Rotary pipeline clamping device

A clamping device and rotary technology, applied in the direction of roller table, transportation and packaging, conveyor, etc., can solve the problems of many processes, slow production cycle, cumbersome operation steps, etc., to reduce friction, reduce the probability of failure, Structurally Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

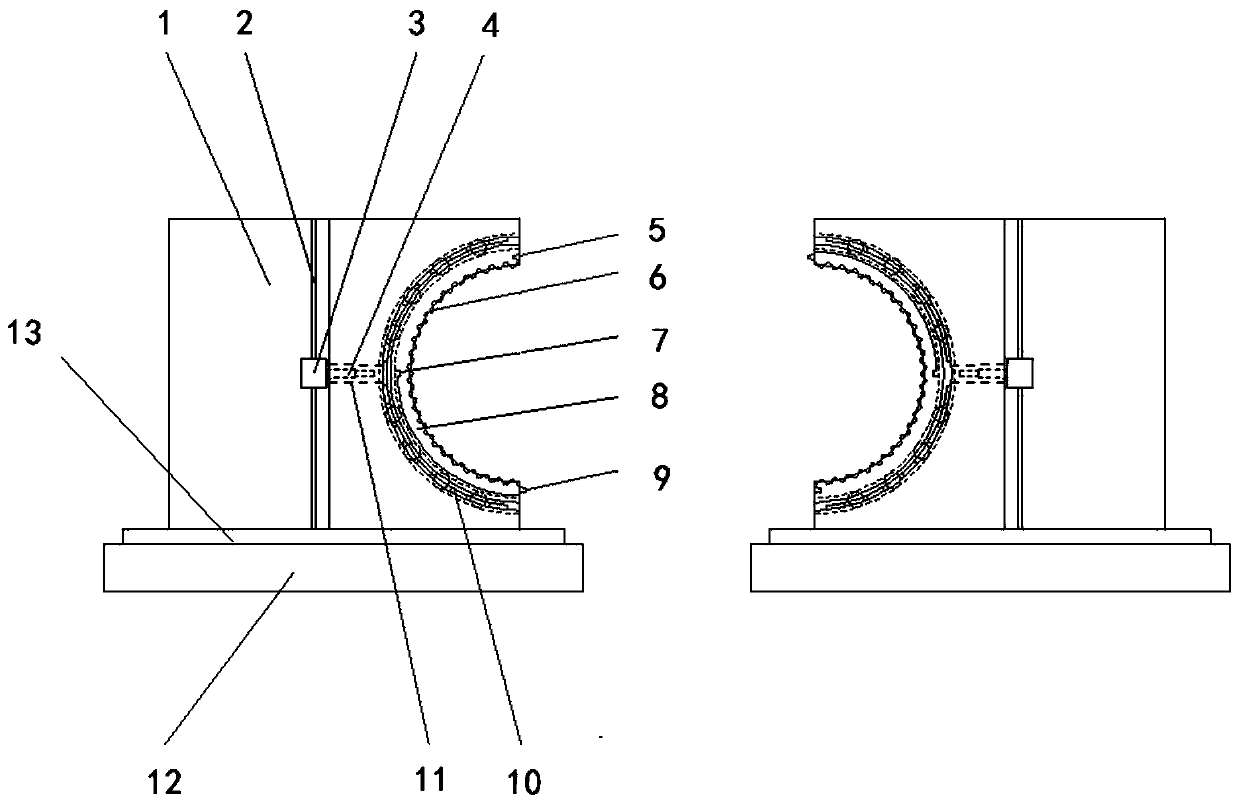

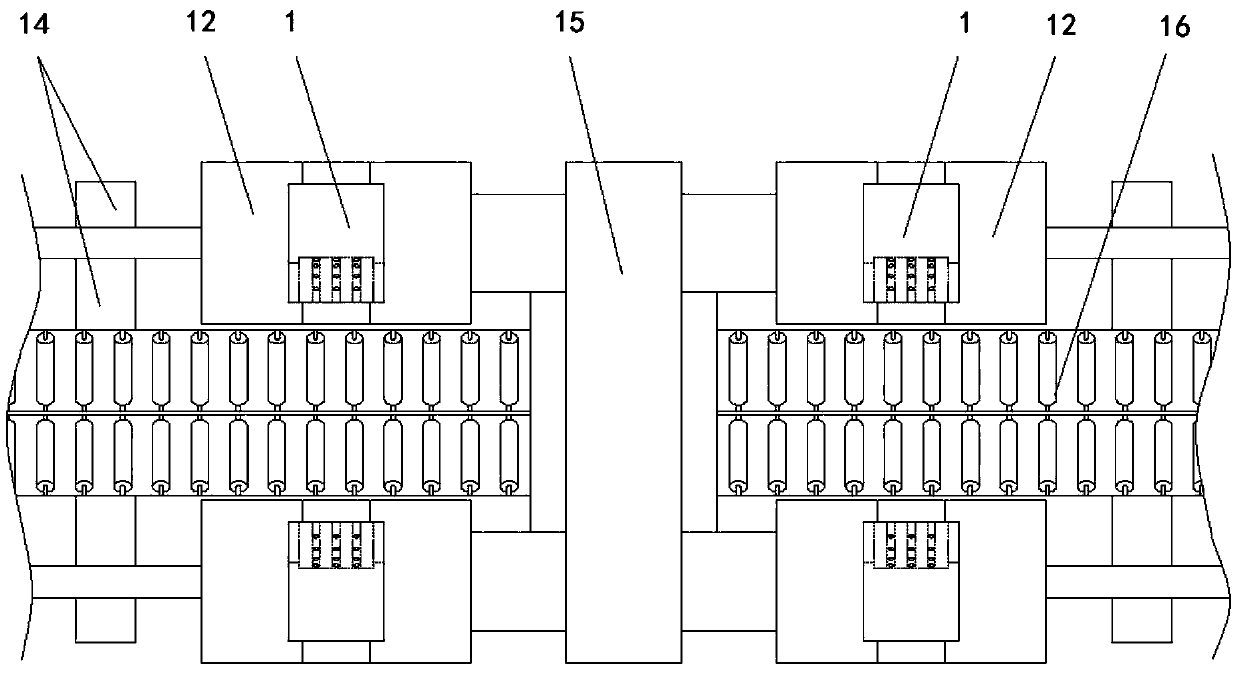

[0022] Such as figure 1 with figure 2 As shown: a rotary pipe clamping device, including a control system placed on a bracket 14 and two clamping blocks 1, the two clamping blocks 1 are symmetrically arranged on both sides of the pipeline conveying device 16, and the two clamping blocks 1 are respectively A transverse driving device is arranged on the slide plates 12 on both sides of the pipeline conveying device 16, and the two slide plates 12 are connected as a whole through a connecting piece. The opposite sides of the two clamping blocks 1 are symmetrically provided with arc-shaped chute, and an arc-shaped clamping piece 8 is respectively slidably arranged in the arc-shaped chute of the two clamping blocks 1, and the groove of the arc-shaped clamping piece 8 and the arc-shaped chute A plurality of arc-shaped brackets 10 with steel balls are arranged between the walls, and the arc-shaped brackets 10 are fixedly arranged on the inner wall of the arc-shaped chute. The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com