Patents

Literature

33results about How to "Reduce eccentricity error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

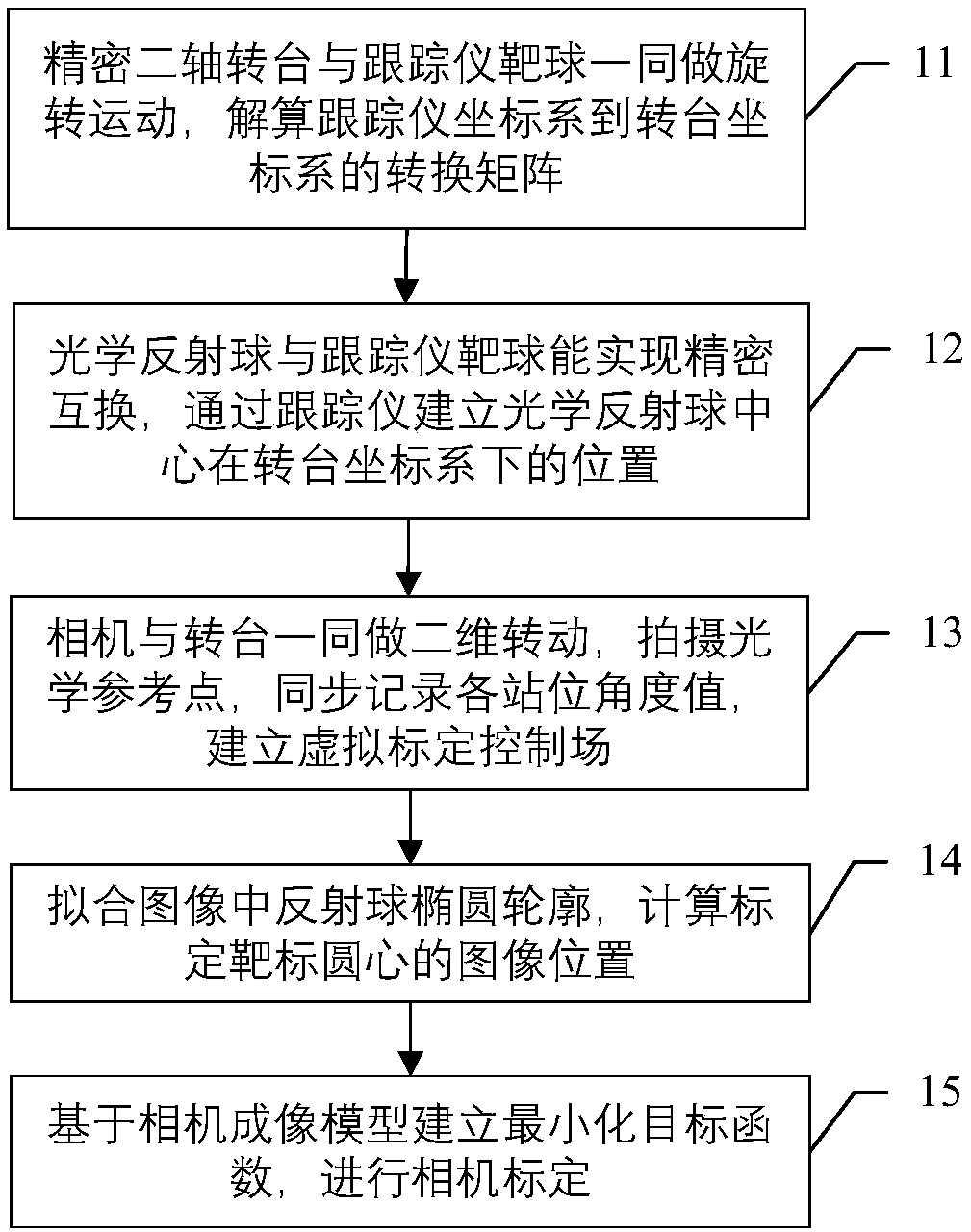

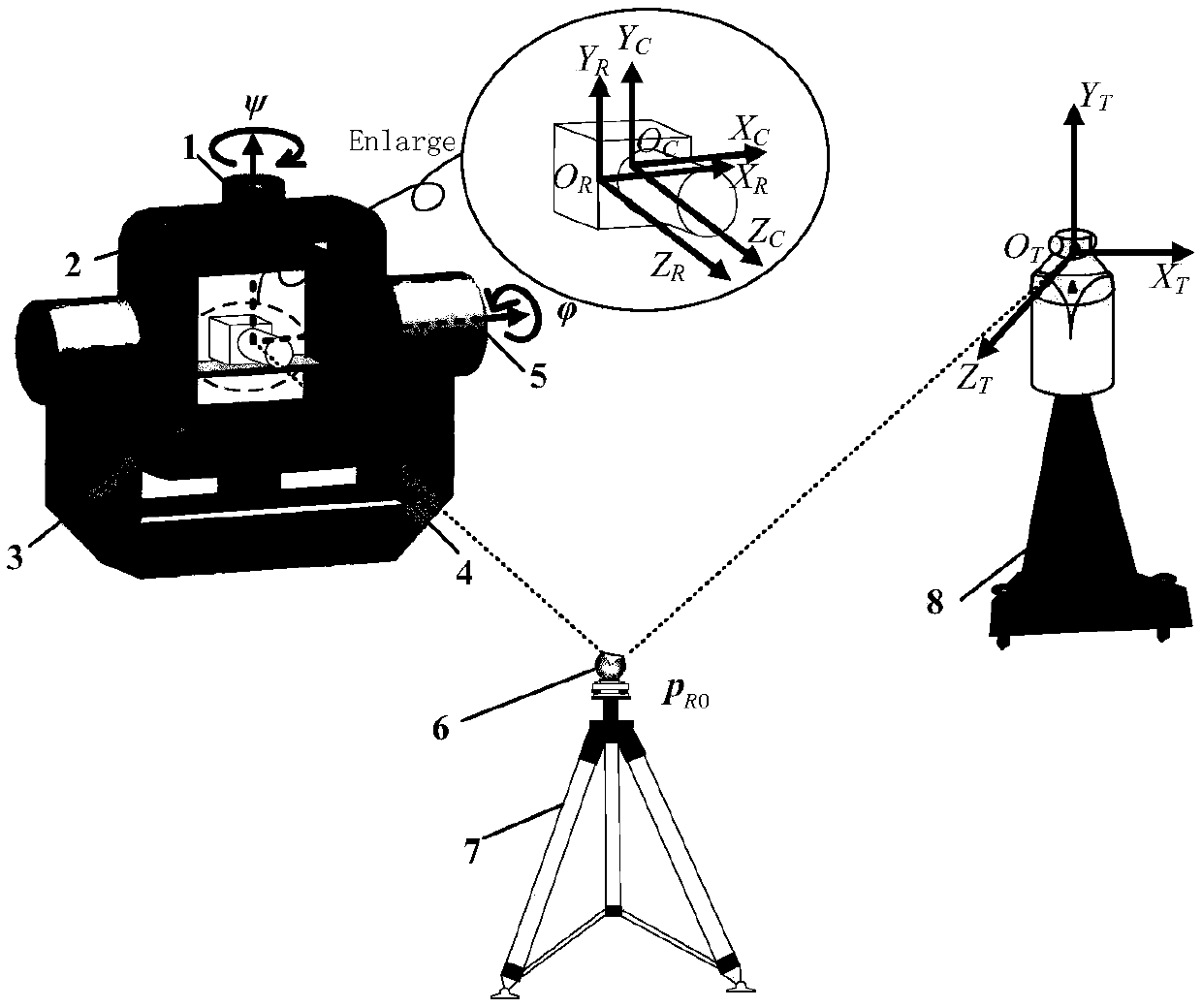

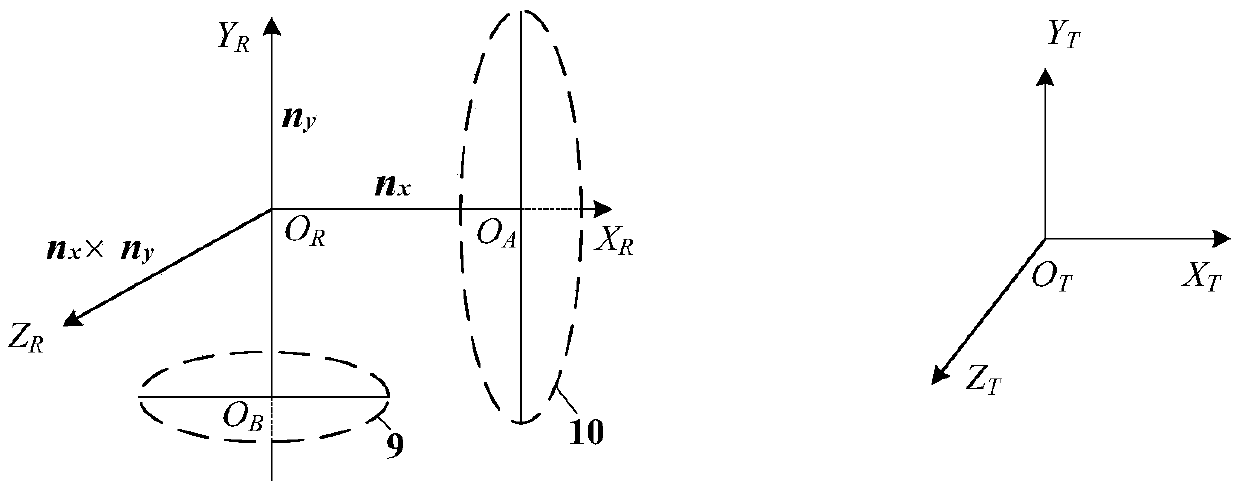

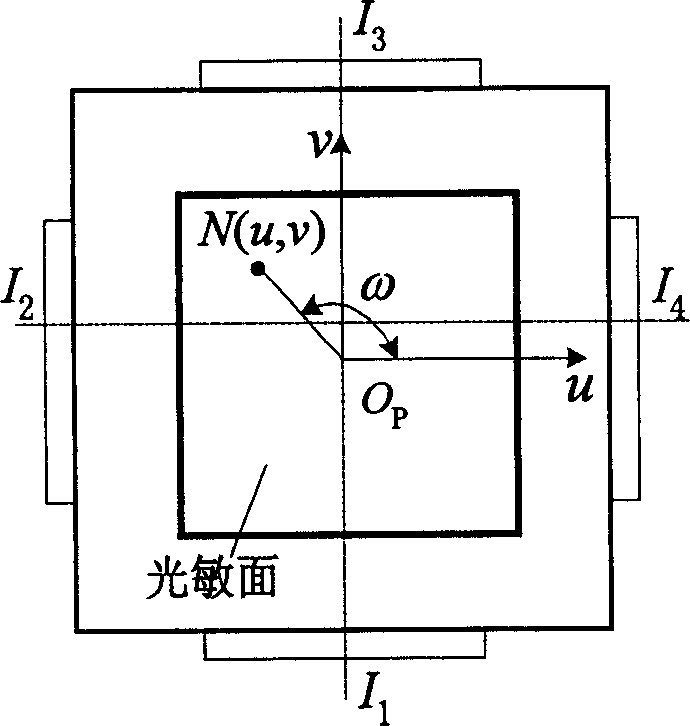

Large field of view camera calibration method based on precision two-axis turntable and laser tracker

ActiveCN108921901AReduce eccentricity errorExact image locationImage analysisOptical reflectionStanding Positions

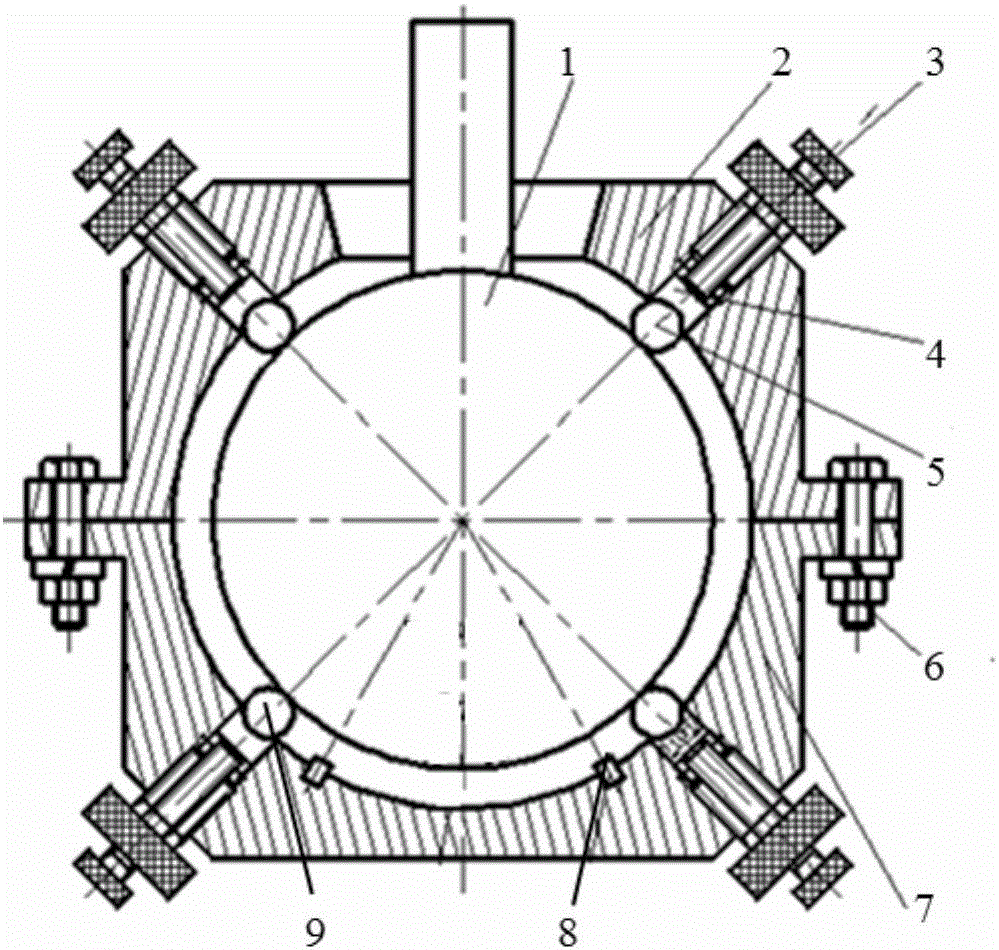

The invention relates to a large field of view camera calibration method based on a precision two-axis turntable and a laser tracker. The large field of view camera calibration method is characterizedin that the precision two-axis turntable and a laser tracker target ball perform a rotary motion together, and a conversion matrix from a tracker coordinate system to a turntable coordinate system issolved; an optical reflection ball is used as an optical reference point of the camera calibration and is fixed in front of the turntable; a position of an optical reflection ball center is established in the turntable coordinate system through precise exchange between the optical reflection ball and the tracker target ball and tracker measurement; the camera and the turntable perform two-dimensional rotation together to shoot the optical reference point and simultaneously record an angle value of each stand position, and a virtual calibration control field is established; an elliptical contour of the reflection ball in the image is fitted to calculate an image position of a calibration target center; and a minimum objective function is established on the basis of a camera imaging model to perform camera calibration. The invention is suitable for completing high-precision camera internal reference calibration in a large field of view environment, and is particularly suitable for occasions where change of the camera measurement depth is large and the traditional calibration target is difficult to design and manufacture.

Owner:BEIHANG UNIV

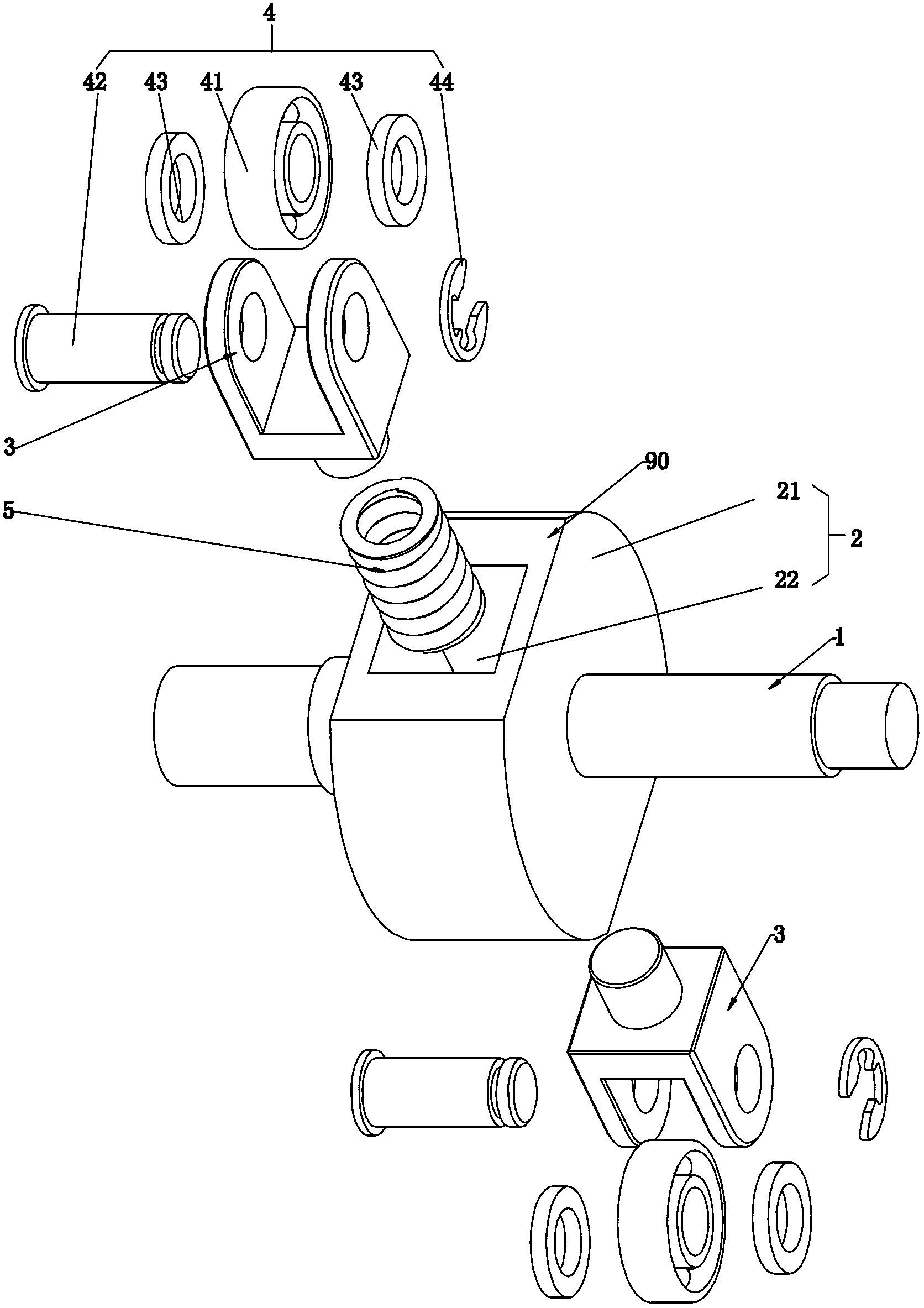

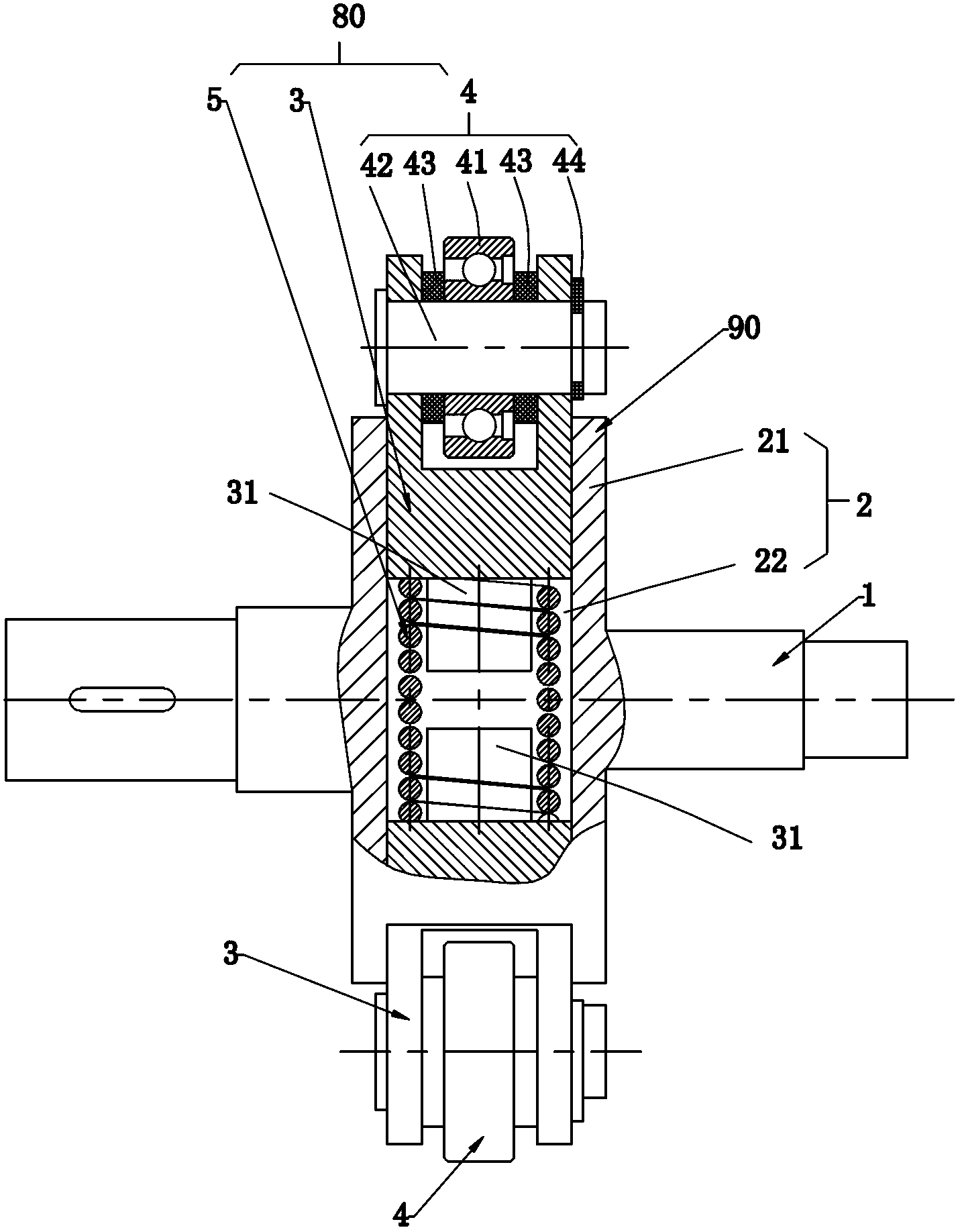

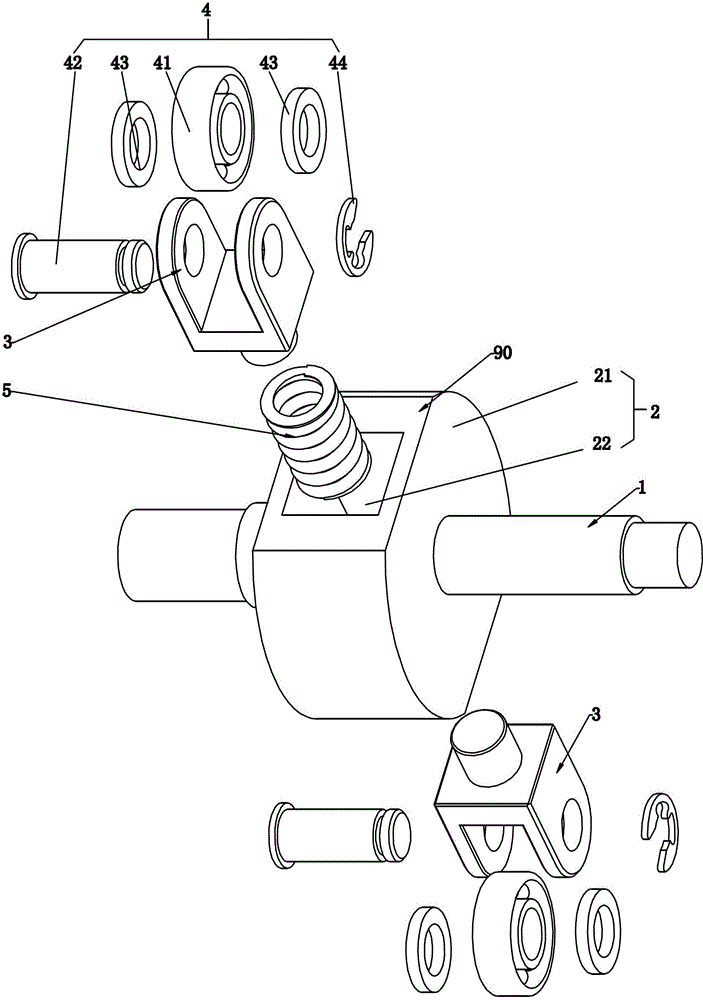

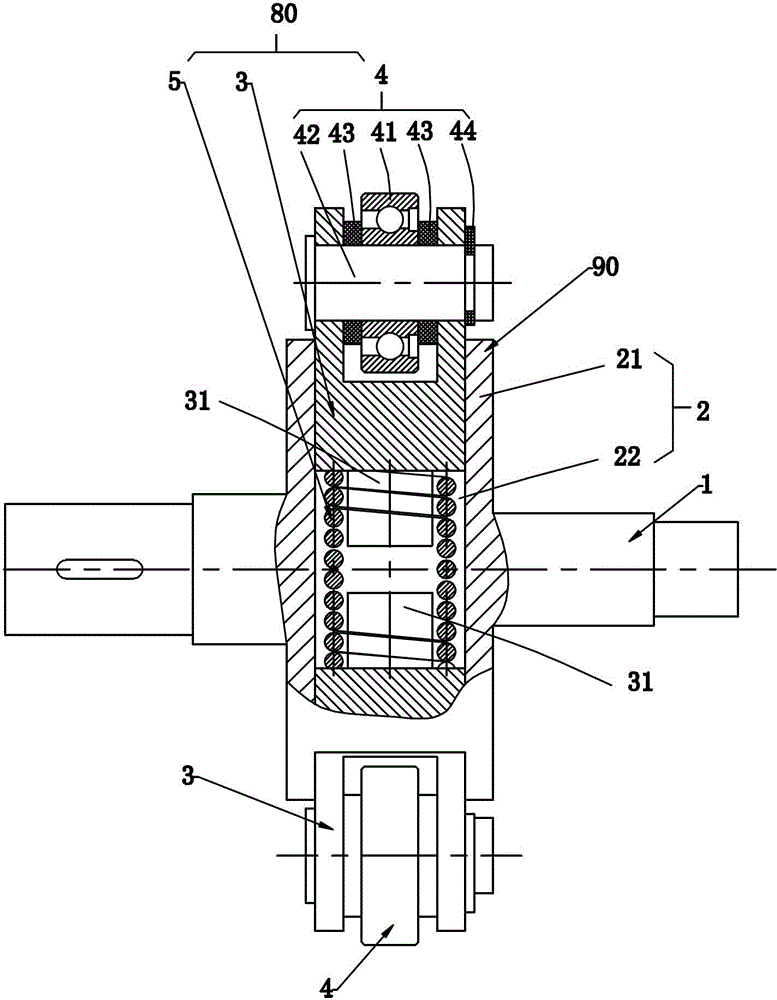

Center-adjustable ball spherical hinge joint and center adjusting method of center-adjustable ball spherical hinge joint

ActiveCN106015311ASimple structureMature processing technologyBearing repair/replacementShaft repair/replacementSteel ballEngineering

The invention discloses a center-adjustable ball spherical hinge joint and a center adjusting method of the center-adjustable ball spherical hinge joint. Due to machining and assembling errors, a spherical hinge joint is in an eccentric state usually. Supporting ball guide holes are formed in a supporting ball socket of the ball spherical hinge joint. A displacement sensor is installed in a sensor installation hole of the supporting ball socket. Restraining ball guide holes are formed in a restraining ball socket. Double-thread center adjusting mechanisms are installed in the supporting ball guide holes and the restraining ball guide holes to adjust ball steel balls. The center adjusting method includes the steps that the center-adjustable ball spherical hinge joint is installed; when the double-thread center adjusting mechanisms are installed, main threaded columns and auxiliary threaded columns rotate in the opposite directions, and the restraining ball steel balls and the supporting ball steel balls are quickly located; and when centering adjustment is conducted by the double-thread center adjusting mechanisms, the main threaded columns and the auxiliary threaded columns rotate in the same direction. The double-thread structures rotate in the opposite directions when the eccentric error is relatively large, and the eccentric error is quickly reduced; and the double-thread structures rotate in the same direction when the eccentric error is relatively small, and the centering condition of the balls and the ball sockets are finely adjusted.

Owner:HANGZHOU DIANZI UNIV

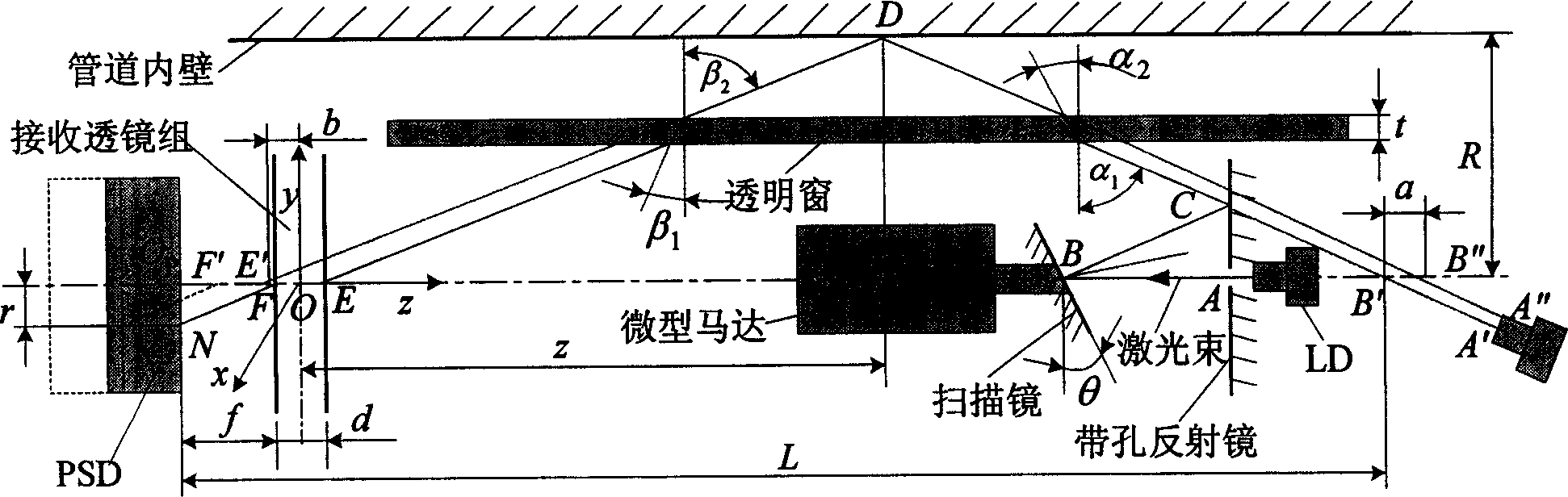

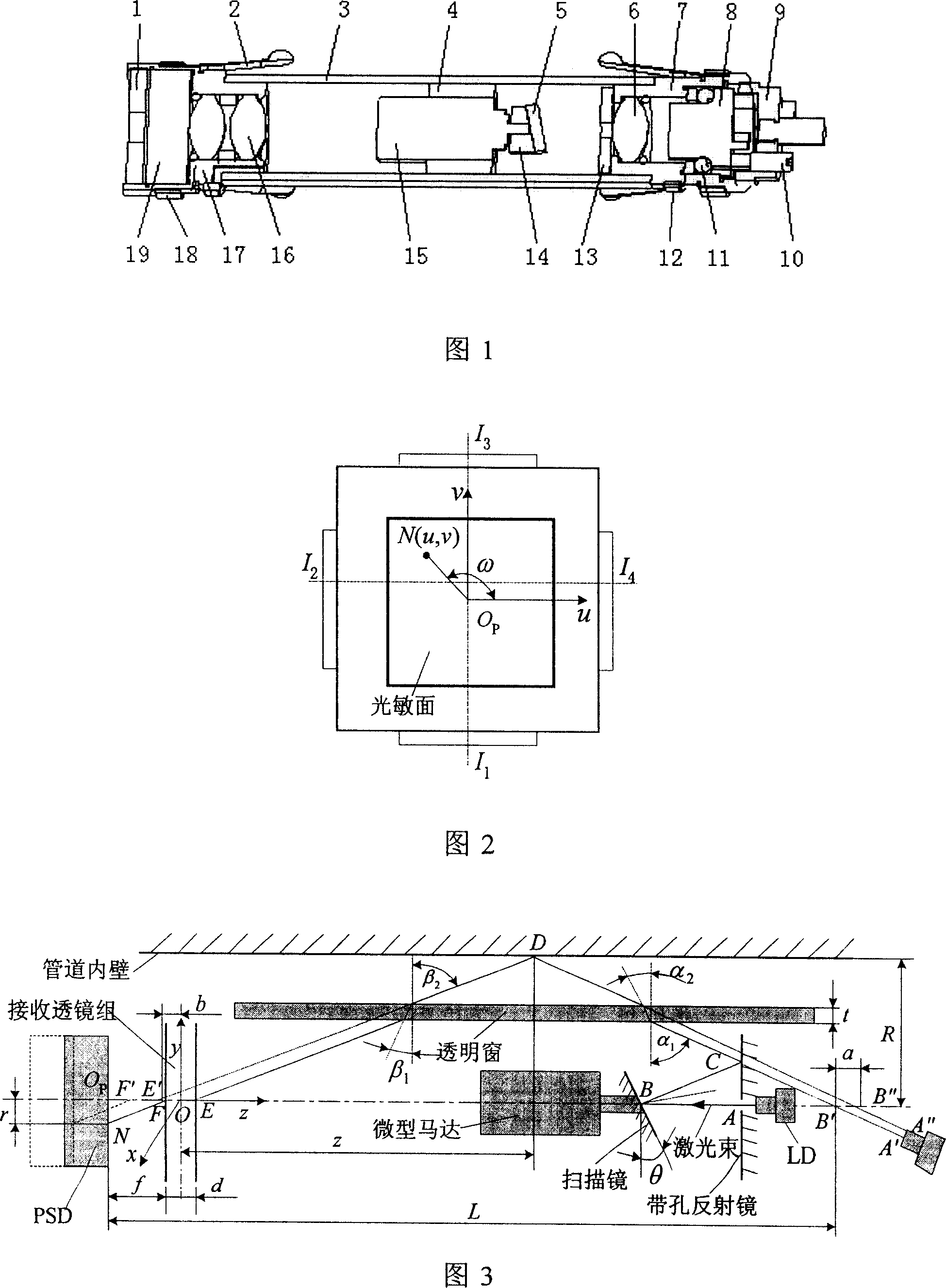

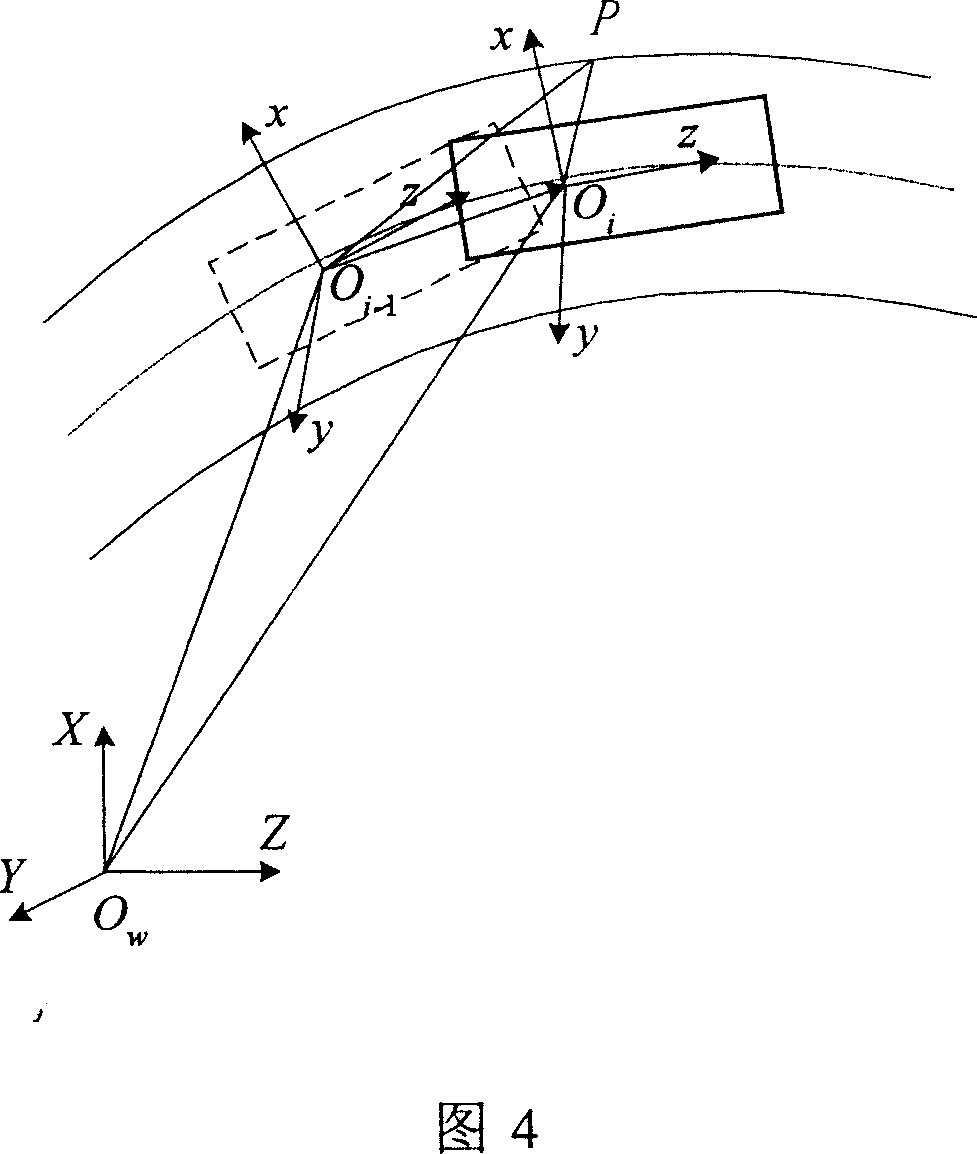

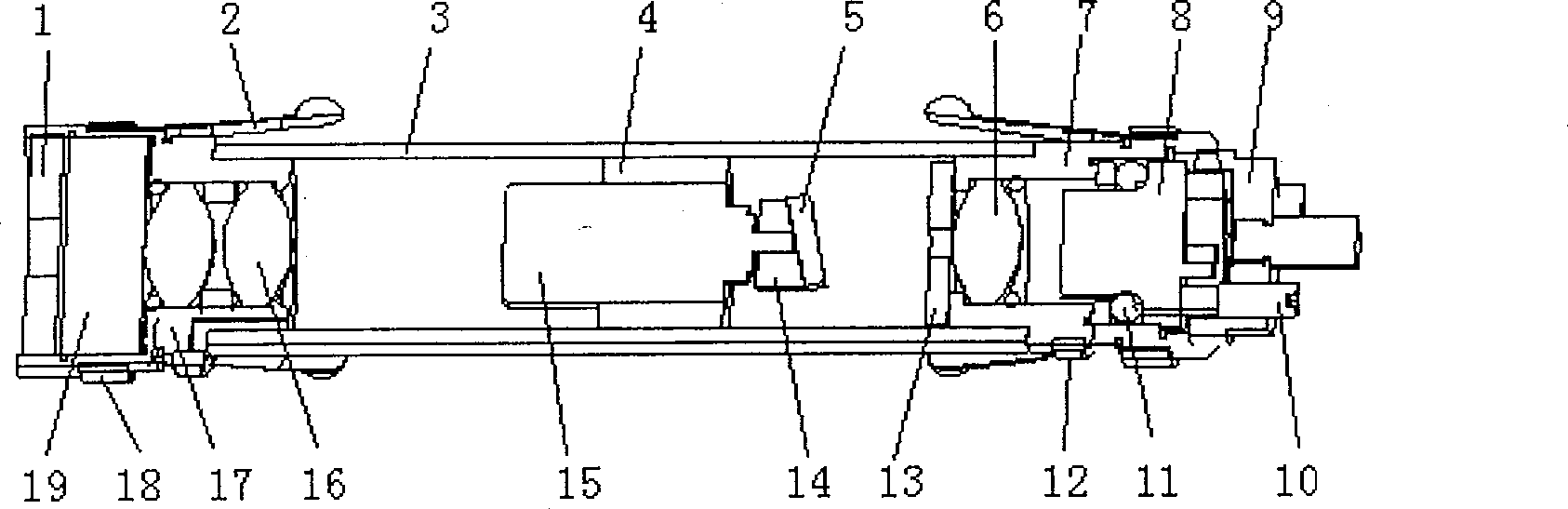

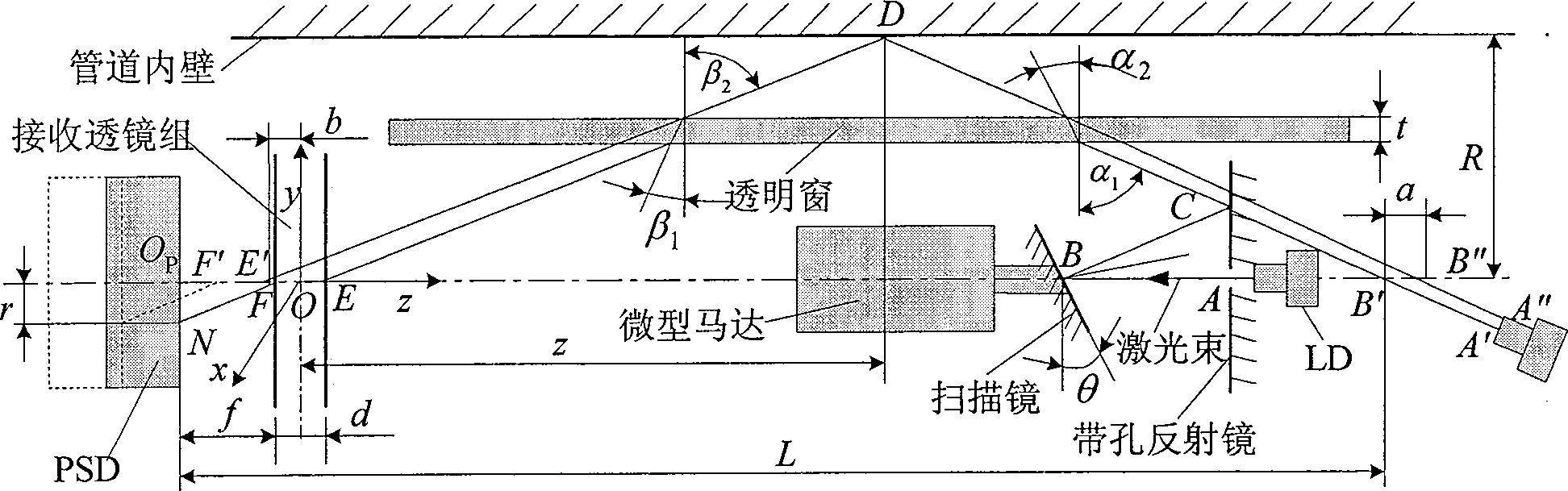

Measuring instrument for space curve type long distance fine pipe internal surface shape and its detecting method

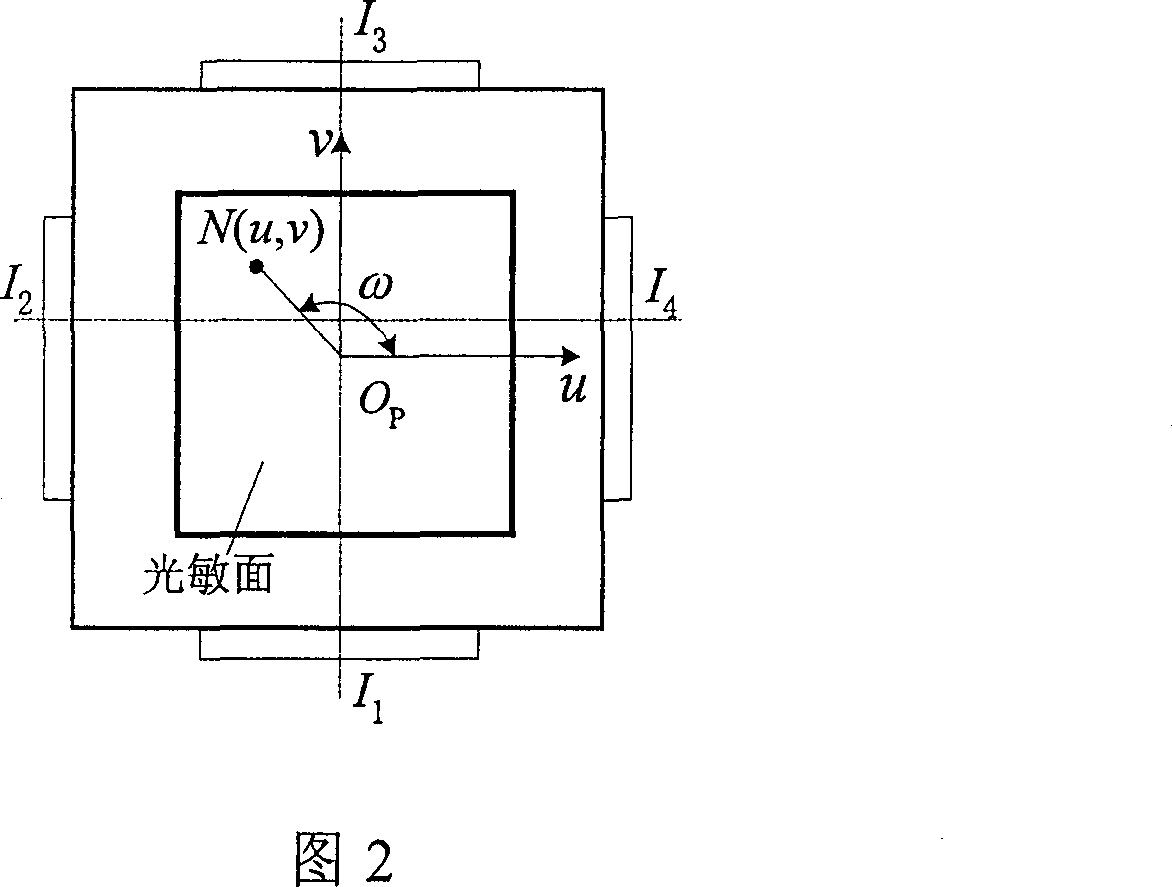

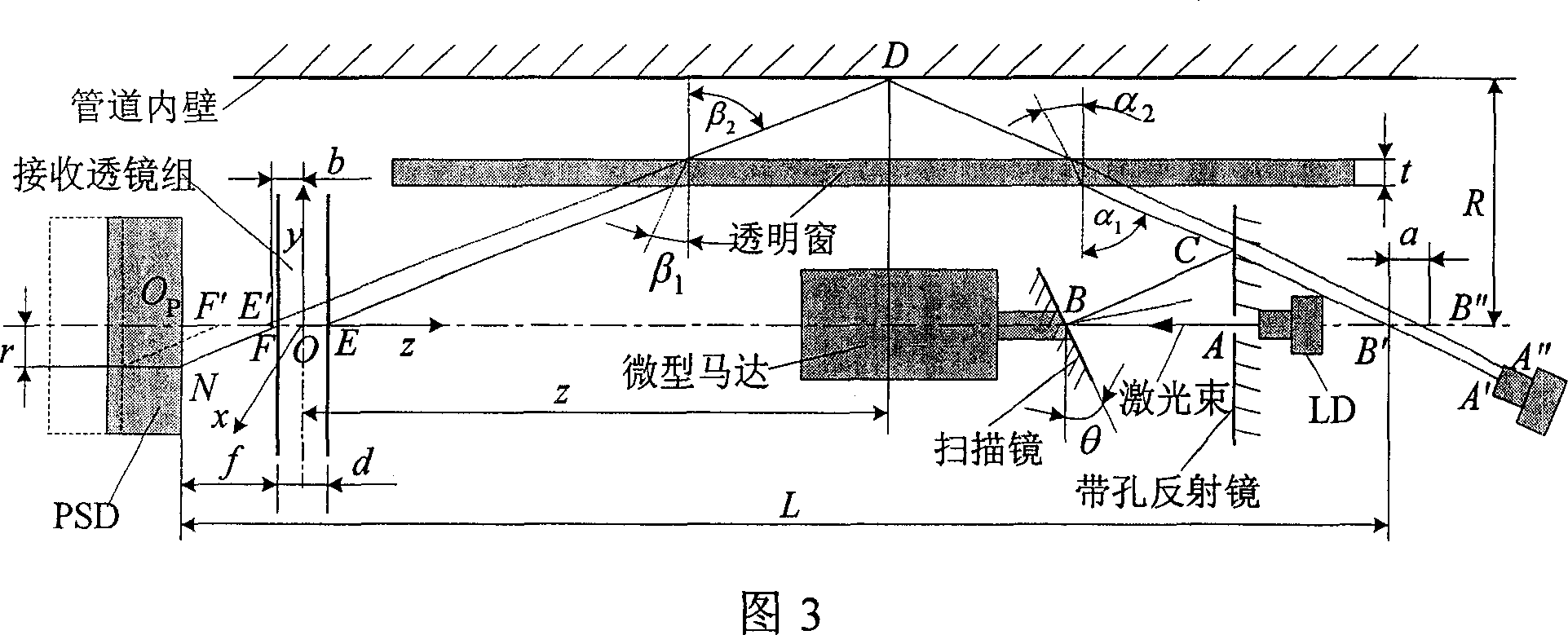

InactiveCN1719191AShorten the lengthReduce weightFluid-tightness measurementUsing optical meansMeasuring instrumentThree dimensional measurement

The present invention discloses a space curve type long-distance microfine pipe internal surface form measurement instrument and its detection method. Said pipe internal surface form measurement instrument is formed from the components of 2-D position sensor, semiconductor laser, transparent window, micromotor, scanning lens, reflector, convergent lens and receiving lens group, etc. Said measurement instrument is applicable to defect detection and 3-D measurement of curve type microfine pipe internal wall whose inner diameter is 9-11 mm and curvature radius is greater than 100 mm, and its measuring accuracy can be up to plus or minus 0.1 mm.

Owner:ZHEJIANG UNIV

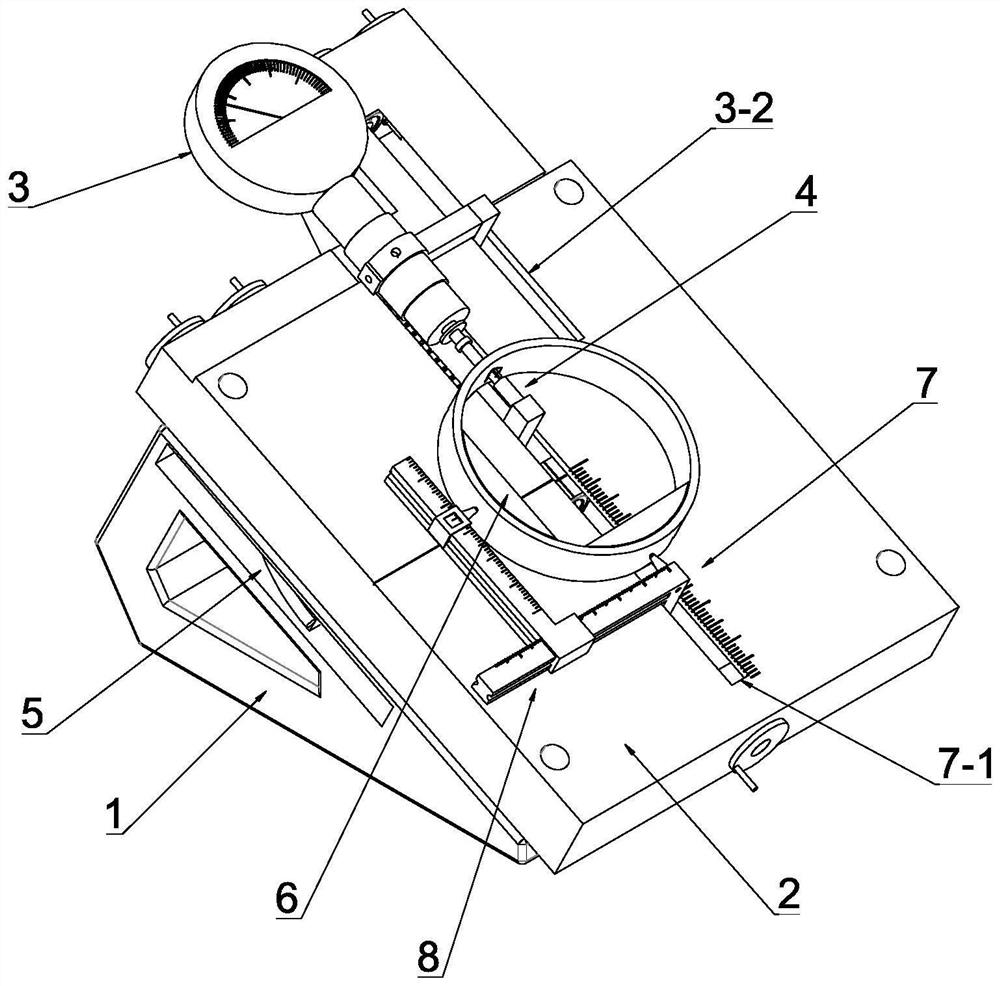

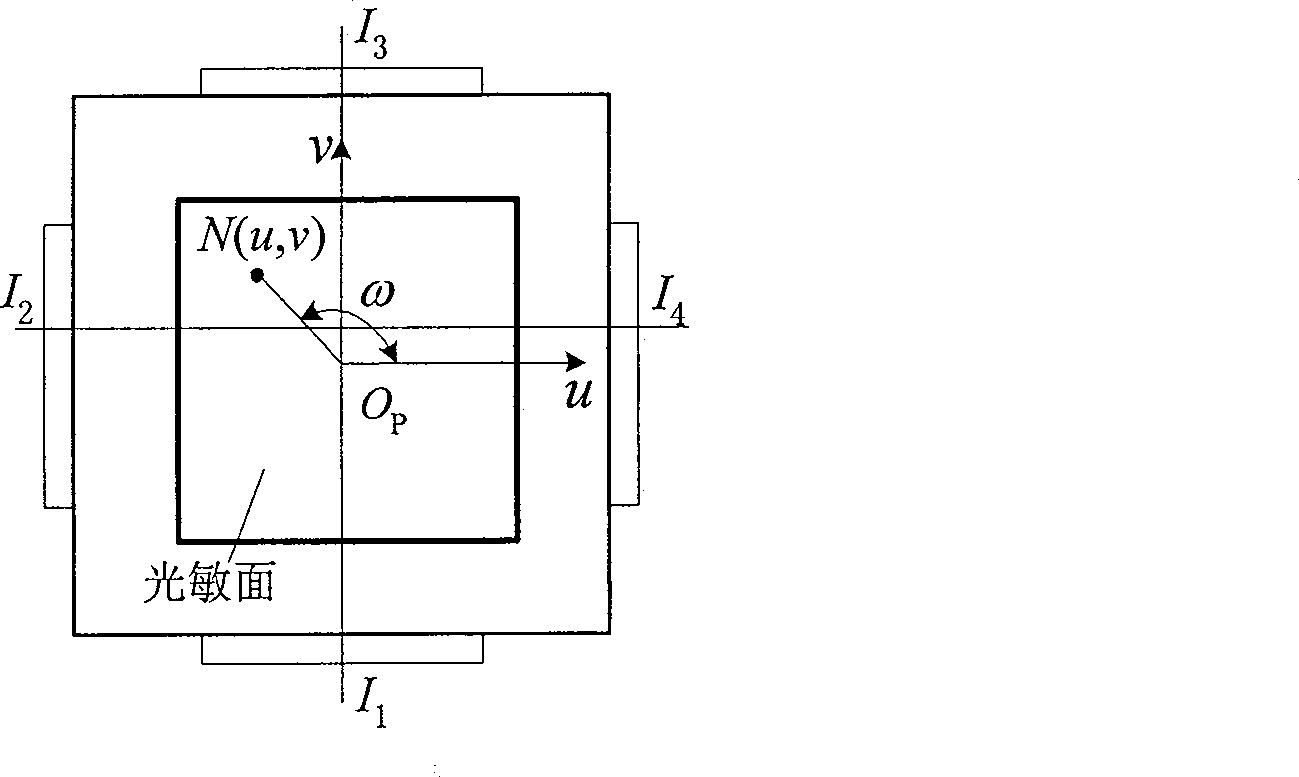

Appearance measuring and detecting method for inner surface of space curve type long-distance microtubule

InactiveCN101012912AShorten the lengthReduce weightPipeline systemsDimension measurementThree dimensional measurement

The invention discloses a method for checking the surface condition of spatial curvature long-distance micro tube. The inventive machine is mainly formed by a two-dimension position sensor, a semi-conductor laser, a transparent window, a micro motor, a scanning mirror, a reflector, a convergent lens, and a receiving lens. The light of laser via two reflections will form a micro spot on the inner wall of tube, while said spot is received by the two-dimension position sensor. Via the current signal of two-dimension position sensor and the structural parameters of inventive machine, the invention calculates out the position of the spot in local three-dimension coordinate. The micro motor rotates the scanning mirror one round to obtain the positions of all sampling points of one section of inner wall of tube. The invention can be used in the defect check and three-dimension measurement of the inner wall of the curvature micro tube whose inner diameter is 9-11mm and radius is larger than 100mm, while the measurement accuracy can reach +- 0.1mm.

Owner:ZHEJIANG UNIV

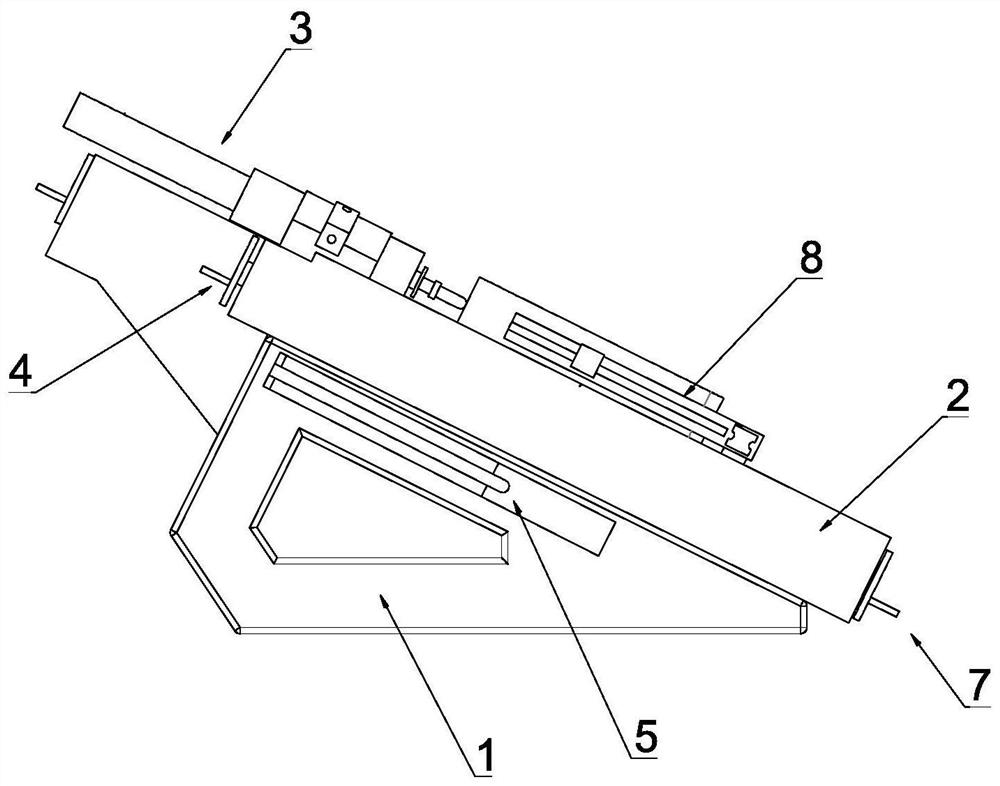

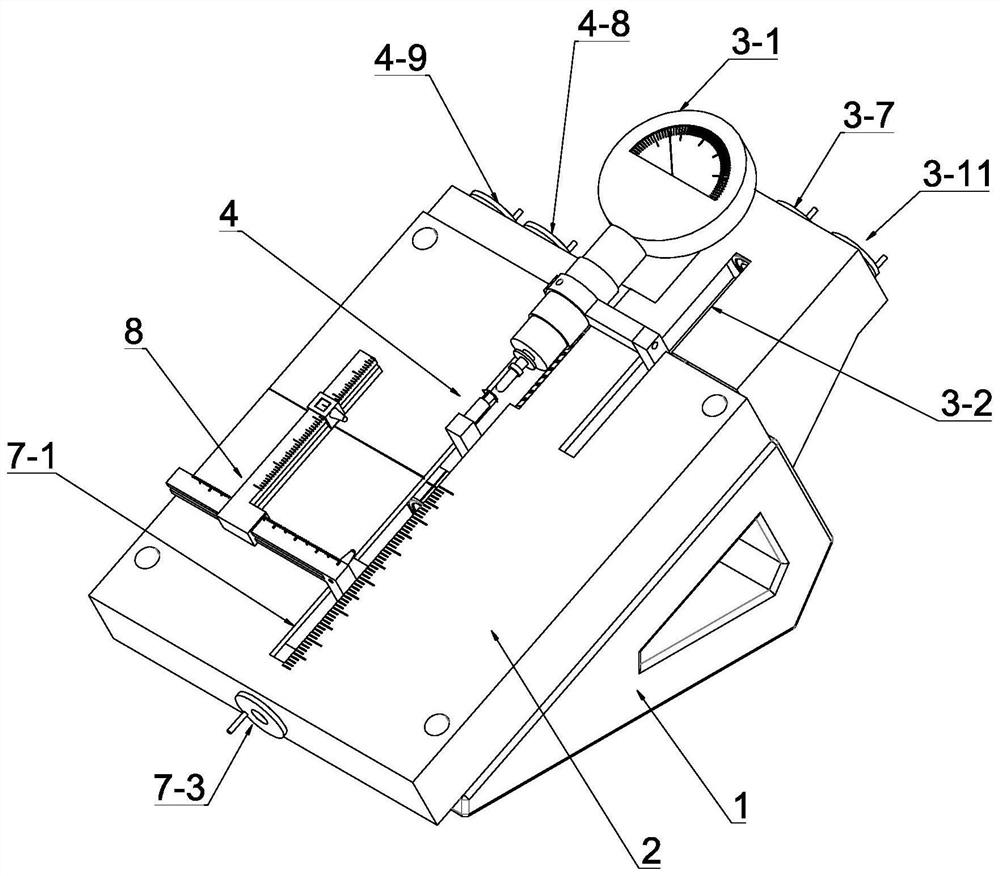

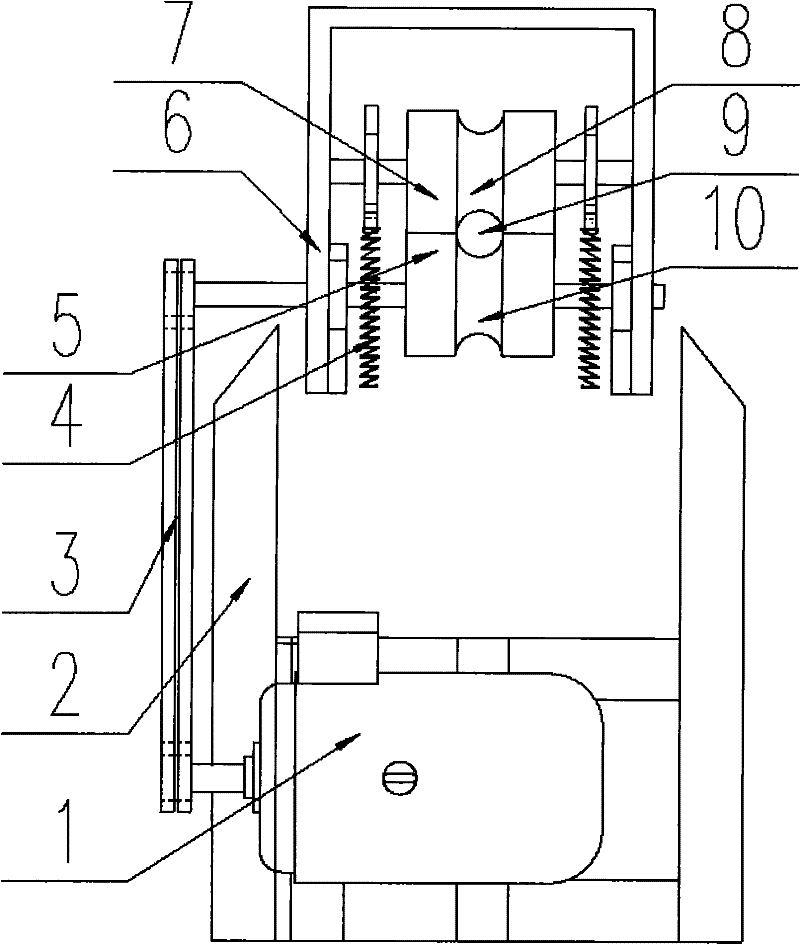

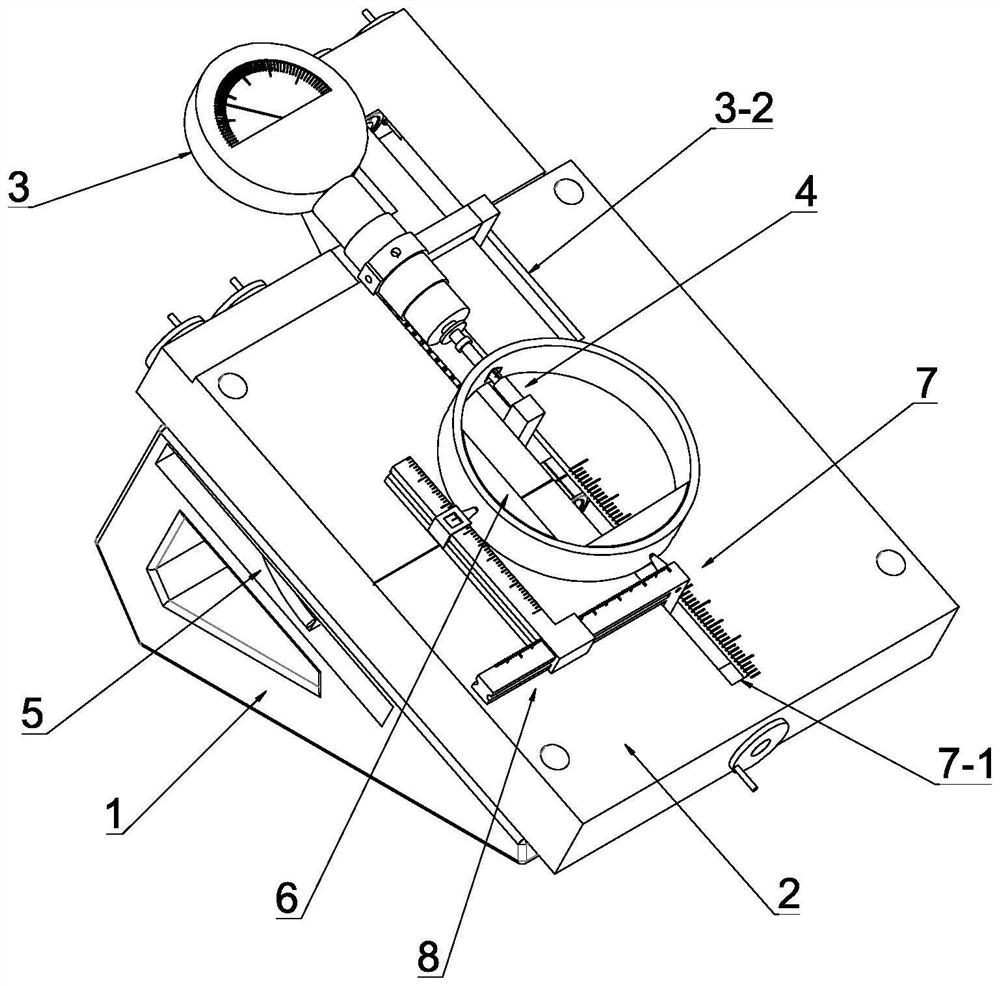

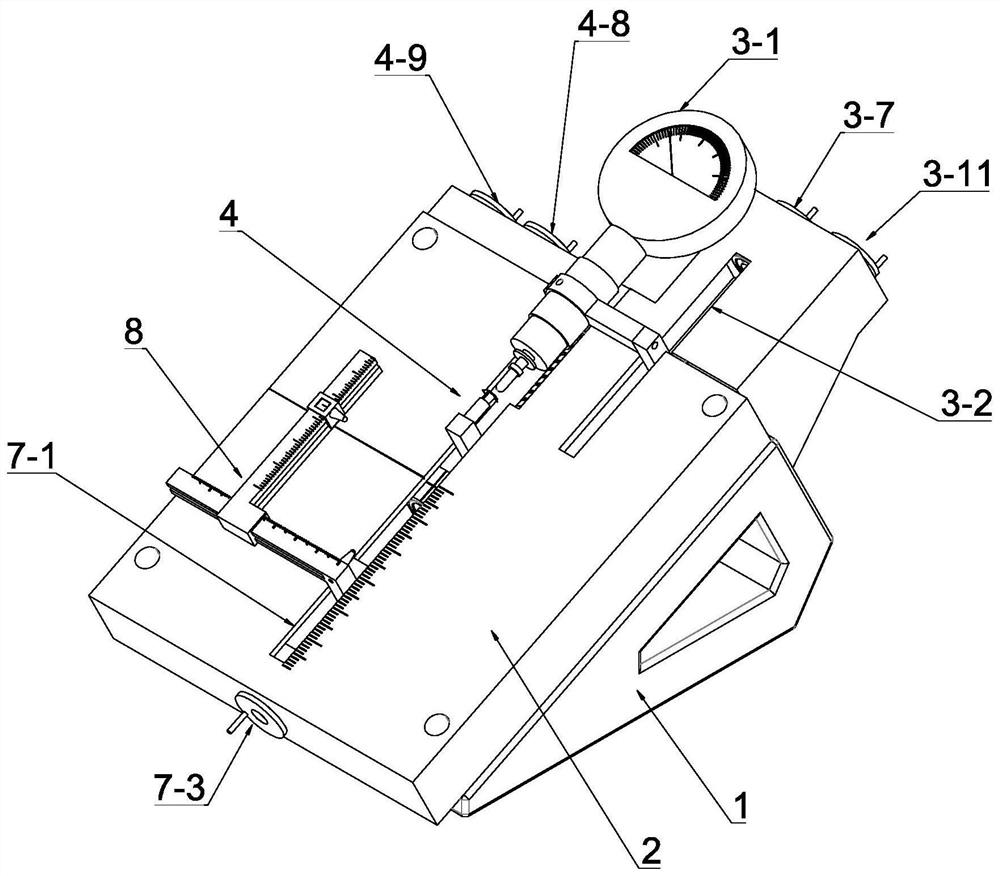

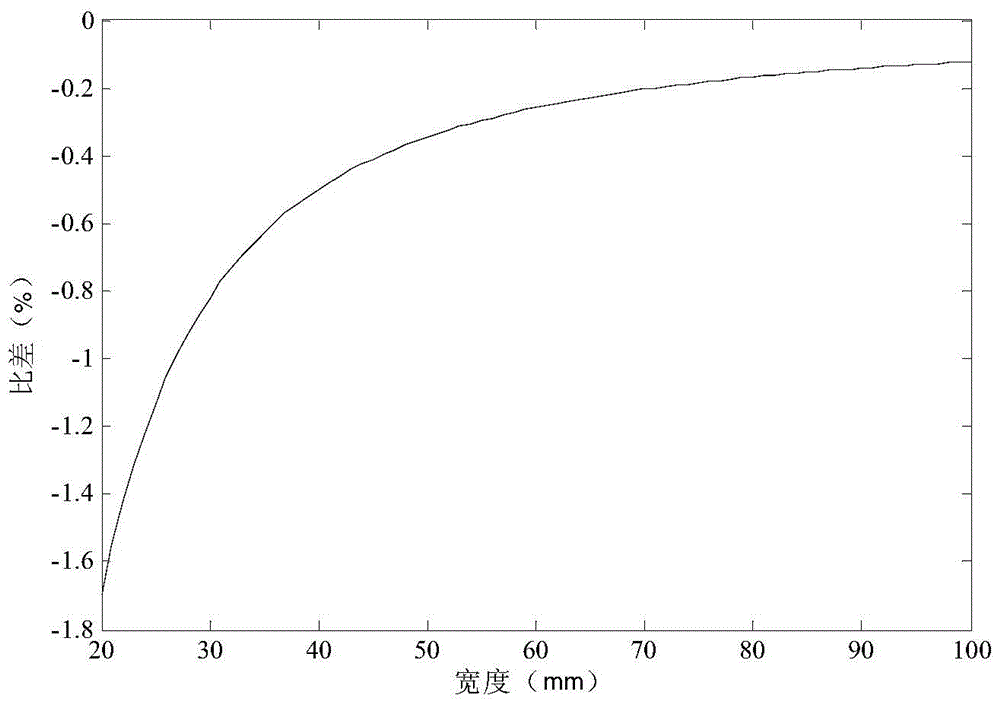

Outer diameter measuring device and method for thin-wall bearing ring

ActiveCN111692950AReduce eccentricity errorHigh precisionMechanical diameter measurementsMeasurement deviceTorsion spring

The invention discloses an outer diameter measuring device and method for a thin-wall bearing ring. The device comprises a supporting frame, a workbench arranged on the supporting frame, a positioningmechanism arranged on the workbench, a measuring mechanism and a reverse abutting mechanism. The workbench is provided with a measuring center, and the positioning mechanism comprises a Y-axis positioning mechanism and an X-axis positioning mechanism which are arranged on the workbench; the measuring mechanism comprises a torsion spring comparator arranged on the workbench in a sliding mode and ameasuring adjusting mechanism used for adjusting the torsion spring comparator to move on the workbench in the Y-axis direction. The reverse abutting mechanism comprises a reverse abutting rod arranged between a Y-axis positioning rod and a measuring head of the torsional spring comparator and a reverse abutting adjusting mechanism used for adjusting the reverse abutting rod to move along a Y-axis guide groove. According to the device, when the torsional spring comparator is used for measuring the bearing ring, force measurement errors and eccentric errors of the thin-wall bearing ring in themeasurement process can be reduced, and therefore the outer diameter measurement precision of the thin-wall bearing ring is improved.

Owner:GUANGZHOU UNIVERSITY

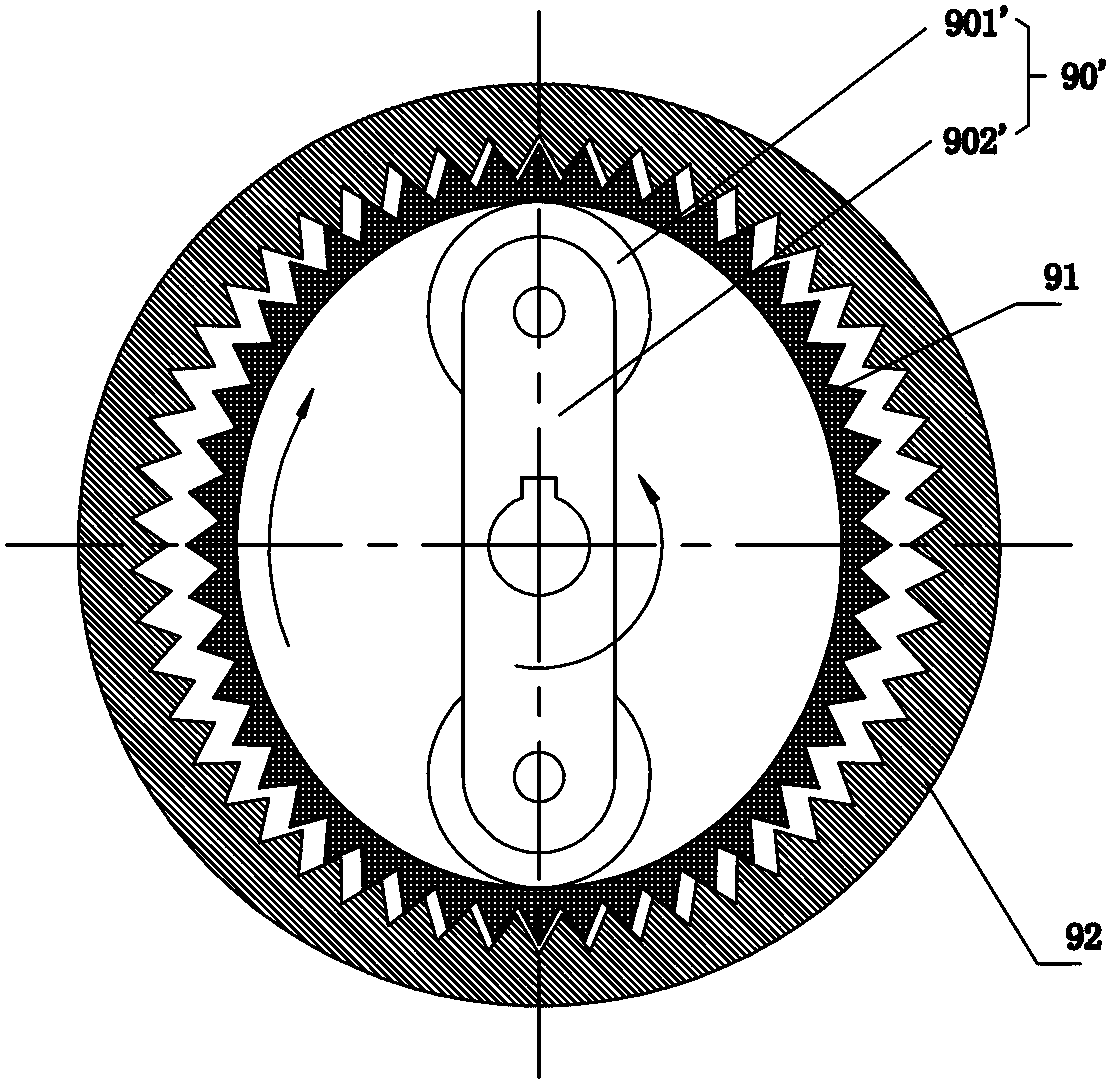

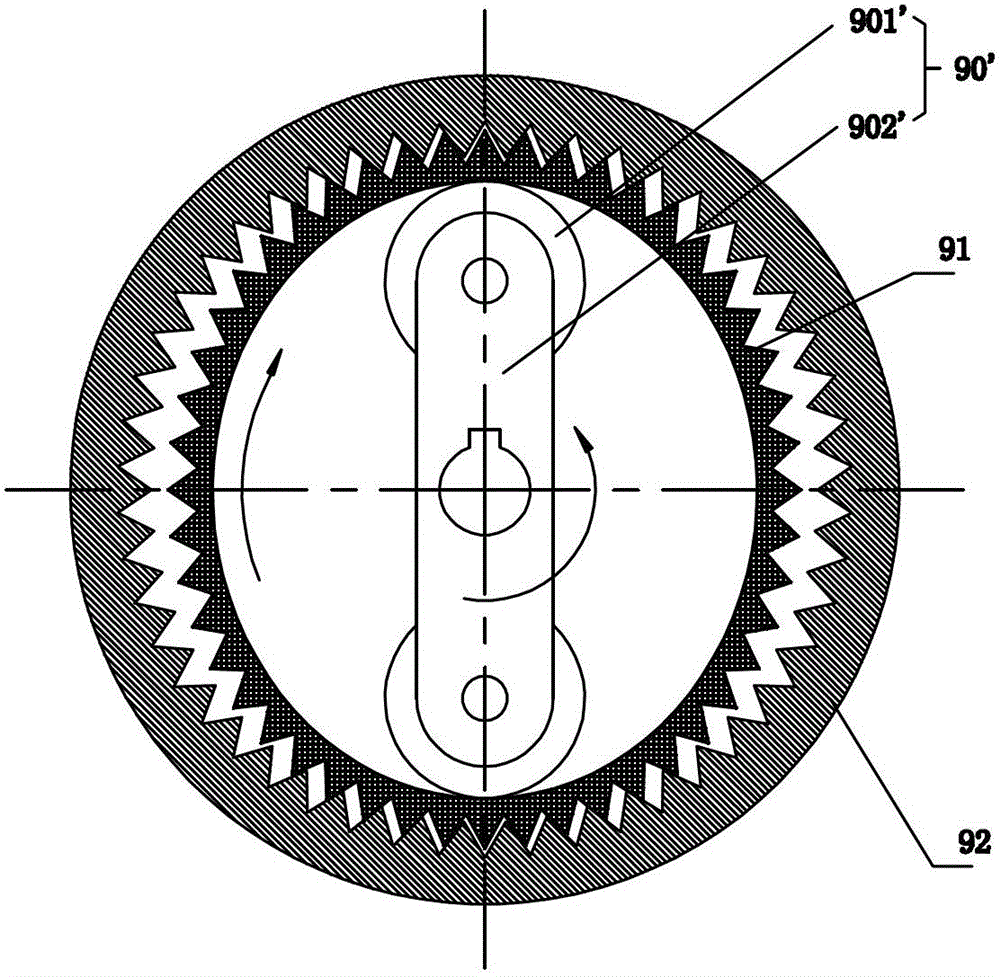

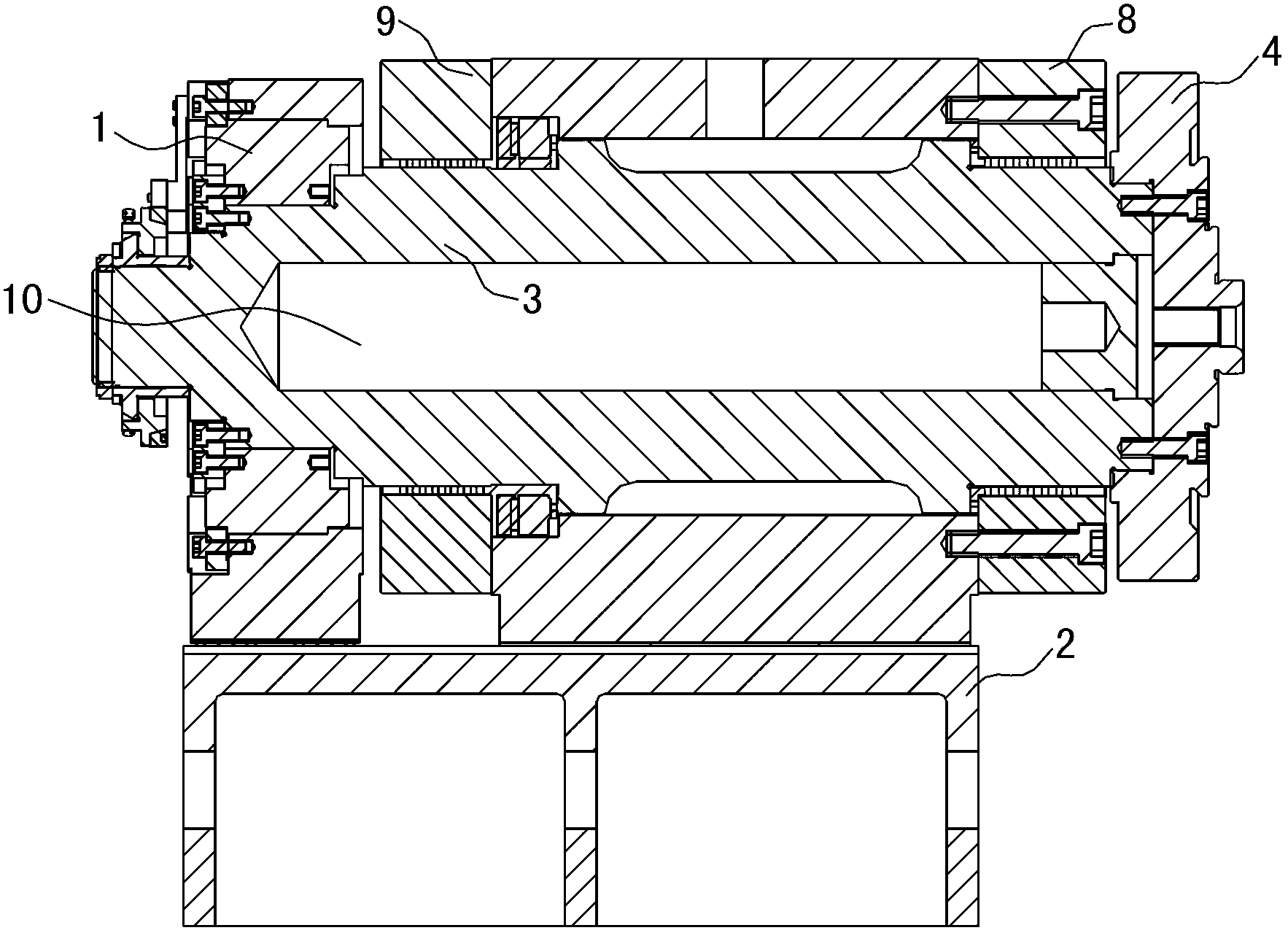

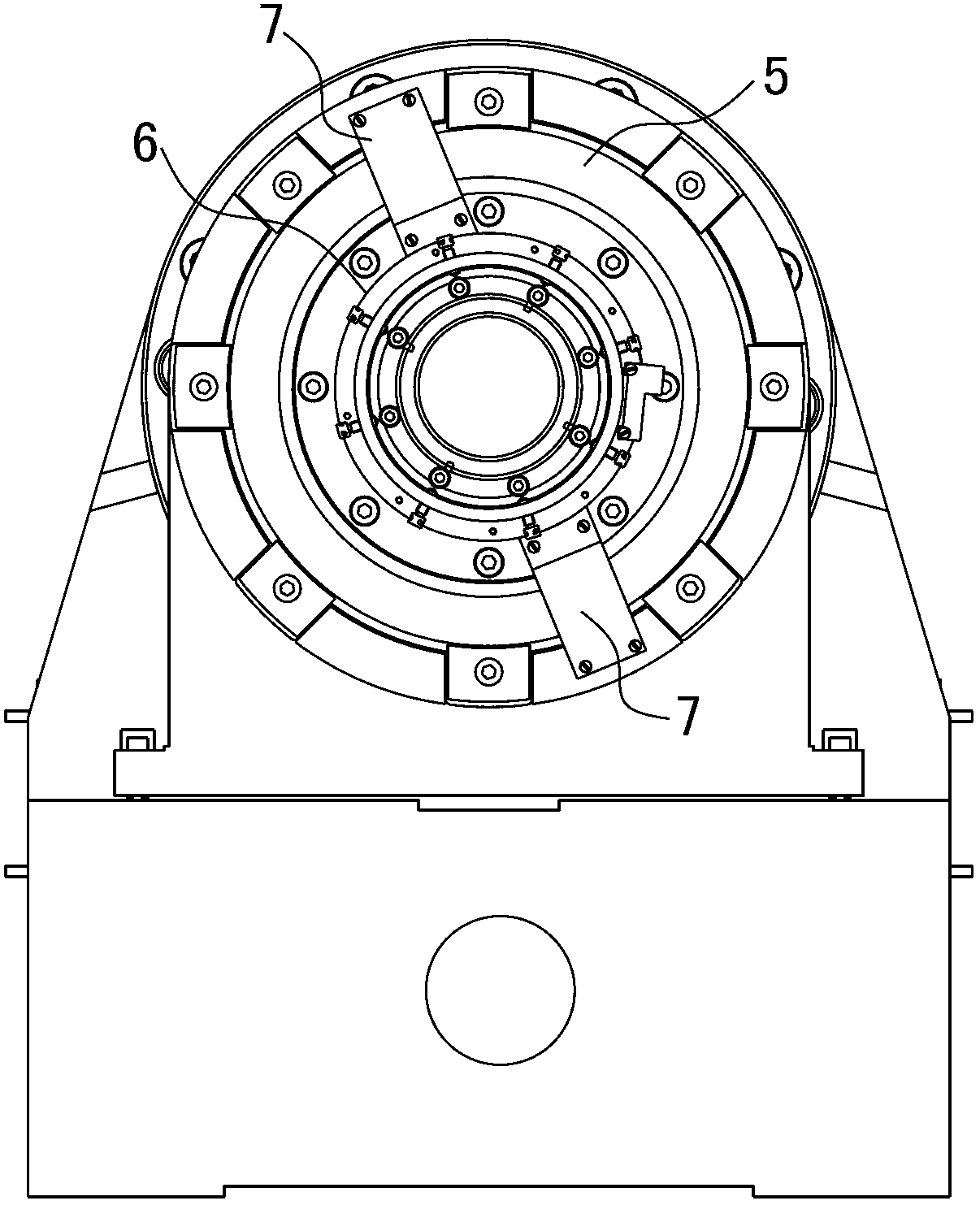

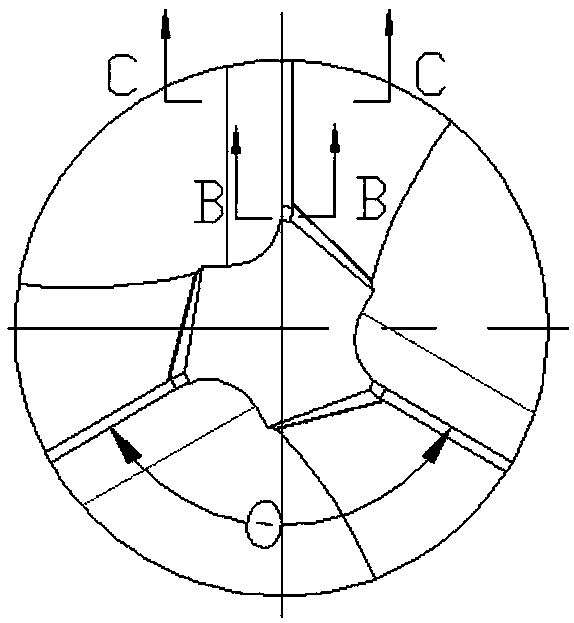

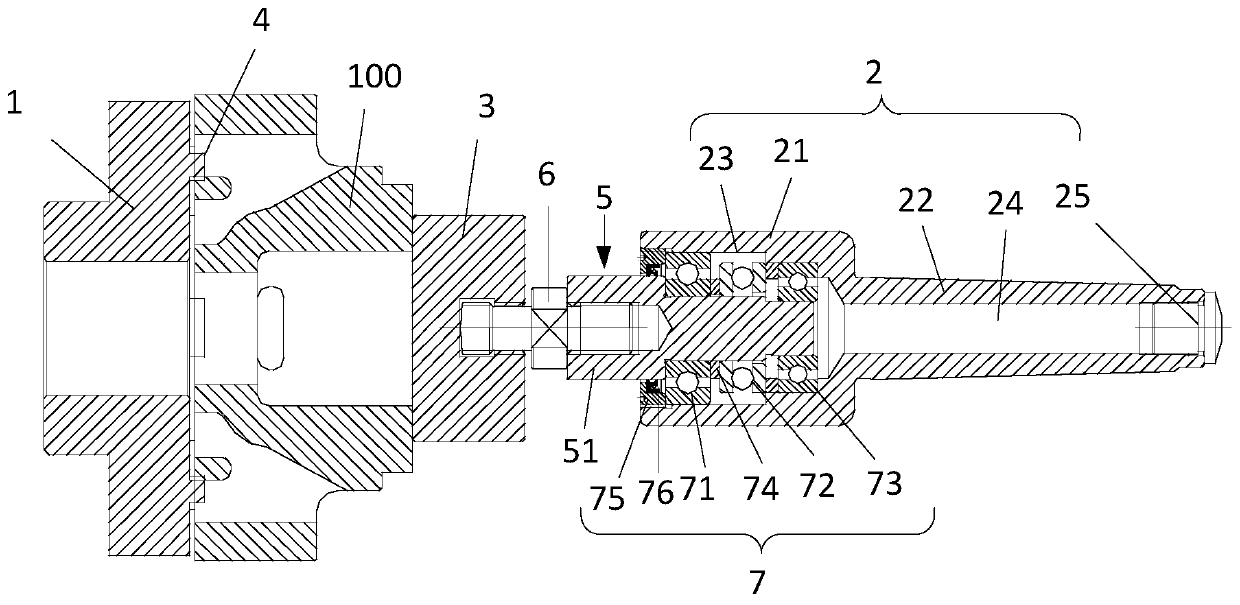

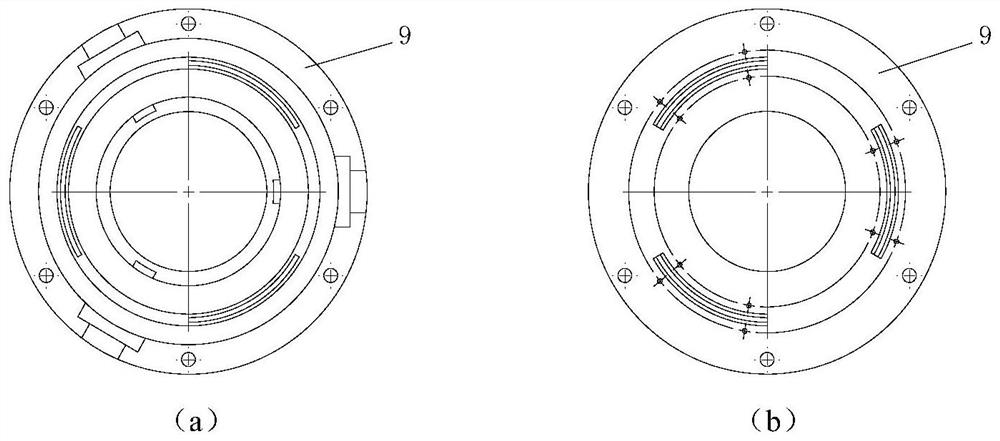

Method for reducing drive eccentric errors of harmonic gear and automatic aligning wave generator

The embodiment of the invention discloses a method for reducing drive eccentric errors of a harmonic gear and an automatic aligning wave generator. The automatic aligning wave generator comprises a turn plate driven by an input shaft and an elastic floating mechanism provided with two rollers. The elastic floating mechanism is flexibly arranged inside the turn plate in a sliding manner in the long axis direction of the automatic aligning wave generator. The elastic floating mechanism comprises two roller brackets symmetrically distributed relatively to the centre of the turn plate and an elastic element arranged between the roller brackets; the elastic element elastically resists against the two roller brackets, and the two rollers are respectively arranged on the two roller brackets, elastically resist against an inner circle of a flexible gear under the action of the elastic element and force the flexible gear to form an ellipse from a round shape, so that gear teeth of the flexible gear are tightly meshed with gear teeth of a rigid gear. The automatic aligning wave generator can reduce the eccentric errors caused by processing and assembling of parts, can remove the gear backlash between the gear teeth of the flexible gear and the gear teeth of the rigid gear and play an overload protection role.

Owner:深圳市东汇精密机电有限公司

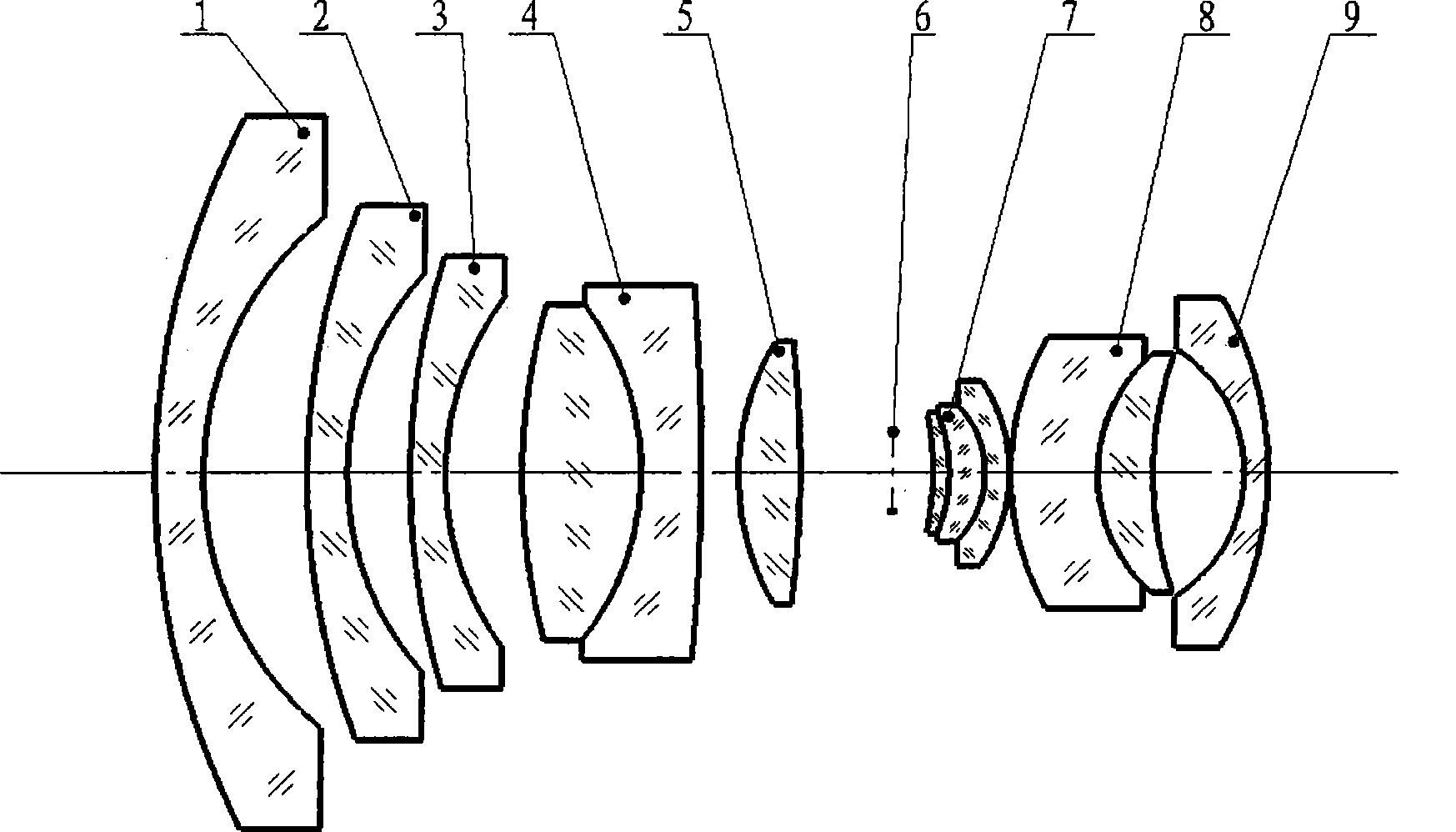

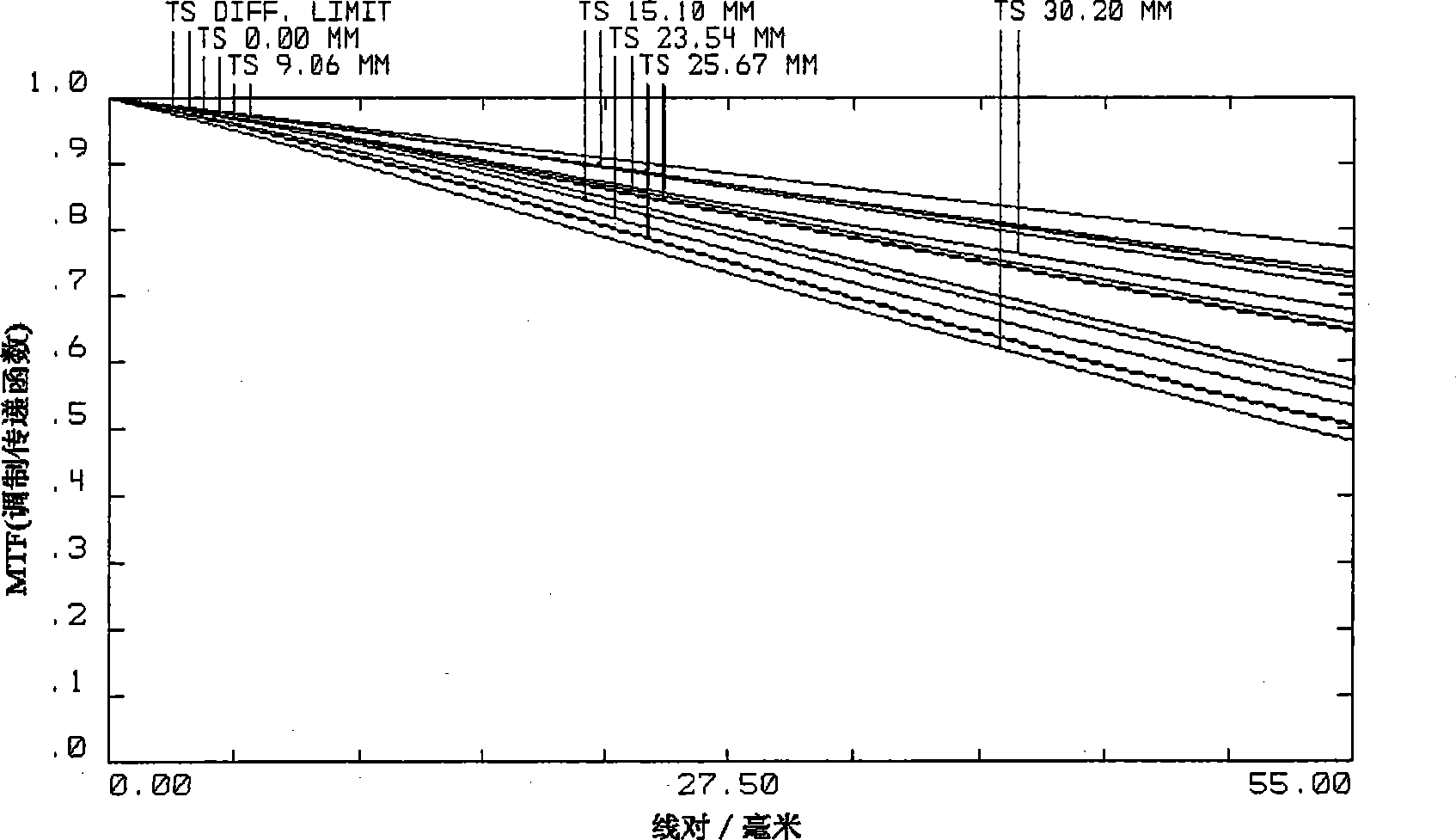

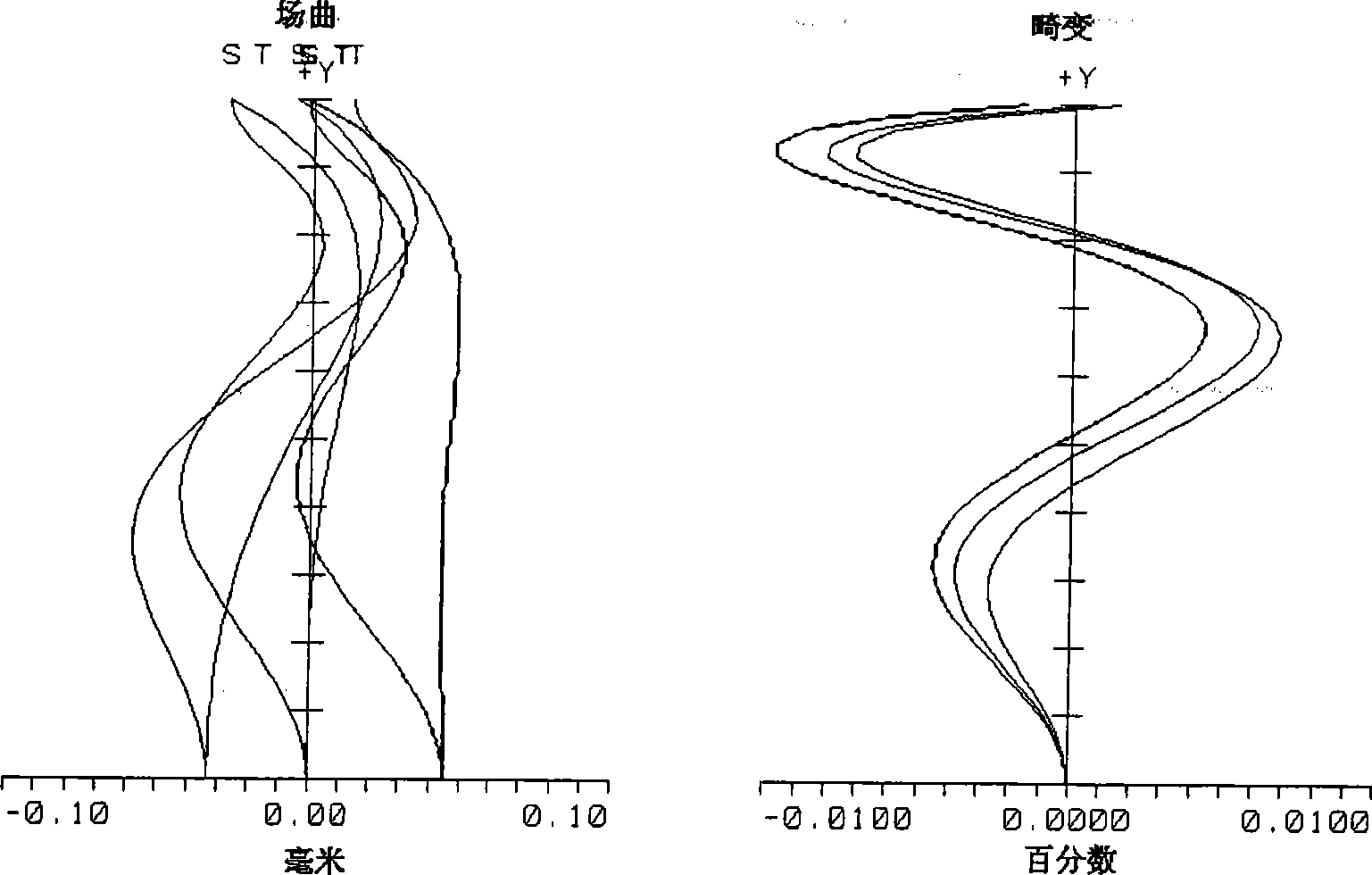

Digital aerial survey full-color camera lens

InactiveCN101482645ALarge field of viewLarge lateral field of viewPicture taking arrangementsOptical elementsVisual field lossCamera lens

A digital aerial surveying colorful camera lens is characterized by comprising a front set of lenses, a light diaphragm and a rear set of lenses, and all lenses are deposited on the same one optical axis in order; the front set of lenses are composed of a first spherical shell lens, a second spherical shell lens, a third spherical shell lens, a first double cemented lens and a double convex lens; the rear set of lenses are composed of a triple cemented lens, a second double cemented lens and a fourth spherical shell lens. The digital aerial surveying colorful camera lens of the invention solves the problem that the high resolution and the low distortion are difficult to implement under the large visual field. When the visual field is 87. 8 degrees, on the 55 line pair, MTF>=0. 4, the full visual field distortion is less than 0. 01, and the structure is compact, the miniaturisation and the light weighing can be implemented.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

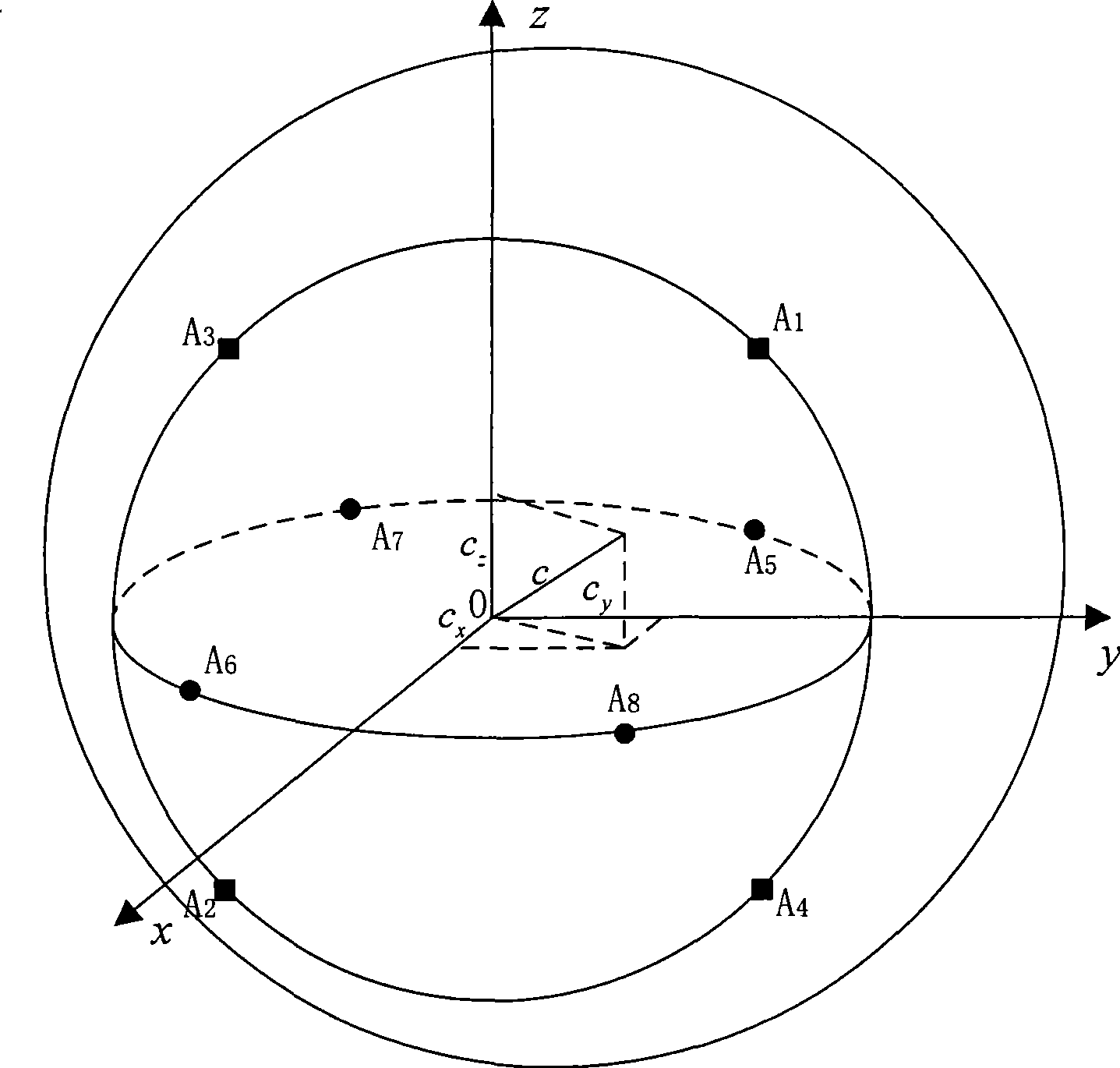

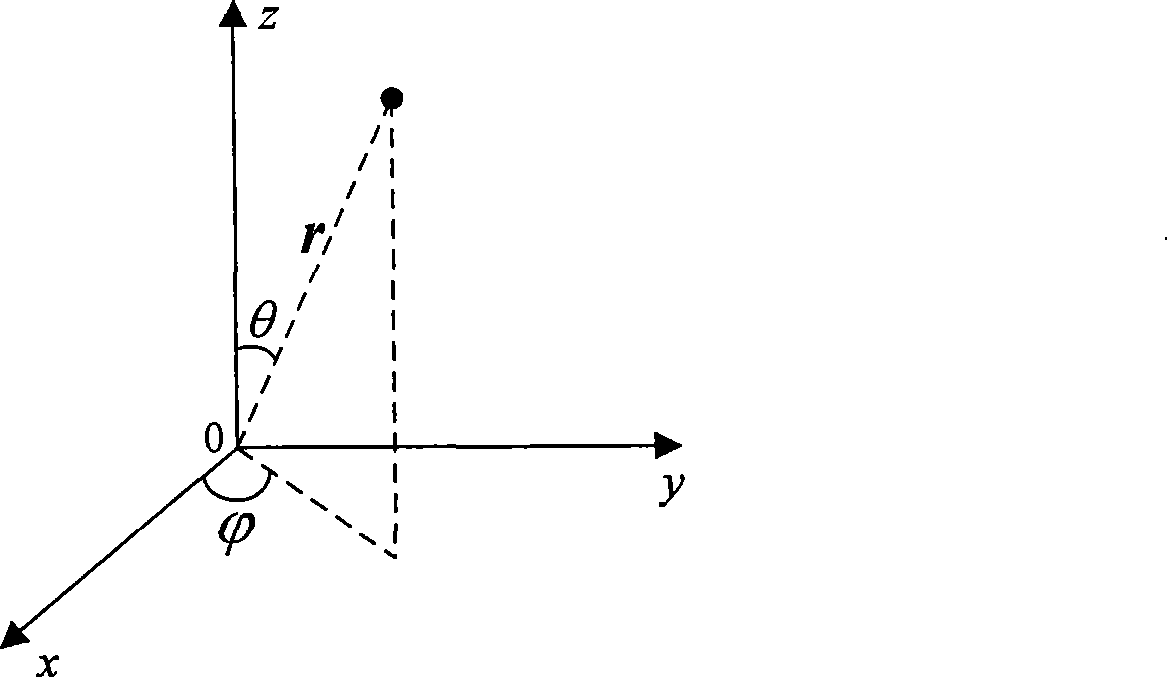

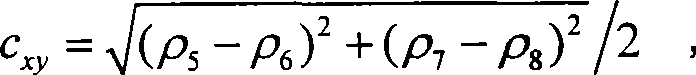

Sphere clearance measurement method

InactiveCN101458076AEliminate the effects ofReduce eccentricity errorMeasurement devicesRectangular coordinatesClassical mechanics

The invention relates to a measuring method for spherical surface clearance, which belongs to the measuring technical field. Firstly, two great circles which are mutually vertical are optionally intercepted by the centre of sphere on the inside spherical surface of two measured spherical surface; four measuring points are respective uniformly distributed along the circumference of the two great circles; a rectangular coordinate system is established by taking the center of sphere of the inside spherical surface of the two measured spherical surface as a base point; a spherical coordinate system is established based on the rectangular coordinate system; the two measured spherical radiuses and the corresponding distance between every measuring point and the outside spherical surface of the two measured spherical surface are respectively obtained; the center of sphere coordinates of the outside spherical surface of the two measured spherical surface are obtained by calculating according to the distance of a polyline, thus figuring out the distance between any point M of the inside spherical surface of the two measured spherical surface and the outside spherical surface. The measuring method is accurate, fast, effectively deals with the measuring data of the spherical surface clearance, can be used for measuring the distance between the spherical surfaces with 0-2mm clearance. The measuring resolution factor is 0.001mm and the measuring precision is minus or plus 0.02mm.

Owner:TSINGHUA UNIV

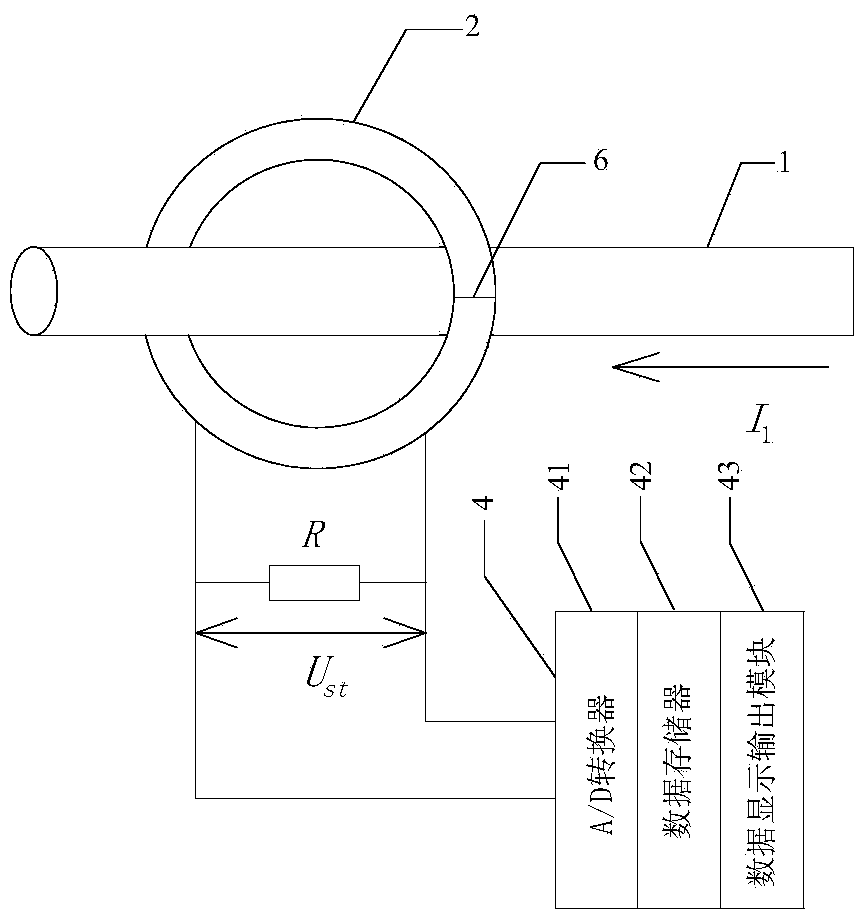

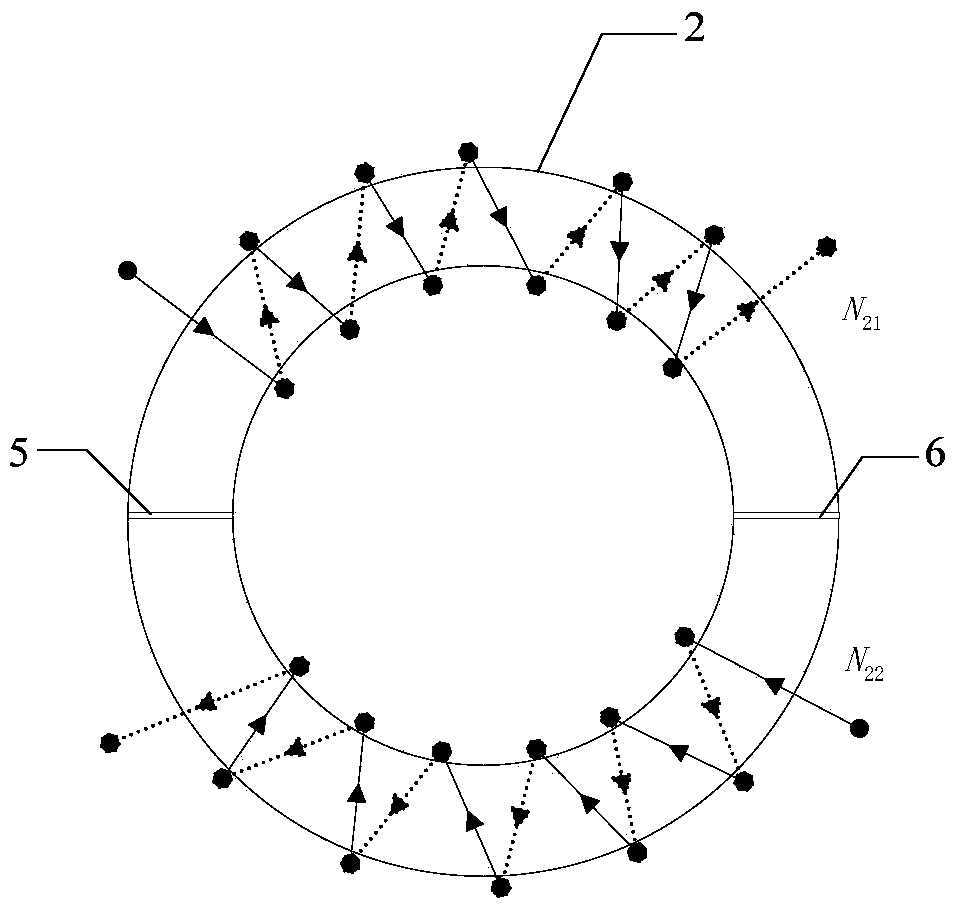

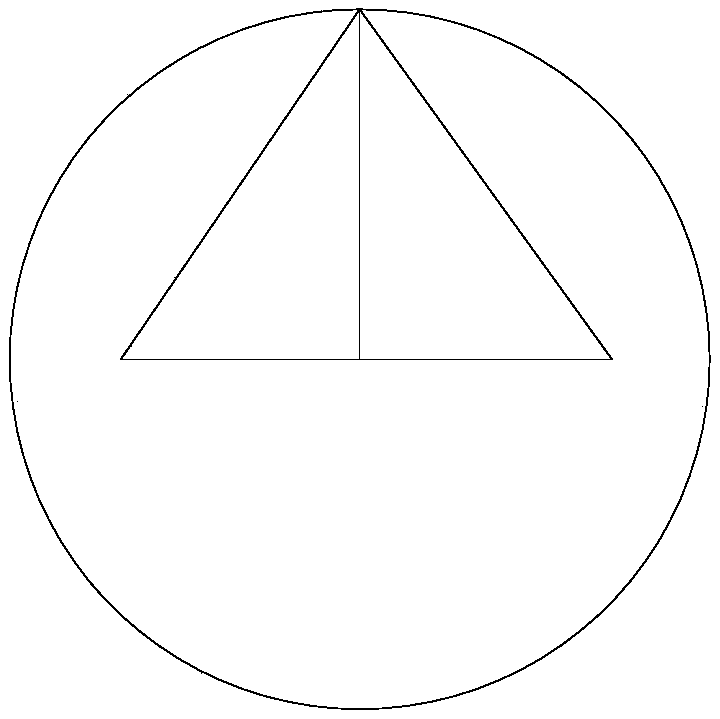

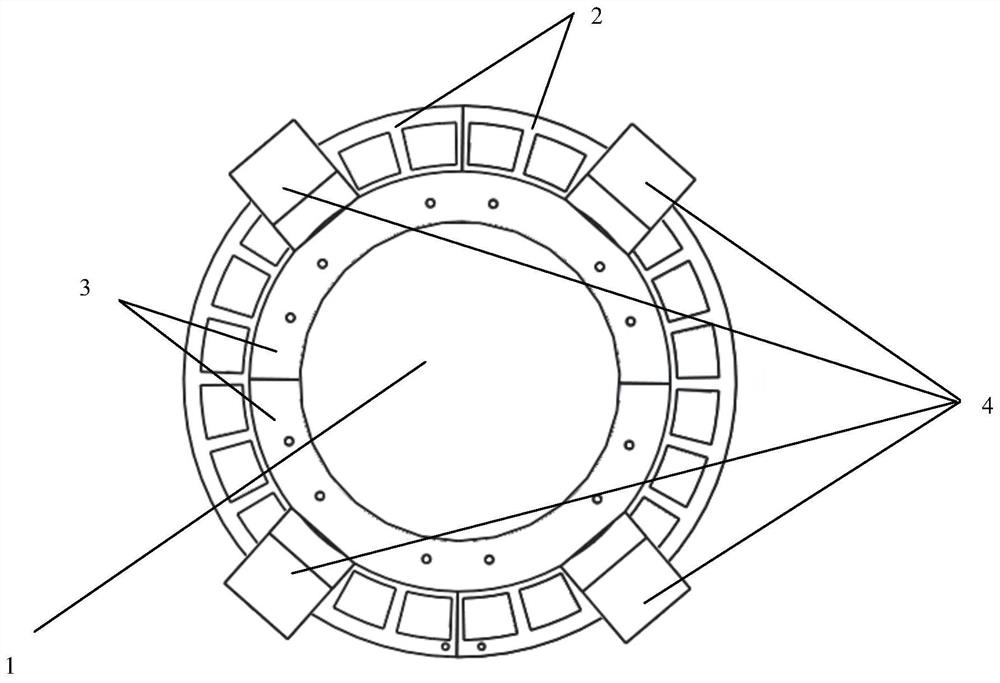

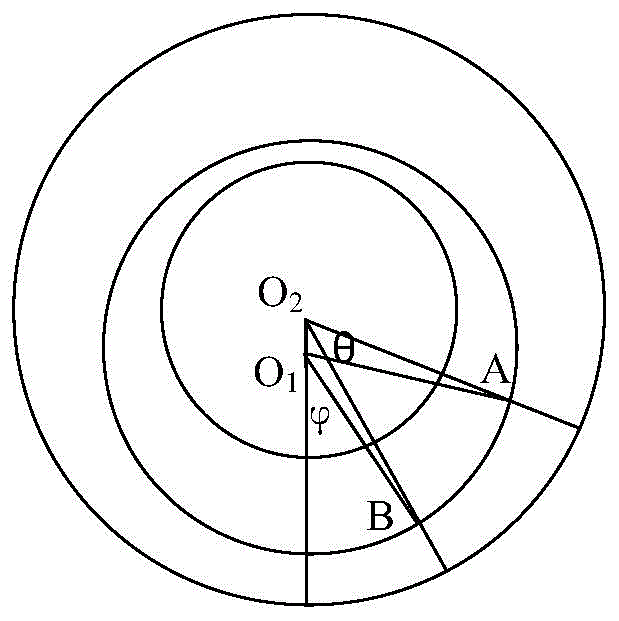

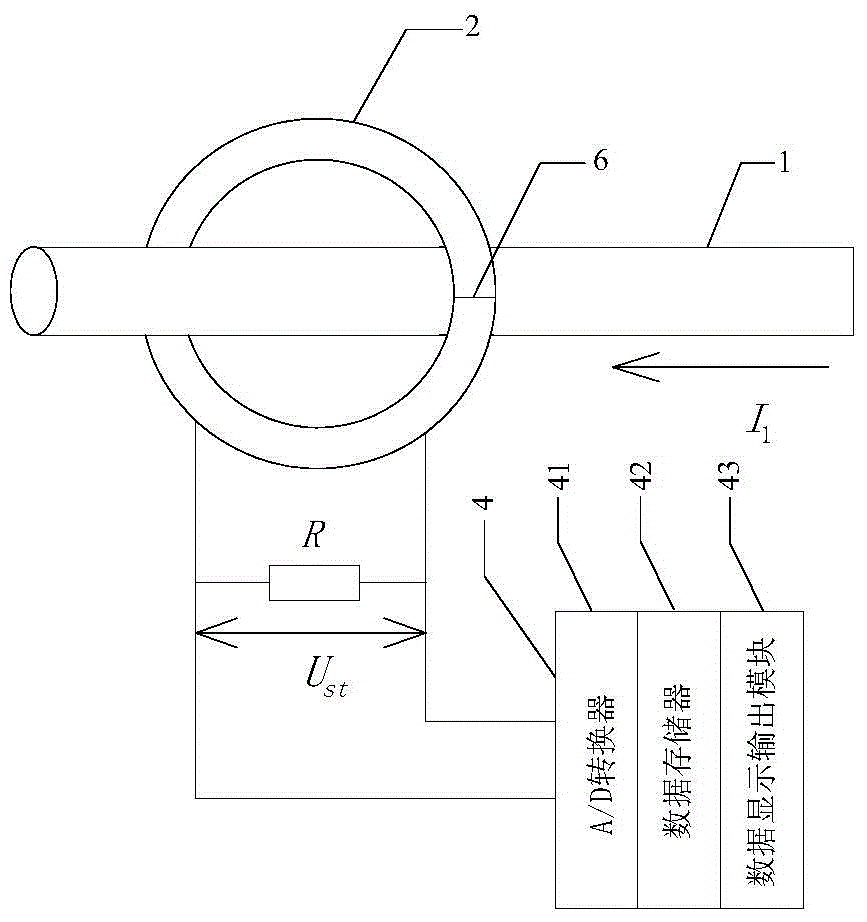

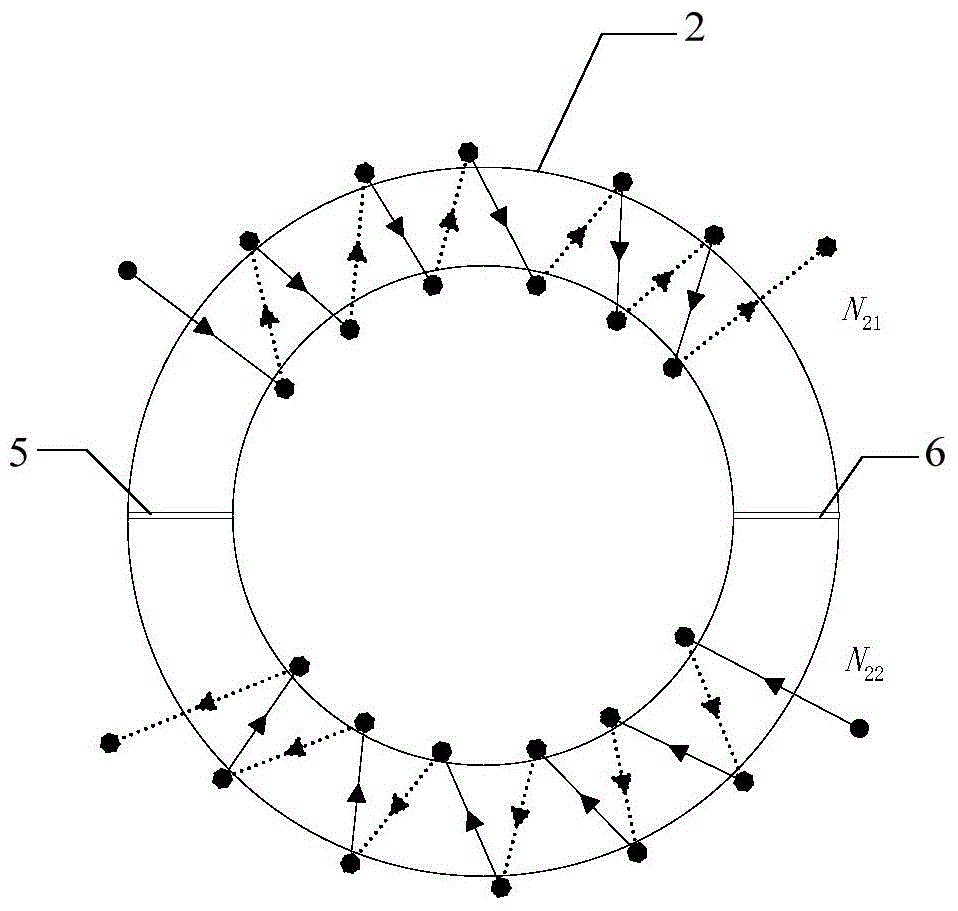

Double-air-gap core electronic current transformer

ActiveCN103632823AConvenient live installationEasy to disassembleTransformersTransformers/inductances magnetic coresElectrical conductorData treatment

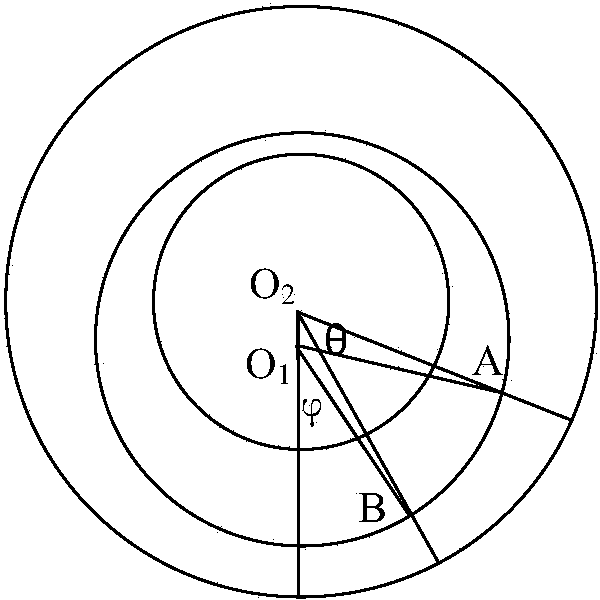

The invention provides a double-air-gap core electronic current transformer. The double-air-gap core electronic current transformer comprises a first double-air-gap core and a second double-air-gap core; the first double-air-gap core is provided with a first air gap and a second air gap, and the connecting line between the first air gap and the second air gap passes through the circle center of the first double-air-gap core; the second double-air-gap core is connected in series with the first double-air-gap core and is coaxial with the first double-air-gap core, the second double-air-gap core is provided with a third air gap and a fourth air gap, and the connecting line between the third air gap and the fourth air gap passes through the circle center of the second double-air-gap core and is perpendicular to the connecting line between the first air gap and the second air gap; a conductor sequentially passes through the centers of the first double-air-gap core and the second double-air-gap core; a data processing chip is connected with coils of the first double-air-gap core and the second double-air-gap core and used for receiving measured data and displaying and outputting the measured data after converting the measured data from analog to digital.

Owner:STATE GRID CORP OF CHINA +2

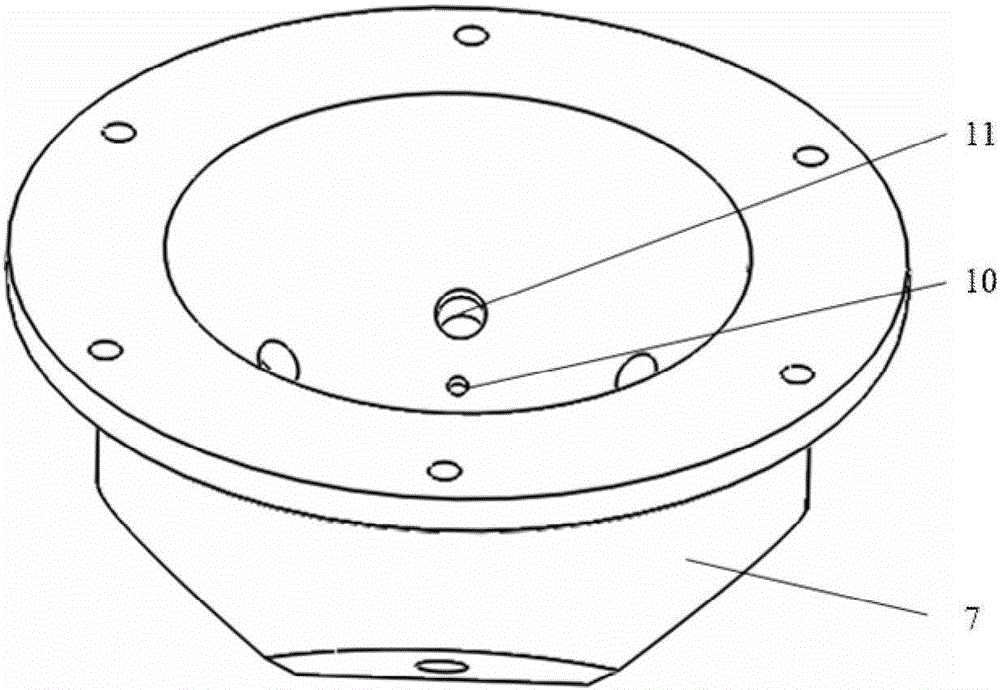

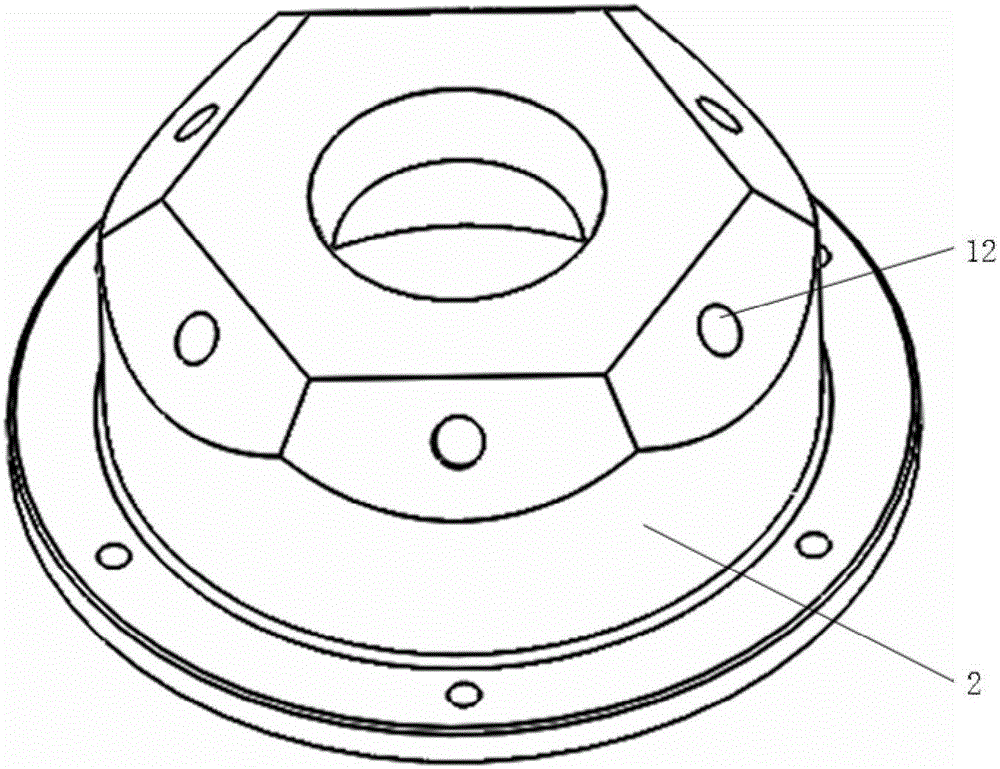

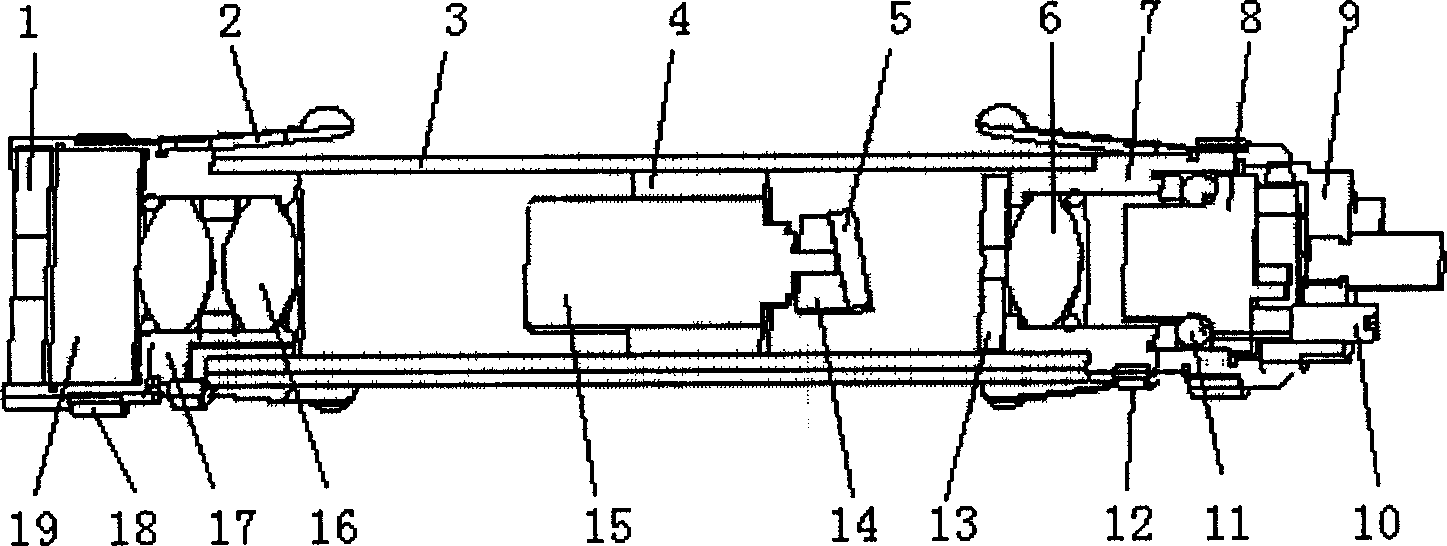

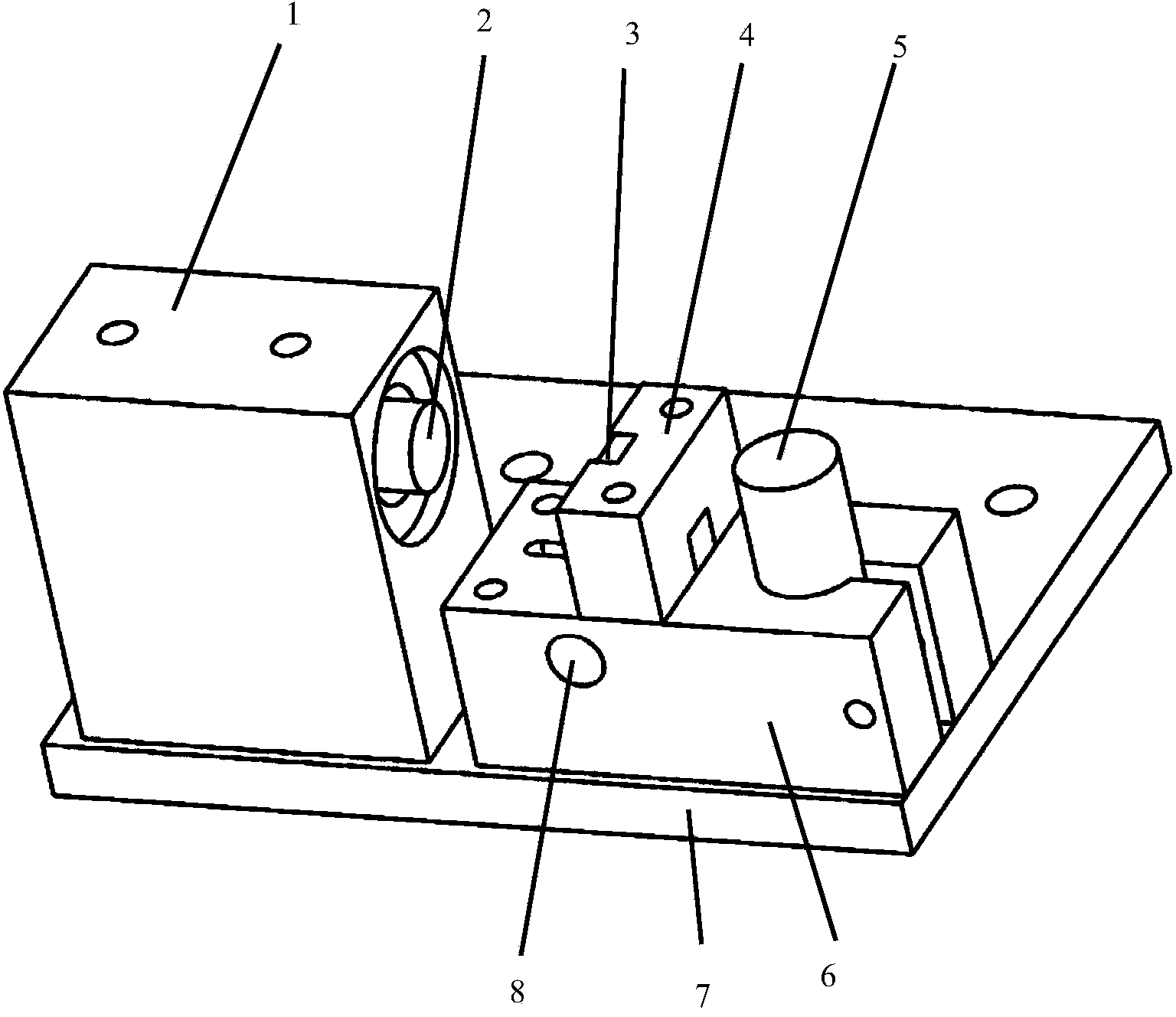

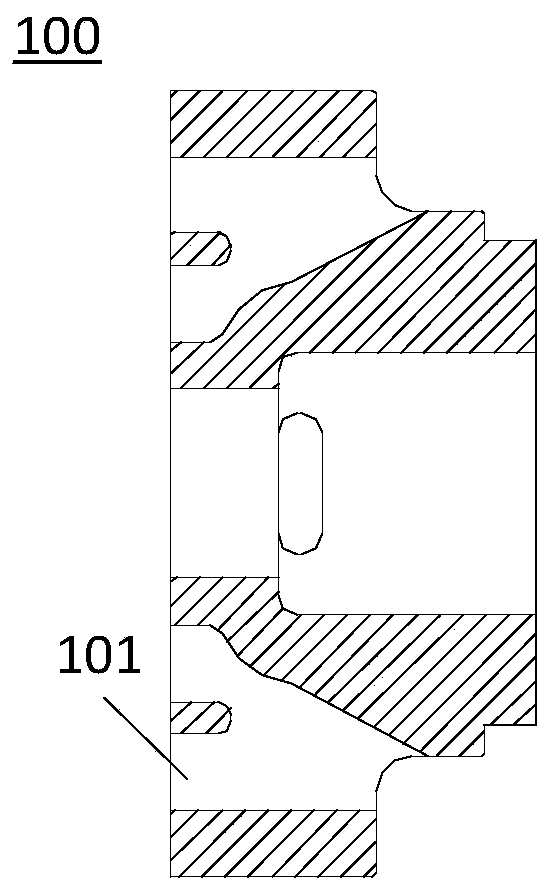

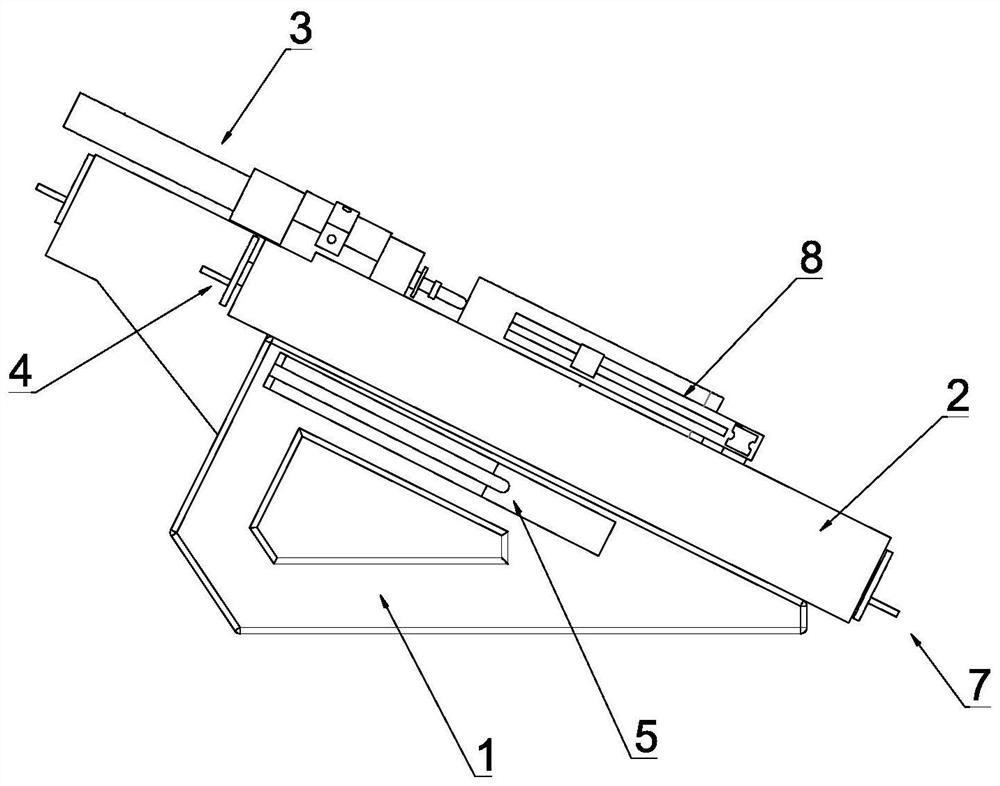

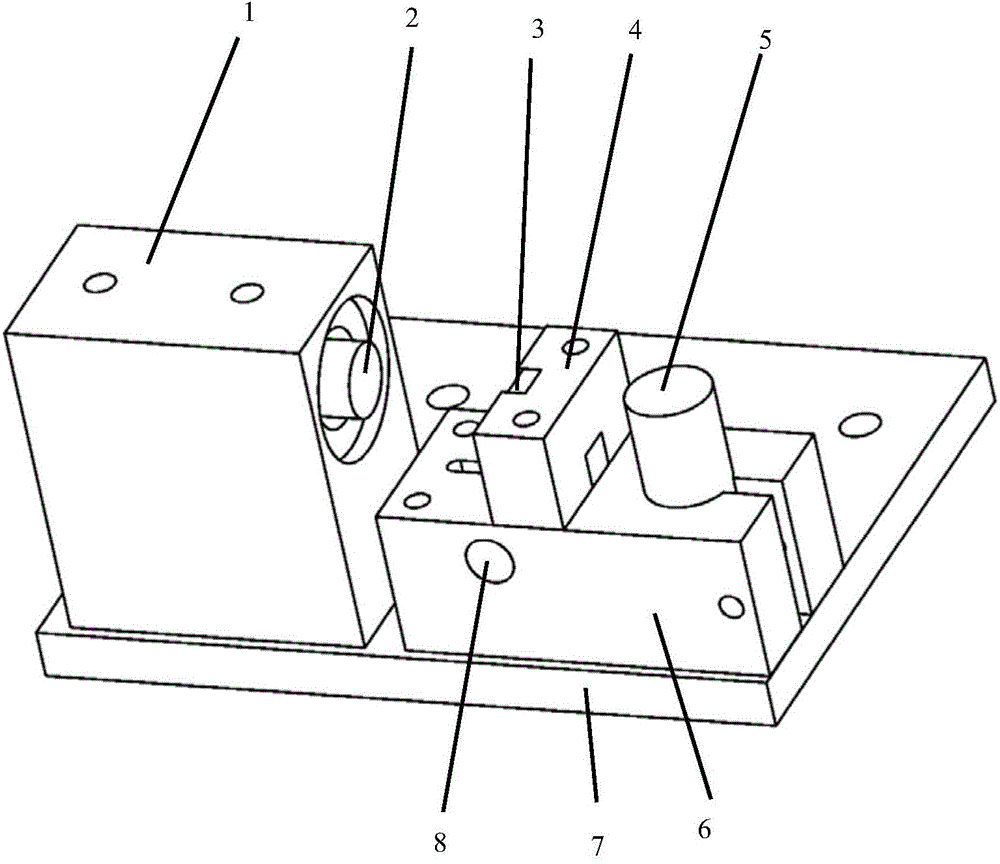

Ship shafting torque measuring probe in eccentric error correcting mode

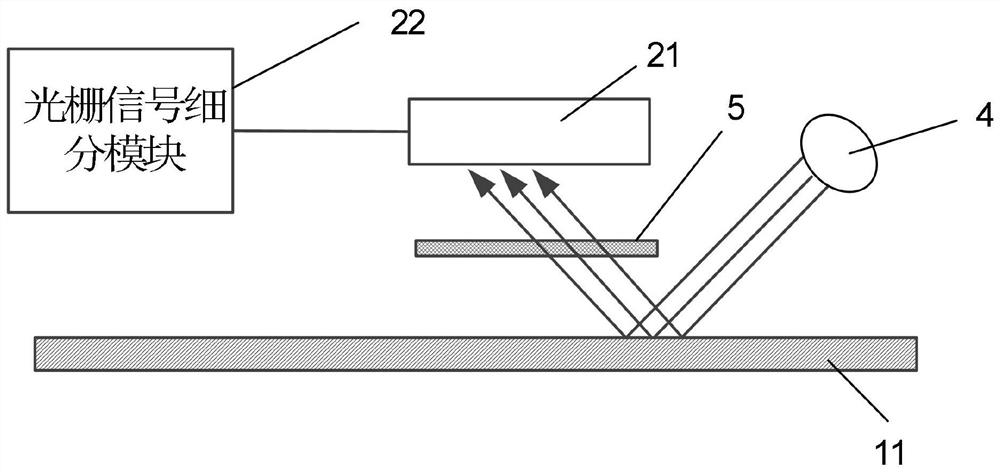

InactiveCN103900747AEliminate errorsReduce eccentricity errorWork measurementTorque measurementEddy currentError correcting

The invention relates to a ship shafting torque measuring probe in an eccentric error correcting mode. The ship shafting torque measuring probe in the eccentric error correcting mode is mainly composed of a photoelectric receiving module (4), an eddy current displacement sensor (5), a photoelectric diode (3), a semiconductor laser (2), a laser clamping block (1) and a middle block (6), wherein the laser clamping block (1) and the middle block (6) are arranged on a base (7). The laser clamping block (1) is provided with through holes which are used for containing and fixing the semiconductor laser (2), and the photoelectric receiving module (4) is fixed to the middle block (6) and serves as an upholder of the photoelectric diode (3). The middle block (6) is used for clamping a connecting leading wire of the eddy current displacement sensor (5) and the photoelectric diode (3). According to the ship shafting torque measuring probe in the eccentric error correcting mode, an optimization design is adopted overall, space is saved, and the torsion phase angle deviation caused by code disc eccentric errors is eliminated. Meanwhile, the invention further provides two methods for obtaining an initial phase angle.

Owner:WUHAN UNIV OF TECH

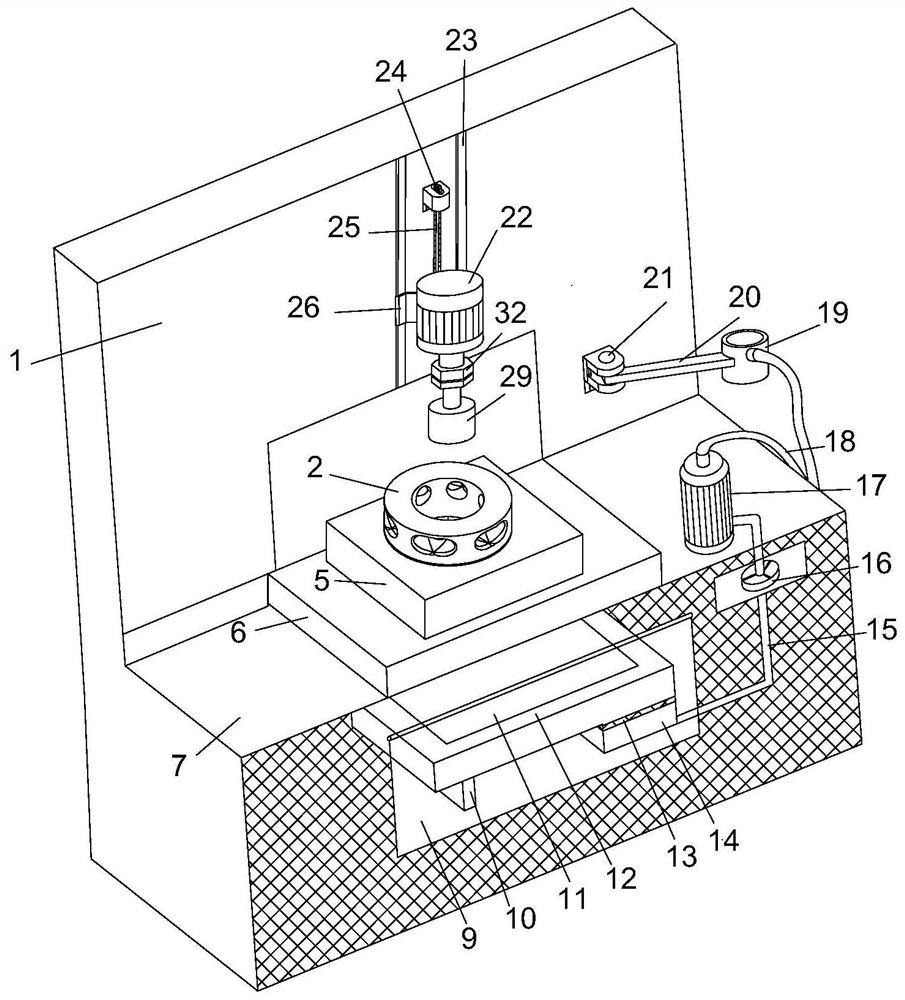

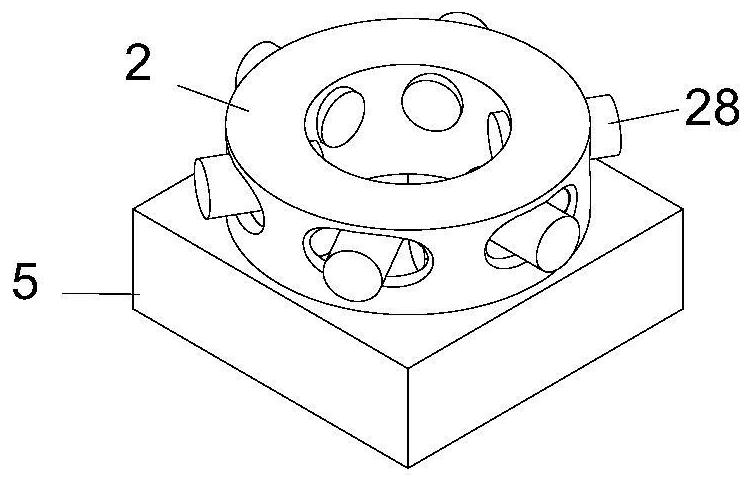

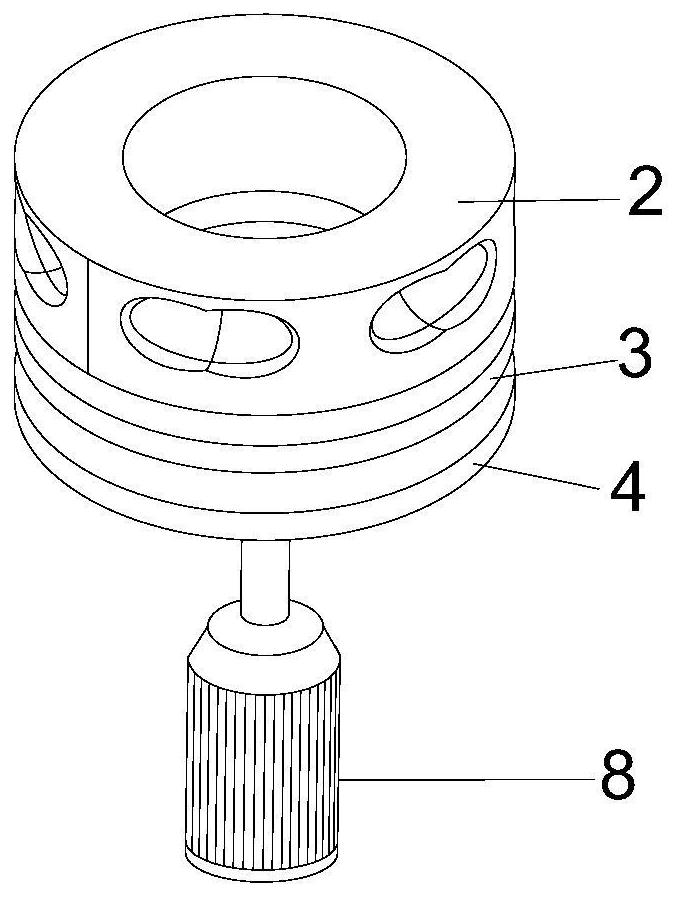

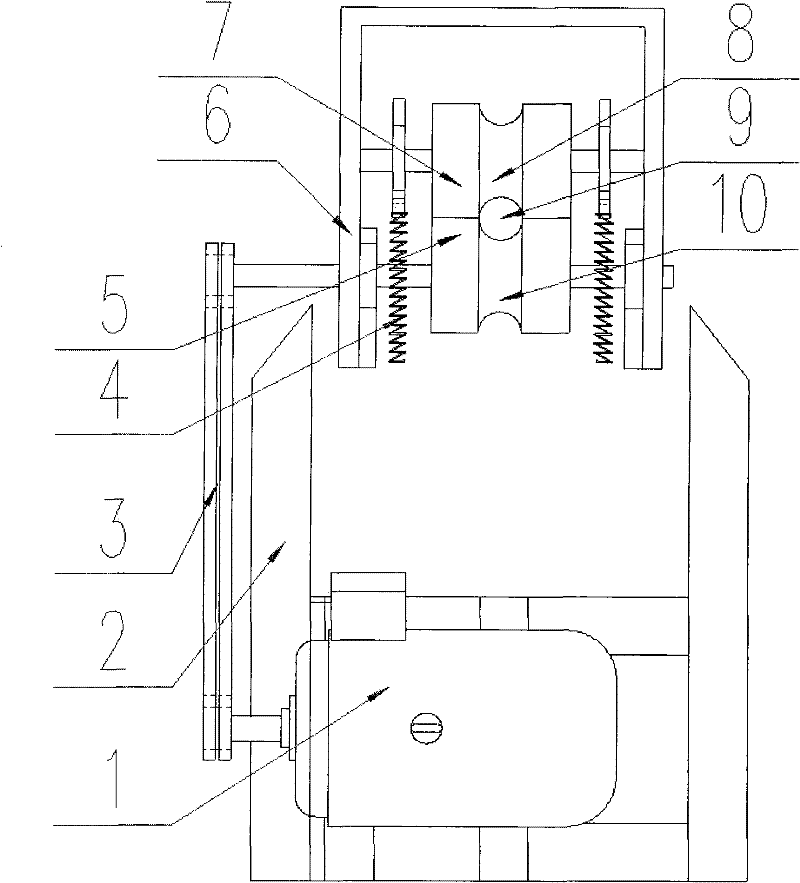

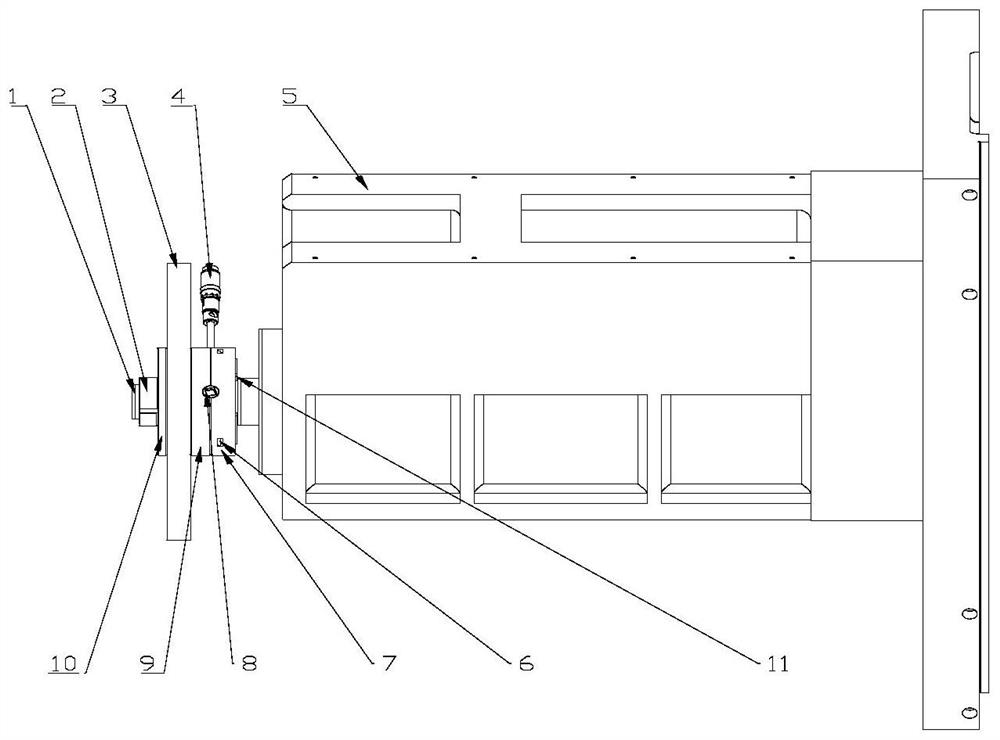

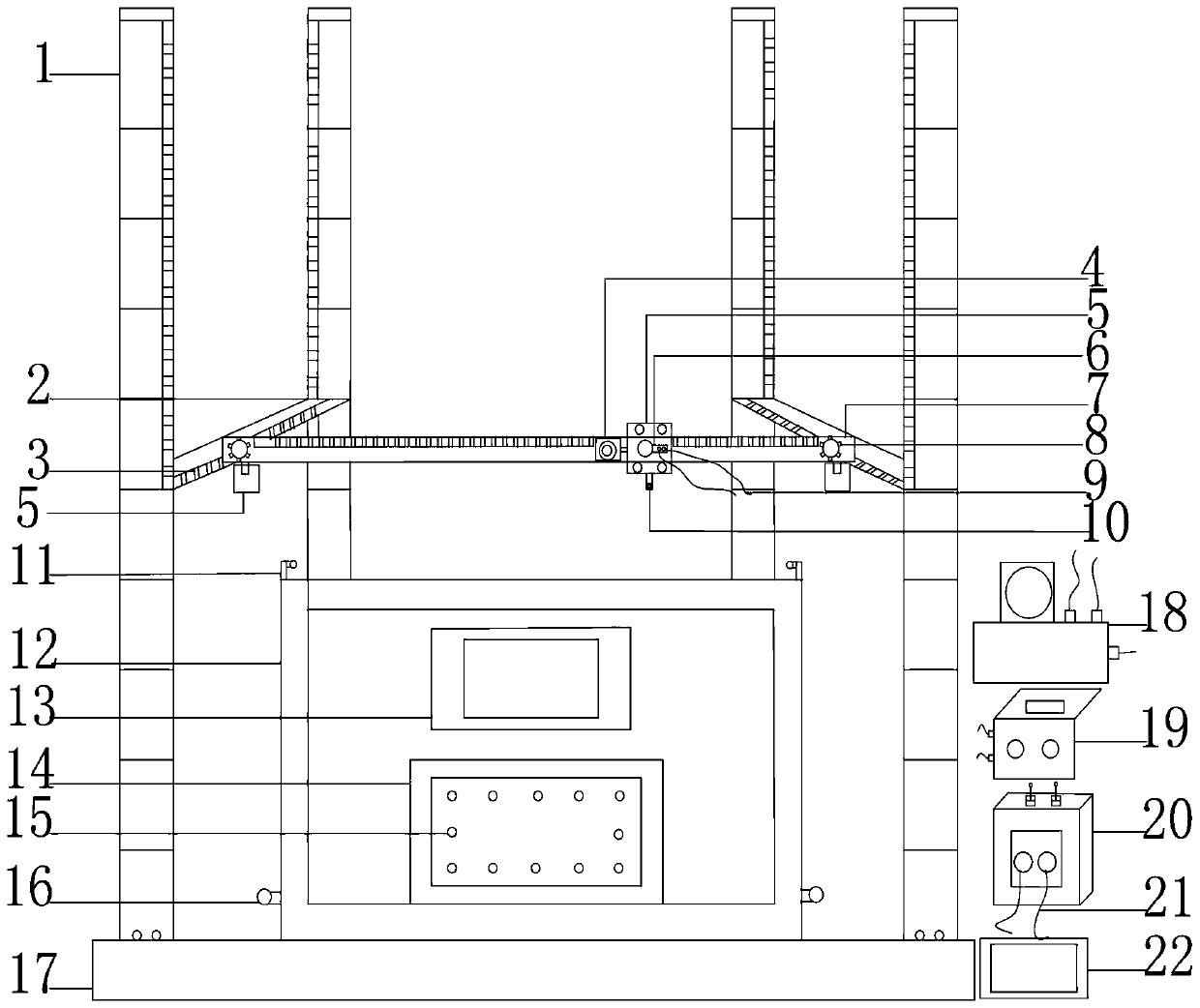

Single-drive efficient high-precision magneto-rheological polishing machine for outer surface of ceramic tube

PendingCN112276686AEasy to replaceAchieve spray uniformityEdge grinding machinesPolishing machinesPolishingElectric machinery

The invention discloses a single-drive efficient high-precision magneto-rheological polishing machine for the outer surface of a ceramic tube. The single-drive efficient high-precision magneto-rheological polishing machine comprises a rack, a polishing head, a spray head and a magneto-rheological polishing liquid supply mechanism. A sliding rail arranged in the vertical direction is fixed to a back plate of the rack, a lifting frame is connected to the sliding rail slidably, a first motor is fixed to the lifting frame, and an output shaft of the first motor is connected with a fixing clamp forfixing the ceramic tube through a coupler. The polishing head is arranged on the tabletop of the rack and located under the first motor, the polishing head is of an annular structure, the inner sideof the polishing head is connected with a plurality of magnetic poles A and magnetic poles B which are arranged in an annular Halbach array, the magnetic poles A and the magnetic poles B are alternately arranged and are cylindrical, the magnetic poles A are tangentially arranged in the circumferential direction, the magnetic poles B are radially arranged in the circumferential direction, and the magnetic poles B are rotationally connected to the polishing head, and are driven by a driving mechanism to rotate synchronously. The single-drive efficient high-precision magneto-rheological polishingmachine has high efficiency, economical efficiency, practicability and high precision.

Owner:FUJIAN UNIV OF TECH

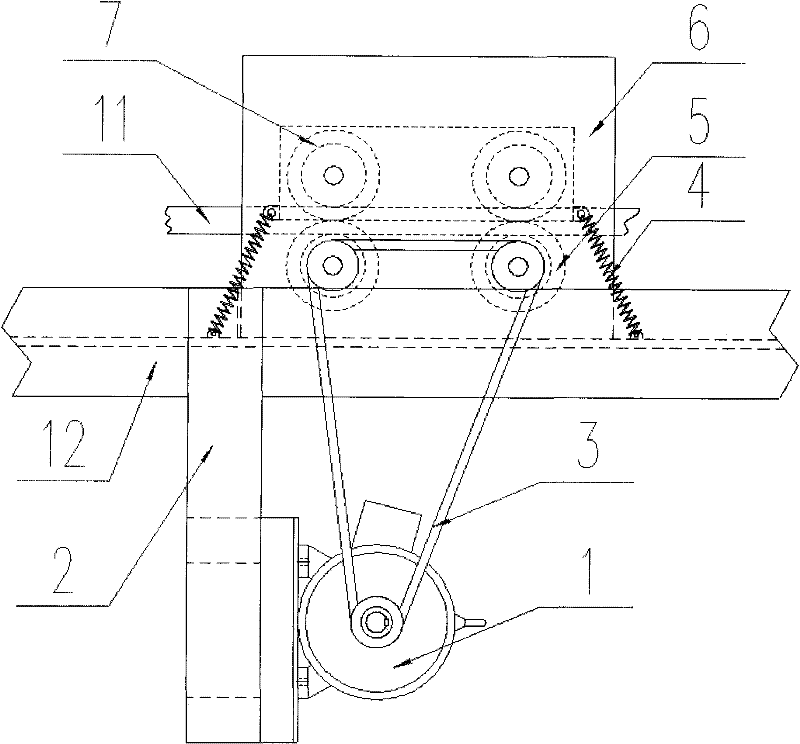

Tube stock loading device

The invention relates to a tube stock loading device and belongs to the field of tube processing, and the tube stock can be used for solving the defects that the artificial drawing machine in the prior art is hard to load and the production efficiency is low. The tube stock loading device comprises a driving mechanism, a bracket and a shell; and the driving mechanism is fixed on the bracket, and the shell is arranged above the bracket. The tube stock loading device is characterized in that the corresponding upper roller and lower roller are fixed in the shell through a rotary shaft, an upper groove and a lower groove are respectively arranged in the middle parts of the upper roller and the lower roller, and the upper groove and the lower groove are combined into a tube stock placing hole; and the lower roller is connected with the power output shaft of a motor through a transmission mechanism. The tube stock loading device is used for drawing machines.

Owner:SHANDONG ZHONGJIA NEW MATERIALS

Encoder coded disc eccentricity detection equipment and eccentricity adjusting method

ActiveCN112729172AReduce eccentricity errorHigh measurement accuracyUsing optical meansGratingMechanical engineering

The invention discloses encoder coded disc eccentricity detection equipment. The equipment comprises a rotating device used for driving a rotating shaft of an encoder to be detected to rotate, a first optical grating which is fixedly arranged on a coded disc of the encoder to be tested and is a circular optical grating or a circular optical grating which is concentric with a code channel of the coded disc, a light source, a second optical grating fixed in relative position with the rotating shaft and a Moire fringe detector, wherein light output by the light source passes through the first optical grating and the second optical grating to generate Moire fringes changing along with rotation of the coded disc; the Moire fringe detector is used for detecting the Moire fringes and outputting eccentric data according to the Moire fringes so as to determine the eccentricity of the coded disc relative to the rotating shaft. According to the invention, the eccentric data of the coded disc relative to the rotating shaft is determined by utilizing the Moire fringes formed by the first optical grating and the second optical grating, so that the eccentric error of the encoder is reduced to a great extent, and the measurement precision of the encoder is improved. The invention further provides an encoder eccentricity adjusting method which has the above beneficial effects.

Owner:长春长光启衡传感技术有限公司

Method for reducing drive eccentric errors of harmonic gear and automatic aligning wave generator

The embodiment of the invention discloses a method for reducing drive eccentric errors of a harmonic gear and an automatic aligning wave generator. The automatic aligning wave generator comprises a turn plate driven by an input shaft and an elastic floating mechanism provided with two rollers. The elastic floating mechanism is flexibly arranged inside the turn plate in a sliding manner in the long axis direction of the automatic aligning wave generator. The elastic floating mechanism comprises two roller brackets symmetrically distributed relatively to the centre of the turn plate and an elastic element arranged between the roller brackets; the elastic element elastically resists against the two roller brackets, and the two rollers are respectively arranged on the two roller brackets, elastically resist against an inner circle of a flexible gear under the action of the elastic element and force the flexible gear to form an ellipse from a round shape, so that gear teeth of the flexible gear are tightly meshed with gear teeth of a rigid gear. The automatic aligning wave generator can reduce the eccentric errors caused by processing and assembling of parts, can remove the gear backlash between the gear teeth of the flexible gear and the gear teeth of the rigid gear and play an overload protection role.

Owner:深圳市东汇精密机电有限公司

Spindle system

InactiveCN103317155AExtended service lifeSmall repeatability errorMeasurement/indication equipmentsGear-cutting machinesEngineeringMechanical engineering

The invention relates to the technical field of photoelectric measurement, and specifically to a spindle system. The spindle system comprises a motor, a base and a spindle arranged on the base, wherein a measuring device is arranged at the end part of one end of the spindle while a dividing head is arranged at the end part of the other end of the spindle; the spindle is arranged on the base through a holding frame; and multiple rolling balls are arranged between the spindle and the holding frame. The spindle system reduces 0.5 times eccentric error of the spindle, can position a cutter on a cutter head exactly, enables the cutter to be adjusted conveniently, reduce friction between the spindle and the holding frame, prolongs the service life of the spindle efficiently and reduces repeated error of the spindle system. In addition, the spindle system also has the advantages of a light weight and a great supporting capacity.

Owner:贵阳新天光电科技有限公司

Measuring instrument for space curve type long distance fine pipe internal surface shape and its detecting method

InactiveCN1314941CShorten the lengthReduce weightFluid-tightness measurementUsing optical meansMeasuring instrumentThree dimensional measurement

The present invention discloses a space curve type long-distance microfine pipe internal surface form measurement instrument and its detection method. Said pipe internal surface form measurement instrument is formed from the components of 2-D position sensor, semiconductor laser, transparent window, micromotor, scanning lens, reflector, convergent lens and receiving lens group, etc. Said measurement instrument is applicable to defect detection and 3-D measurement of curve type microfine pipe internal wall whose inner diameter is 9-11 mm and curvature radius is greater than 100 mm, and its measuring accuracy can be up to plus or minus 0.1 mm.

Owner:ZHEJIANG UNIV

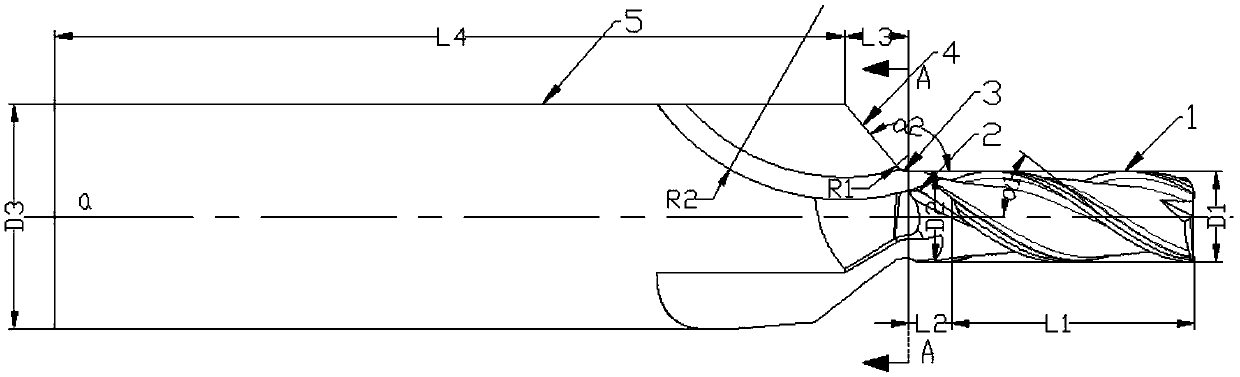

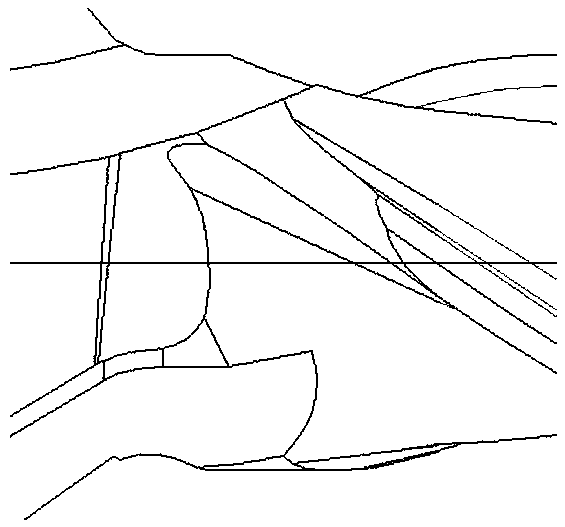

Helical hole milling-spot-spotting-rounding integrated tool

The invention discloses a helical hole milling-dimpling-rounding integrated tool. The helical hole milling-dimpling-rounding integrated tool comprises a tool body composed of a tool handle and a cutting part. The cutting part comprises a helical hole milling cutting edge part, a helical hole milling cutting neck part, a rounding cutting edge part and a dimpling cutting edge part which are arranged sequentially from front to back. The dimpling cutting edge part is connected with the tool handle. The helical hole milling cutting edge part comprises three helical hole milling cutting edges arranged in the peripheral direction of the tool body. The rounding cutting edge part comprises three rounding cutting edges arranged in the peripheral direction of the tool body. The dimpling cutting edge part comprises three dimpling cutting edges arranged in the peripheral direction of the tool body. The edge parts of the three rounding cutting edges are located in the non-slotted position of the helical hole milling cutting neck part. The front ends of the rounding cutting edges are all tangential to the outer diameter of the helical hole milling cutting neck part, and the rear end of each rounding cutting edge is tangential to the front end of the correspondingly arranged dimpling cutting edge. The three rounding cutting edges and the helical hole milling cutting edge part are arranged in a staggered mode. The machining precision is improved by adopting the helical hole milling-dimpling-rounding integrated tool.

Owner:TIANJIN UNIV

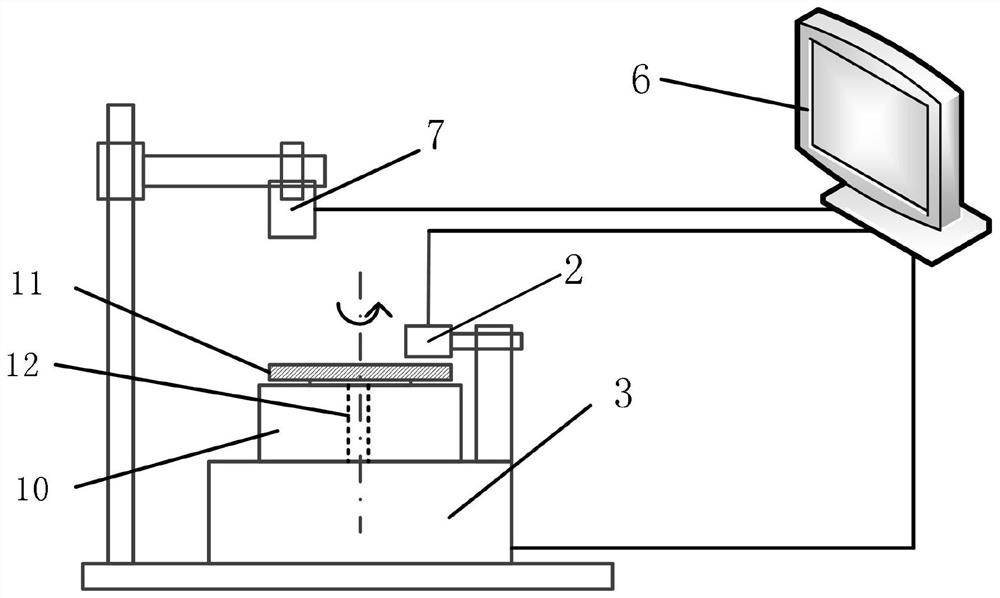

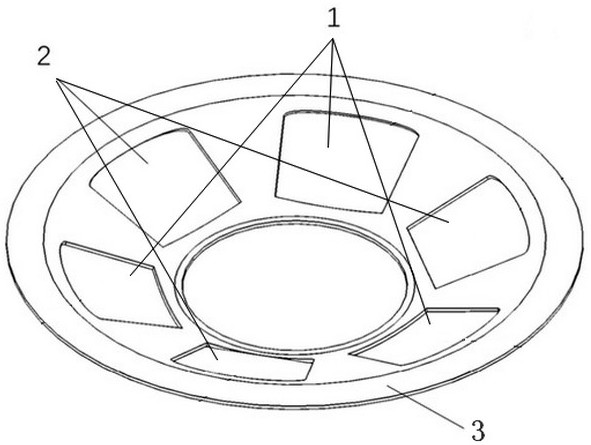

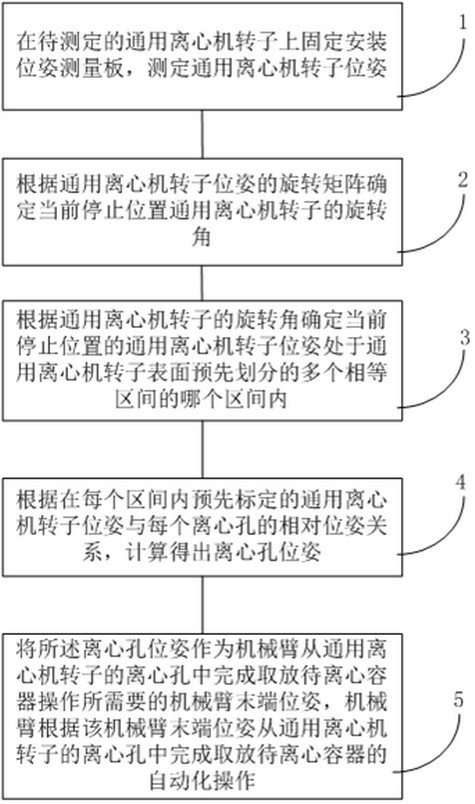

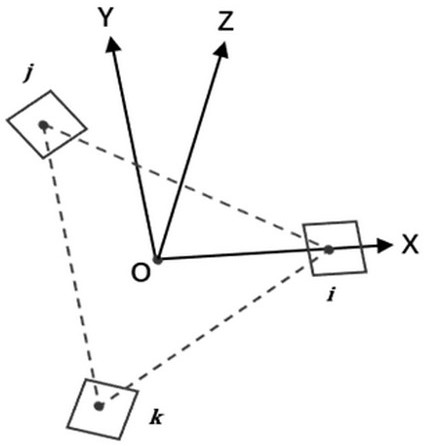

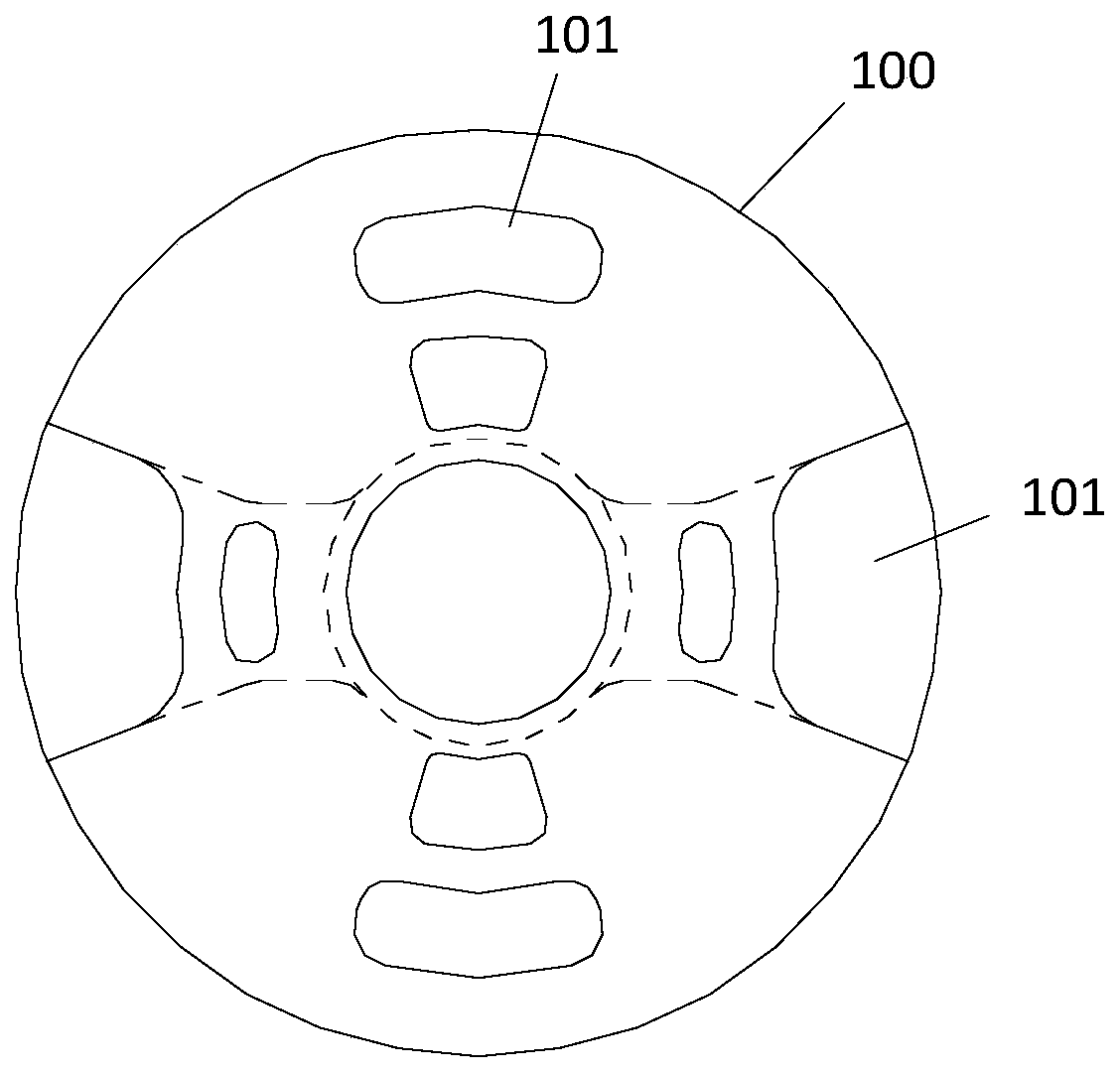

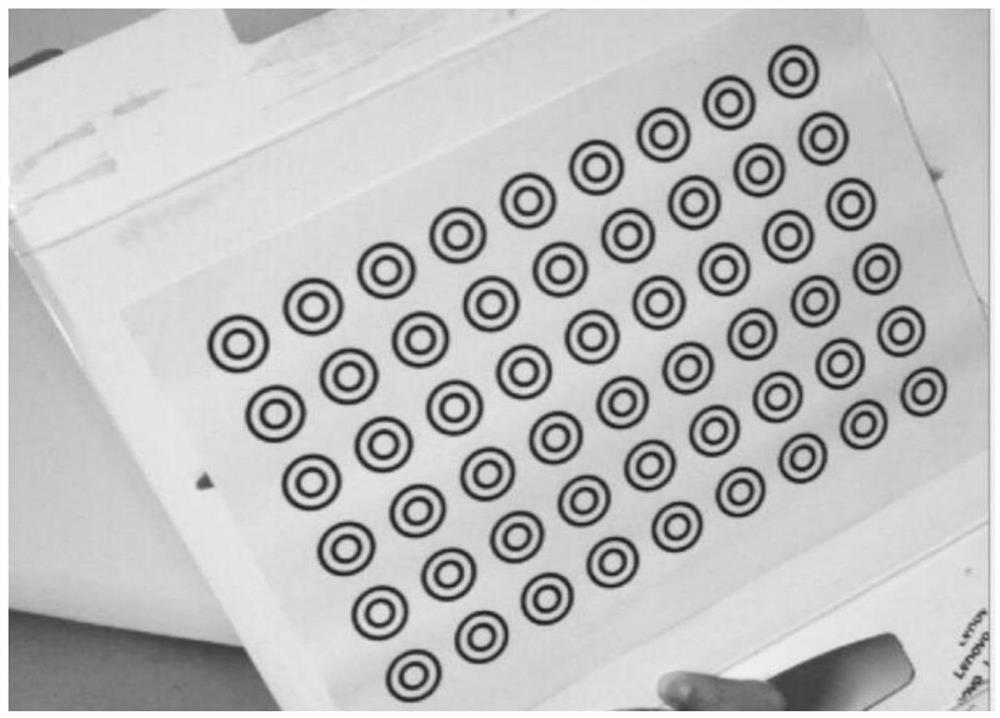

Pose measuring plate and method for automatically operating universal centrifugal machine through mechanical arm

ActiveCN114653490AAccurate operationLow costUsing optical meansCentrifugesClassical mechanicsMachine

The invention discloses a pose measuring plate and a method for automatically operating a universal centrifuge through a mechanical arm, and the method comprises the steps: fixedly installing the pose measuring plate with three labels on a rotor of the universal centrifuge to be measured, measuring the pose of the rotor of the universal centrifuge, determining a rotation angle, and determining which interval the rotor is located in; and according to the relation between the position and posture of the rotor of the universal centrifugal machine calibrated in advance in each interval and the relative position and posture of each centrifugal hole, the position and posture of the centrifugal hole are calculated, and the position and posture of the tail end of the mechanical arm are obtained according to the position and posture of the centrifugal hole. And the mechanical arm completes automatic operation of taking and placing the container to be centrifuged from the centrifugal hole of the rotor of the general centrifugal machine according to the tail end pose of the mechanical arm. The method is suitable for the mechanical arm to operate most centrifugal machines, hardware transformation does not need to be carried out on the interiors of the centrifugal machines, the stopping positions of the rotors before and after centrifugation do not need to be changed, and the method can be universally used for automatic operation of the mechanical arm on the universal centrifugal machines.

Owner:UNIV OF SCI & TECH OF CHINA

Turning clamp of cast iron oil distribution disc

PendingCN110280784ARealize clamping positioningHigh positioning accuracyTailstocks/centresChucksOil distributionTailstock

The invention discloses a turning clamp of a cast iron oil distribution disc. The turning clamp comprises a positioning seat, a pointed end seat and a pressure block, wherein the positioning seat is arranged on a three-jaw chuck of a main shaft of turning equipment and is used for supporting the large end surface of the cast iron oil distribution disc; the end part of the positioning seat is provided with a positioning assembly, and the positioning assembly corresponds to the position of a flow distribution window of the cast iron oil distribution disc; one end of the pointed end seat is connected with a tailstock of the turning equipment and is matched with the tailstock to carry out positioning and pressing on the cast iron oil distribution disc; and the pressure block is connected with the pointed end seat through a rotary component and is used for pressing the small end surface of the cast iron oil distribution disc. According to the turning clamp, the positioning seat is arranged, the positioning assembly is arranged on the positioning seat, the positioning assembly is used for aligning the flow distribution window of the cast iron oil distribution disc, positioning and clamping of the cast iron oil distribution disc are realized, compared with a clamping mode of a three-jaw clamping outer circle in the prior art, the position precision and the coaxiality precision of the cast iron oil distribution disc are greatly improved.

Owner:苏州铼洛威液压泵有限公司

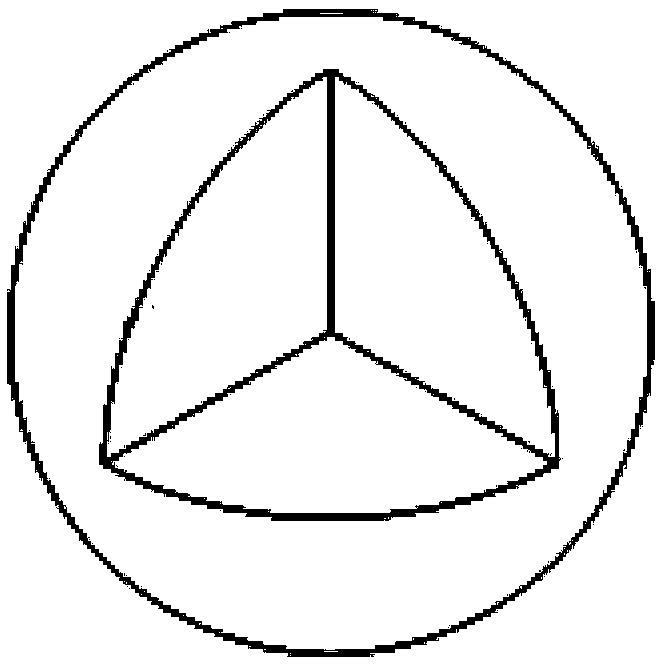

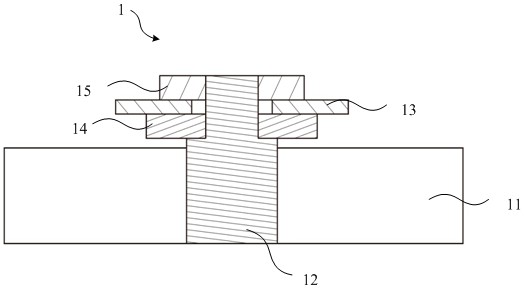

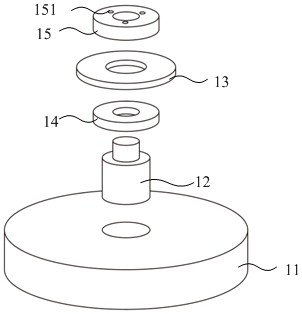

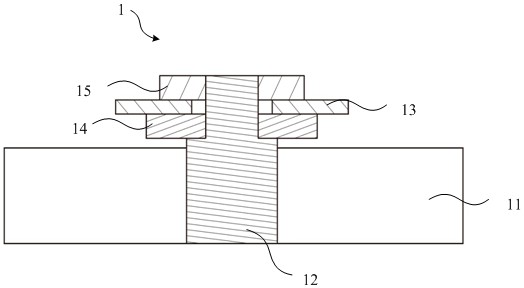

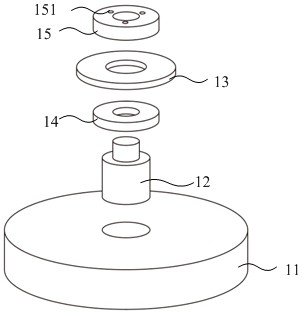

Integrated full metal reflection target ball

InactiveCN108802877ANot easy to damageReduce eccentricity errorUsing optical meansOptical elementsEngineeringMeasurement precision

The invention discloses an integrated full metal reflection target ball. The target ball is shaped in a ball with a groove, and the groove is provided with three faces which are perpendicular to one another. The target ball is integrated, when an environment temperature changes, a material of the target ball deforms integrally, decentration error caused by different dilatation coefficients of materials is avoided, influences of environment temperature change on the accuracy of measurement are reduced, and suitability for different working conditions is realized. The integrated full metal reflection target ball can be produced by only cutting off a triangular pyramid with edges as long as the ball radius and the three faces perpendicular to one another, extra assembling is not required dueto the fact that the target ball only has one part, surfaces of the three perpendicular faces are plated with fold films, and by plating the gold films on reflection faces, reflectivity of visible light waves can be increased.

Owner:四川拉姆达科技有限公司

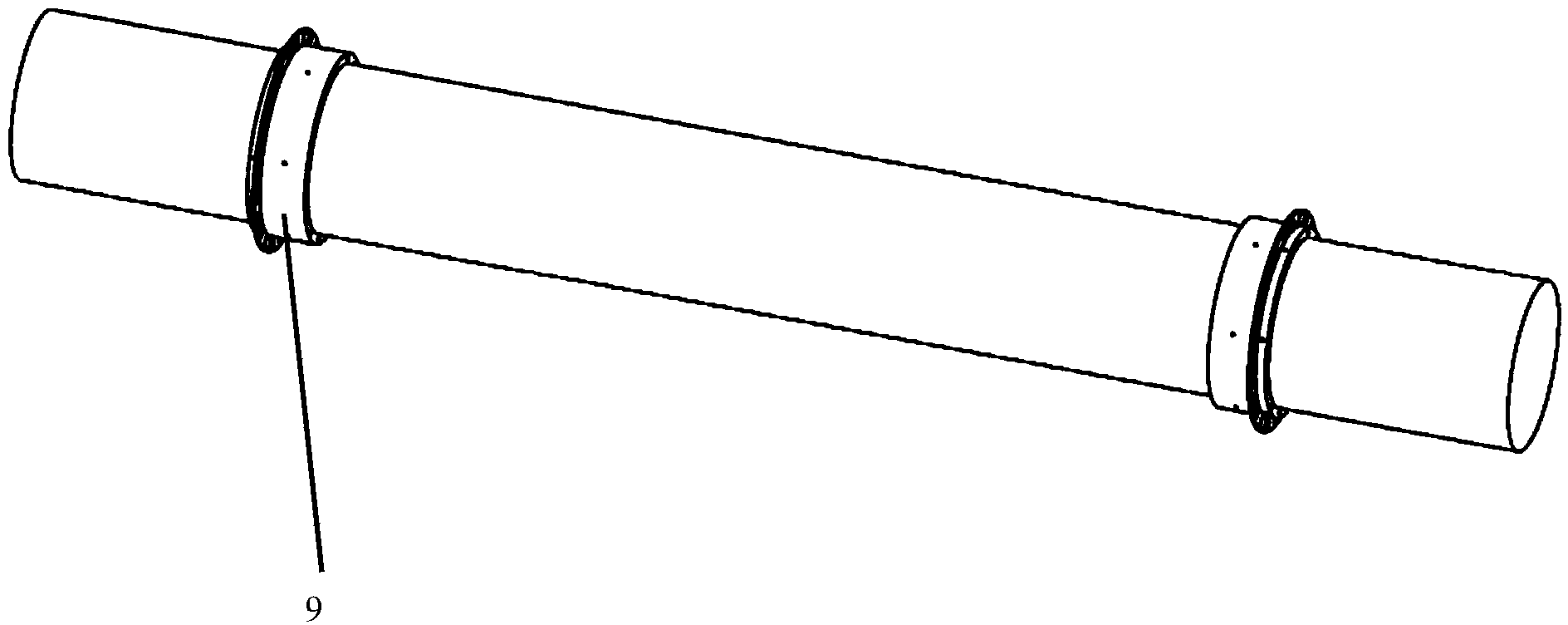

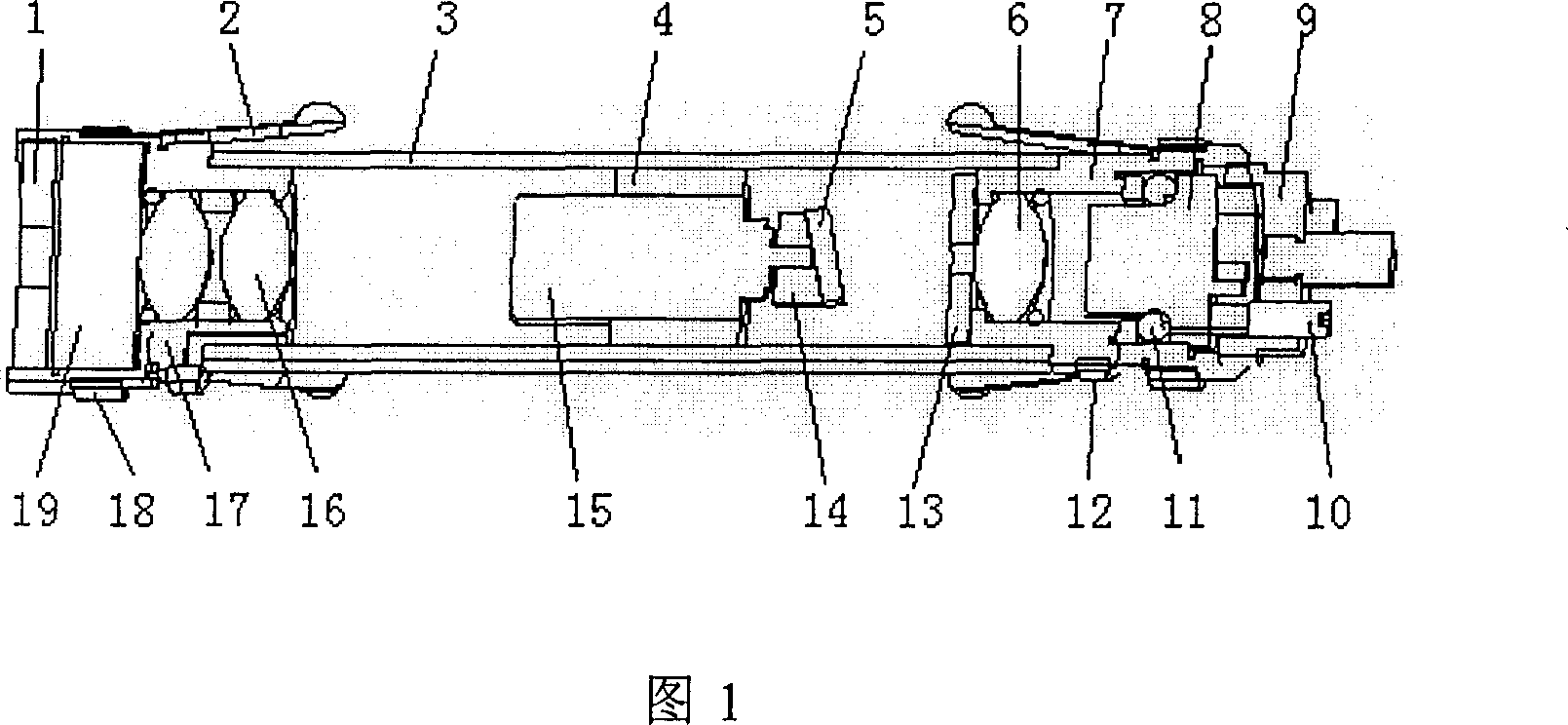

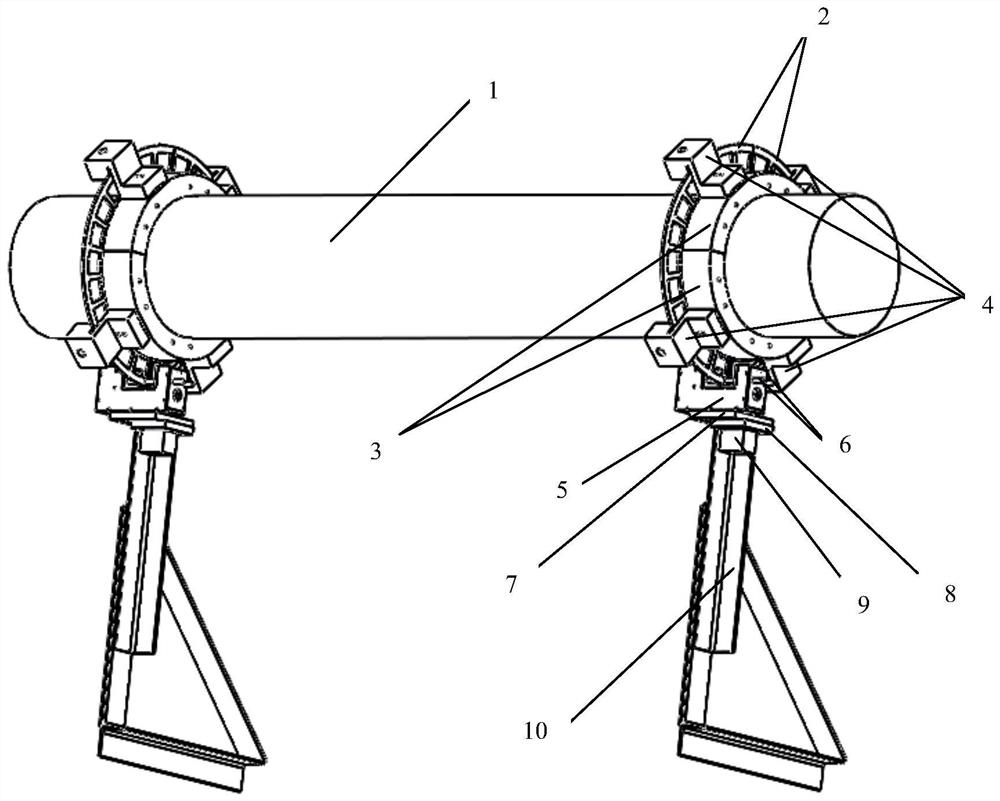

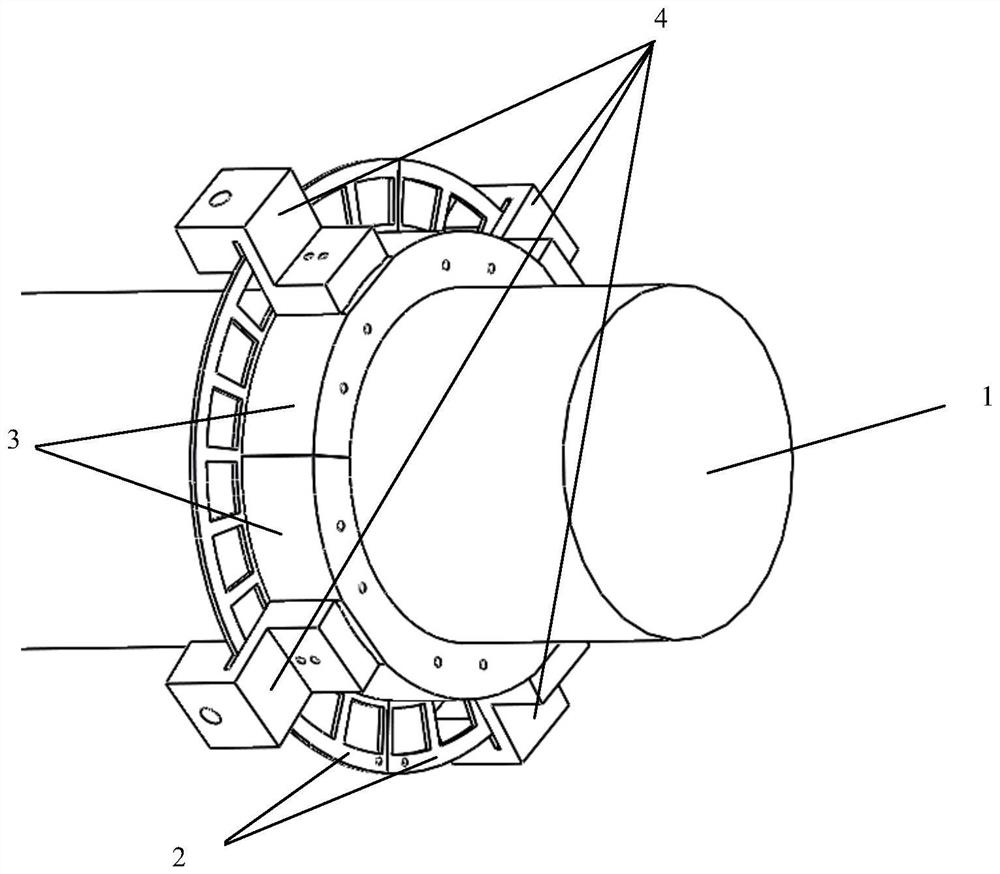

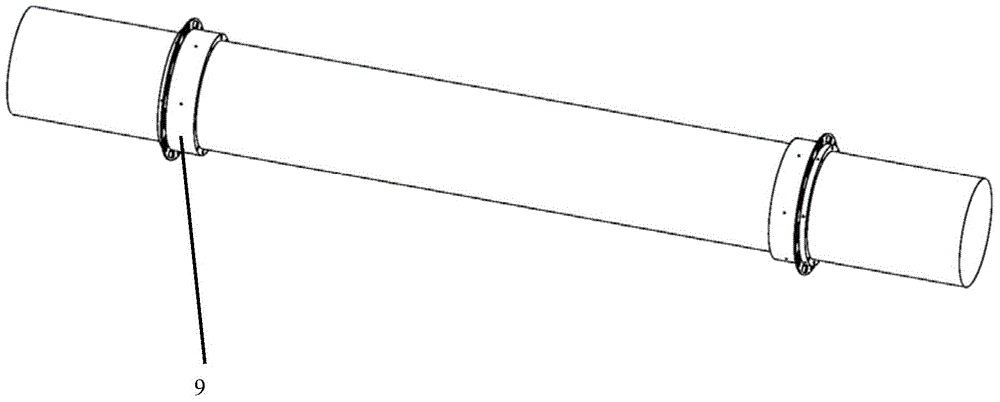

Coded disc mounting and positioning device of photoelectric non-contact ship shaft power meter

The invention relates to the technical field of mounting and positioning devices, in particular to a coded disc mounting and positioning device of a photoelectric non-contact ship shaft power meter. The device comprises a to-be-detected rotating shaft, photoelectric coded disc assemblies are respectively mounted at two ends of a shaft body of the to-be-detected rotating shaft through fixing and mounting accessories, a plane of each photoelectric coded disc assembly is perpendicular to an axis of the to-be-detected rotating shaft, circle centers of the photoelectric coded disc assemblies and the axis of the to-be-detected rotating shaft are coaxially arranged, photoelectric sensors are fixed to the photoelectric coded disc assemblies through fixing assemblies, and the photoelectric sensors are connected to fixed bases or fixed stands on a ship through connecting assemblies. According to the device, an eccentric error caused by the fact that the circle centers of the photoelectric coded disc assemblies do not coincide with the axis of the to-be-detected rotating shaft is eliminated, the problem of an offset error of tiny inclination of the photoelectric coded disc assemblies on the to-be-detected rotating shaft due to overlarge torque in a high-speed rotating process of the to-be-detected rotating shaft is avoided, therefore, the installation error problem of the whole shaft power meter is solved, and the measurement precision of the shaft power is improved.

Owner:WUHAN UNIV OF TECH

Device and method for measuring the outer diameter of a thin-walled bearing ring

ActiveCN111692950BReduce eccentricity errorHigh precisionMechanical diameter measurementsEngineeringTorsion spring

The invention discloses a device and method for measuring the outer diameter of a thin-walled bearing ring. The device includes a support frame, a workbench arranged on the support frame, a positioning mechanism, a measurement mechanism and a counter-arriving mechanism arranged on the workbench; A measuring center is set on the workbench, and the positioning mechanism includes a Y-axis positioning mechanism and an X-axis positioning mechanism arranged on the workbench; the measuring mechanism includes a torsion spring comparator slidingly arranged on the workbench and a The spring comparator moves along the Y-axis direction on the working table; Anti-resistance adjustment mechanism for the anti-resistance rod to move along the Y-axis guide groove. When the device uses a torsion spring comparator to measure the bearing ring, it can reduce the force measurement error and eccentricity error existing in the measurement of the thin-walled bearing ring, thereby improving the measurement accuracy of the outer diameter of the thin-walled bearing ring.

Owner:GUANGZHOU UNIVERSITY

Appearance measuring and detecting method for inner surface of space curve type long-distance microtubule

InactiveCN100501220CShorten the lengthReduce weightPipeline systemsDimension measurementThree dimensional measurement

The invention discloses a method for checking the surface condition of spatial curvature long-distance micro tube. The inventive machine is mainly formed by a two-dimension position sensor, a semi-conductor laser, a transparent window, a micro motor, a scanning mirror, a reflector, a convergent lens, and a receiving lens. The light of laser via two reflections will form a micro spot on the inner wall of tube, while said spot is received by the two-dimension position sensor. Via the current signal of two-dimension position sensor and the structural parameters of inventive machine, the invention calculates out the position of the spot in local three-dimension coordinate. The micro motor rotates the scanning mirror one round to obtain the positions of all sampling points of one section of inner wall of tube. The invention can be used in the defect check and three-dimension measurement of the inner wall of the curvature micro tube whose inner diameter is 9-11mm and radius is larger than 100mm, while the measurement accuracy can reach +- 0.1mm.

Owner:ZHEJIANG UNIV

Torque measurement probe for ship shafting with eccentricity error correction

InactiveCN103900747BEliminate errorsReduce eccentricity errorWork measurementTorque measurementEddy currentEngineering

The invention relates to a ship shafting torque measuring probe in an eccentric error correcting mode. The ship shafting torque measuring probe in the eccentric error correcting mode is mainly composed of a photoelectric receiving module (4), an eddy current displacement sensor (5), a photoelectric diode (3), a semiconductor laser (2), a laser clamping block (1) and a middle block (6), wherein the laser clamping block (1) and the middle block (6) are arranged on a base (7). The laser clamping block (1) is provided with through holes which are used for containing and fixing the semiconductor laser (2), and the photoelectric receiving module (4) is fixed to the middle block (6) and serves as an upholder of the photoelectric diode (3). The middle block (6) is used for clamping a connecting leading wire of the eddy current displacement sensor (5) and the photoelectric diode (3). According to the ship shafting torque measuring probe in the eccentric error correcting mode, an optimization design is adopted overall, space is saved, and the torsion phase angle deviation caused by code disc eccentric errors is eliminated. Meanwhile, the invention further provides two methods for obtaining an initial phase angle.

Owner:WUHAN UNIV OF TECH

A Double Air Gap Iron Core Electronic Current Transformer

ActiveCN103632823BConvenient live installationEasy to disassembleTransformersTransformers/inductances magnetic coresElectrical conductorDual core

The present invention provides an electronic current transformer with double air gap iron core. The electronic current transformer with double air gap iron core includes: a first double air gap iron core, on which a second An air gap and a second air gap, the connecting line between the first air gap and the second air gap passes through the center of the first double-gap iron core; the second double-gap iron core is connected to the first The double-gap iron cores are connected in series and arranged coaxially, the third air gap and the fourth air gap are set on the second double-gap iron core, and the connecting line between the third air gap and the fourth air gap passes through the The center of circle of the second double-gap iron core, and perpendicular to the connecting line between the first air gap and the second air gap; the conductor passes through the first double-gap iron core and the second double-air gap in turn The center of the gap iron core; the data processing chip is connected to the coils of the first double-air-gap iron core and the second double-air-gap iron core for receiving measurement data and performing analog-to-digital conversion on the measurement data displayed and output.

Owner:STATE GRID CORP OF CHINA +2

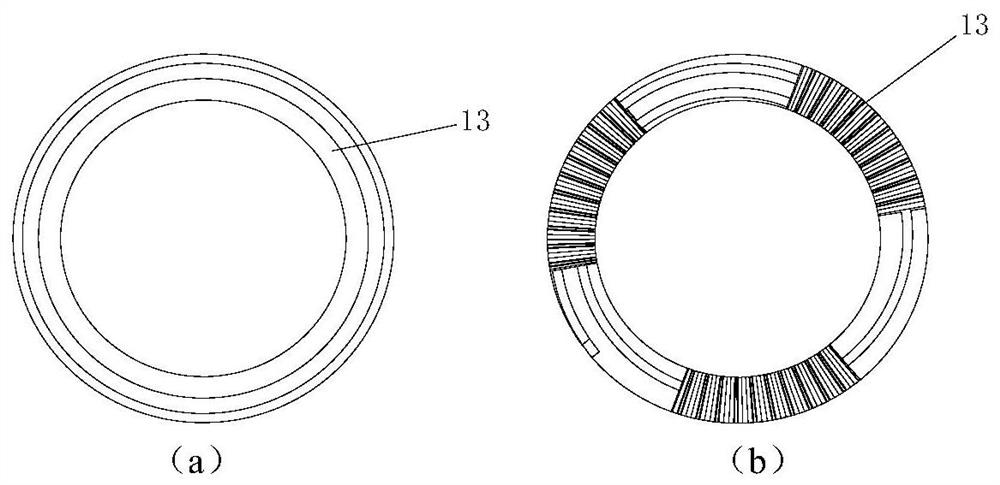

Assembly method of circular grating

Owner:CHOTEST TECH INC

A fast-clamping and self-aligning grinding wheel flange for precision grinding machines

ActiveCN109623652BReduce eccentricity errorPrecise alignment workGrinding wheel securing apparatusGear driveGear wheel

The utility model relates to a fast-clamping and self-aligning grinding wheel flange for a precision grinding machine, which relates to the field of precision grinding. Equipped with machine tool spindle, grinding wheel fixing nut, grinding wheel, self-aligning wrench, jaws, back end of centering device back cover, small bevel gear, front end of centering device back cover, centering device front cover, ball cover, bearing, large cone Gears and balls; first, install the statically balanced grinding wheel flange into the taper front end of the machine tool spindle, and pre-tighten it with the grinding wheel fixing nut, then insert the self-aligning wrench into the self-aligning hole of the flange, and the self-aligning wrench passes through the small bevel gear and The gear transmission of the large bevel gear drives the large bevel gear to rotate. At the same time, the feed movement of the claw is realized through the rack transmission between the plane thread on the large bevel gear and the claw. The claw that moves in three directions at the same time grasps the machine tool spindle to solve The problem of eccentricity between the center of the grinding wheel and the axis of the machine tool spindle is solved. The structure is simple, economical and reliable, and the clamping of the grinding wheel is realized; the eccentricity error in the assembly of the grinding wheel is effectively overcome.

Owner:XIAMEN UNIV

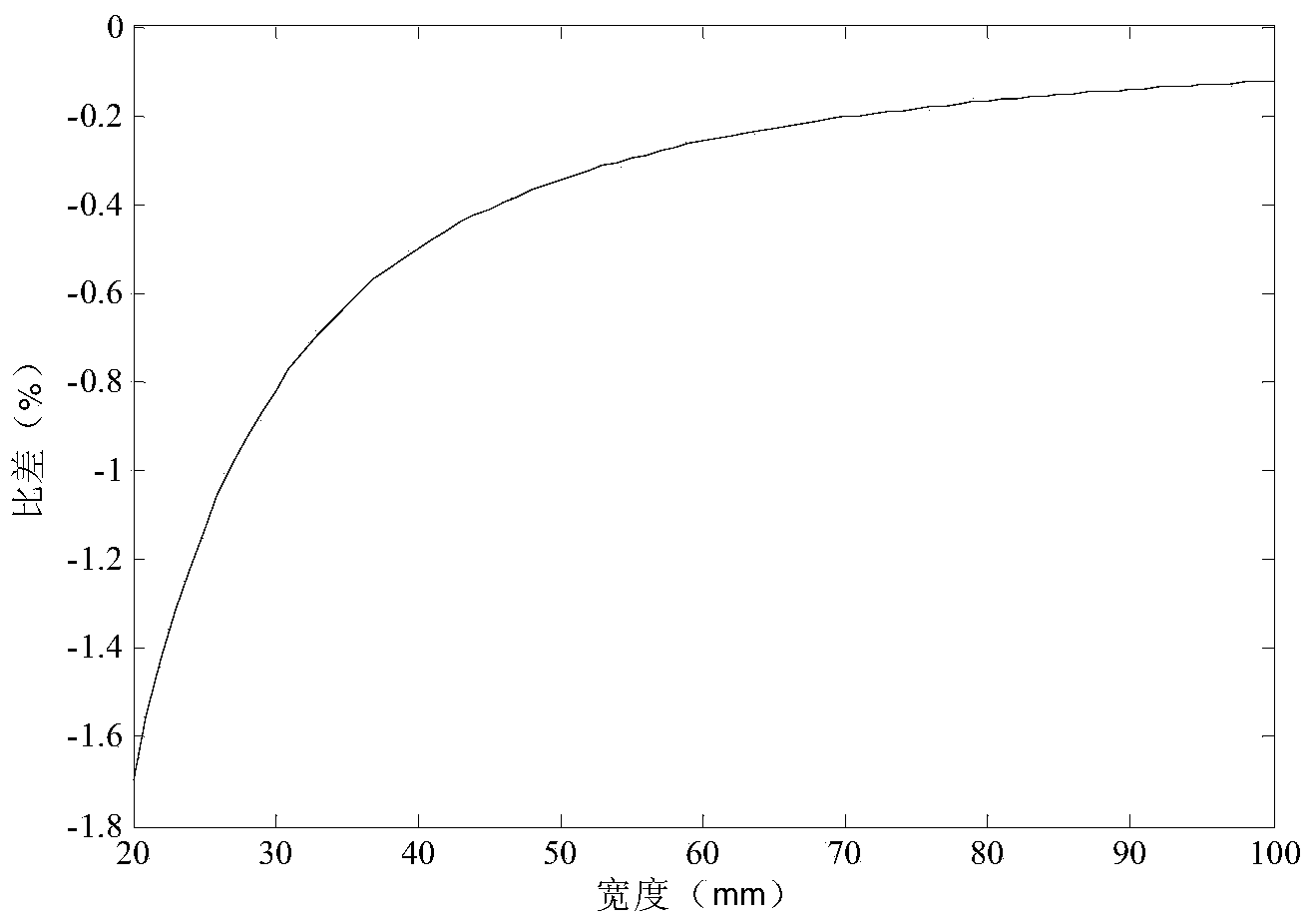

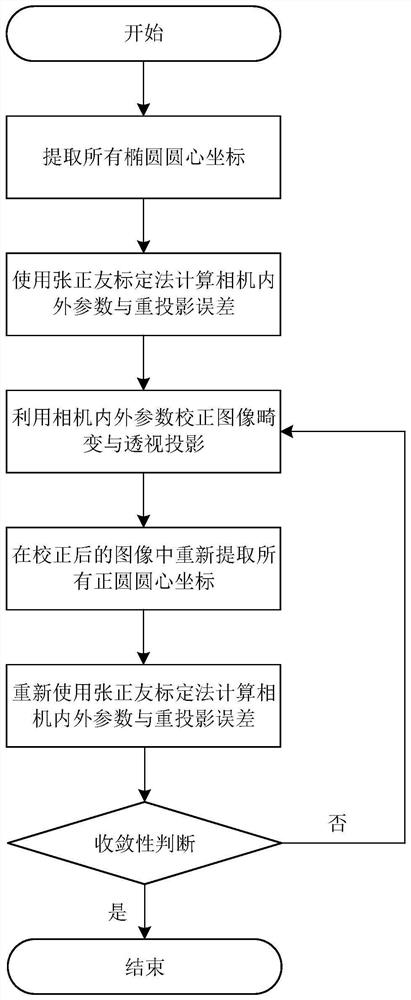

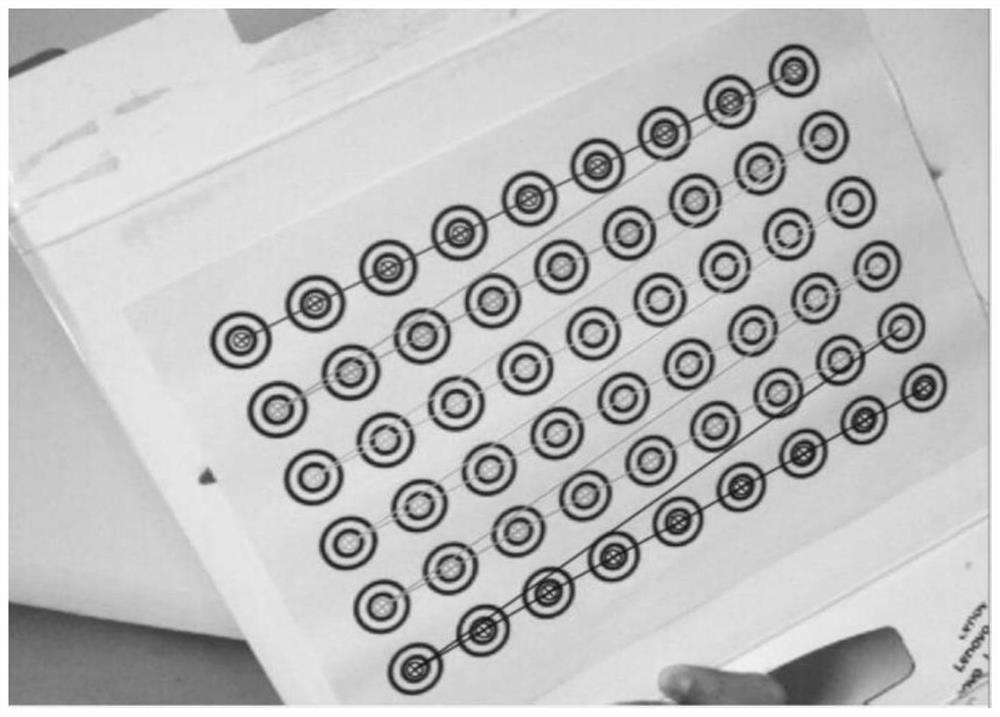

Iterative camera calibration method and device based on elliptic dual quadratic curve

ActiveCN114782553AImprove calibration accuracyHigh precisionImage analysisPattern recognitionComputer graphics (images)

The invention relates to an iterative camera calibration method based on an ellipse dual quadratic curve. The method comprises the following steps: extracting ellipse circle center coordinates on a calibration plate image; calibrating the camera according to the two-dimensional pixel coordinates and the three-dimensional space coordinates corresponding to the ellipse circle center coordinates, and solving to obtain camera parameters and a first projection error; correcting perspective projection and lens distortion in the calibration plate image, and converting the calibration plate image to a forward view; extracting circle center coordinates of a perfect circle on the corrected calibration plate image; re-projecting the perfect circle center coordinate back to the camera coordinate system, re-calibrating the camera according to the coordinate of the perfect circle center coordinate in the camera coordinate system, and solving to obtain a second re-projection error; and carrying out convergence judgment according to the first projection error and the second projection error. According to the iterative camera calibration method based on the elliptic dual quadratic curve, the re-projection error can be reduced by 92.4%, and the calibration precision of the camera is greatly improved.

Owner:JIANGNAN UNIV

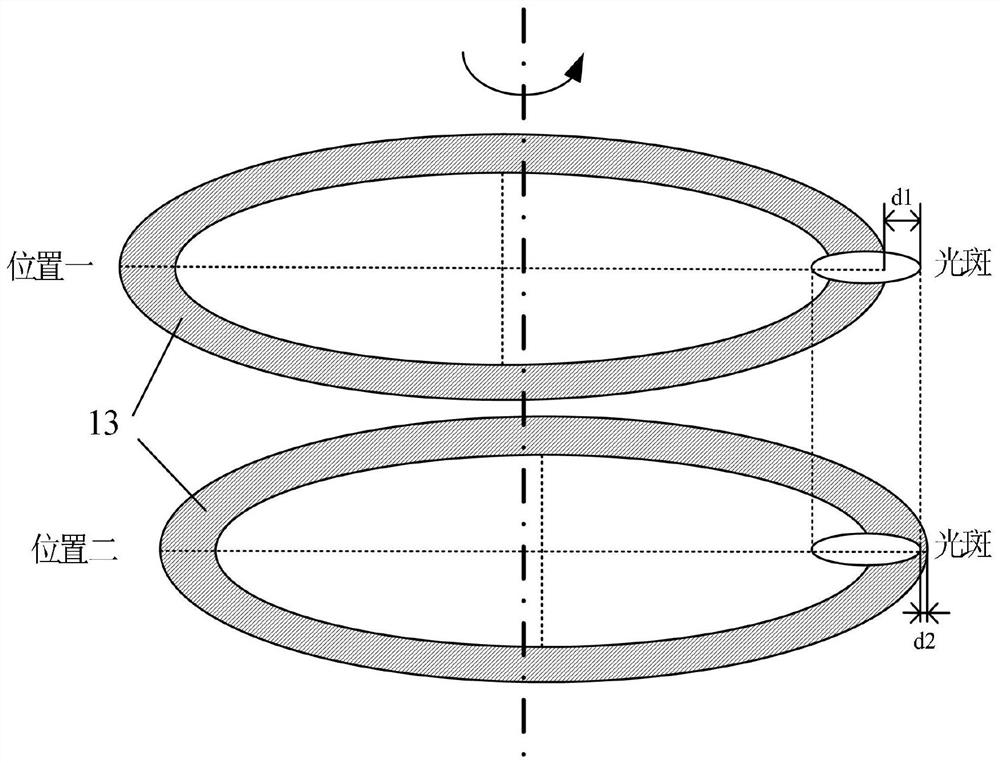

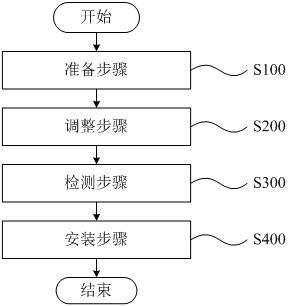

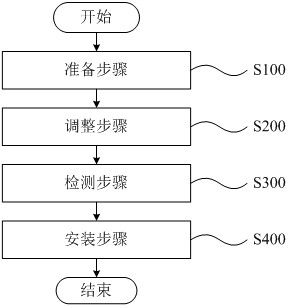

Assembling method of circular grating

ActiveCN113325539AReduce eccentricity errorUsing optical meansMountingsCentre of rotationRotational axis

The invention provides an assembling method of a circular grating. The assembling method comprises the steps: arranging the circular grating on a grating rotating shaft so that the circular grating can rotate relative to a base with the axis of the grating rotating shaft as the rotating center; capturing and presenting a grid line image with a grid line in the rotation process of the circular grating, and adjusting the relative position of the circular grating and a grating rotating shaft so as to enable the edge of one side of the grid line image to move to the dynamic range of the edge of the side; capturing grid line images of the circular grating at the at least two positions, converting the grid line images into a first electric signal and a second electric signal, obtaining an eccentric error of the circular grating based on the first electric signal and the second electric signal, and determining whether the eccentric error is smaller than a preset threshold; and a mounting step: if the eccentric error is smaller than a preset threshold value, fixing the relative position of the circular grating and the grating rotating shaft. In this case, the relative positions of the circular grating and the grating rotating shaft can be adjusted on the basis of the difference between the center of the circular grating and the axis of the grating rotating shaft.

Owner:CHOTEST TECH INC

Laboratory self-control pile sinking device

PendingCN109736367AReal-time monitoring of verticalityGuaranteed verticalityFoundation testingBulkheads/pilesSupporting systemElectric machinery

The invention belongs to the technical field of traffic transportation and building test equipment. The invention relates to a laboratory self-control pile sinking device. A hydraulic oil cylinder isconnected with a high-pressure oil pump and a loading controller serving as a controller to form the pile sinking device. When pile sinking is automatically controlled in a laboratory, a counter-forceframe is used as a supporting system for automatically controlling pile sinking; a gear and a rack are driven by a motor to perform lifting control of the laboratory self-control pile sinking device;a miniature laser displacement meter monitors the positions of the pile sinking device and a pile body and the perpendicularity condition of the pile body in a laboratory; and a leveling rod is usedfor monitoring the perpendicularity of the pile body during initial pile sinking, and the miniature laser displacement meter and the leveling rod are used for monitoring the perpendicularity of the pile body at the same time. Therefore, the perpendicularity of the pile body is guaranteed, a pipe pile can be conveniently, rapidly and accurately sunk to a designated position, and a laboratory modelpipe pile test is successfully completed.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com