Turning clamp of cast iron oil distribution disc

A technology of oil distribution plate and cast iron, applied in turning equipment, turning equipment, clamping, etc., can solve the problems affecting the quality of hydraulic equipment, large eccentric error between oil tank and pump core, etc., to eliminate eccentric error and improve position accuracy and coaxial precision, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

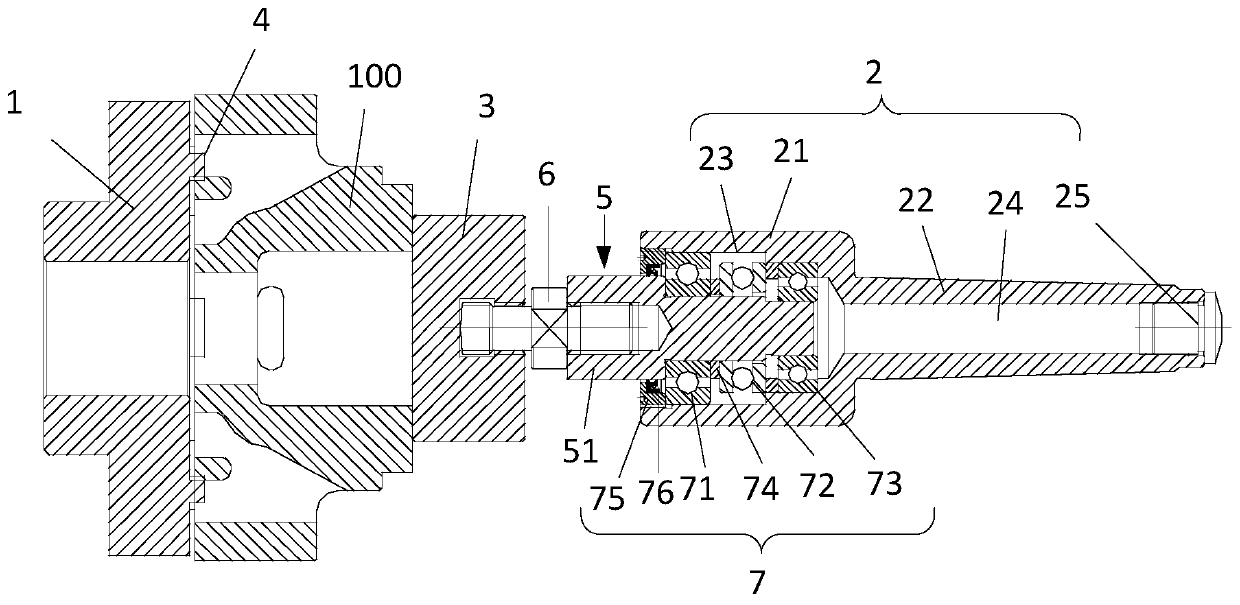

[0023] In order to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the drawings of the present invention are all in simplified form and use inaccurate scales, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

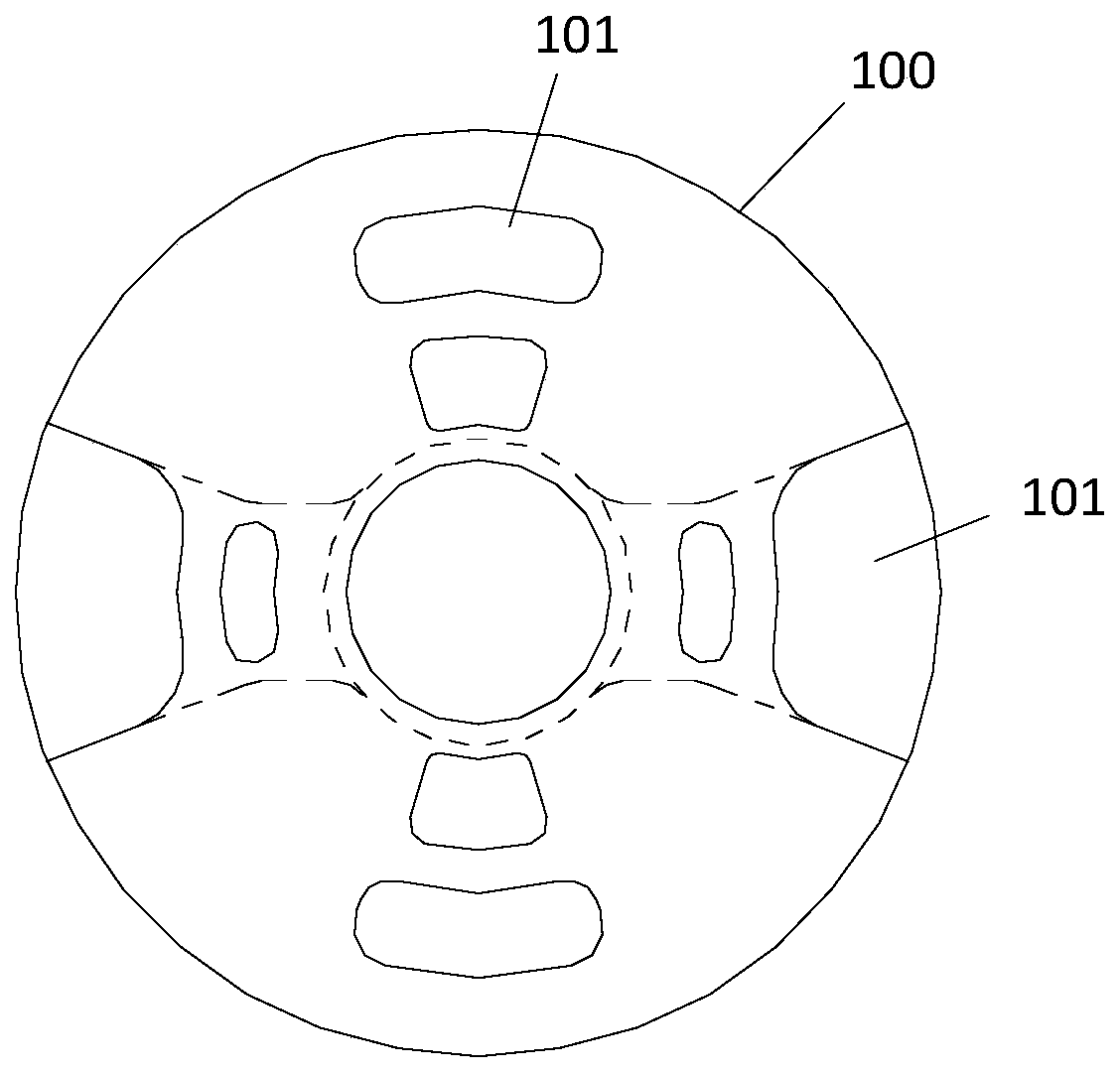

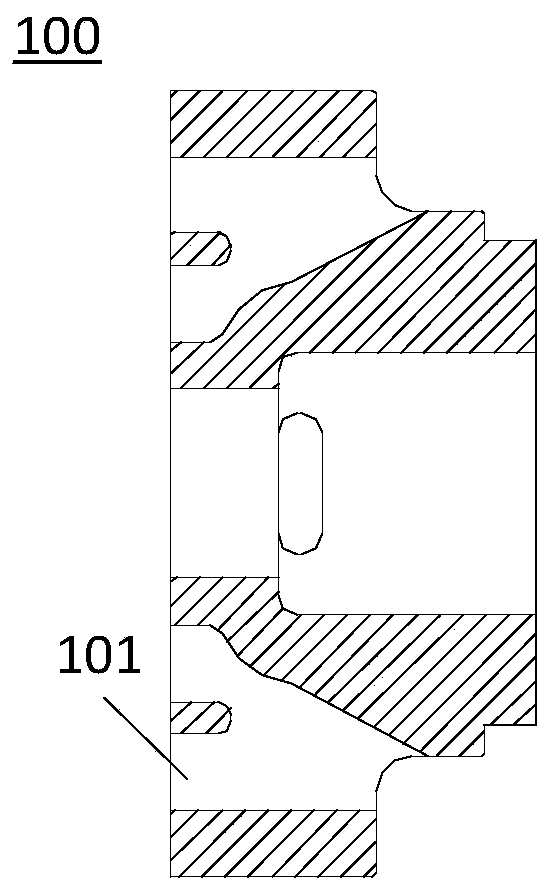

[0024] refer to Figure 1 to Figure 6 , the present invention provides a turning fixture for cast iron oil distribution plate, comprising: a positioning seat 1 installed on the three-jaw chuck of the main shaft of the turning equipment, a pointed seat 2 installed on the tailstock of the turning equipment, and a pointed seat installed on the tip The pressing block 3 on the head seat 2 , wherein the positioning seat 1 is used to support the large end surface of the cast iron oil di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com