Integrated full metal reflection target ball

An all-metal, reflective target technology, applied in optics, measuring devices, instruments, etc., can solve problems such as different expansion coefficients, insufficient firmness, eccentricity errors, etc., and achieve the effect of improving reflectivity, simple structure, and small eccentricity errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

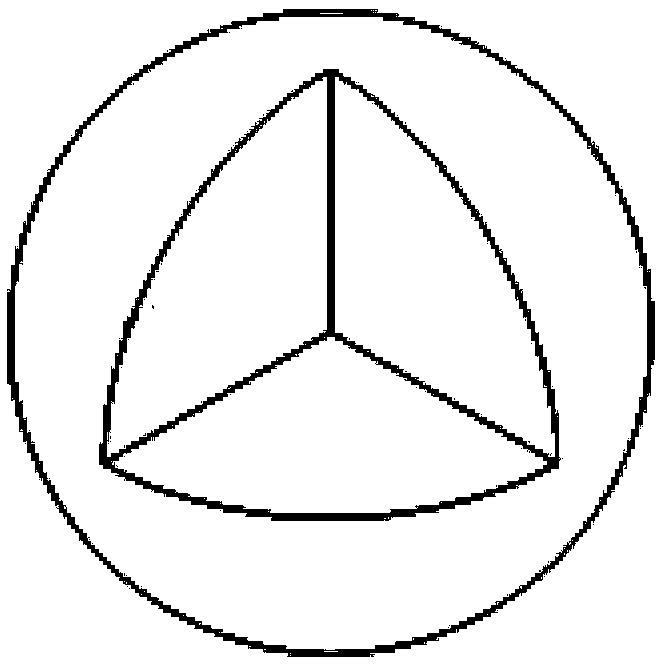

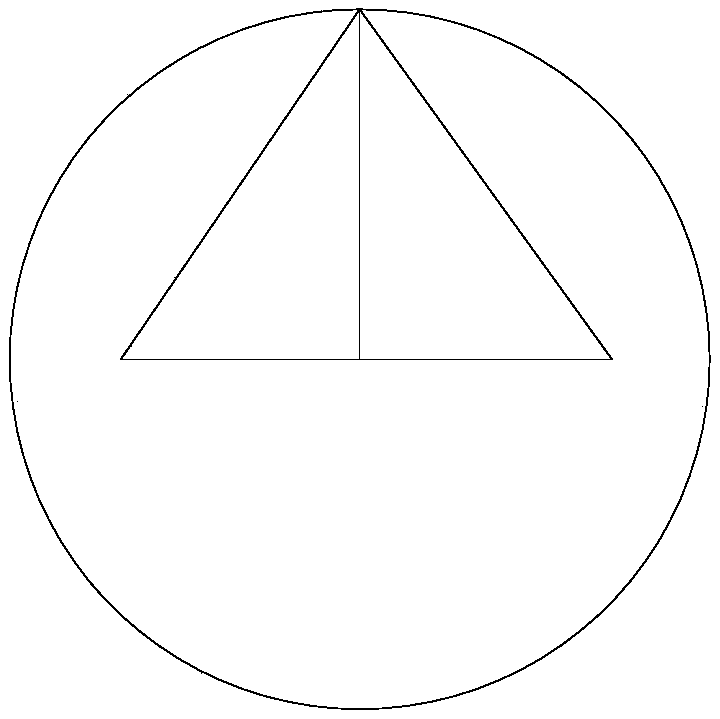

[0021] like figure 1 , 2 , 3, an integrated all-metal reflection target ball, the shape of the target ball is a sphere with a groove, and the groove has three mutually perpendicular surfaces. The entire target ball is integrated. When the ambient temperature changes, the overall uniform deformation of the material will not cause eccentricity errors caused by different material expansion coefficients, which reduces the impact of ambient temperature changes on the measurement accuracy, and is suitable for various working conditions. To use, it is only necessary to cut a triangular pyramid whose edge length is the radius of the sphere and the three faces are perpendicular to each other on a complete sphere. Only one part does not require additional adjustment. The surfaces of the three mutually perpendicular faces are plated with Gold film, the gold film on the reflective surface can improve the reflectivity of visible light waves. In this embodiment, the reflectivity can reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com