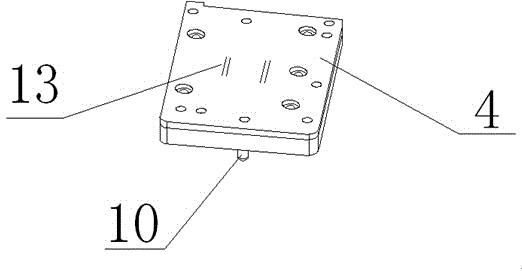

[0016] Such as Figure 1~2 As shown, an adapter plate needle mold mechanism includes a test board 1, a cable 2, a lower needle mold 3, an upper needle mold 4, a cover plate 5 and an adapter plate 6, and a cavity 7 and an adapter plate 6 are provided on the test board 1. The lower fixed plate 8 and the cavity 7 are fixed with the lower needle mold 3, one end of the cable 2 is connected to the lower fixed plate 8, and the other end is connected to the upper fixed plate 9, and the upper fixed plate 9 is installed on the lower part of the cover plate 5, and the lower part of the cover plate 5 The upper needle mold 4 is fixedly installed, the upper needle mold 4 is arranged directly above the lower needle mold 3, the lower part of the upper needle mold 4 is provided with pins 10, the adapter plate 6 is arranged on the upper surface of the cover plate 5; the lower needle mold 3 is provided with The vacuum suction head 11 is provided with a positioning groove 12 on the lower needle m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com