Single-drive efficient high-precision magneto-rheological polishing machine for outer surface of ceramic tube

A magnetorheological polishing, high-precision technology, used in surface polishing machine tools, grinding drives, grinding/polishing equipment, etc. It does not meet the requirements of magnetic strength and other problems, and achieves the effect of realizing practicality and high precision, improving coaxiality and firmness, and improving magnetic field strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

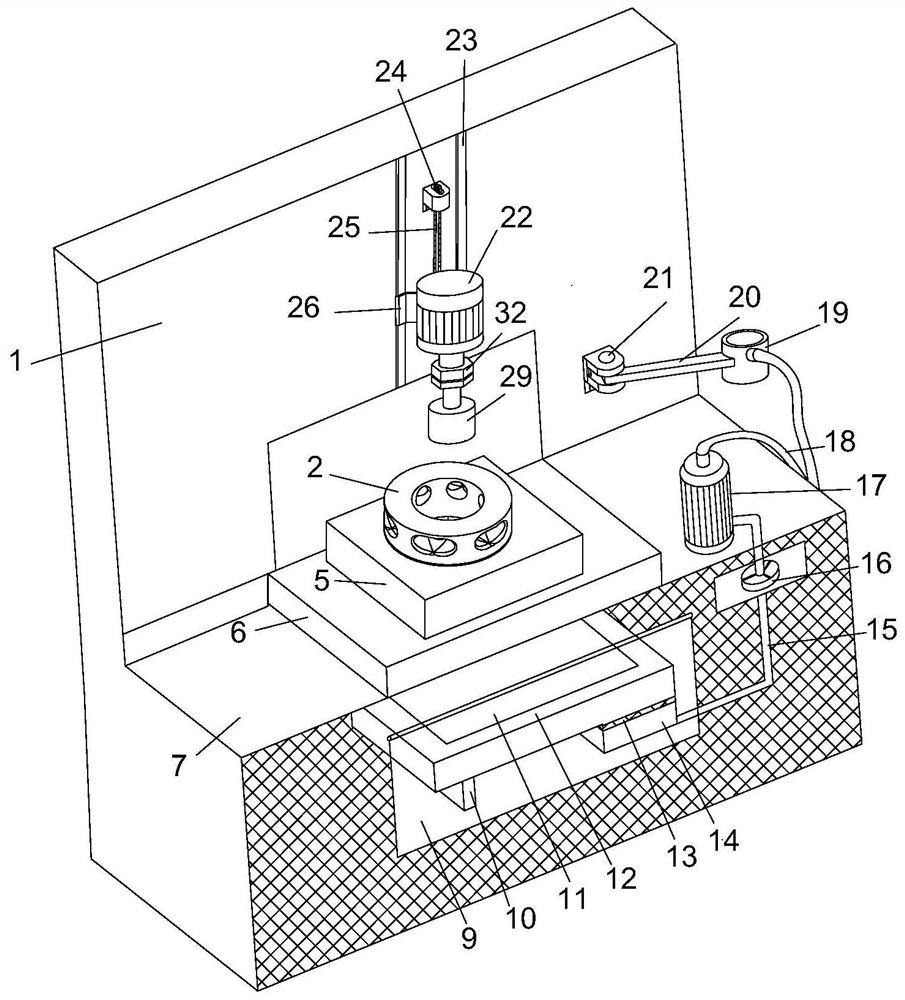

[0033] Such as Figure 1-8 As shown, a single-drive high-efficiency and high-precision ceramic tube outer surface magnetorheological polishing machine of the present invention includes a stand 1, a polishing head 2, a nozzle 19 and a magnetorheological polishing liquid supply mechanism;

[0034] A slide rail 23 arranged vertically is fixed on the back plate of the stand 1, and a lift frame 26 is slidably connected to the slide rail 23, and the lift frame 26 is driven by a lifting drive mechanism to move up and down along the slide rail 23, so The lifting frame 26 is fixed with a first motor 22, and the output shaft of the first motor 22 is connected with a fixing fixture 29 for fixing the ceramic tube through a coupling 32;

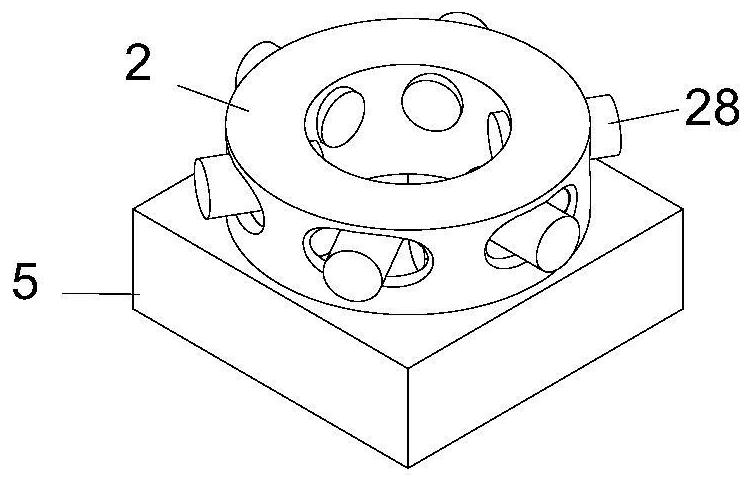

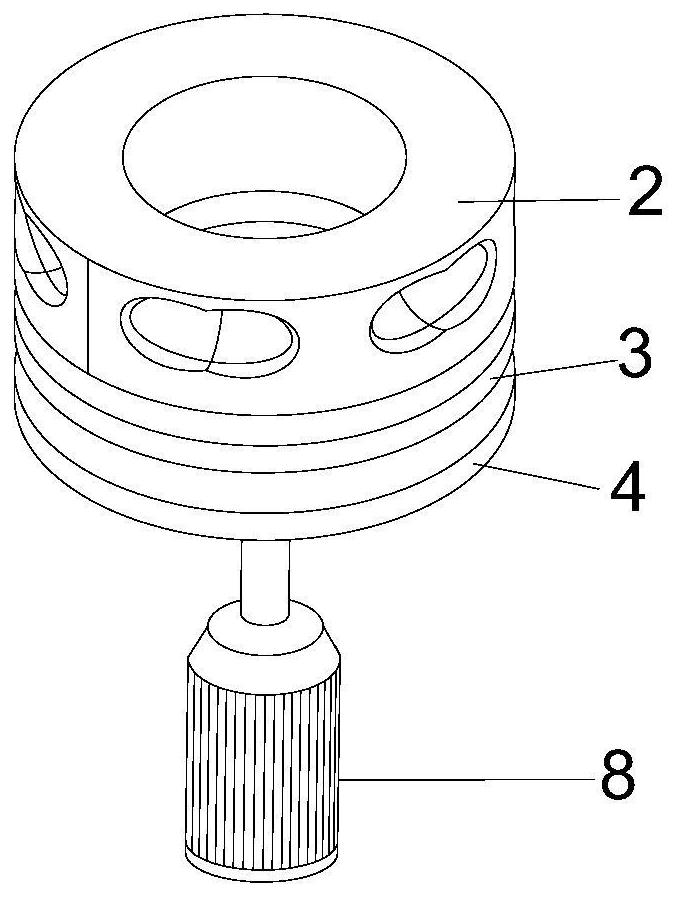

[0035] The polishing head 2 is placed on the table 7 of the stand 1 and is located directly below the first motor 22. The polishing head 2 has a ring structure, and the inside of the polishing head 2 is connected with a plurality of ring-shaped Halbach ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com