Helical hole milling-spot-spotting-rounding integrated tool

A technology of helical hole milling and corner rounding, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve problems such as the depth error of the spot facing, the matching of the tightening bolts of the spot facing hole, and the lack of rounding function, and reduce the number of corners. The number of tools, the effect of reducing the axis eccentricity error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

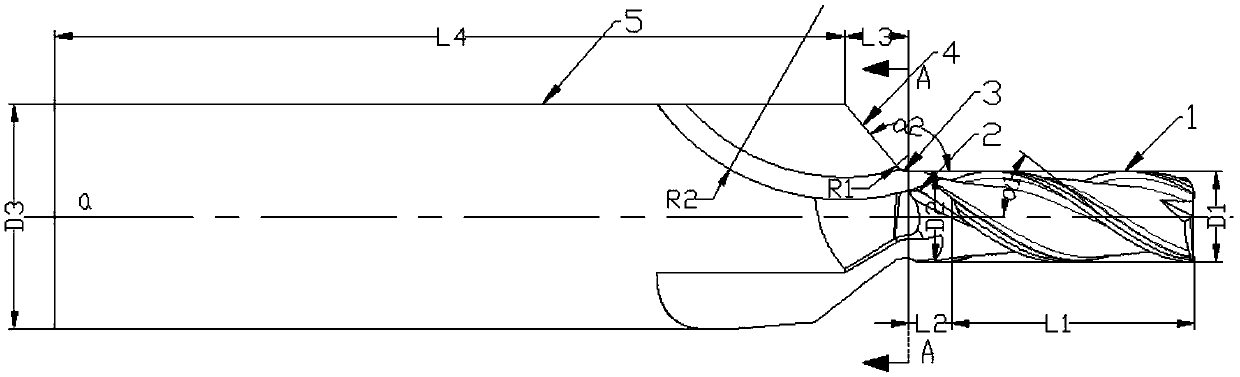

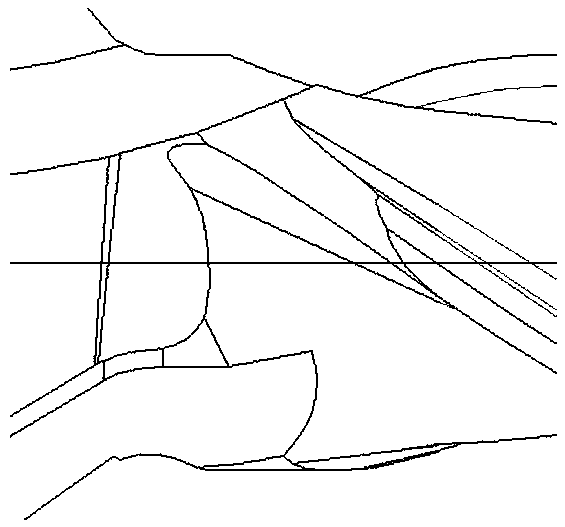

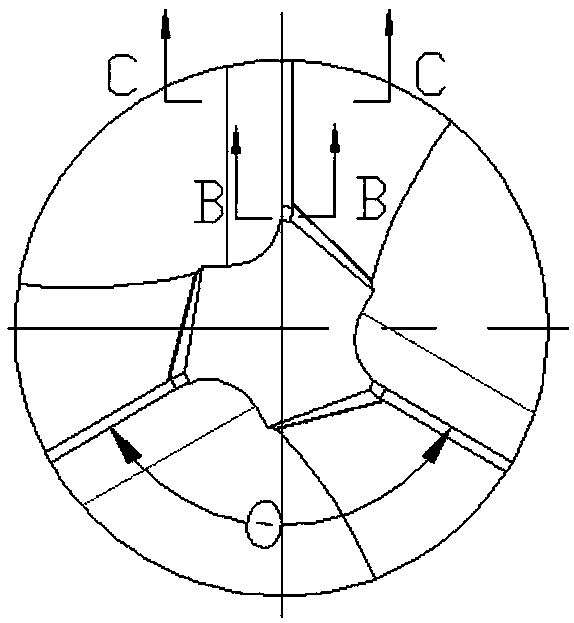

[0017] As shown in the accompanying drawings, the helical milling hole-sinking-rounding integrated tool of the present invention includes a cutter body composed of a handle 5 and a cutting part, and the cutting part includes helical milling holes arranged in sequence from front to back Cutting edge portion 1 , helical milling cutting neck portion 2 , rounded cutting edge portion 3 and spot facing cutting edge portion 4 . The countersink cutting edge is in contact with the handle, the helical milling cutting edge includes three helical milling cutting edges arranged along the circumferential direction of the cutter body, and the rounded cutting edge includes There are three rounded cutting edges arranged in the circumferential direction of the cutter body, and the countersinking edge portion includes three countersinking cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com