Insulating board for circuit board production, circuit board and circuit board production method

A production method and circuit board technology, applied in the directions of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of many processing procedures, short circuits, and complicated etching processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

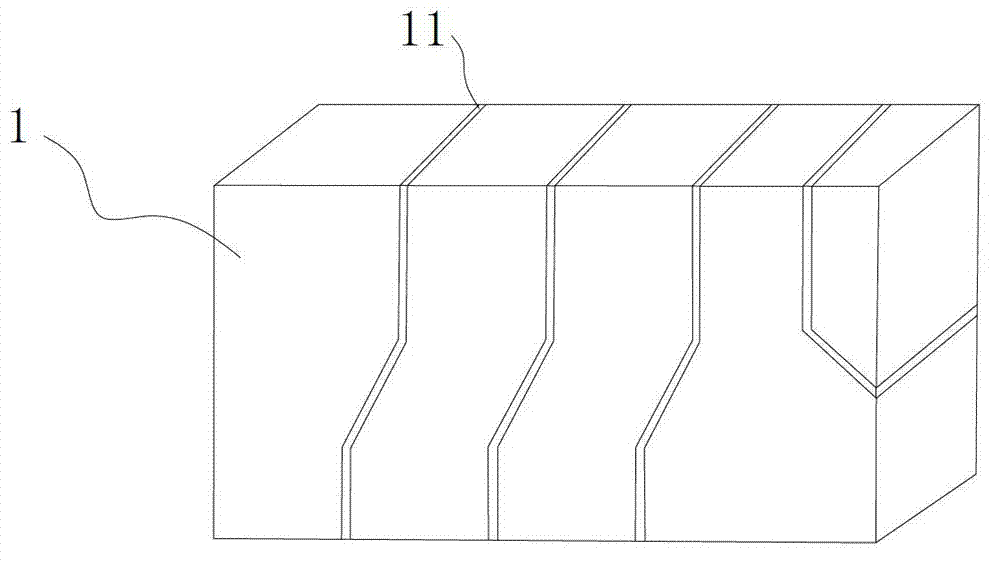

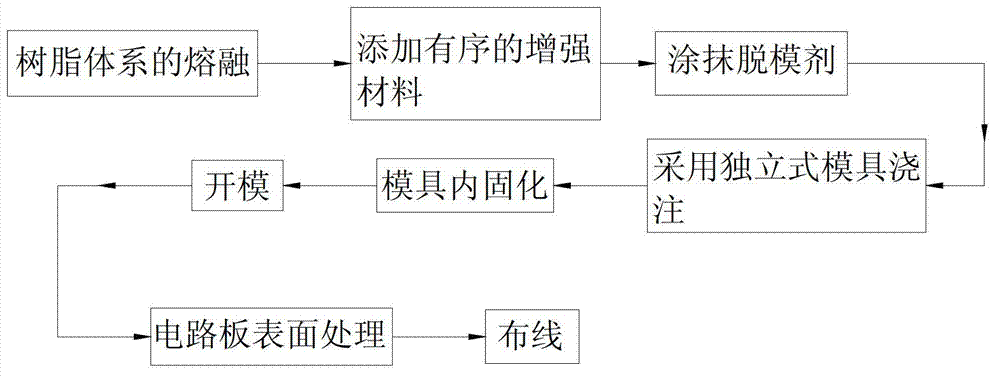

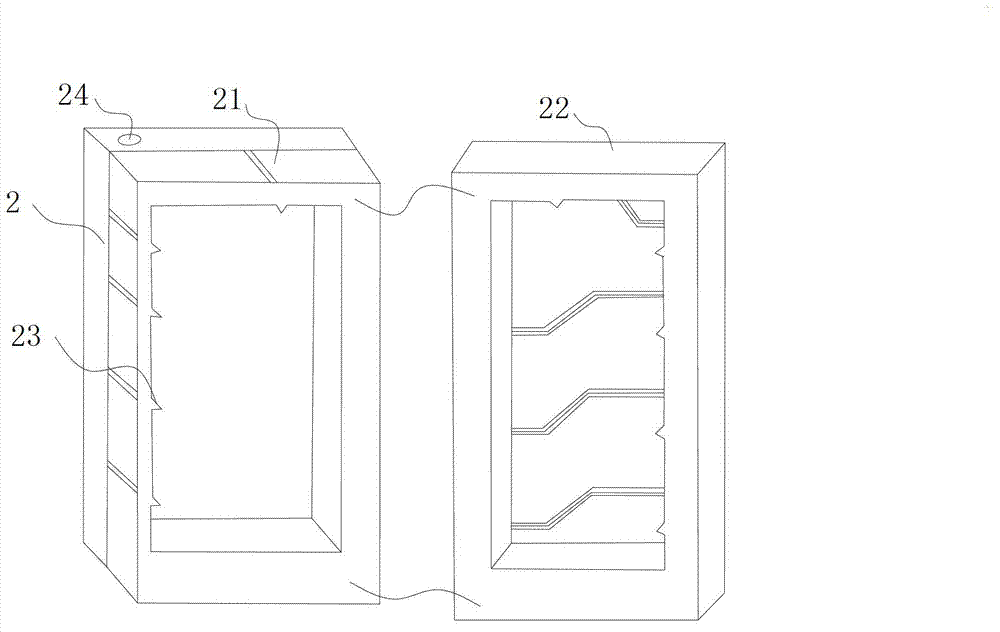

[0132] Such as figure 2 with 3 As shown, in this embodiment, the resin system adopts phenolic resin in the thermosetting resin, and the mold adopts a casting mold, and the casting mold is selected as image 3 Shown free-standing mold 2, its concrete production method comprises the following steps:

[0133] The first step: the melting of the resin system, the resin system is physically mixed, mixed evenly and then heated up to semi-cure, and the resin system is kept in a molten state after semi-cured to a certain extent;

[0134]Step 2: add orderly reinforcing materials, and orderly hang the reinforcing materials in the independent mold 2;

[0135] The third step: apply a release agent, apply a release agent to the side of the independent mold 2 in contact with the resin system,

[0136] Wherein, the structure of independent mold 2 is as image 3 As shown, it includes an upper mold 21 and a lower mold 22. The upper mold 21 and the lower mold 22 have a cavity for containing...

Embodiment 2

[0145] Such as Figure 4 with 5 As shown, in this embodiment, the resin system adopts the phenolic resin in the thermosetting resin, and the mold adopts a compression mold, where the compression mold is selected as Figure 5 Shown free-standing mold 3, its concrete production method comprises the following steps:

[0146] The first step: the melting of the resin system, the resin system is physically mixed, mixed evenly and then heated up to semi-cure, and the resin system is kept in a molten state after semi-cured to a certain extent;

[0147] Step 2: Add disordered reinforcing materials, add reinforcing materials to the molten resin system, and stir evenly with a stirring tool;

[0148] The third step: the mixture of the resin system and the reinforcing material forms a sheet or a block;

[0149] Step 4: apply a release agent, apply a release agent to the side of the independent mold 3 in contact with the resin system,

[0150] Wherein, the structure of independent mold ...

Embodiment 3

[0160] Such as Image 6 with 12 As shown, in this embodiment, the resin system adopts polyvinyl chloride in thermoplastic resin, and the mold adopts a pouring mold, and the pouring mold is selected such as Figure 7-12 As shown in the assembled mold 4, its specific production method comprises the following steps:

[0161] The first step: the melting of the resin system, the resin system is physically mixed, the temperature is raised after mixing evenly, and the molten state of the resin system is maintained;

[0162] Step 2: Add disordered reinforcing materials, add reinforcing materials to the molten resin system, and stir evenly with a stirring tool;

[0163] The third step: apply a release agent, apply a release agent to the side of the assembled mold 4 in contact with the resin system,

[0164] Wherein, the structure of assembled mold 4 is as follows Figure 7-12 Shown, comprise the first mold 41, the second mold 42, the third mold 43, the fourth mold 44 and the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com