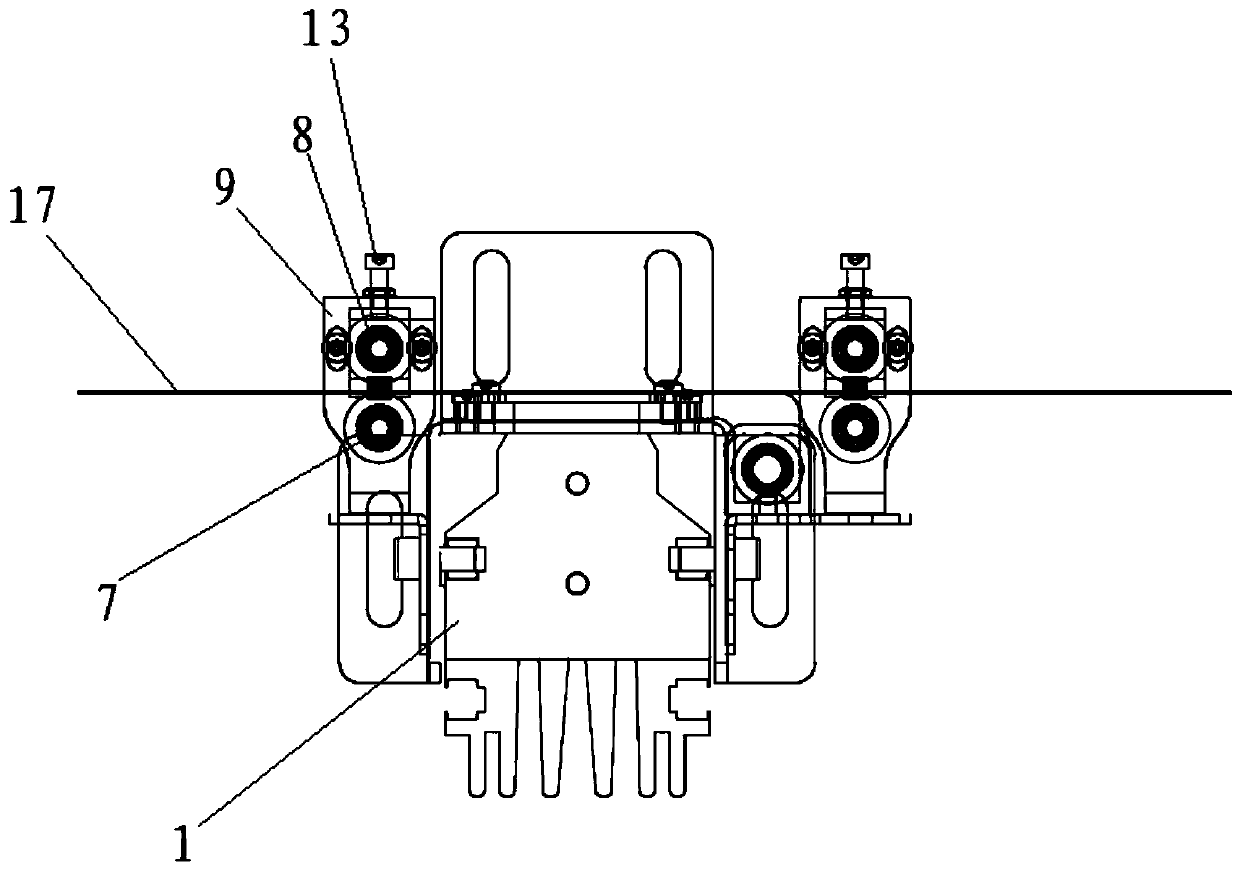

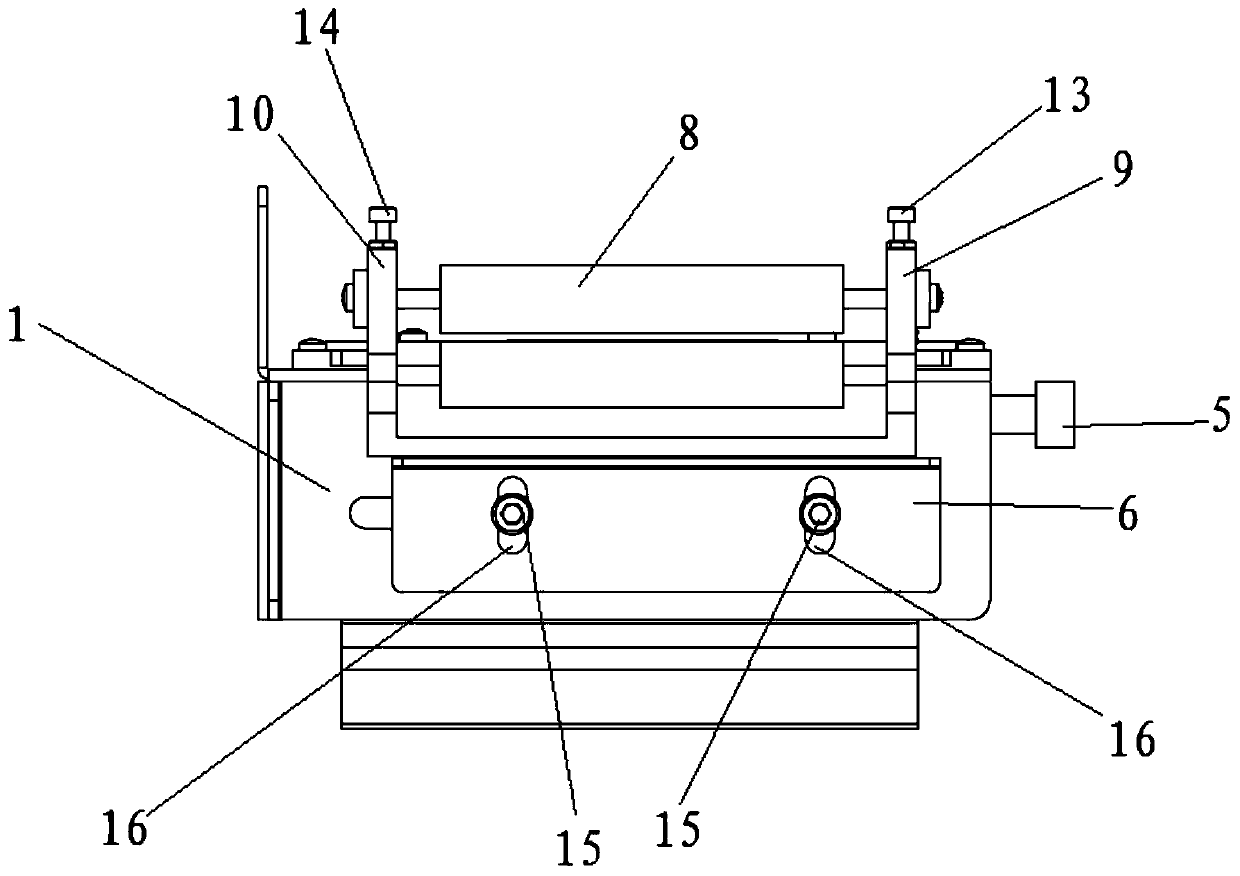

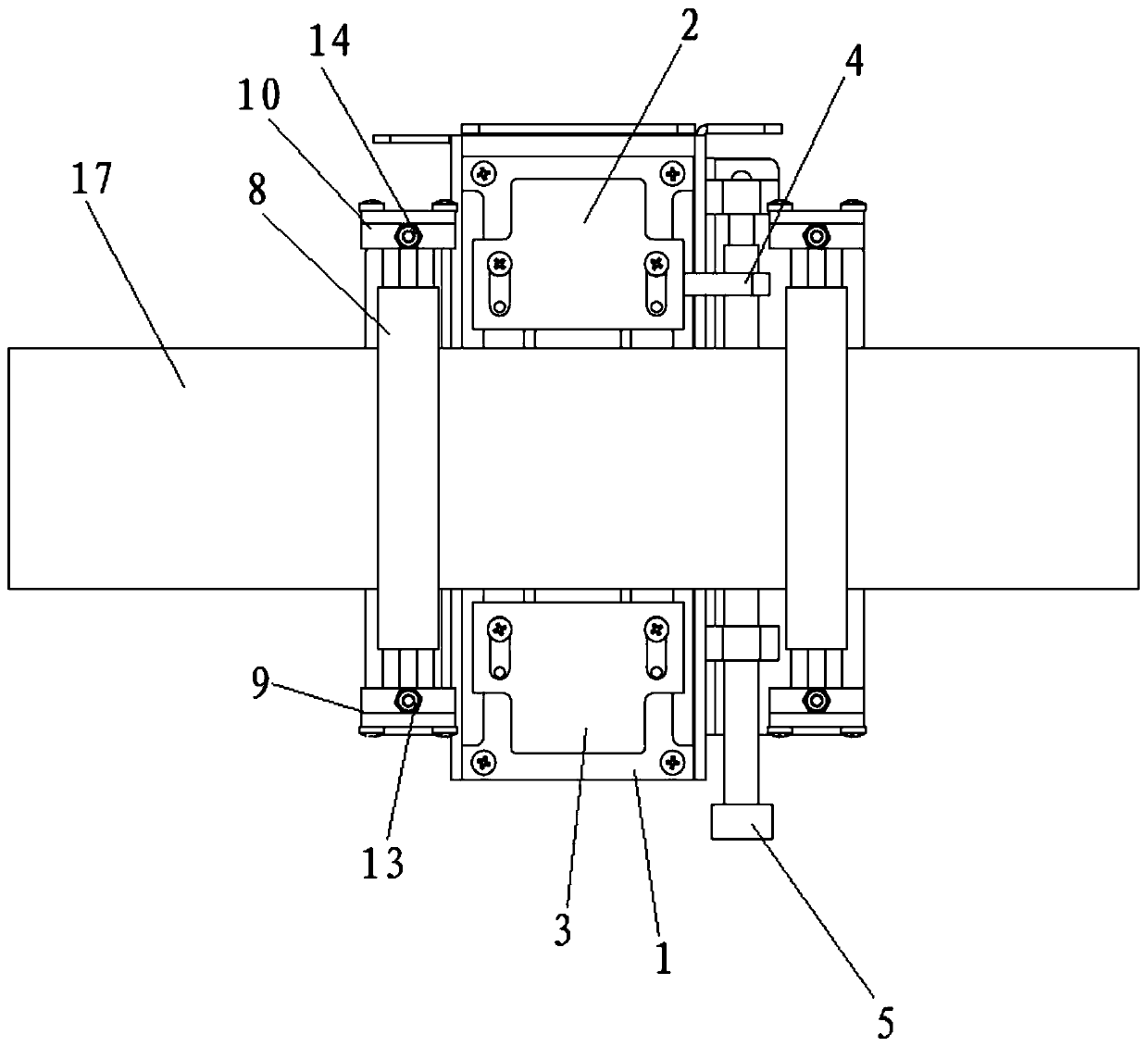

Double-roller-shaft light blocking device

A technology of roller shafts and light baffles, which is applied to measuring devices, transportation and packaging, and material analysis through optical means, and can solve the problems of inaccurate detection, shaking of tipping paper products, and uneven winding of tipping paper trays And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiment of the present invention realizes the technical effect of adaptively adjusting the production tension by providing a double-roller shaft light blocking device.

[0018] The technical solutions in the embodiments of the present invention are to achieve the above-mentioned technical effects, and the general idea is as follows:

[0019] By pressing the two ends of the tensioning spring against the bearing and the adjusting bolt of the pressure roller respectively, the adaptive adjustment of the pressure of the pressure roller can be realized, and then the adaptive adjustment of the production tension can be realized, which ensures accurate detection and avoids tipping paper The paper tray has uneven winding. Specifically, when the pressure needs to be increased, the adjusting bolt is rotated in the positive direction, so that the adjusting bolt is pressed down to tighten the spring. The top tension spring is compressed, thereby exerting downward pressure on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com