Sphere clearance measurement method

A measurement method and gap technology, applied in the field of measurement, can solve problems such as unsuitable for measurement, achieve the effect of fewer measurement points, simple calculation, and elimination of residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The measuring method of two sphere gaps proposed by the present invention comprises the following steps:

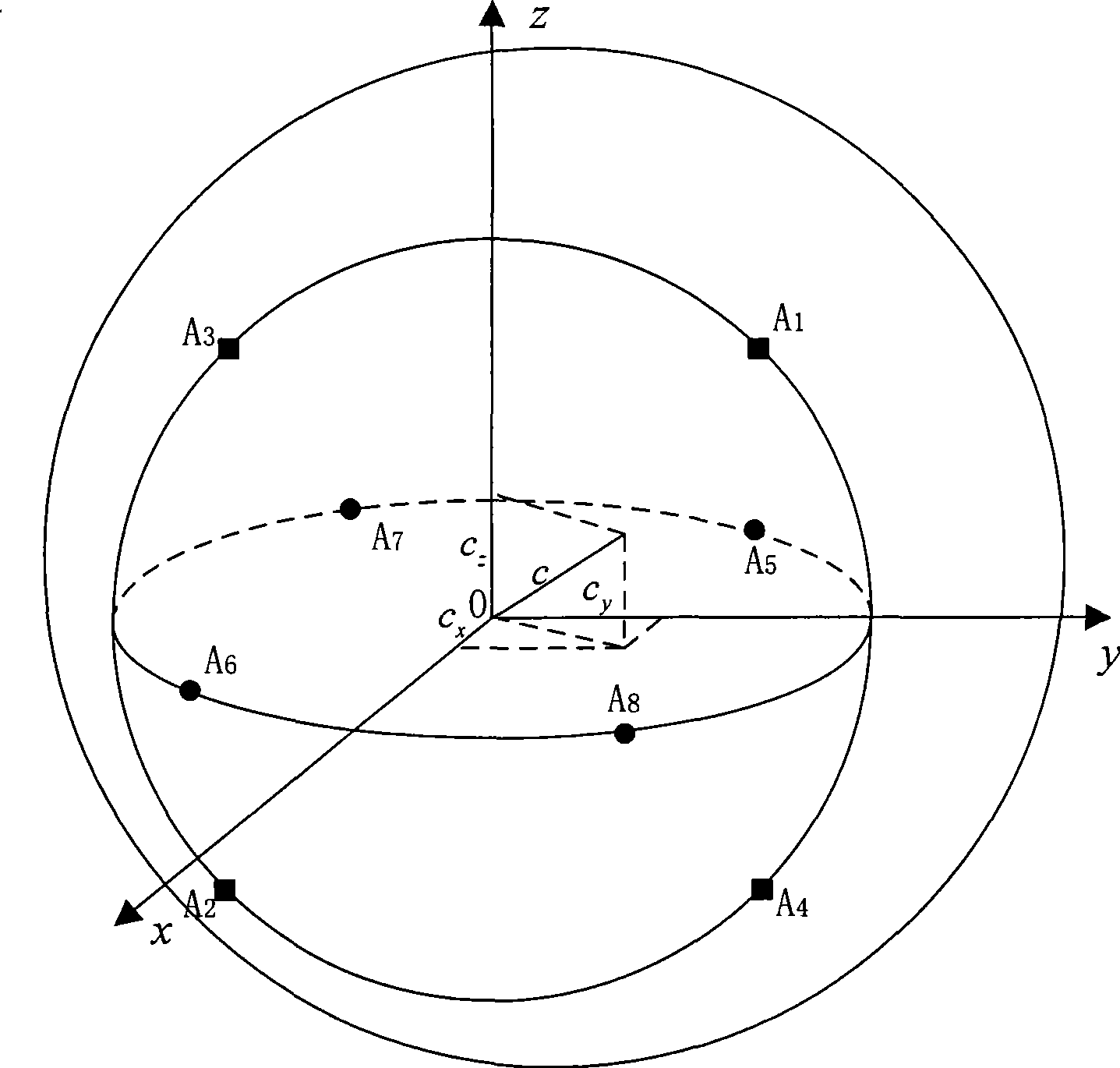

[0022] (1) On the inner spherical surface of the two spheres to be measured, two great circles perpendicular to each other are arbitrarily intercepted through the center of the sphere, and four measuring points are evenly distributed along the circumference lines of the two great circles, which is A 1 、A 2 、A 3 、A 4 、A 5 、A 6 、A 7 、A 8 ,Such as figure 1 shown.

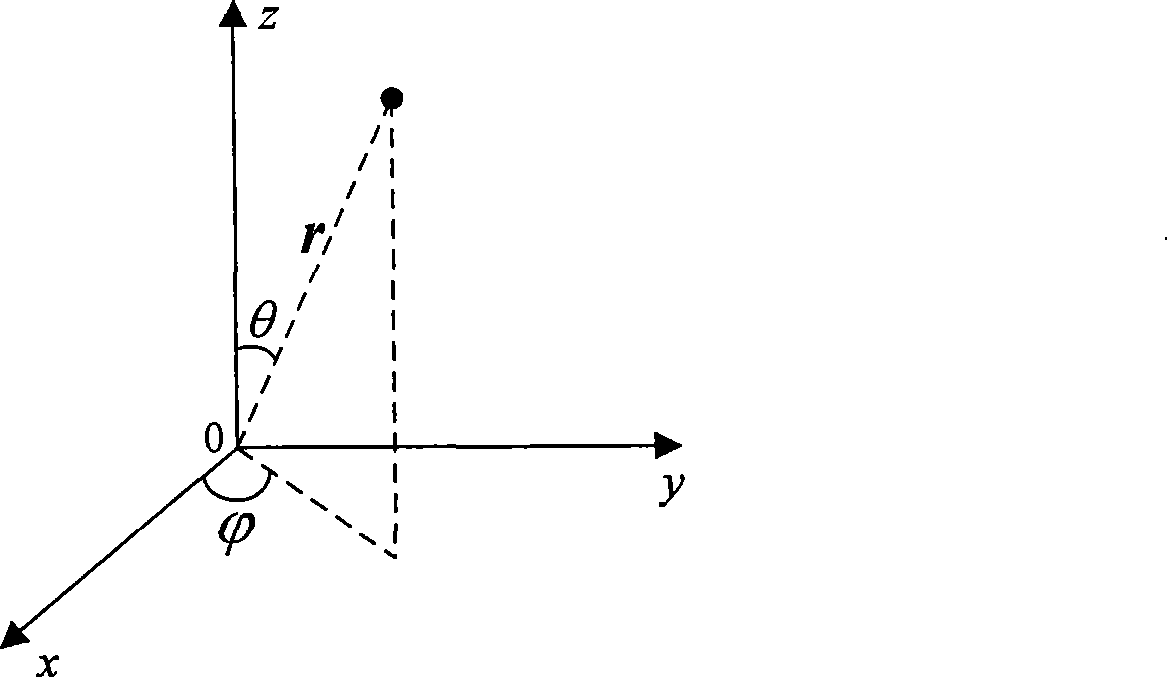

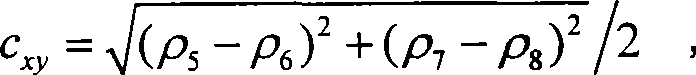

[0023] (2) Take the center of the inner spherical surface of the two measured spheres as the origin, and the intersection line of the two great circle planes where the measuring point is located is the y-axis, located at the measuring point A5 、A 6 、A 7 、A 8 The plane on which it is located and the straight line perpendicular to the great circle intersection is the x-axis, located at measuring point A 1 、A 2 、A 3 、A 4 The plane where it is located and the straight line perpendicular to the gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com