Ship shafting torque measuring probe in eccentric error correcting mode

A technology for eccentricity error and torque measurement, which is applied in the field of torque measurement probes for ship shafting, can solve problems such as large interference, poor anti-interference ability, and complex test circuits, and achieve fast response speed, improved measurement accuracy, and simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

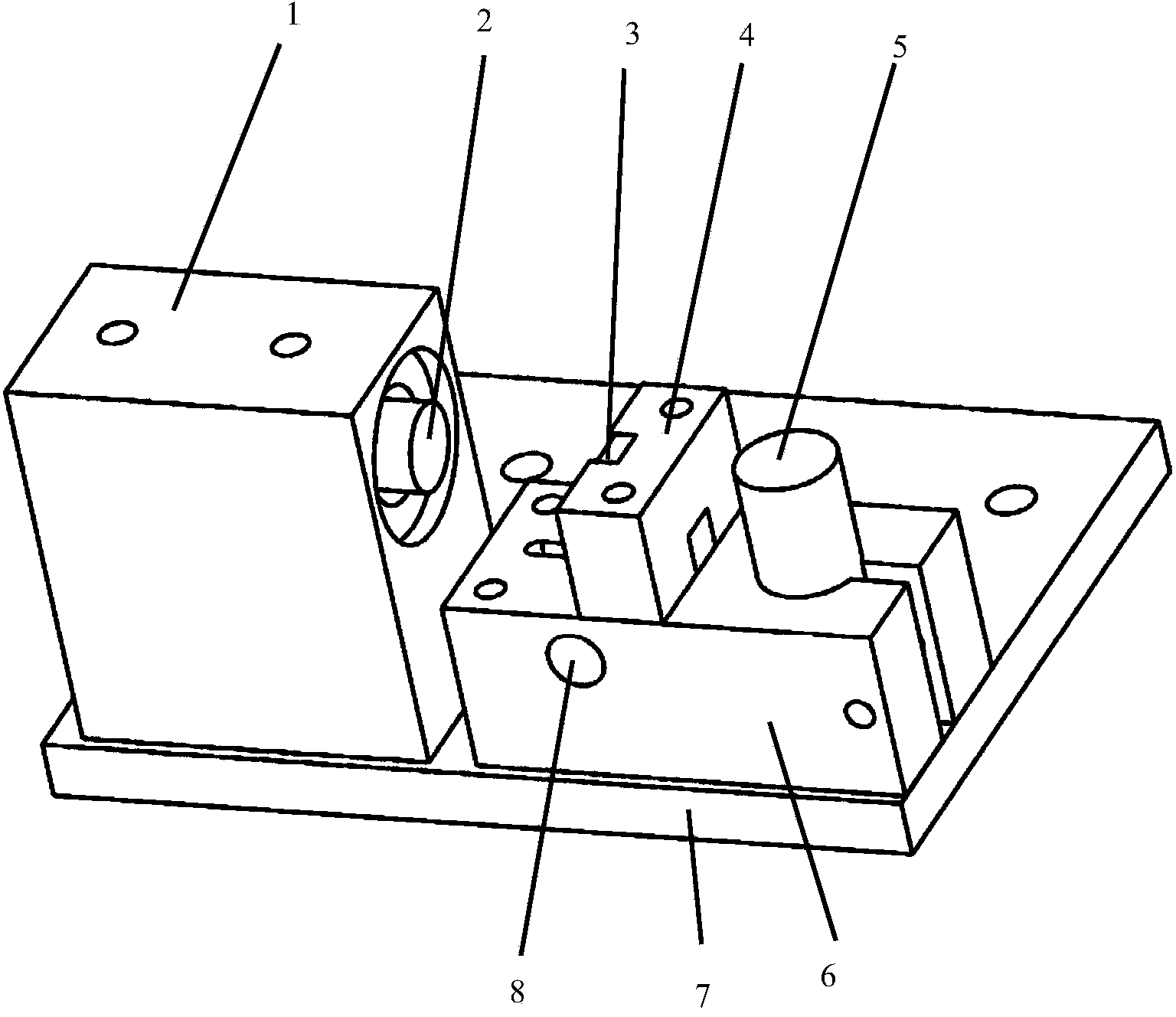

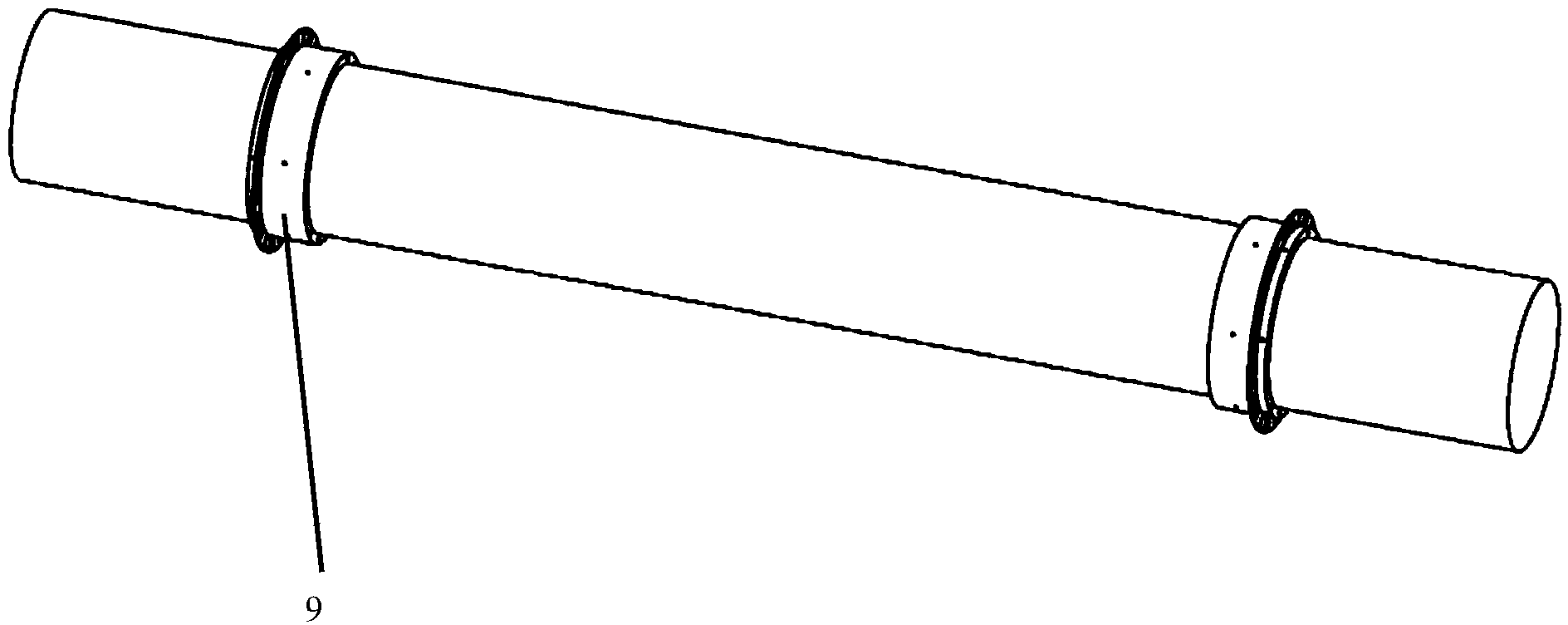

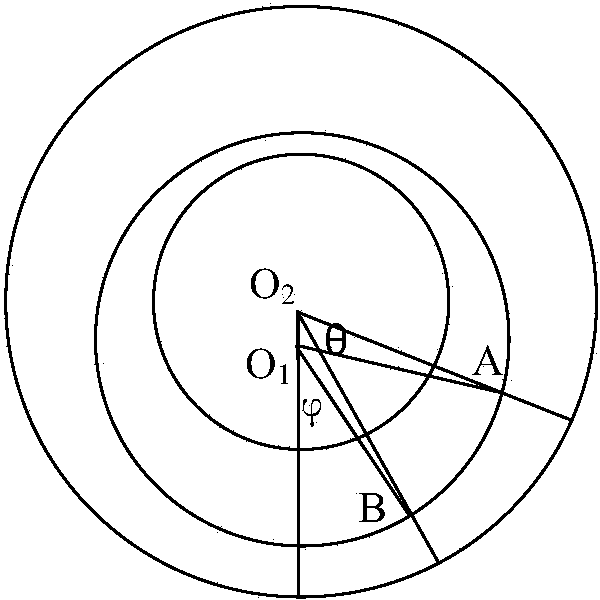

[0036] The eccentricity error correction type ship shafting torque measurement probe provided by the present invention adopts the structure of semiconductor laser + photodiode + eddy current displacement sensor, and the laser clamping block and the middle block are installed on the base at an appropriate distance to ensure that the inlaid The photodiode on the photoelectric receiving block fixed on the middle block and the semiconductor laser on the laser clamping block can form opposite beams. The semiconductor laser is connected with the aviation joint through the wire, the photodiode is connected with the aviation joint on the middle block through the wire, and the aviation joint is connected with the control circuit board through the cable. After the code disc rotates, due to the existence of eccentricity, as the distance between the code disc jacket and the eddy current displacement sensor changes back and forth, a periodic electrical signal appears in the eddy current sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com