Patents

Literature

85results about How to "High coaxial precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

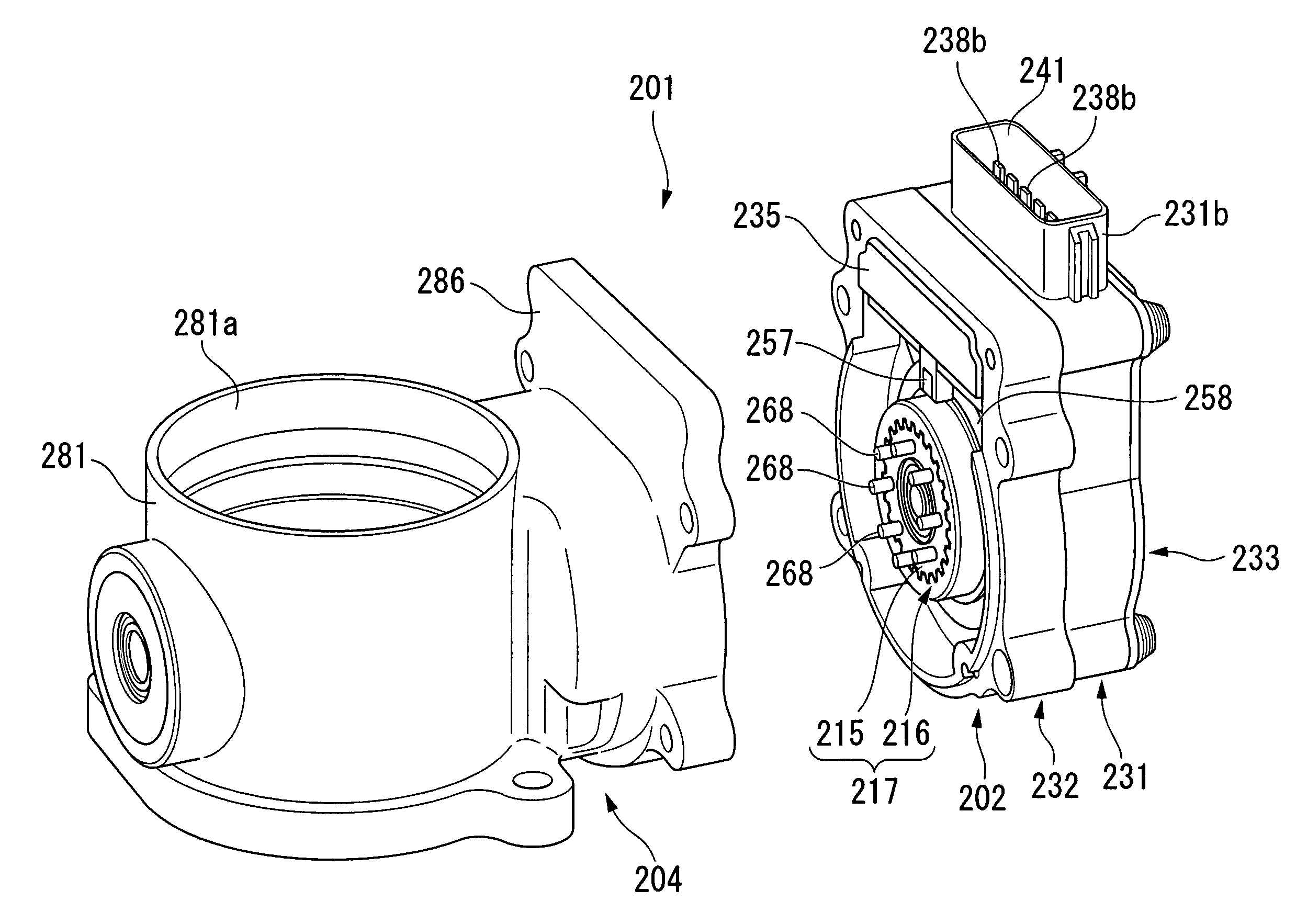

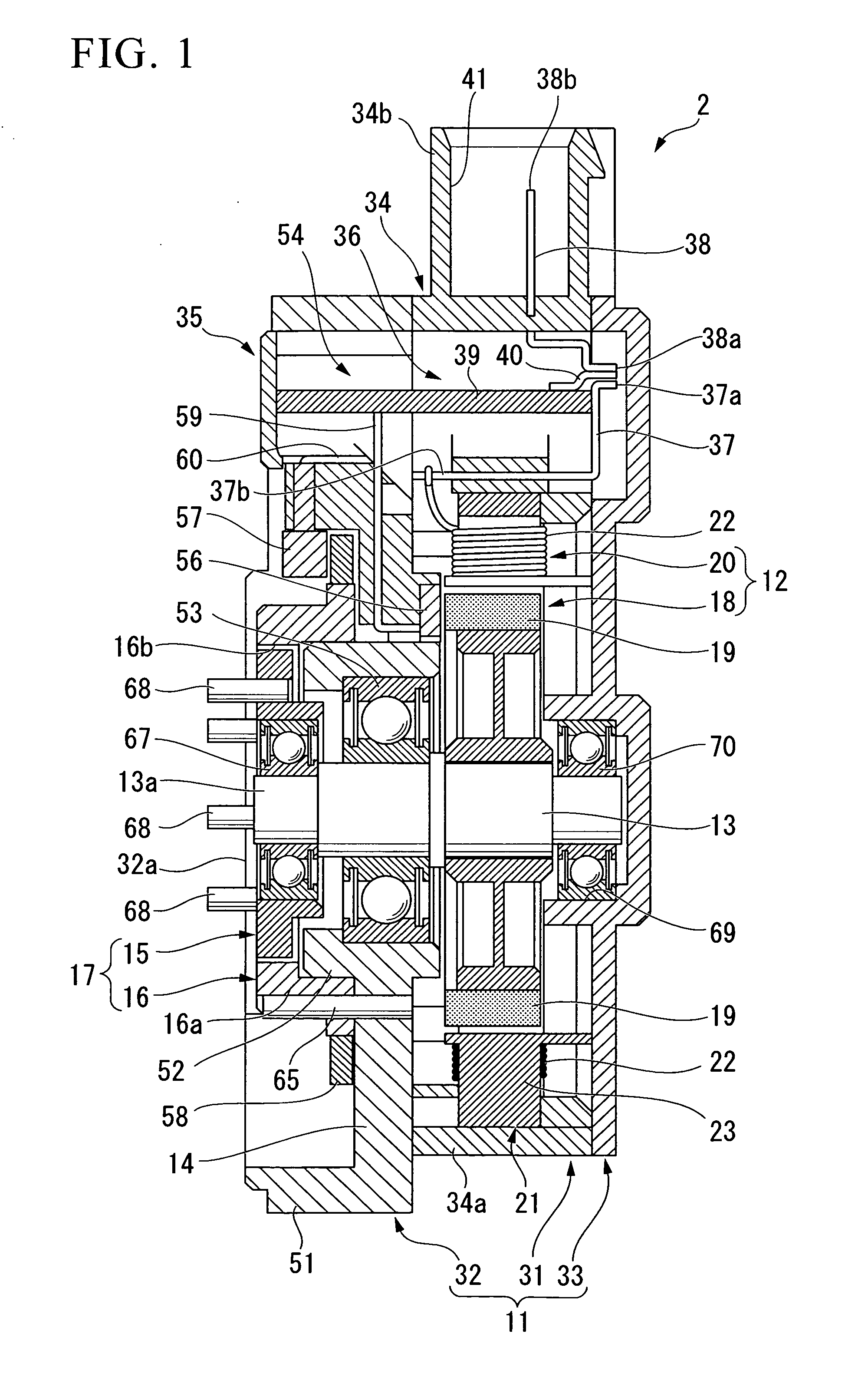

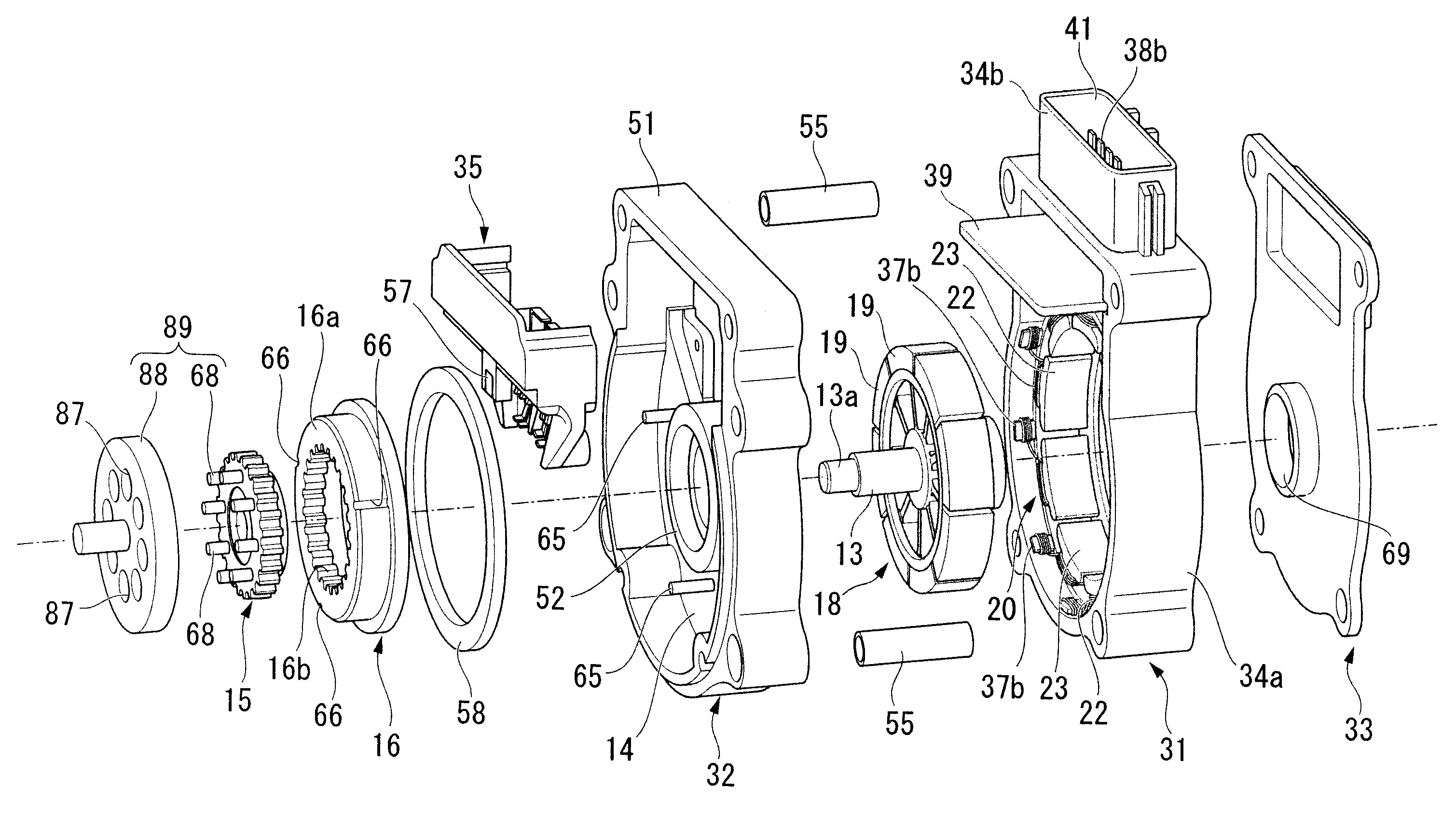

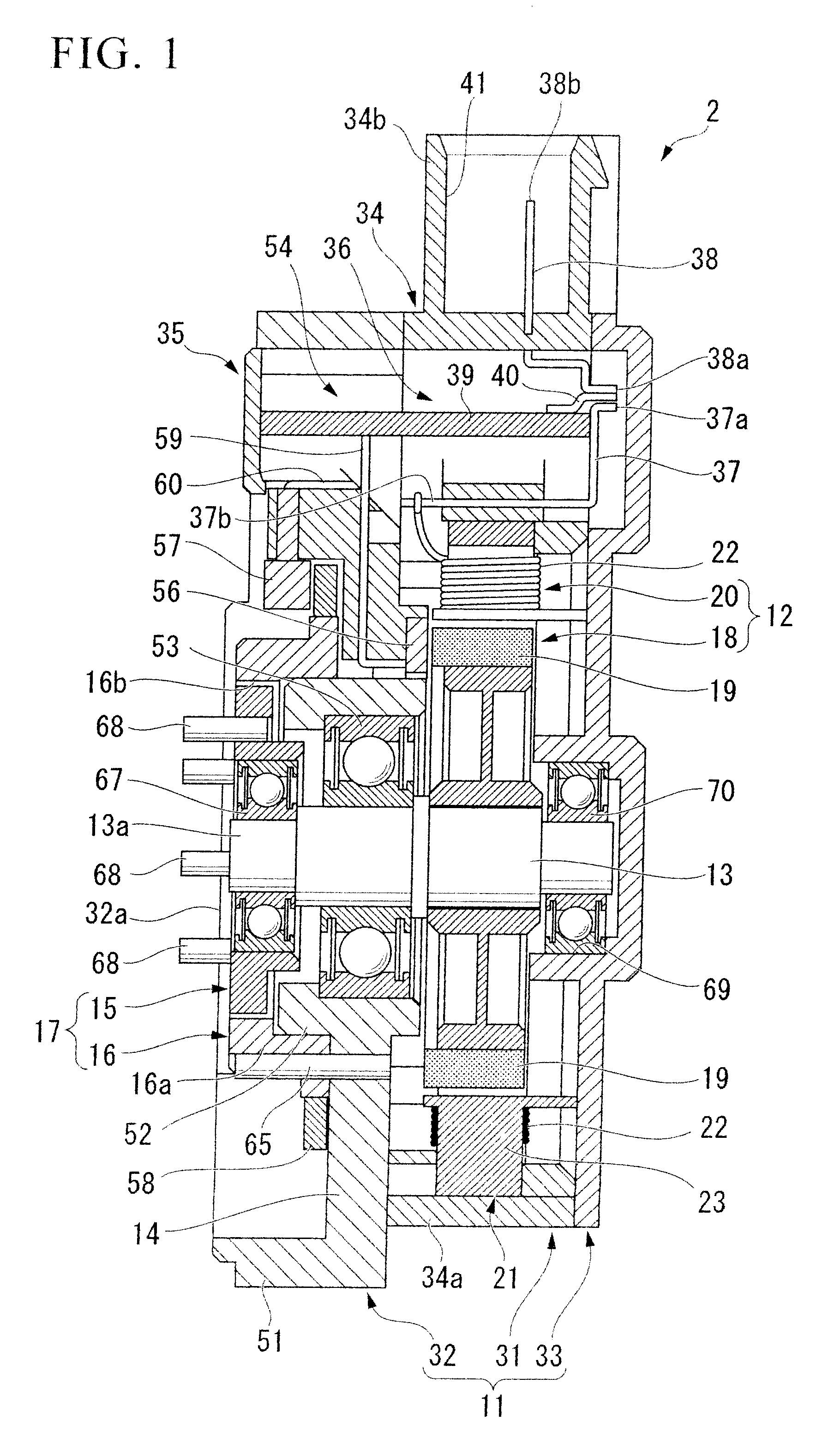

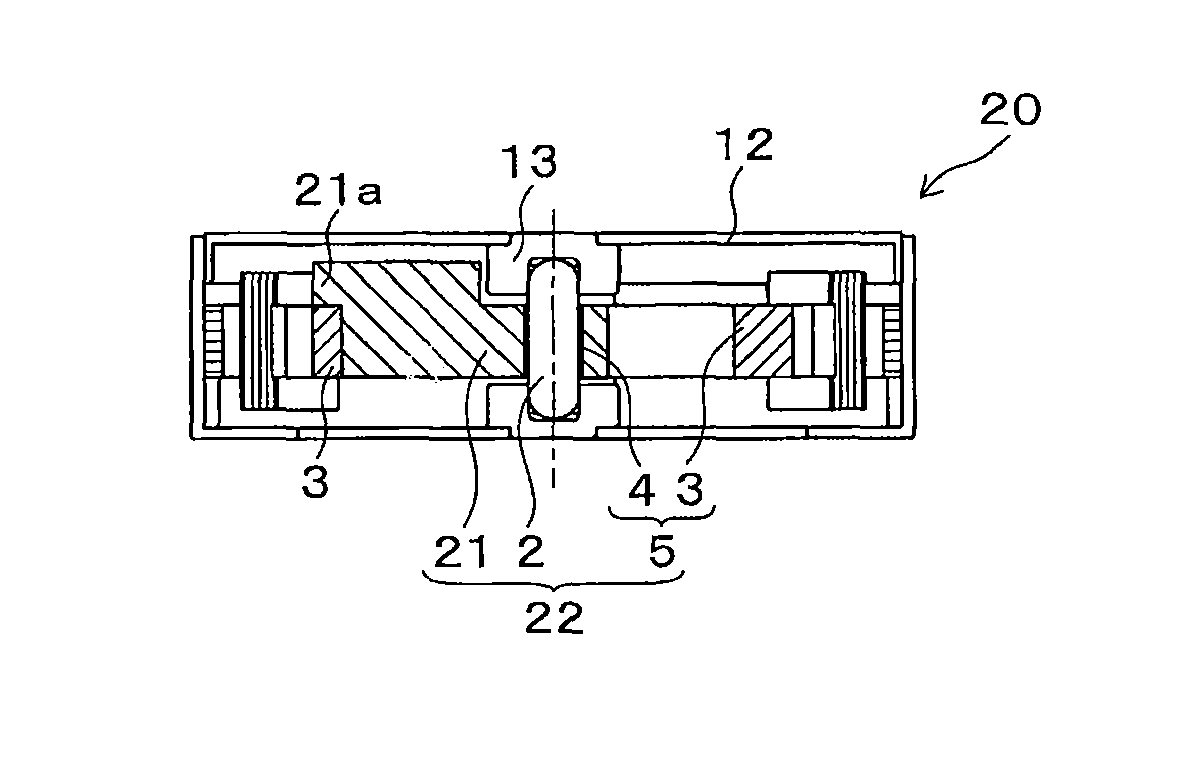

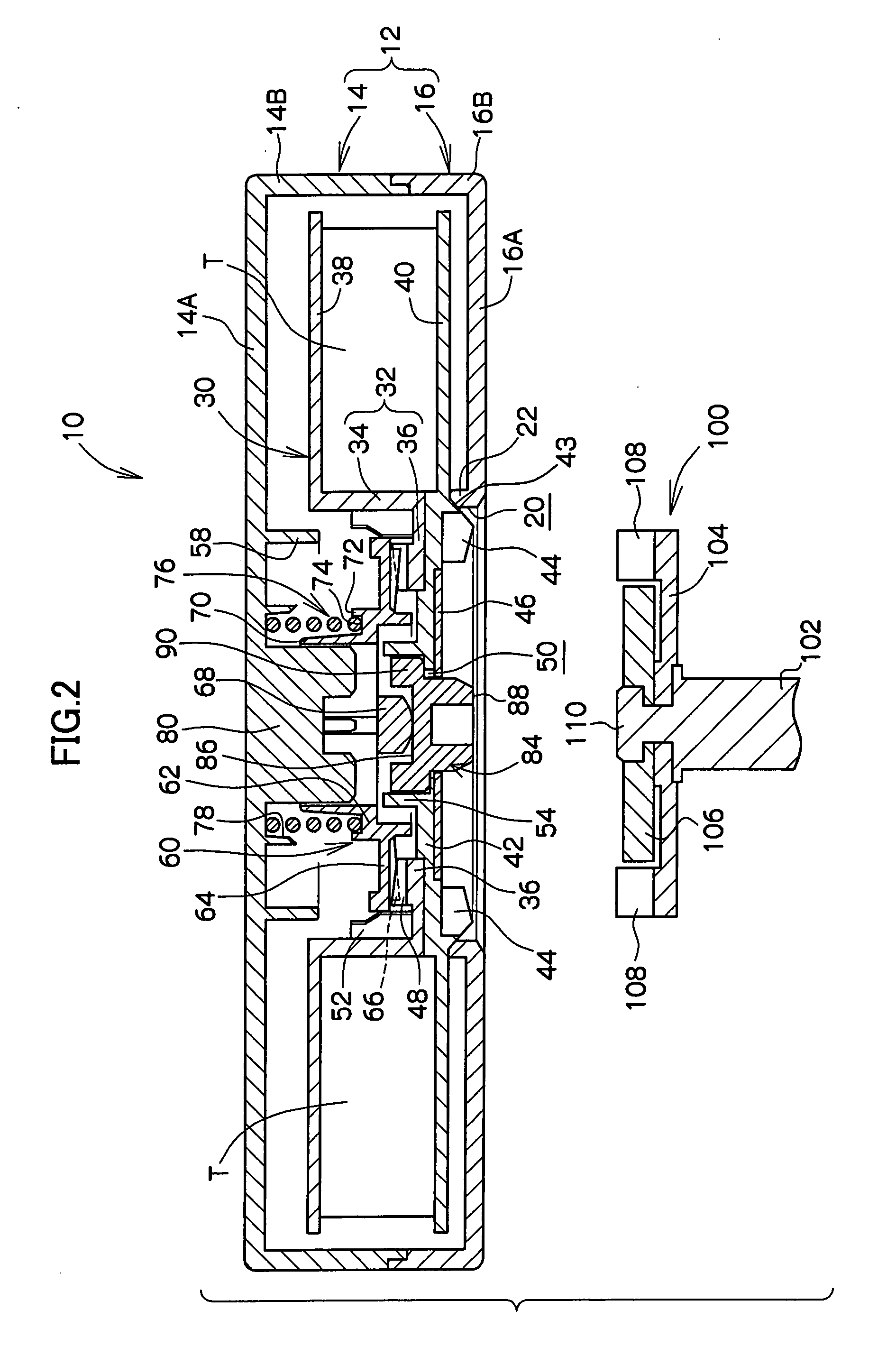

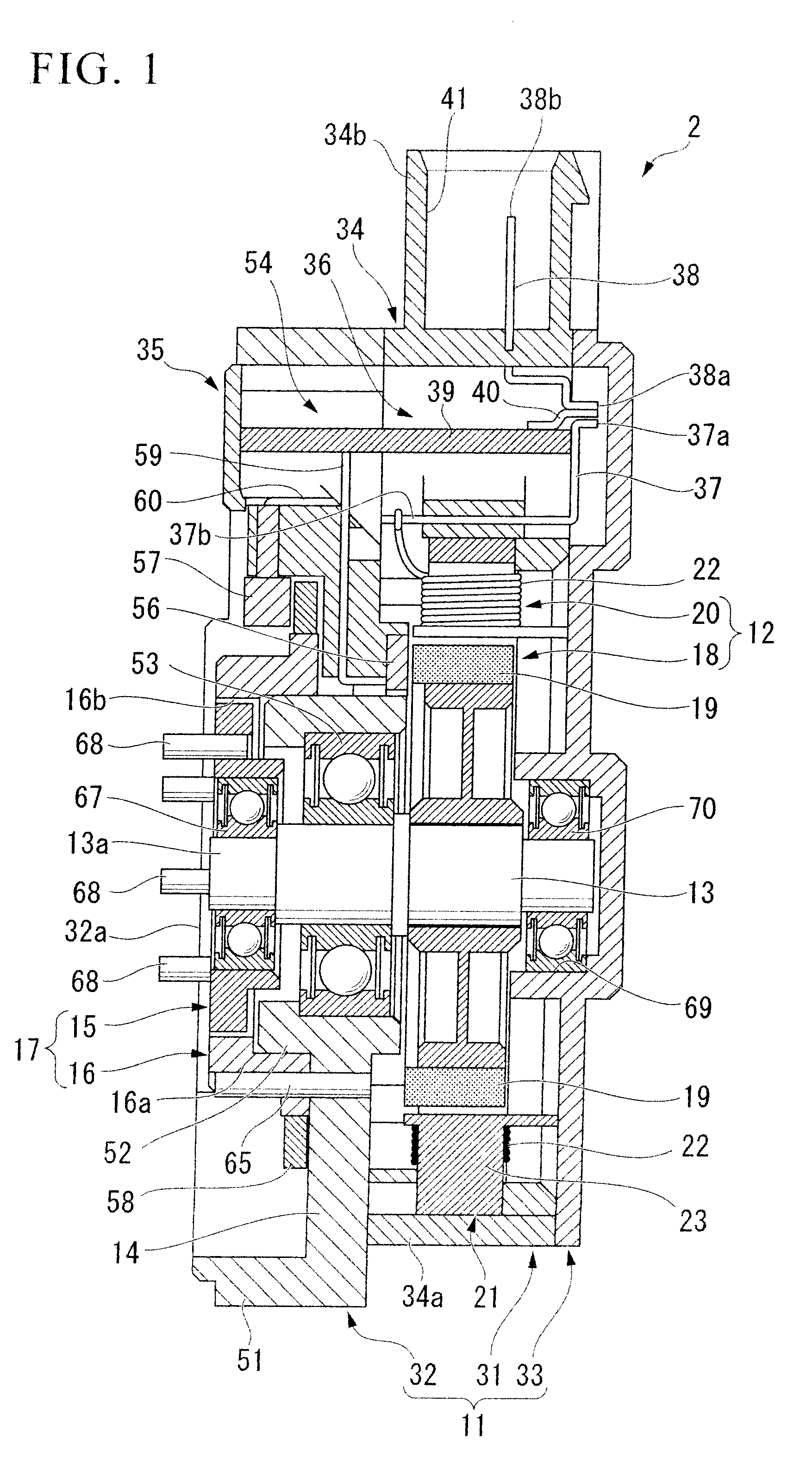

Electric motor, rotary actuator and rotary apparatus

InactiveUS20080224553A1Simple taskEasy to assembleAssociation with control/drive circuitsMechanical energy handlingControl theoryRotary actuator

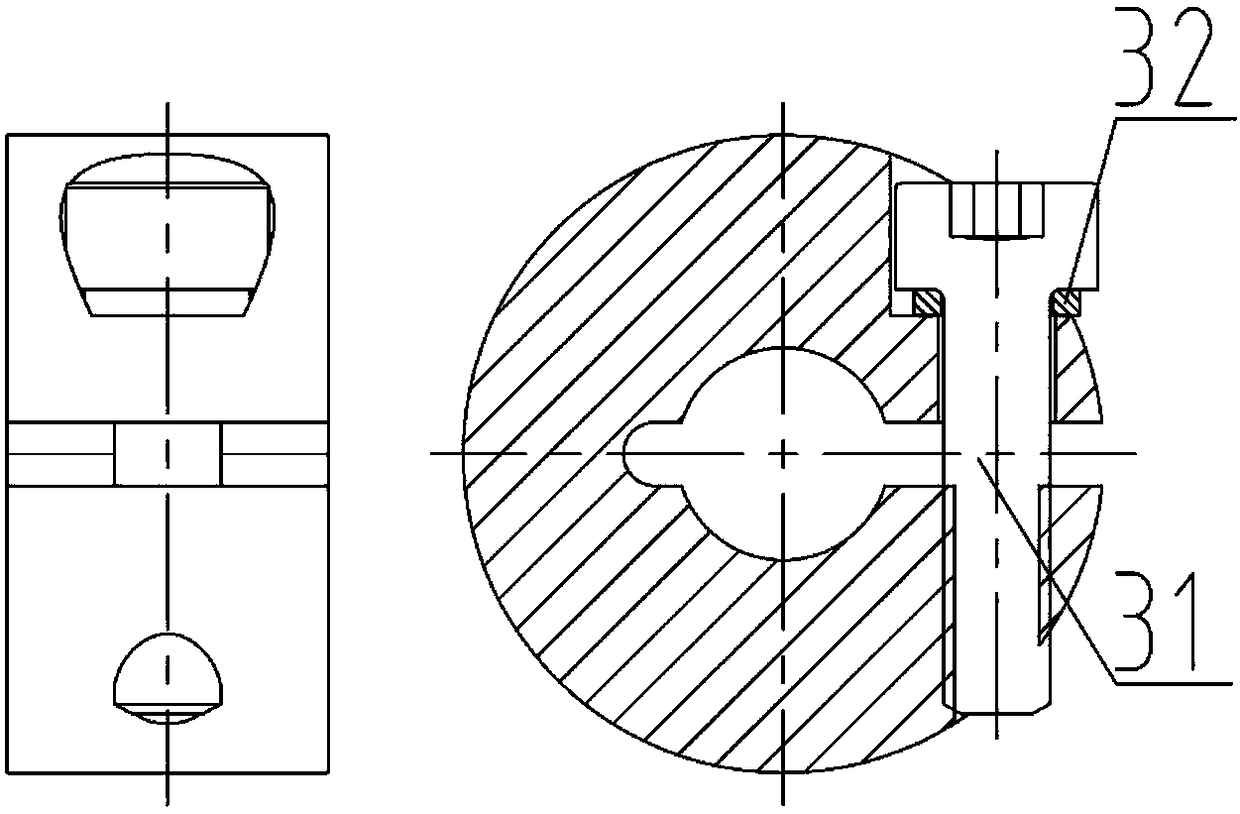

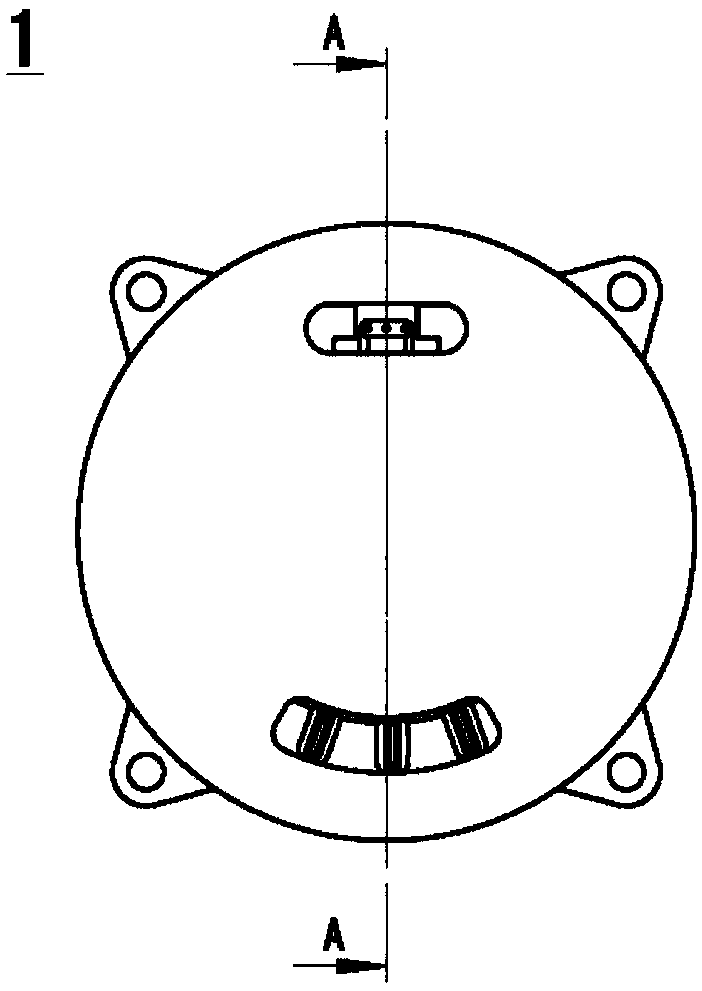

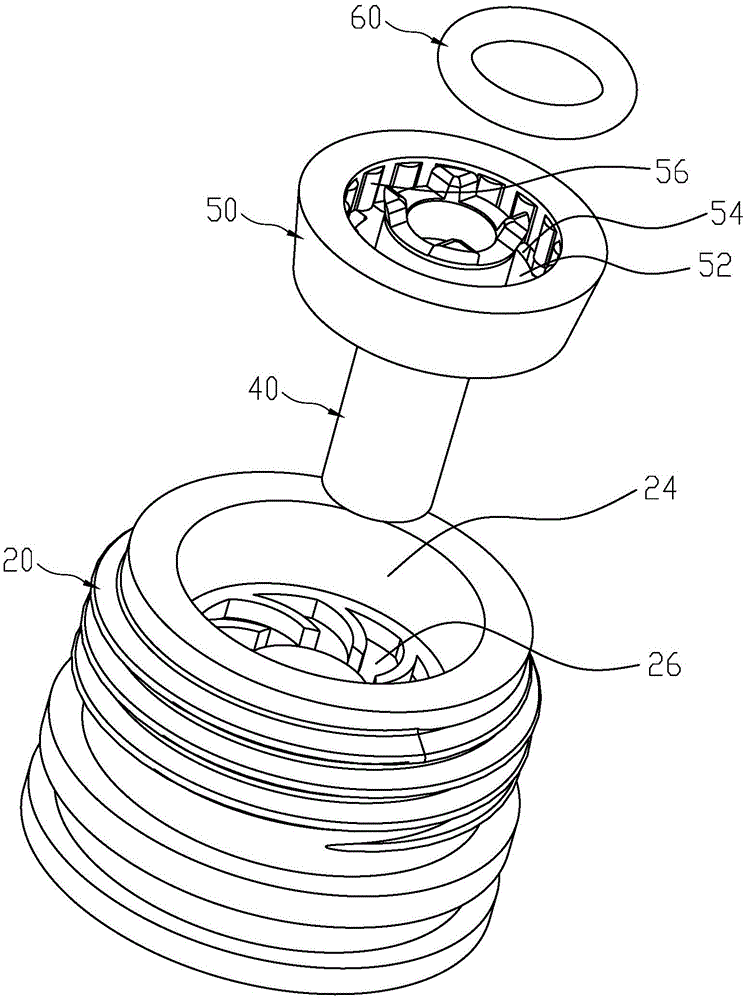

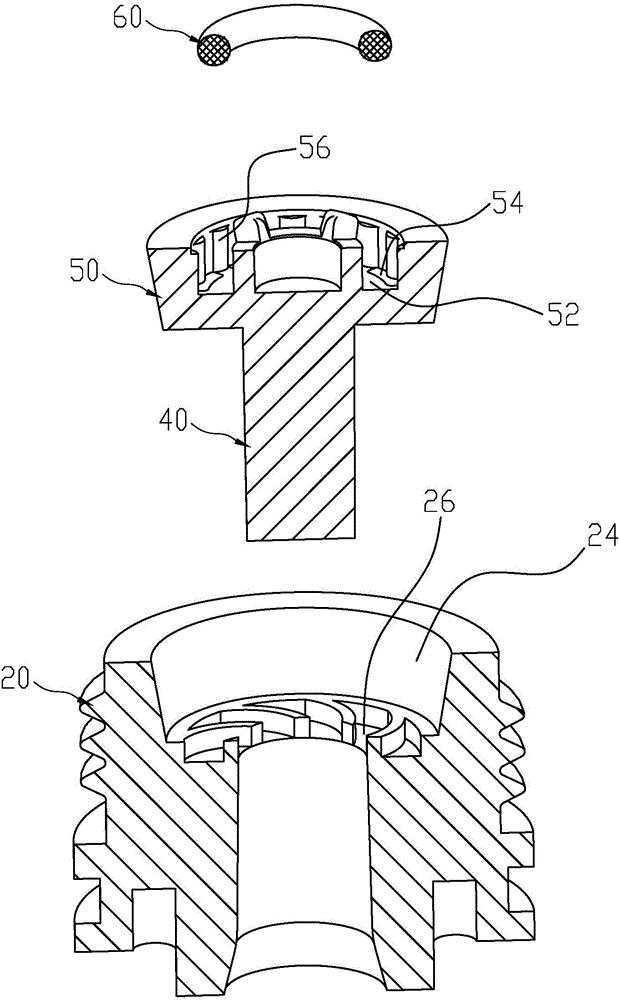

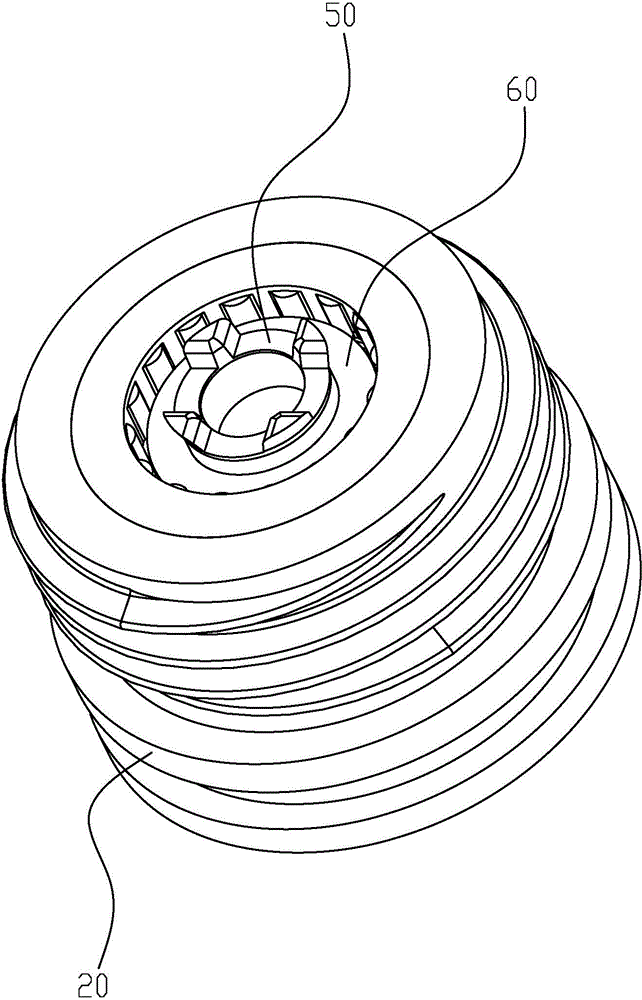

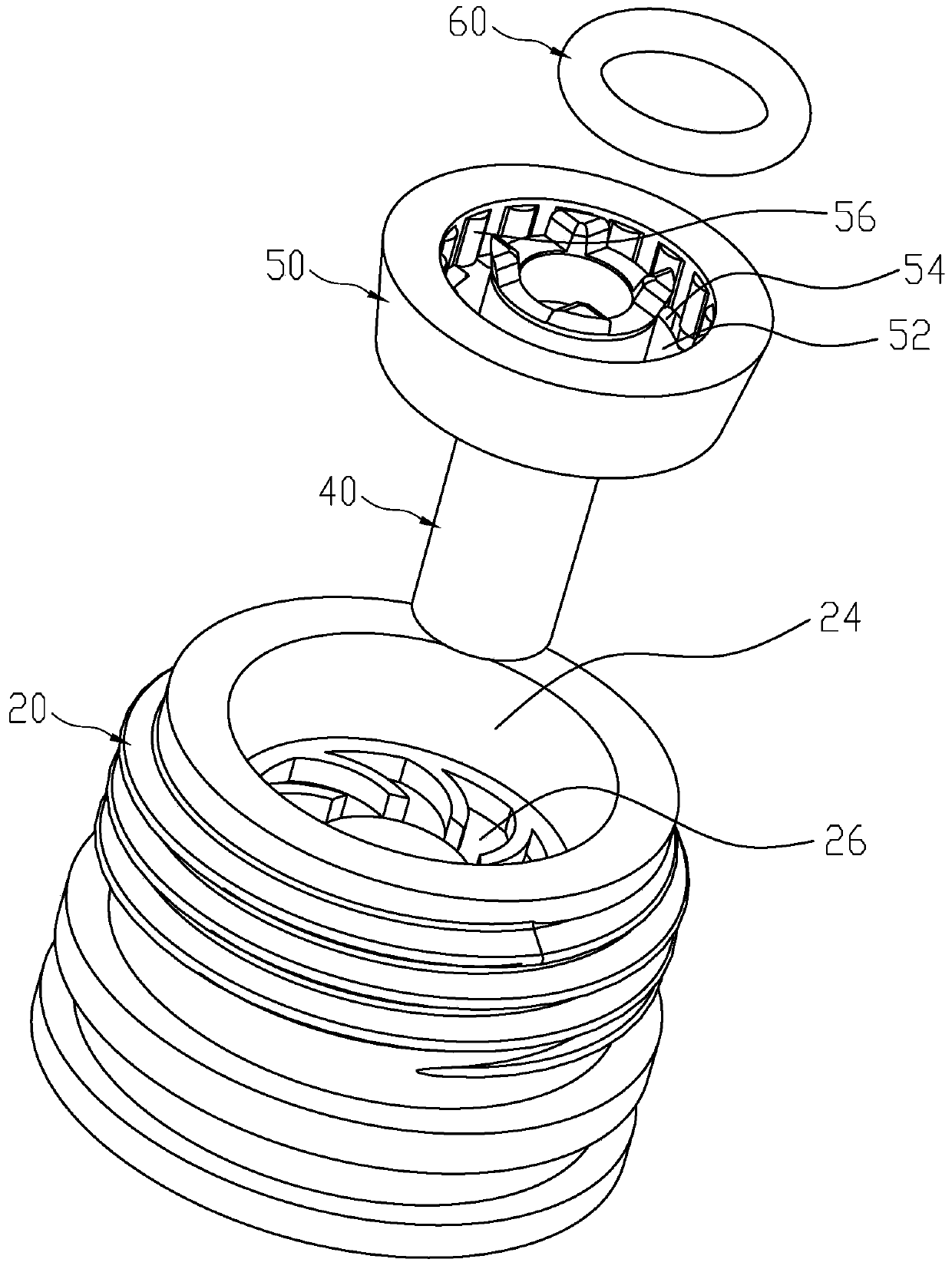

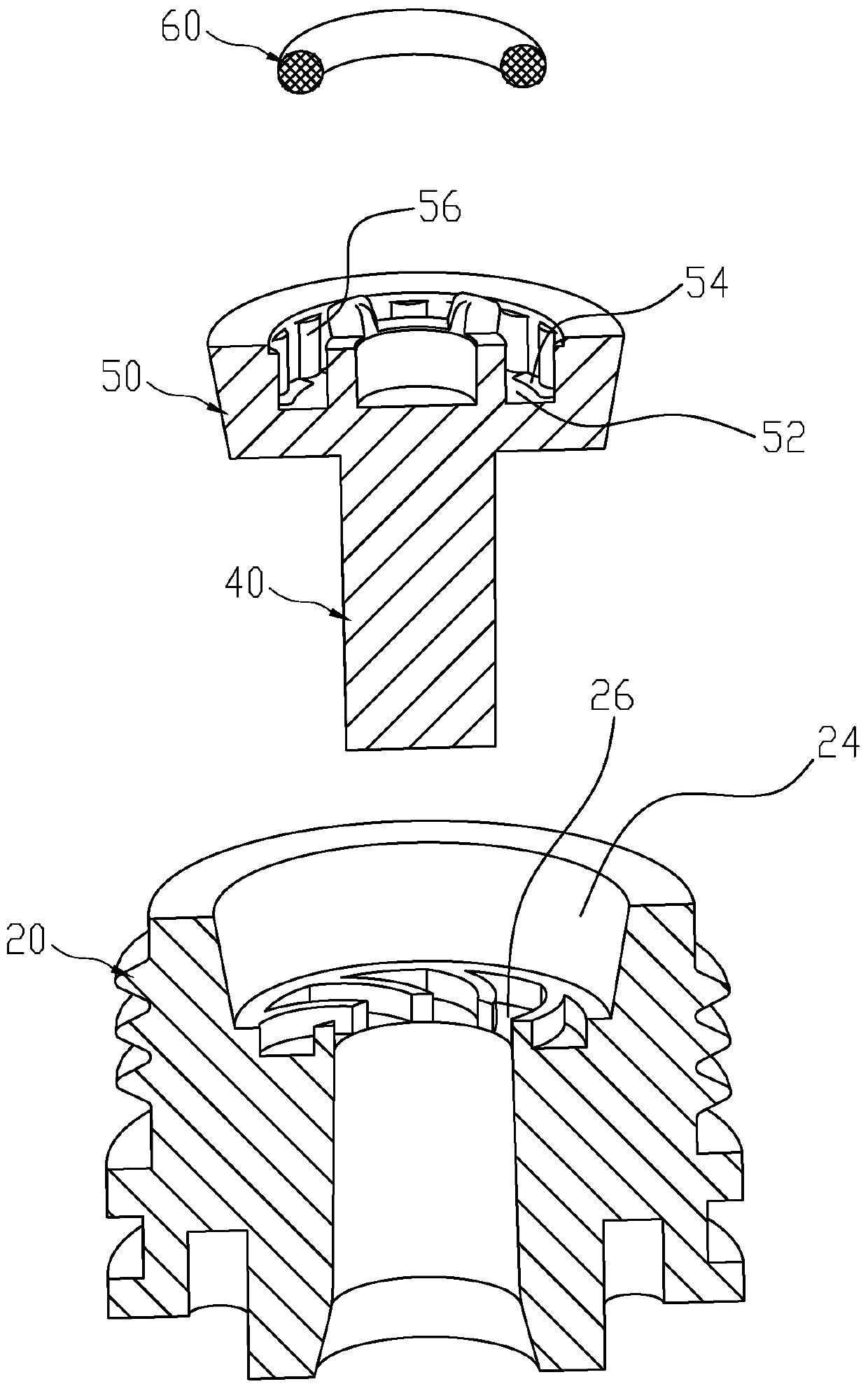

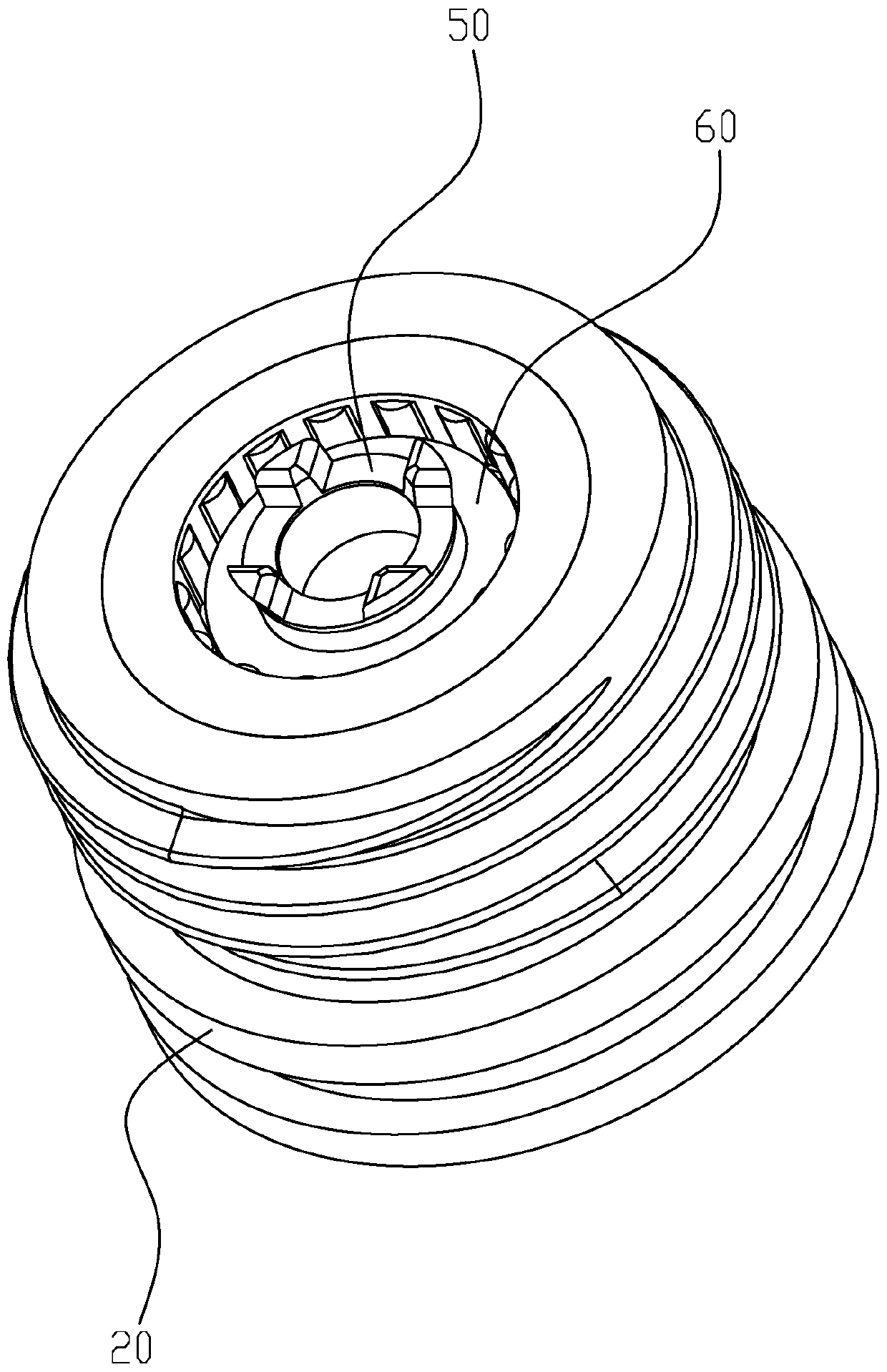

A rotary actuator including: a housing that rotatably supports thereinside a rotor shaft of an electric motor; an eccentric shaft portion that is provided on a protruding end portion of the rotor shaft that protrudes outside the housing; an external gear that is rotatably supported on the eccentric shaft portion via a bearing; an internal gear that is fixed to an outer surface of the housing and meshes with the external gear; and a transmitting portion that is provided on the external gear, and transmits rotation force to an external output shaft.

Owner:KEIHIN CORP

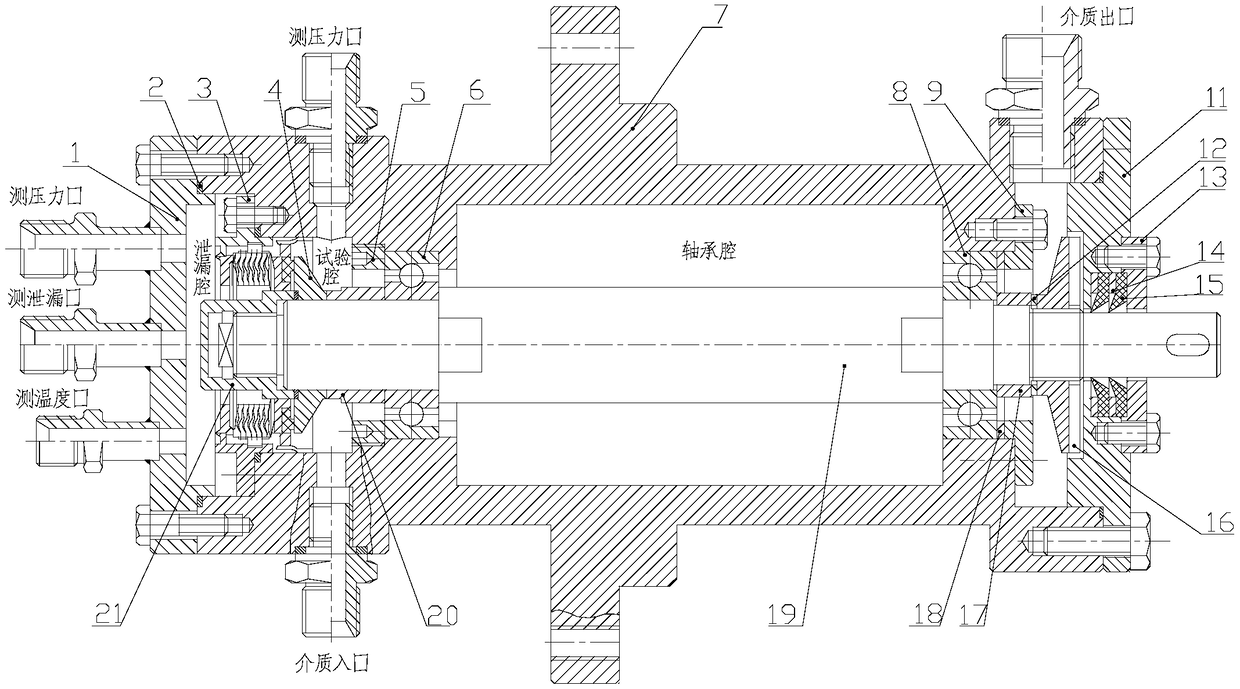

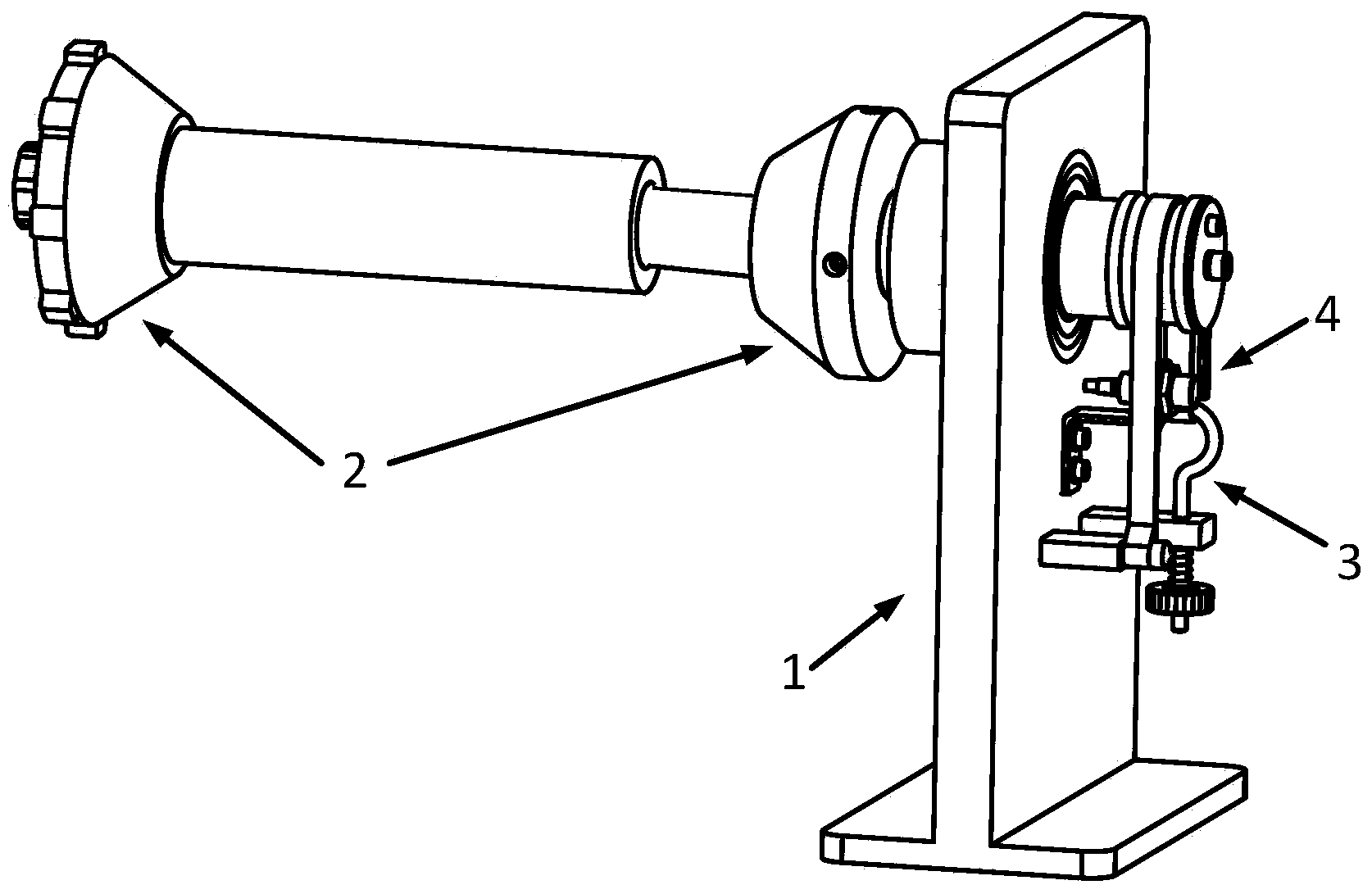

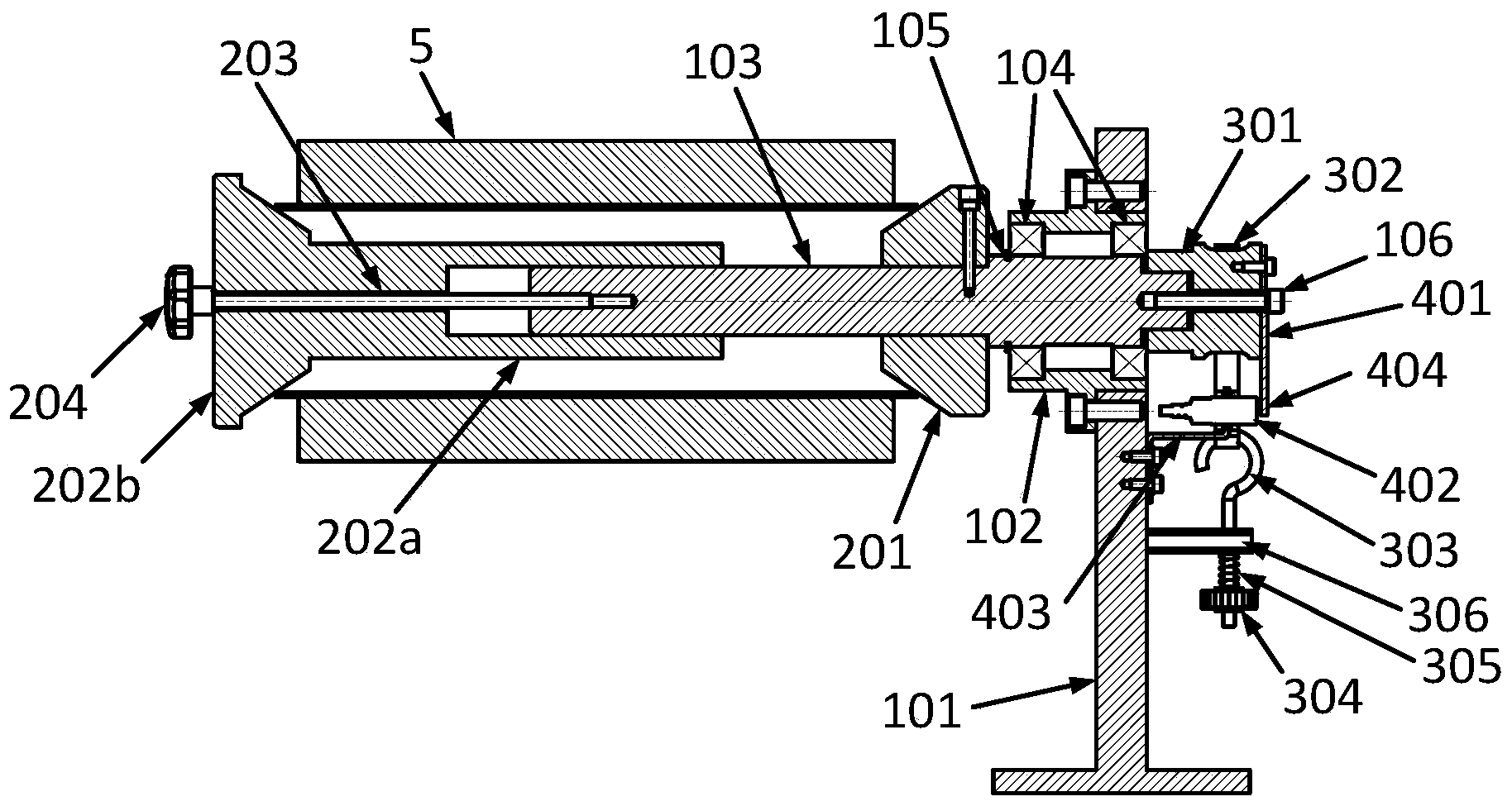

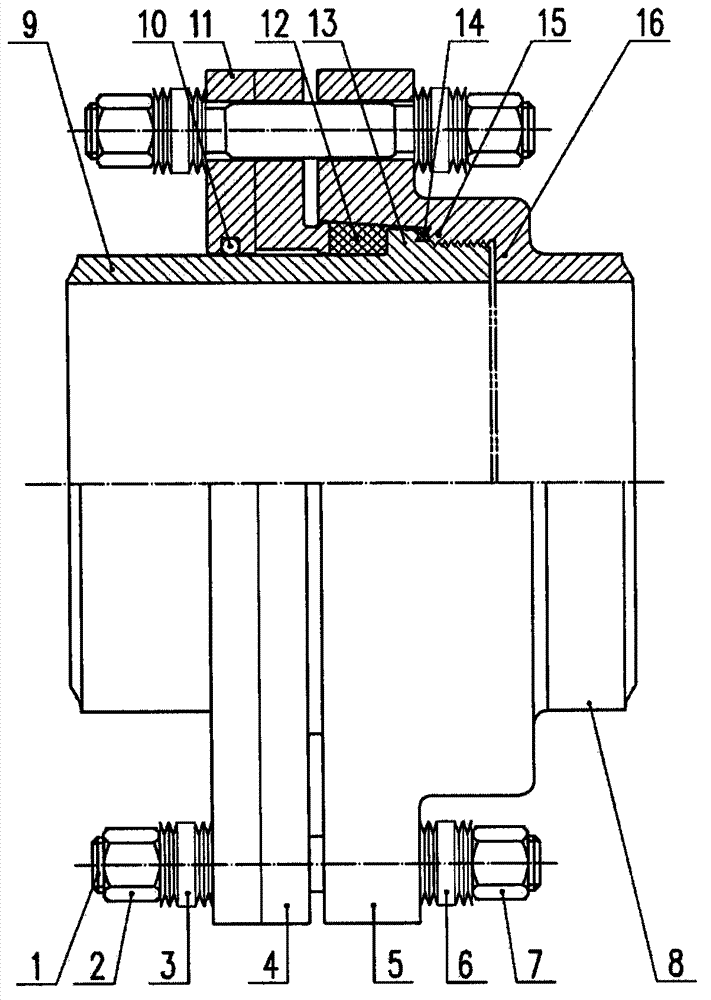

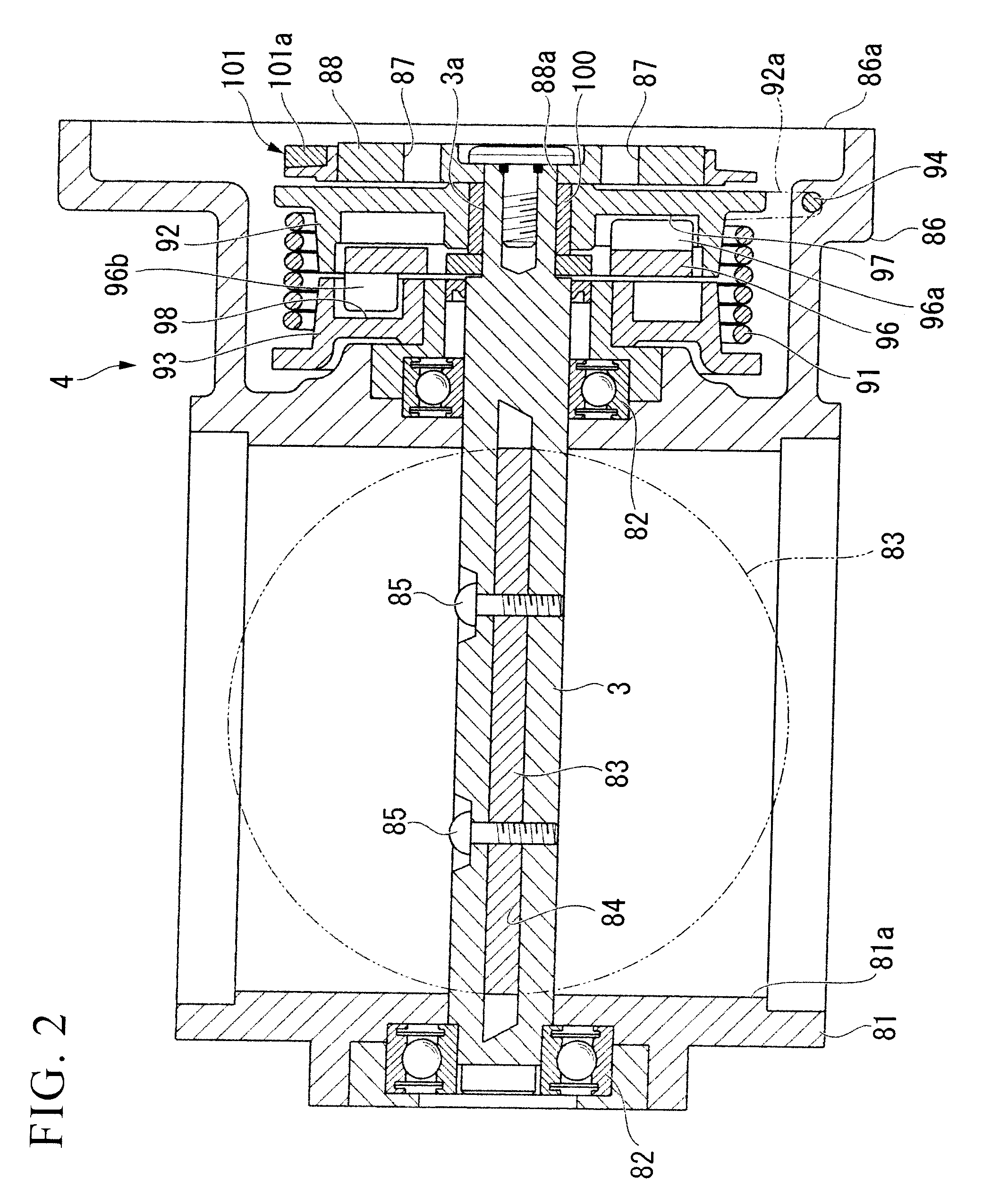

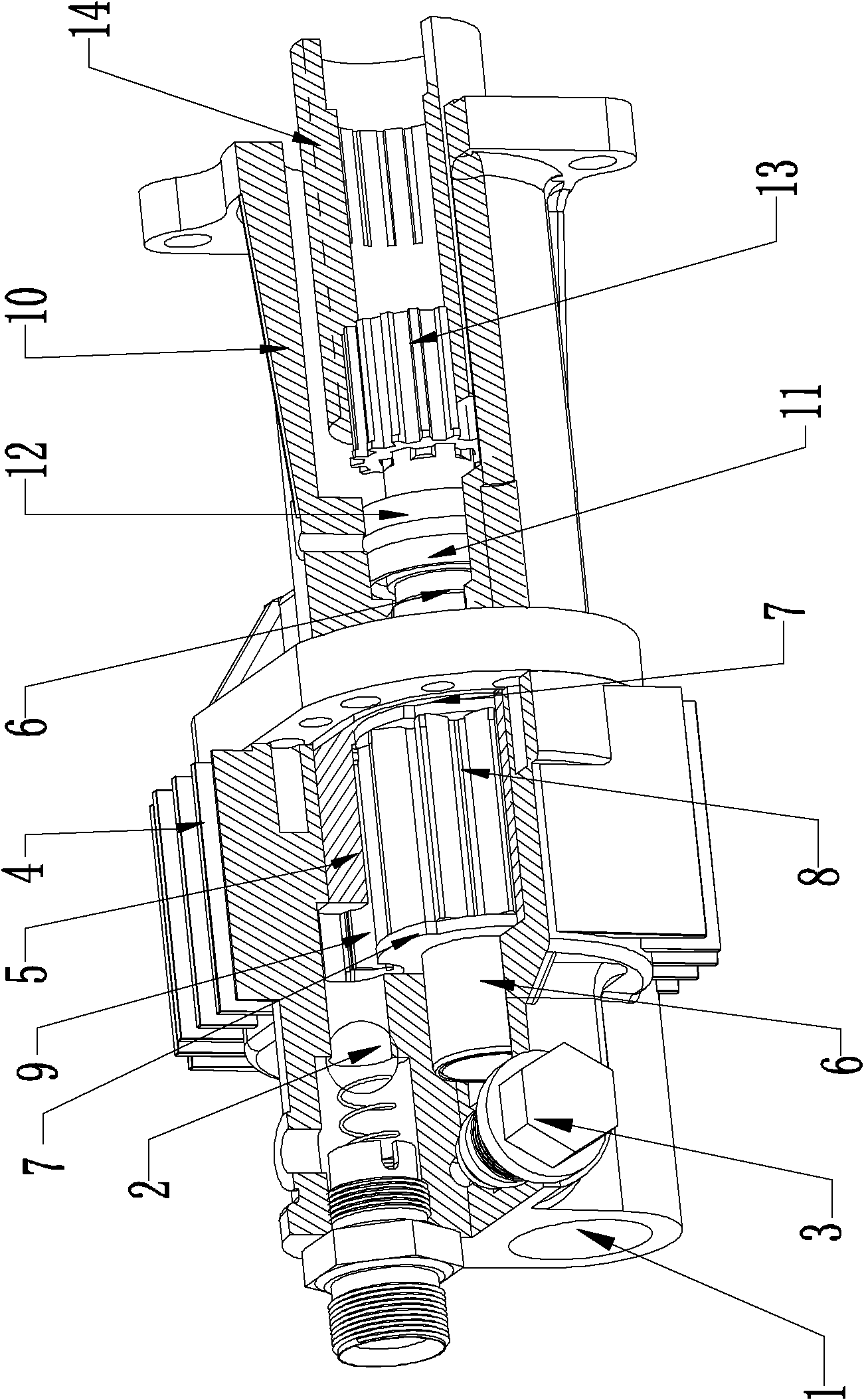

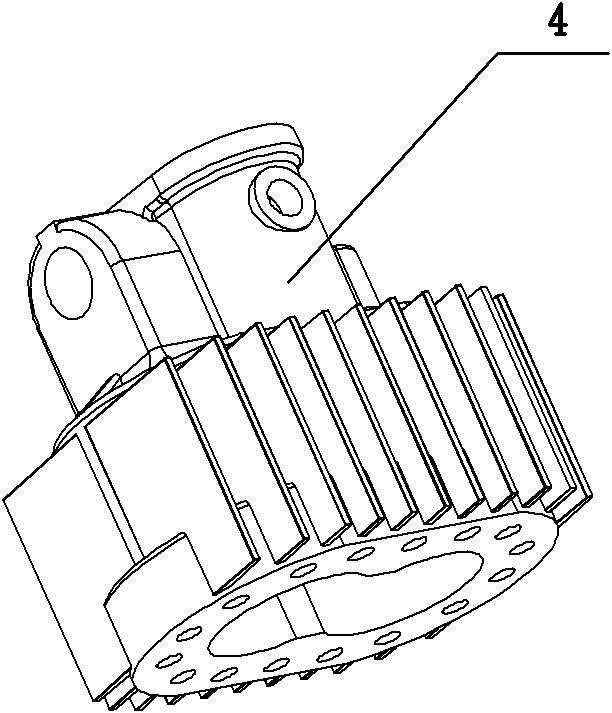

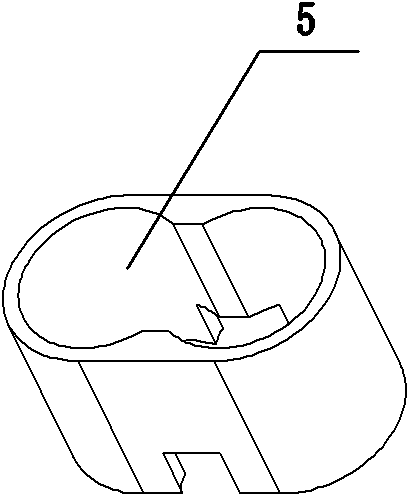

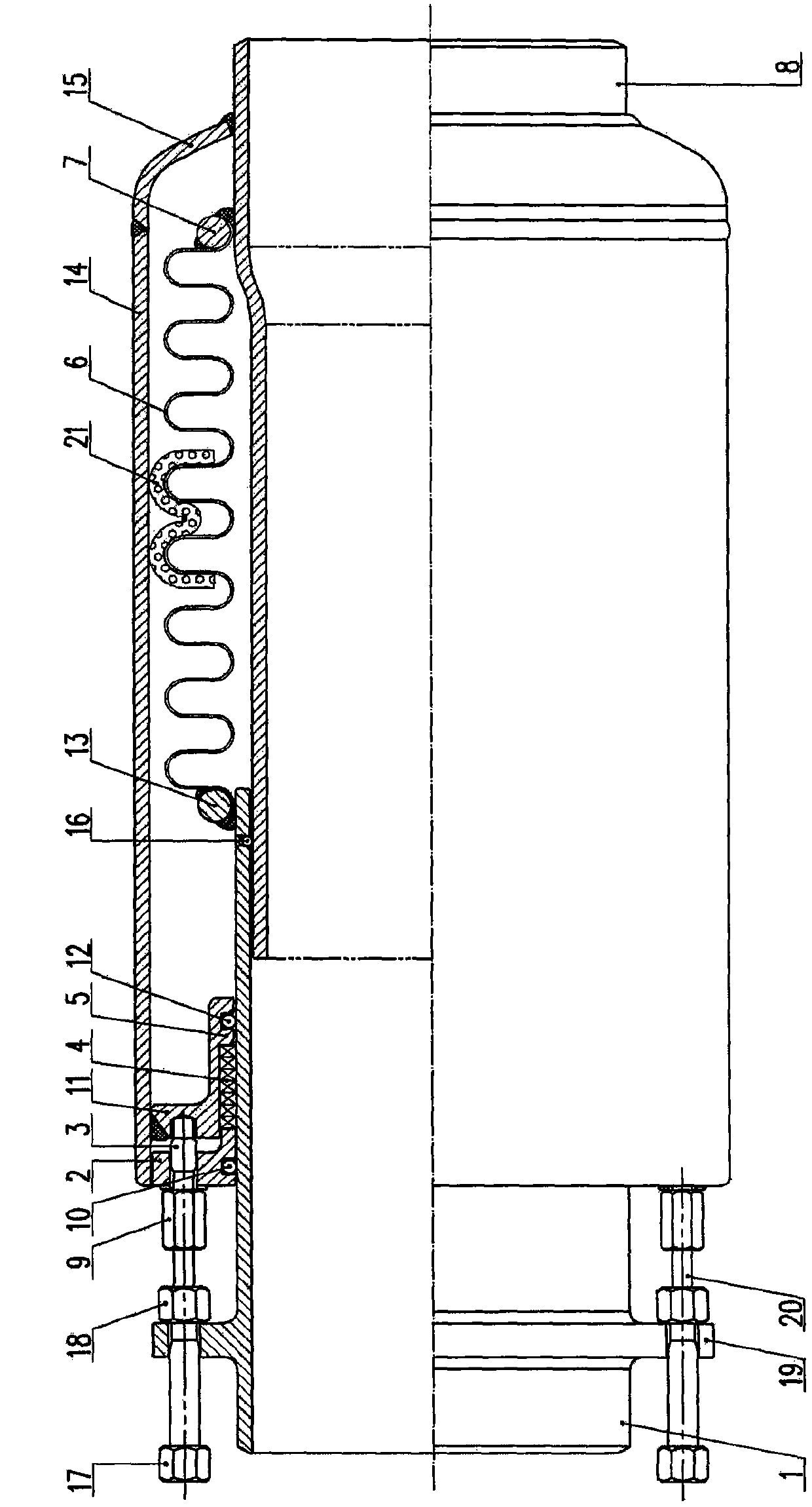

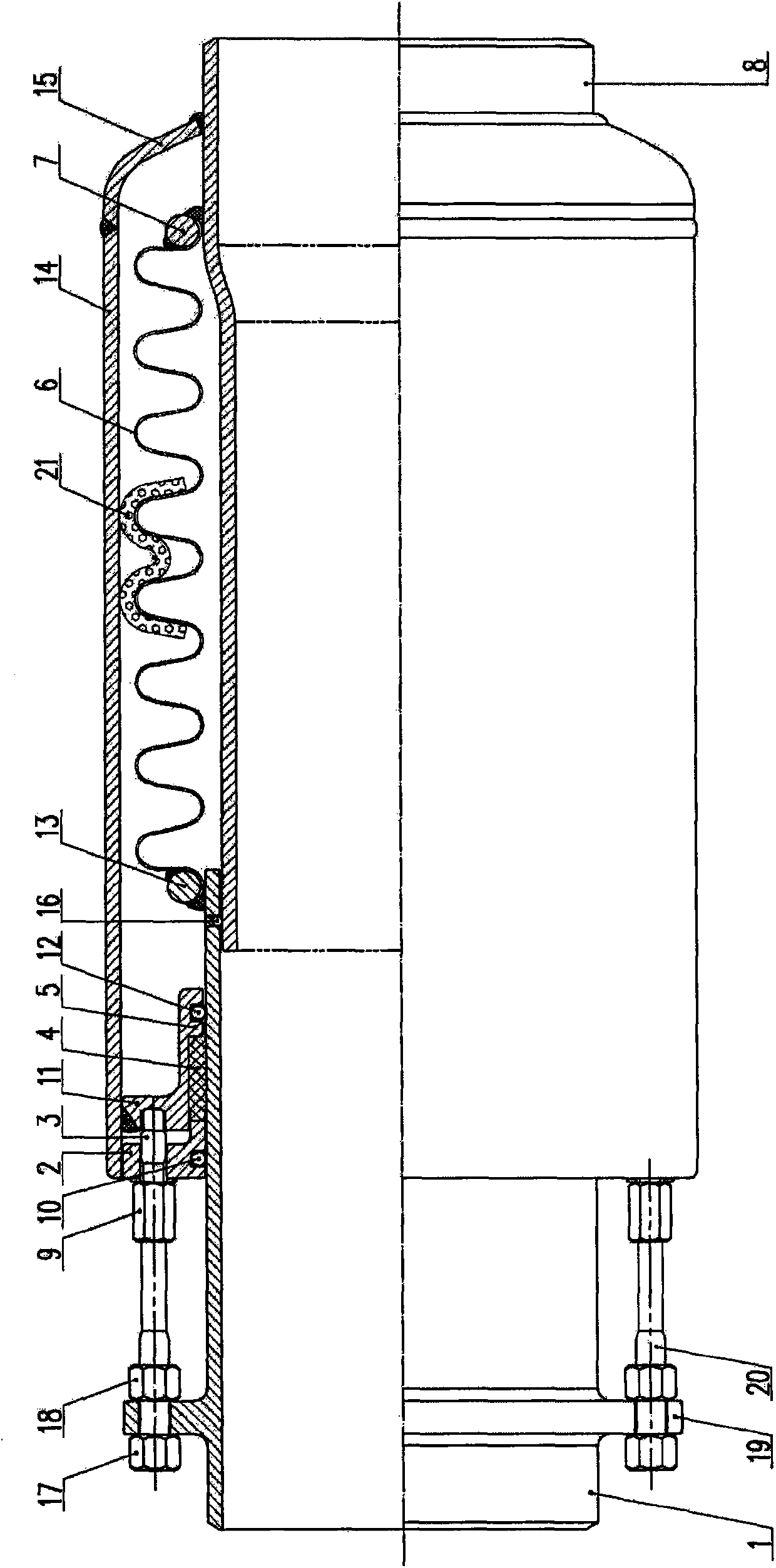

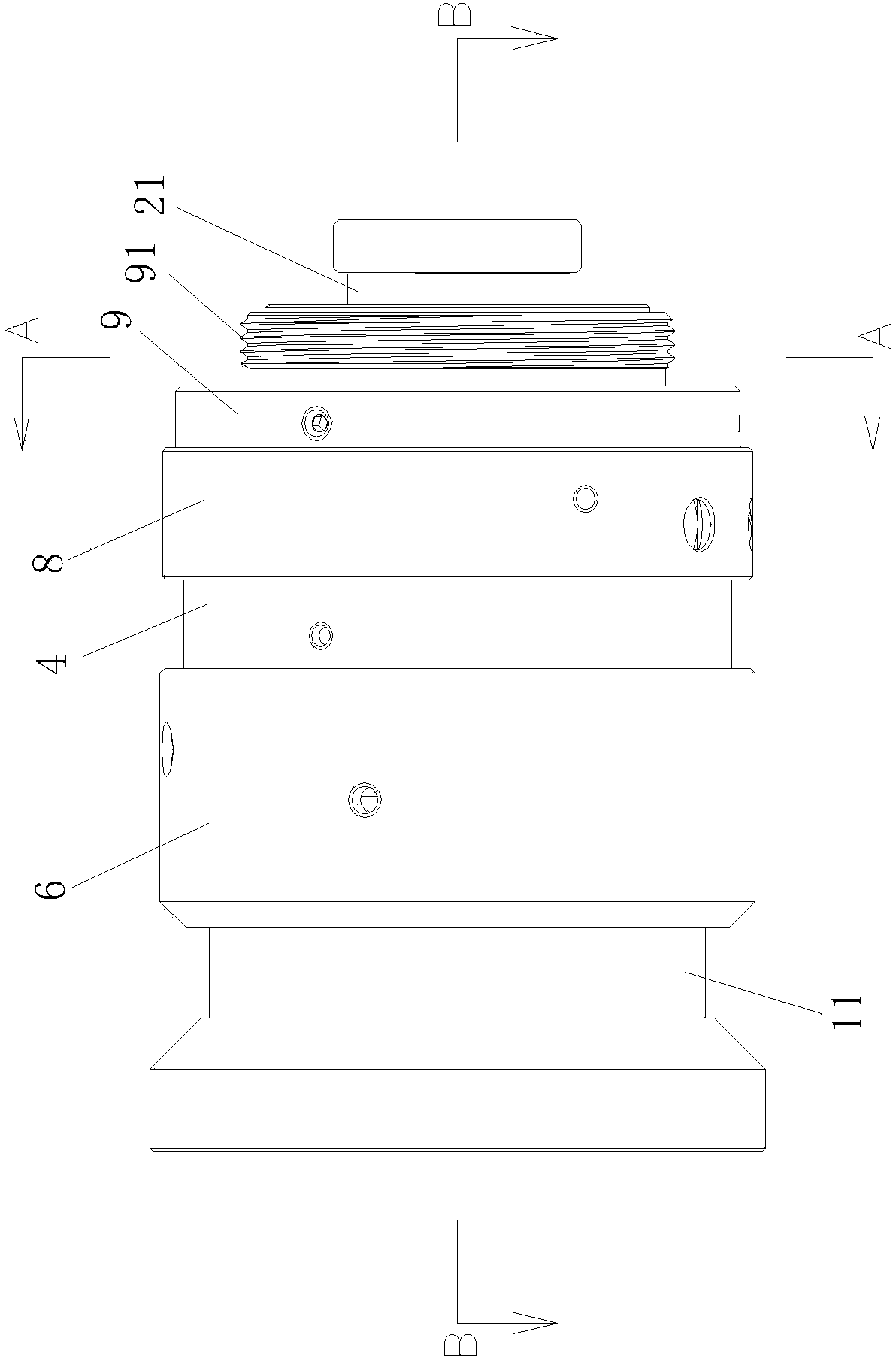

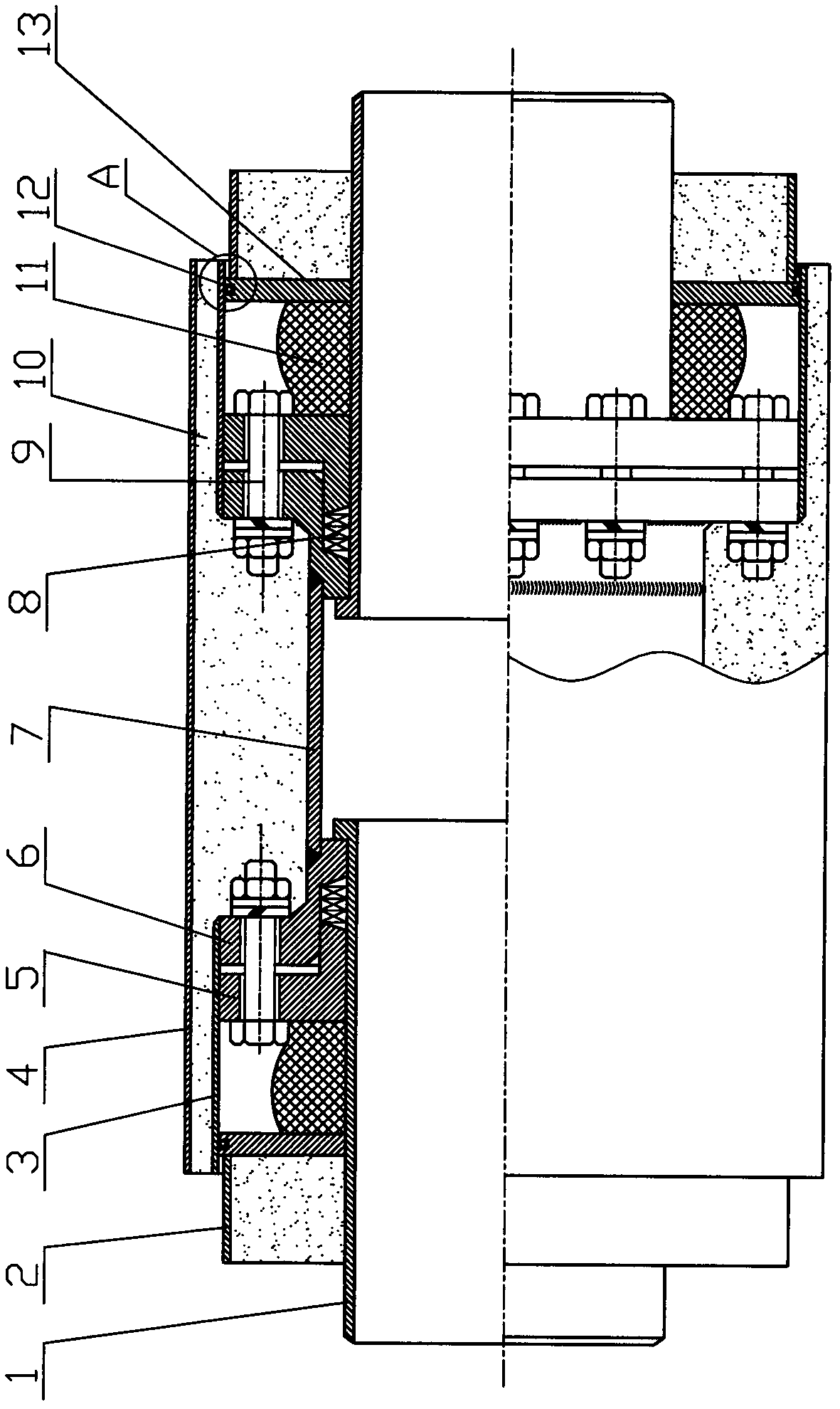

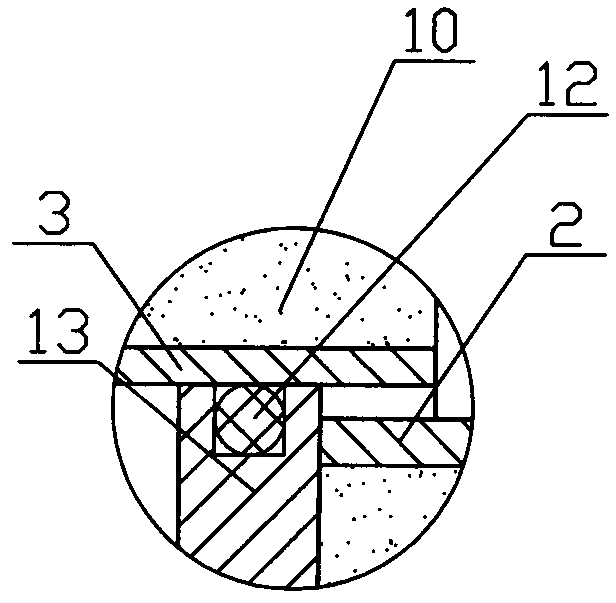

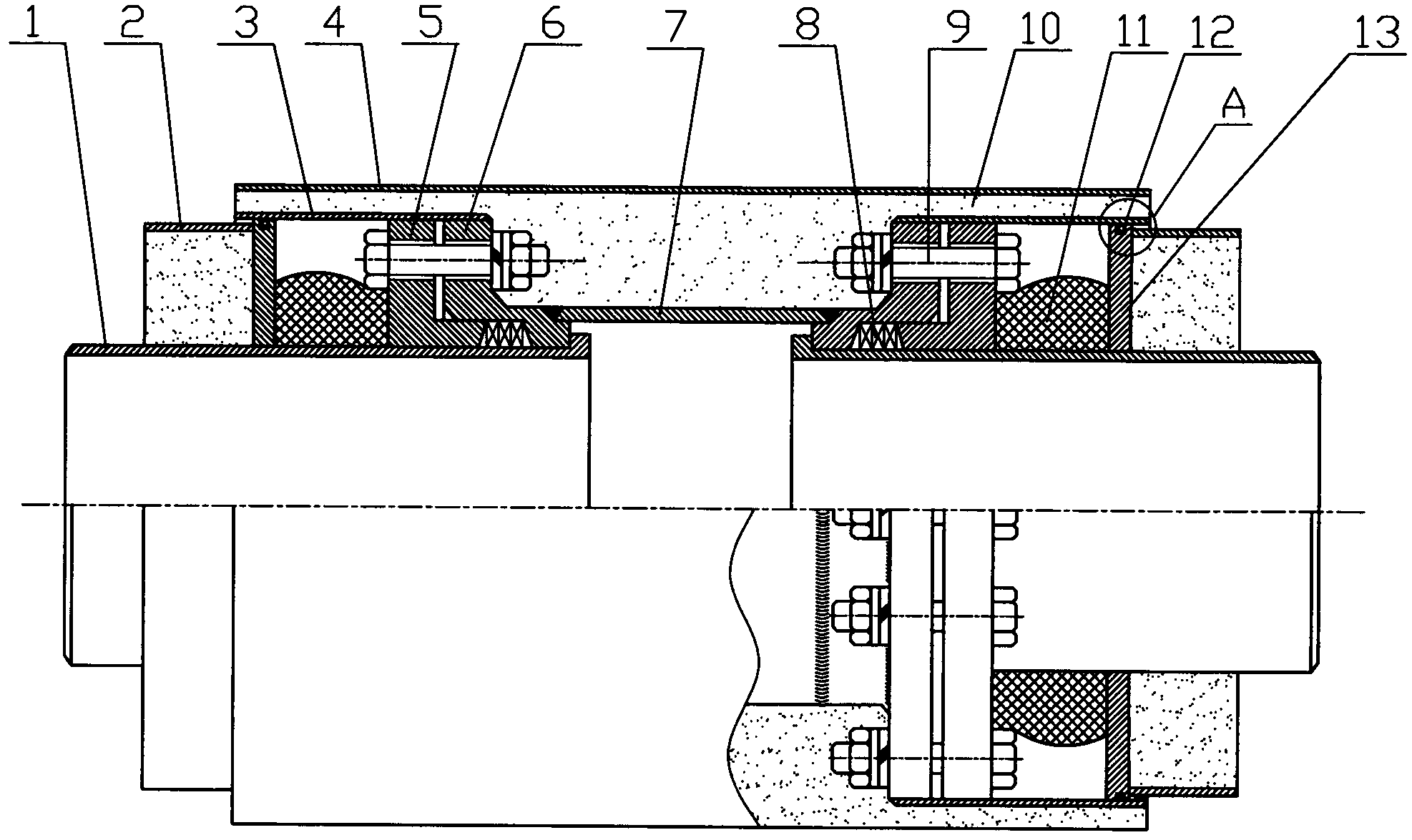

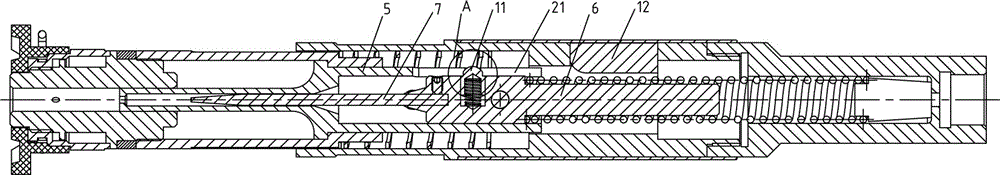

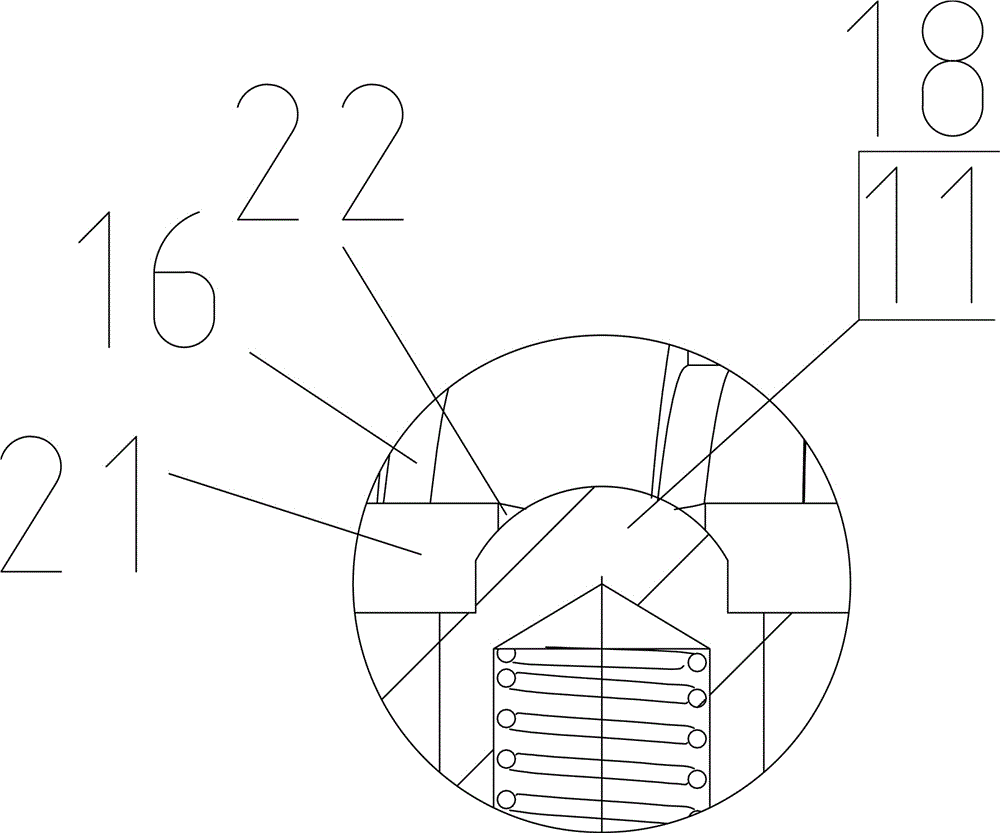

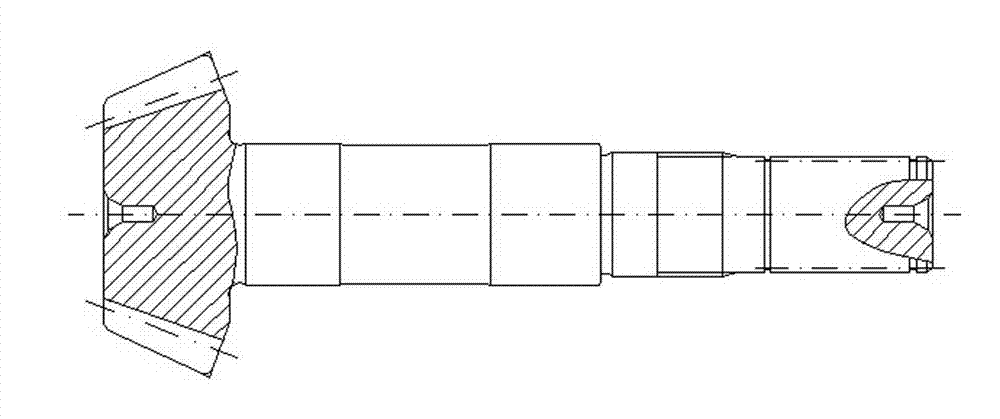

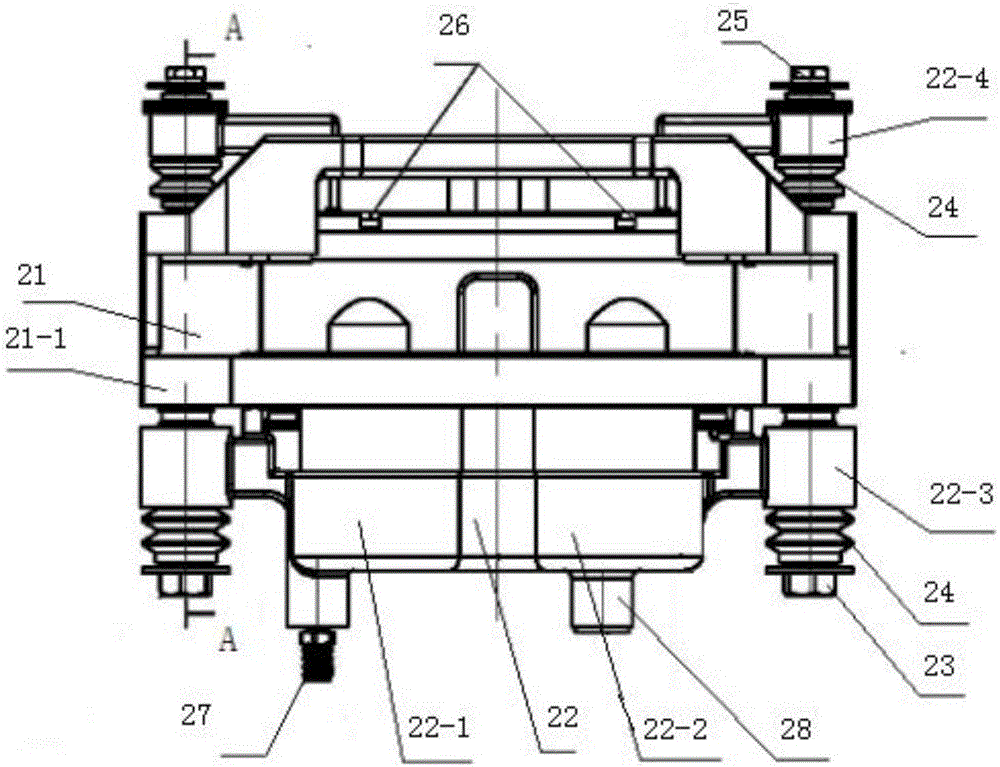

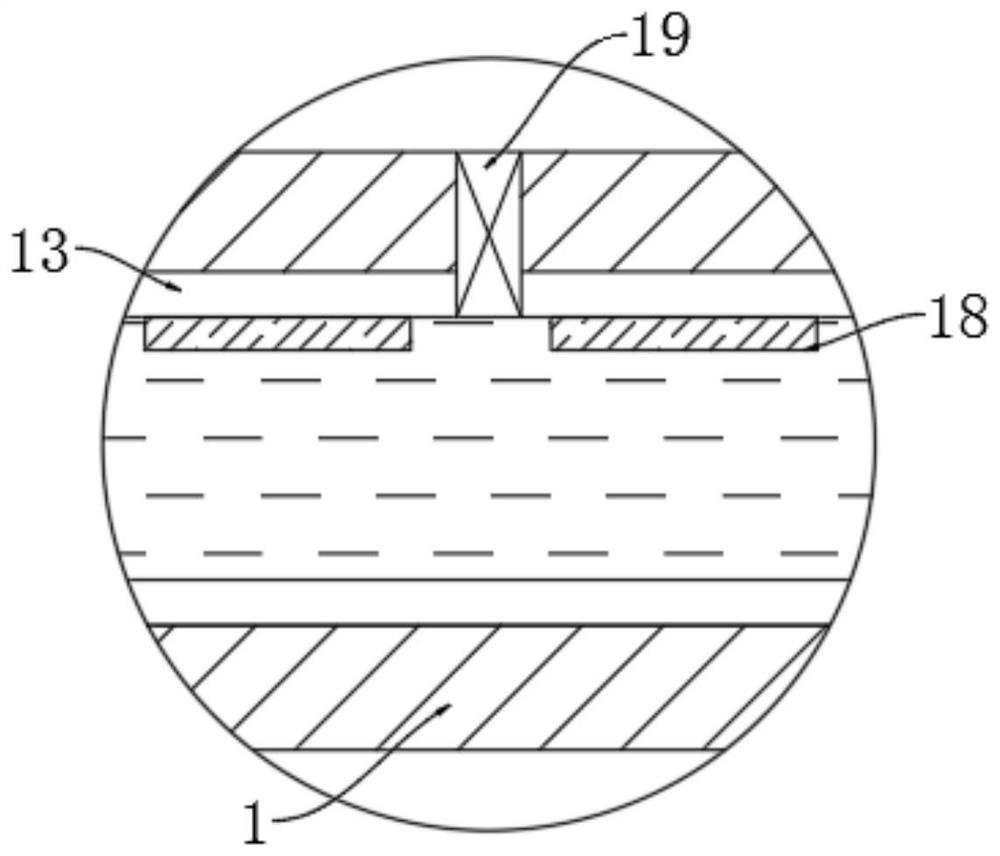

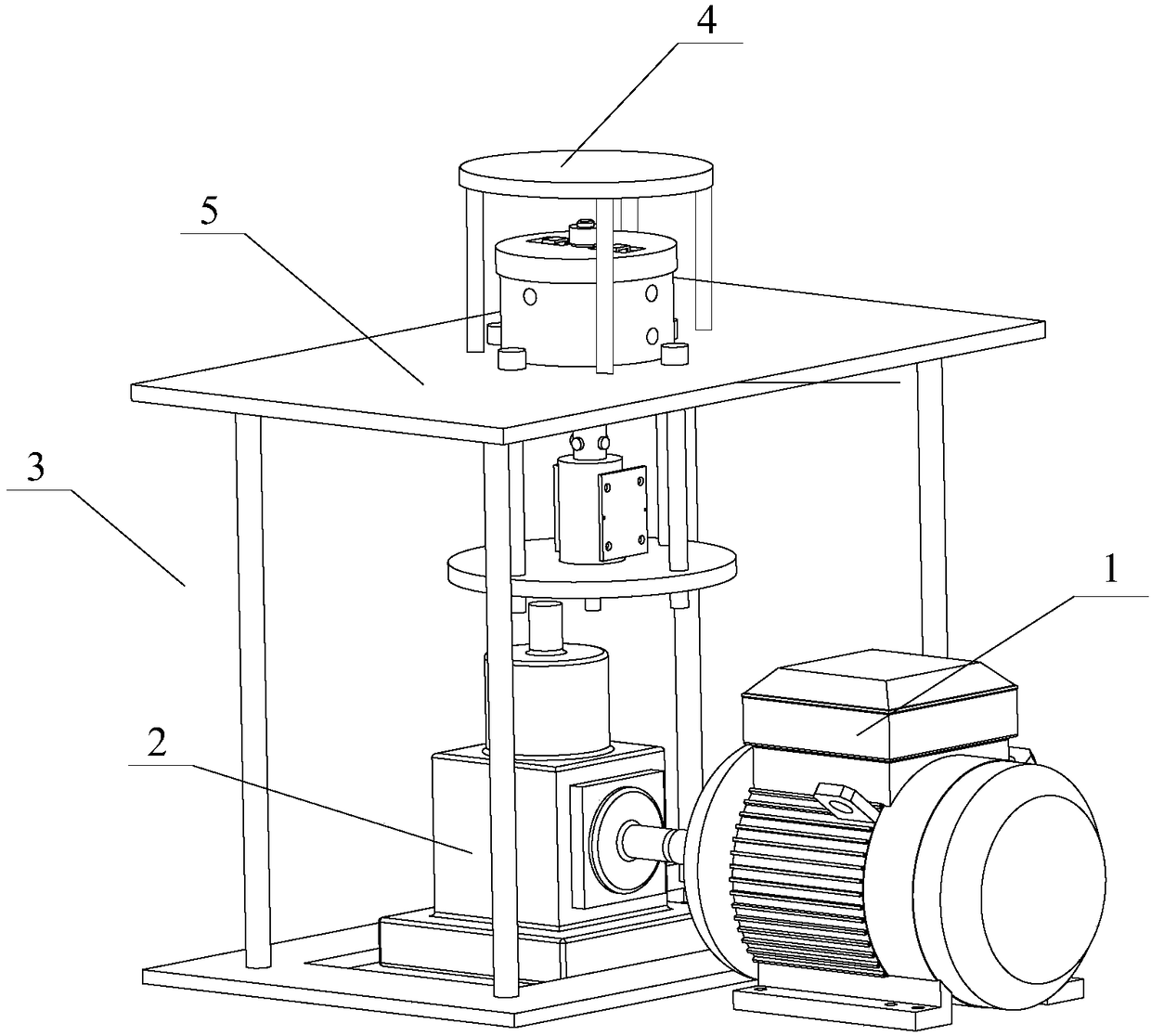

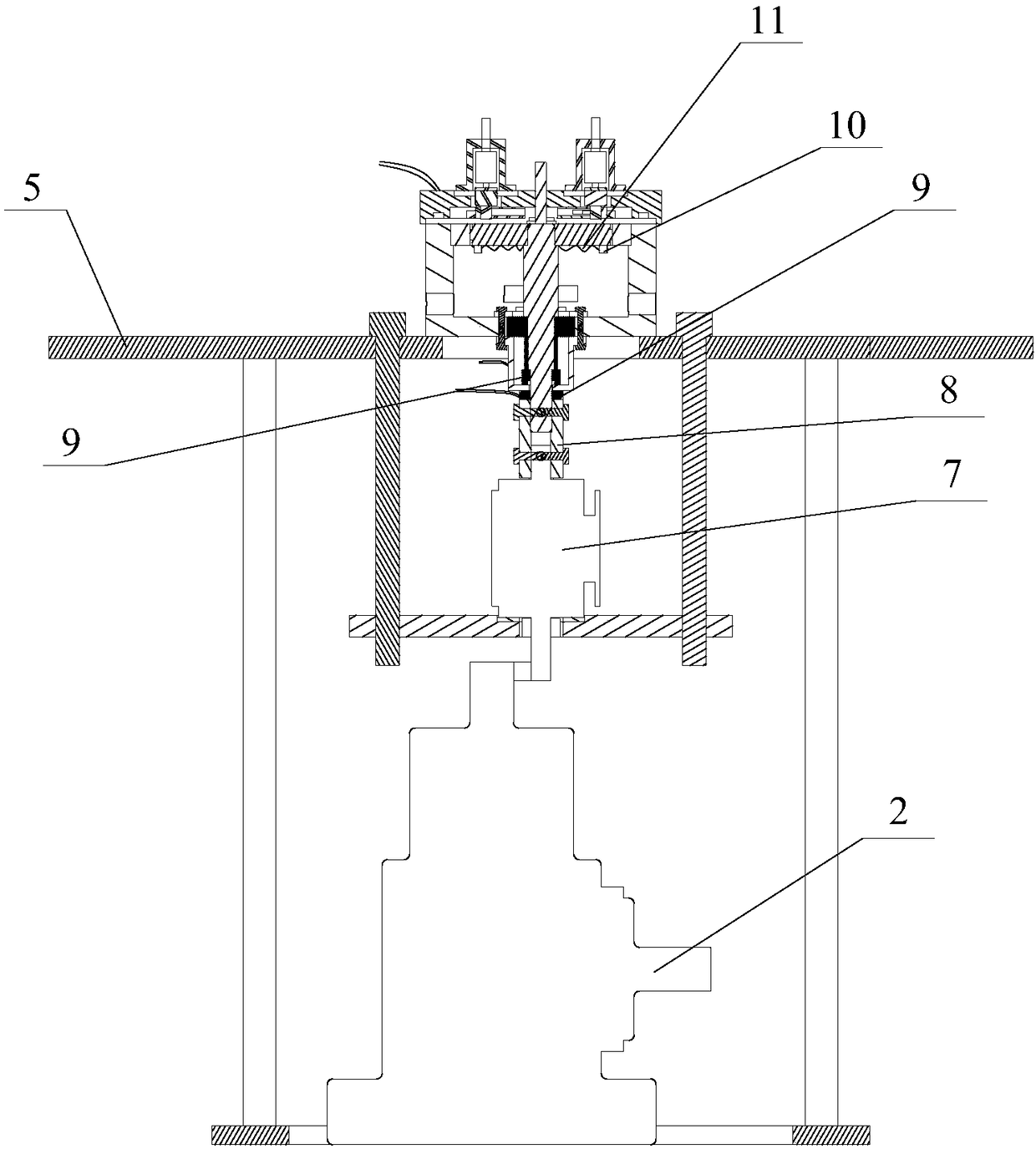

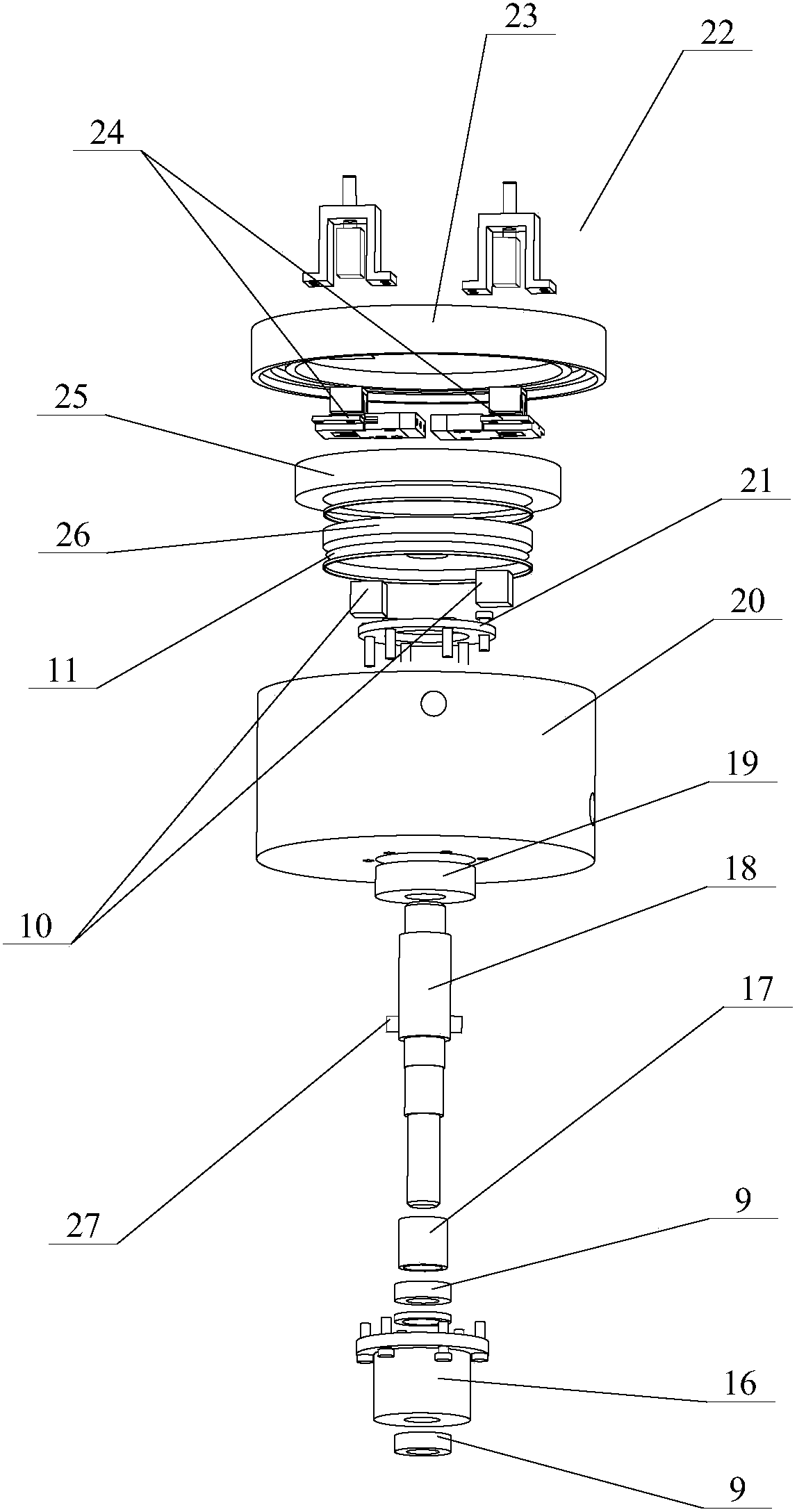

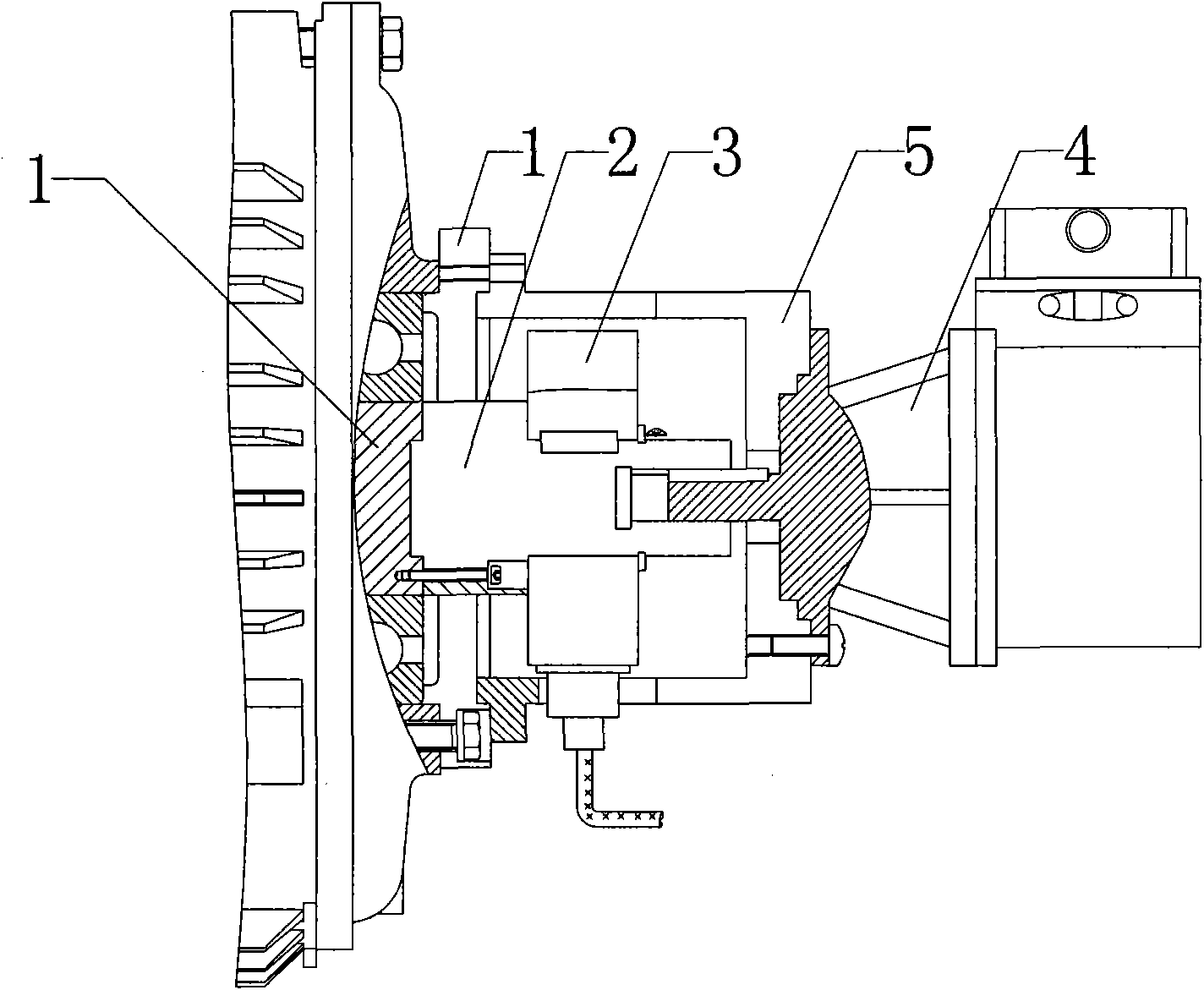

End face sealing test device for liquid rocket engine turbine pump under low-temperature and high-speed

The invention discloses an end face sealing test device for a liquid rocket engine turbine pump under a low-temperature and a high-speed. The device is applied to a sampling test of an end face sealing assembly of a rocket engine of a liquid hydrogen liquid oxygen propellant, in a running-in test and a research performance test, an end face sealing assembly product ( such as an engine static ringassembly and an engine moving ring ) is assembled in the test device of the invention, a working environment of the engine turbine pump is simulated, the sealing performance and the structural rationality of the sealing assembly product are checked, and the sealing performance of the sealing assembly product can be quantitatively detected. According to the device, the test device does not contractand deform under a low-temperature environment, and runs stably at a high speed, the device provides an important basis for improving various problems in the design of the end face sealing assembly product.

Owner:BEIJING AEROSPACE PROPULSION INST

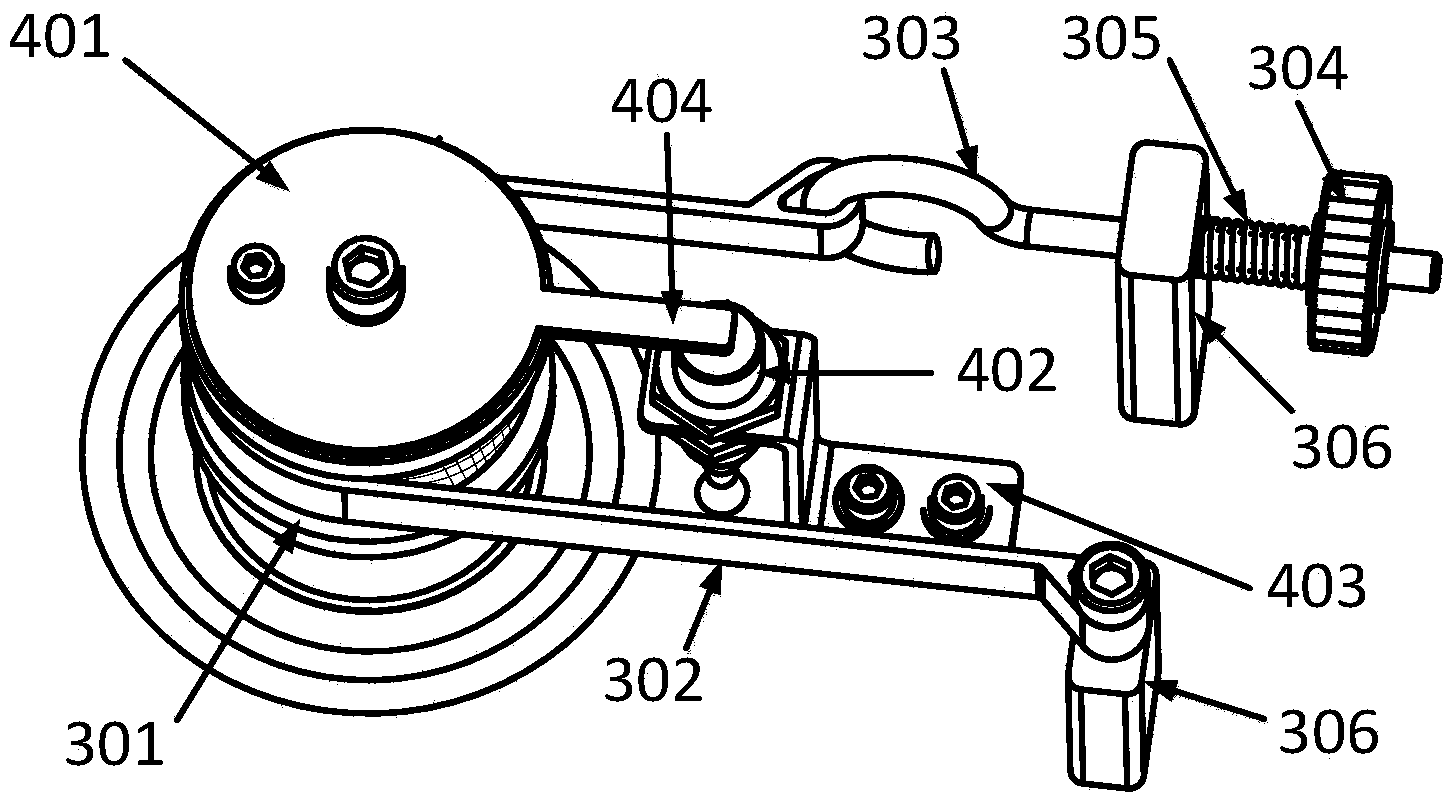

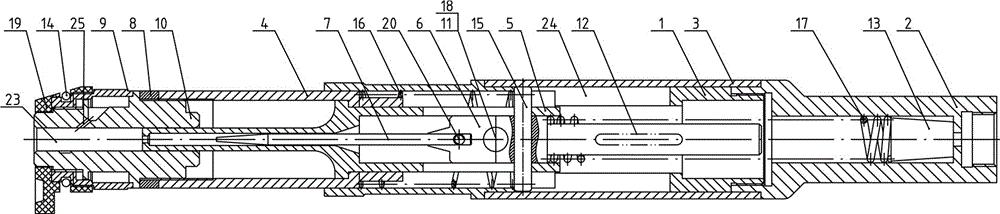

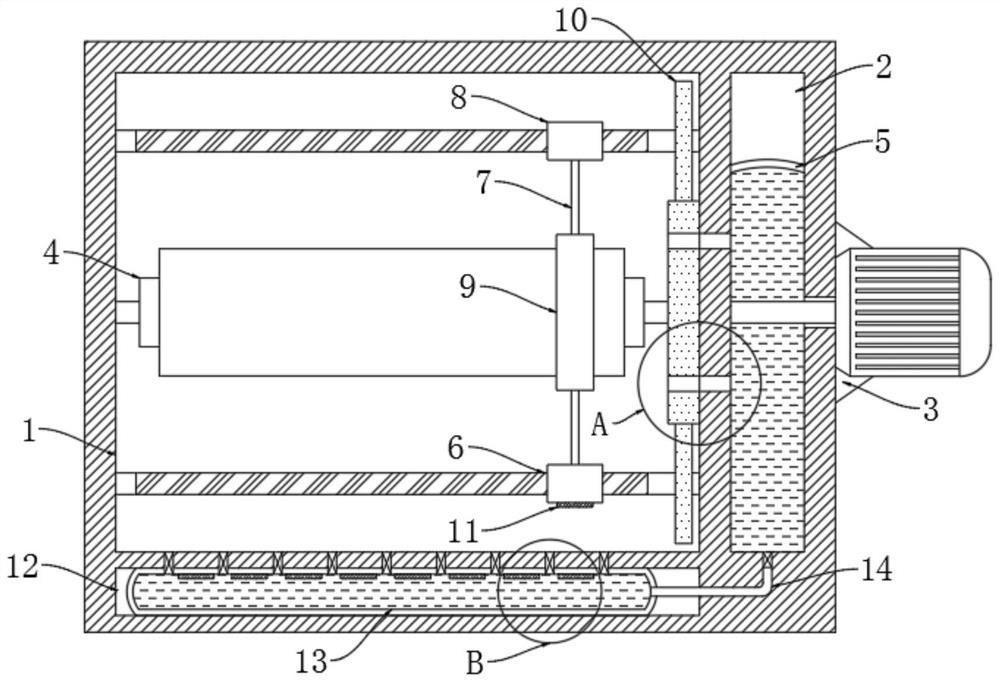

Composite material uncoiling centering adjustment device with damping function

The invention discloses a composite material uncoiling centering adjustment device with a damping function. A rotating central spindle is mounted on an uncoiling support through a pair of deep groove ball bearings in a double-bearing bearing seat. The rotating central spindle is provided with a centering shaft sleeve and a centering adjusting central shaft which are concentric, the centering shaft sleeve and the centering adjusting central shaft are provided with conical faces which are the same, and the distance of the centering shaft sleeve and the centering adjusting central shaft is adjustable, so that a coiling block and the rotating central spindle are concentrically fixed. The other end of the rotating central spindle is provided with a friction drum which is provided with a damping belt in a winding mode, one end of the damping belt is fixedly connected with the uncoiling support, and the other end of the damping belt is connected with a hook head of an adjusting hook. The cylinder end of the adjusting hook is connected to a damping support through an adjusting spring and an adjusting nut, and the tension of uncoiling can be changed by adjusting the adjusting nut. A rotating detecting piece is fixed on the end face of a friction wheel, the detecting end of a proximity sensor directly faces the extending end of the proximity sensor, and whether composite materials are broken is judged by detecting variation of received signals. The composite material uncoiling centering adjustment device has the advantages of being suitable for composite material coiling blocks of different specifications and adjustable in tension in the uncoiling process, and having the function of detecting breakage.

Owner:BEIHANG UNIV

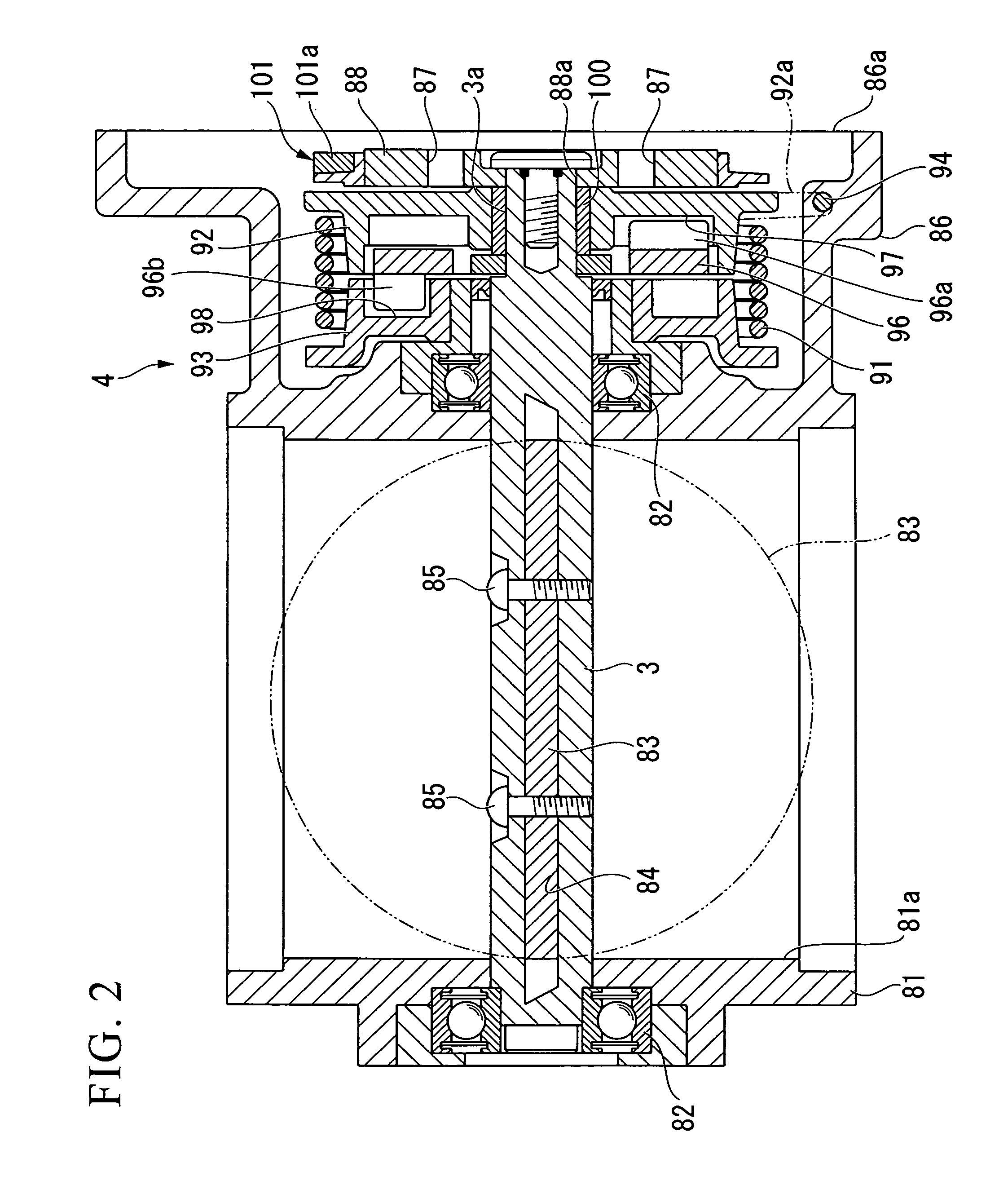

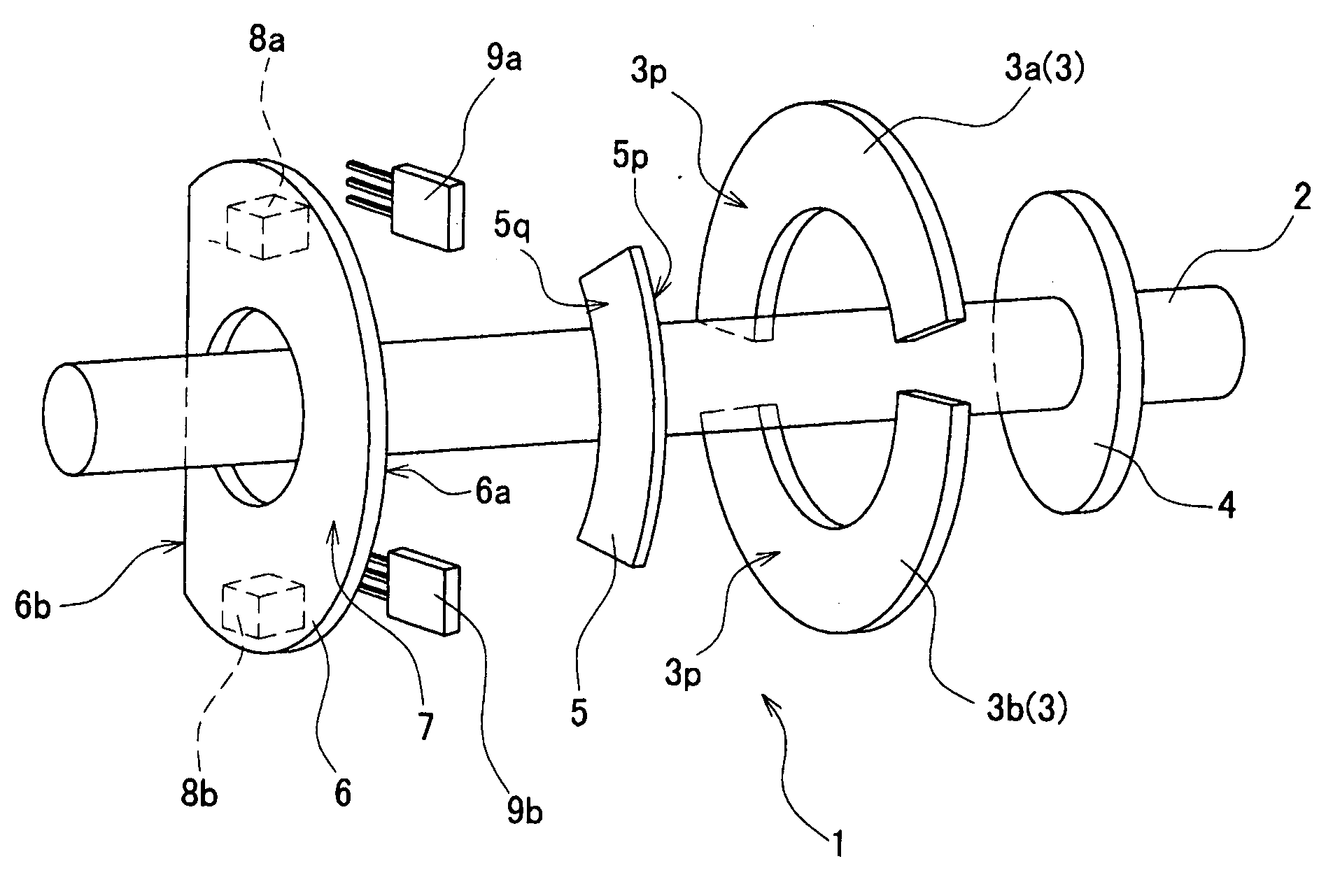

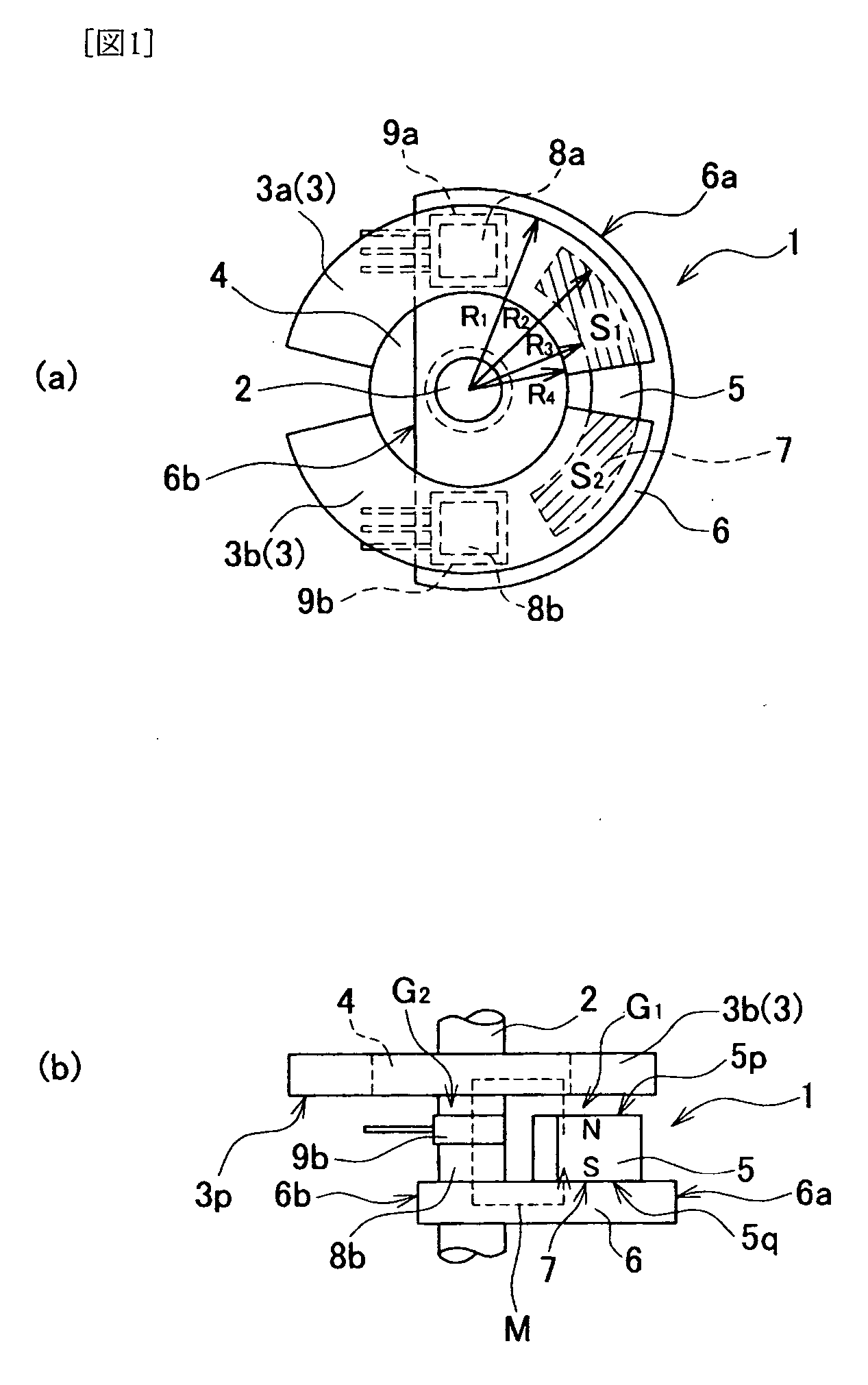

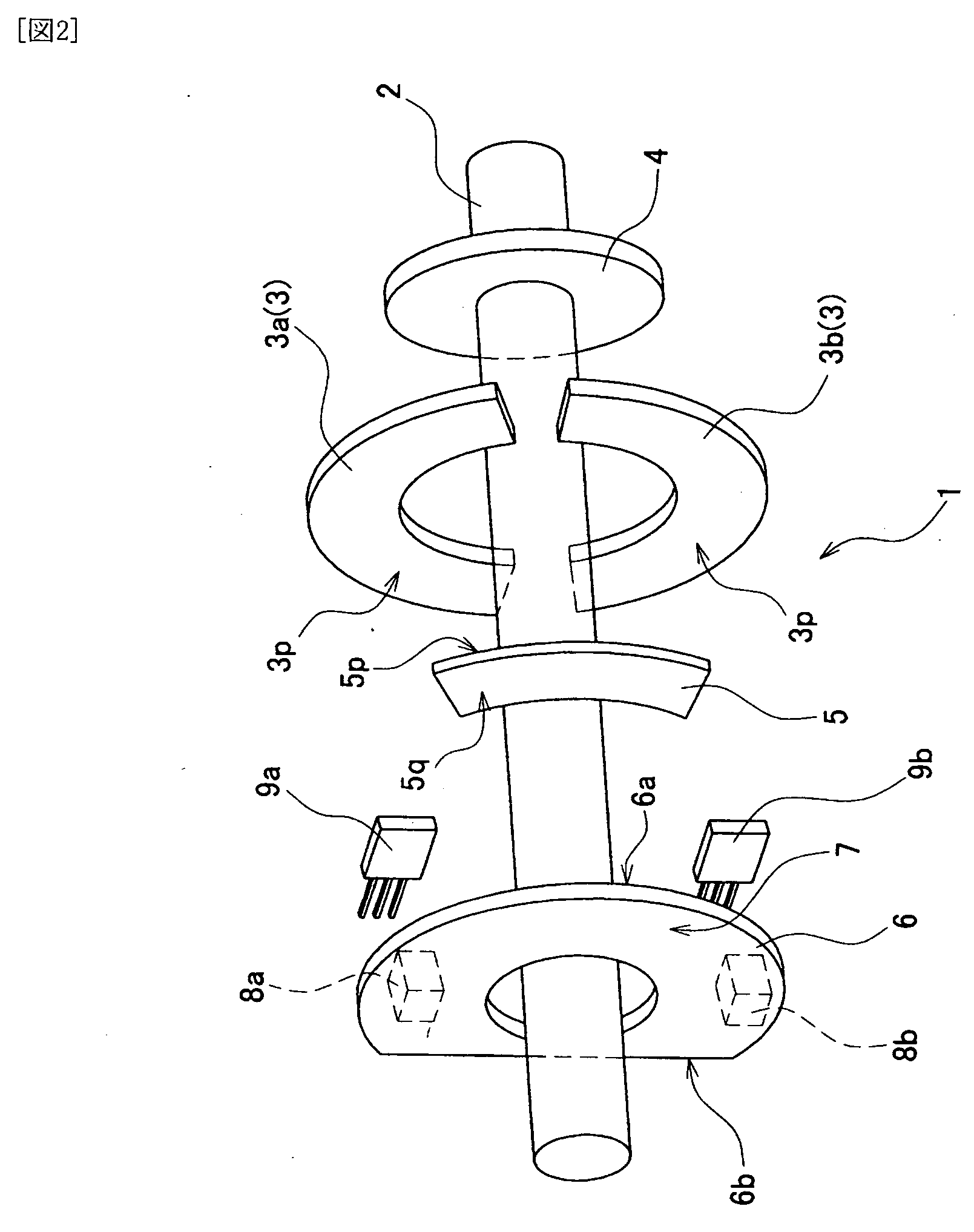

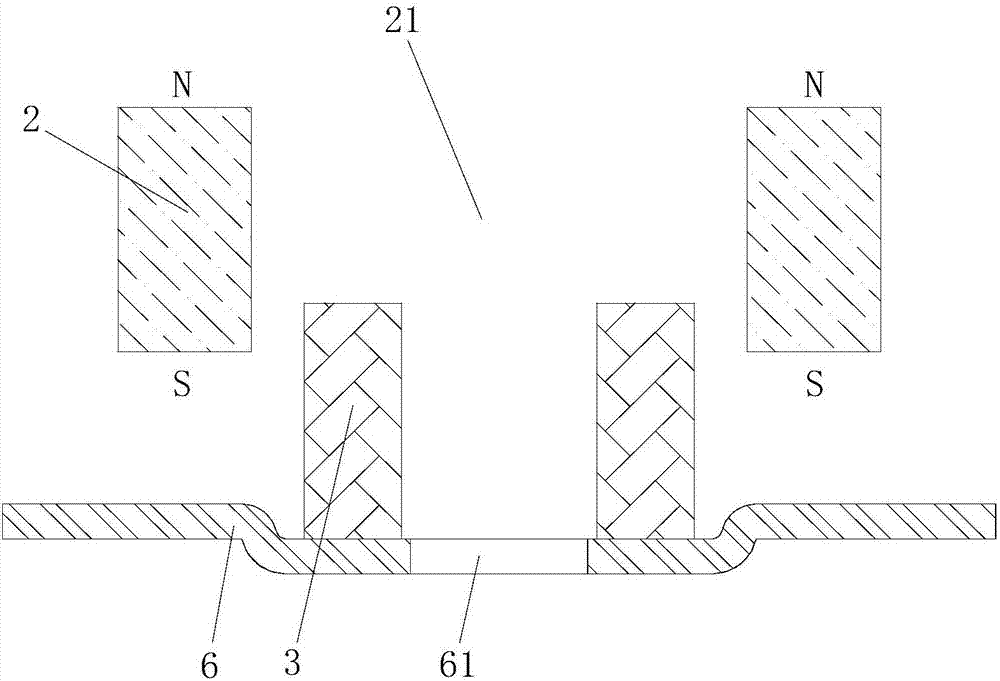

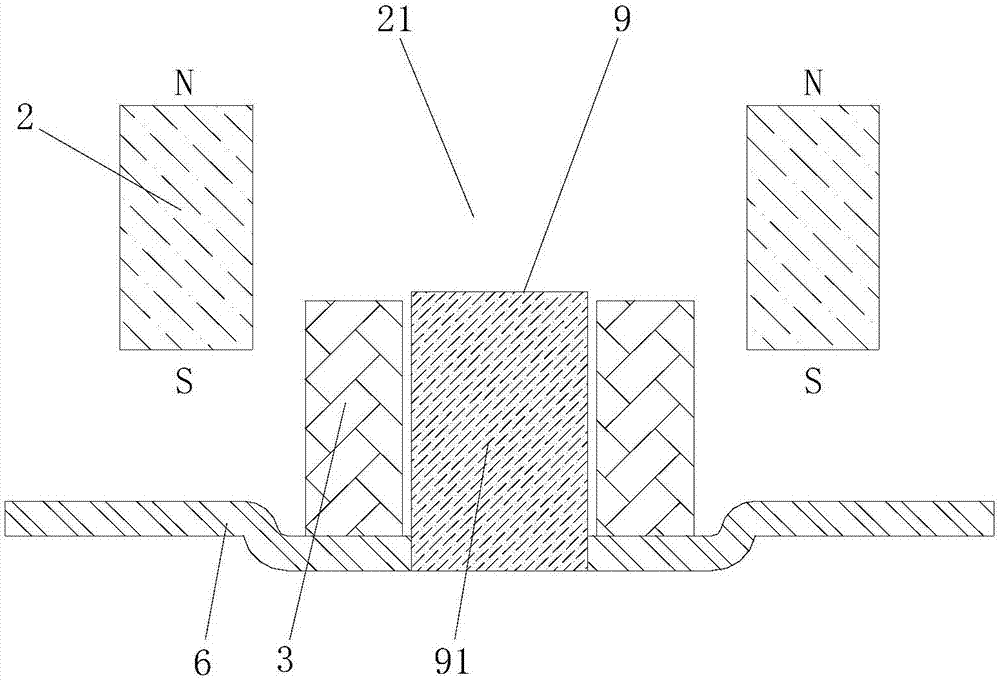

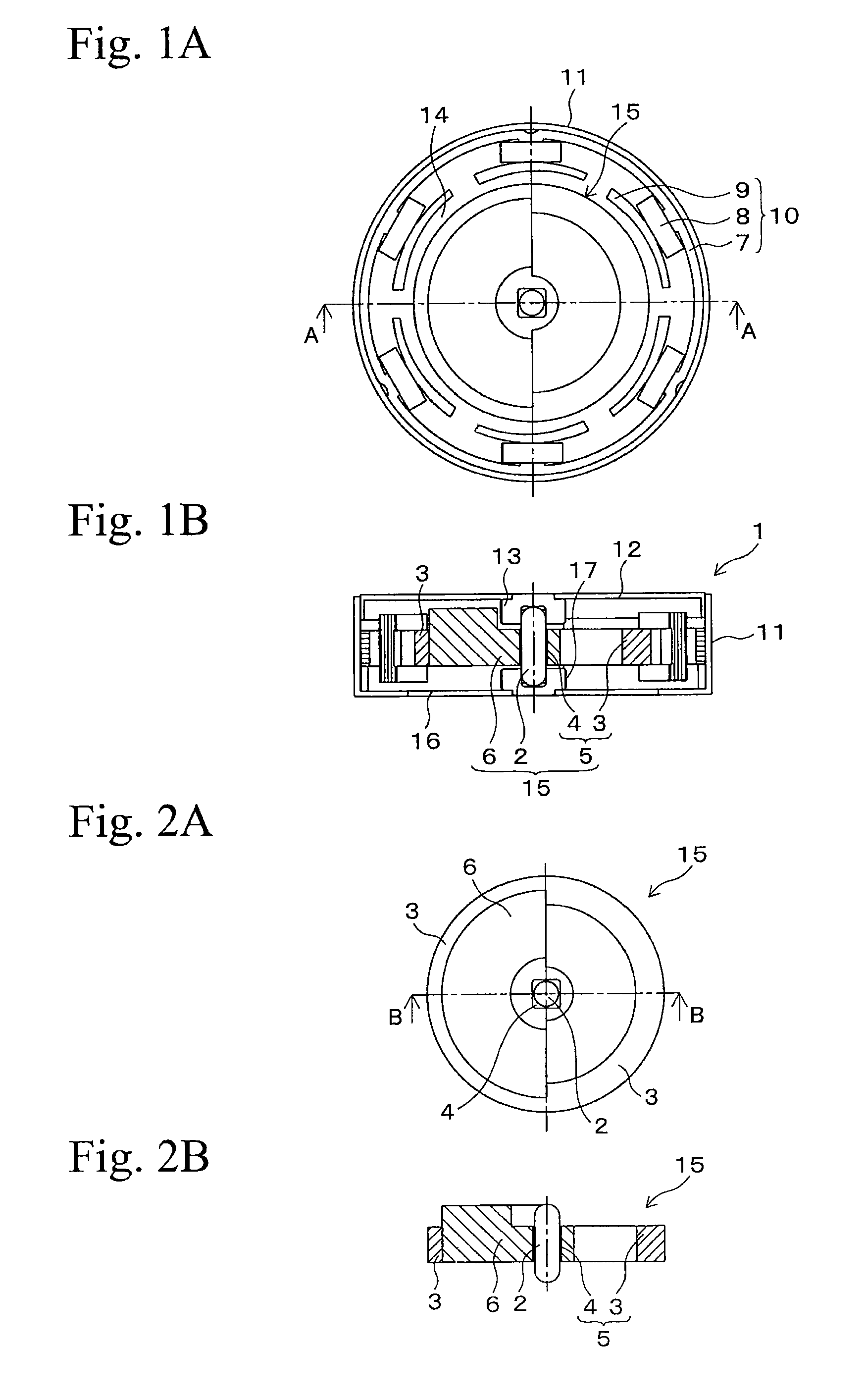

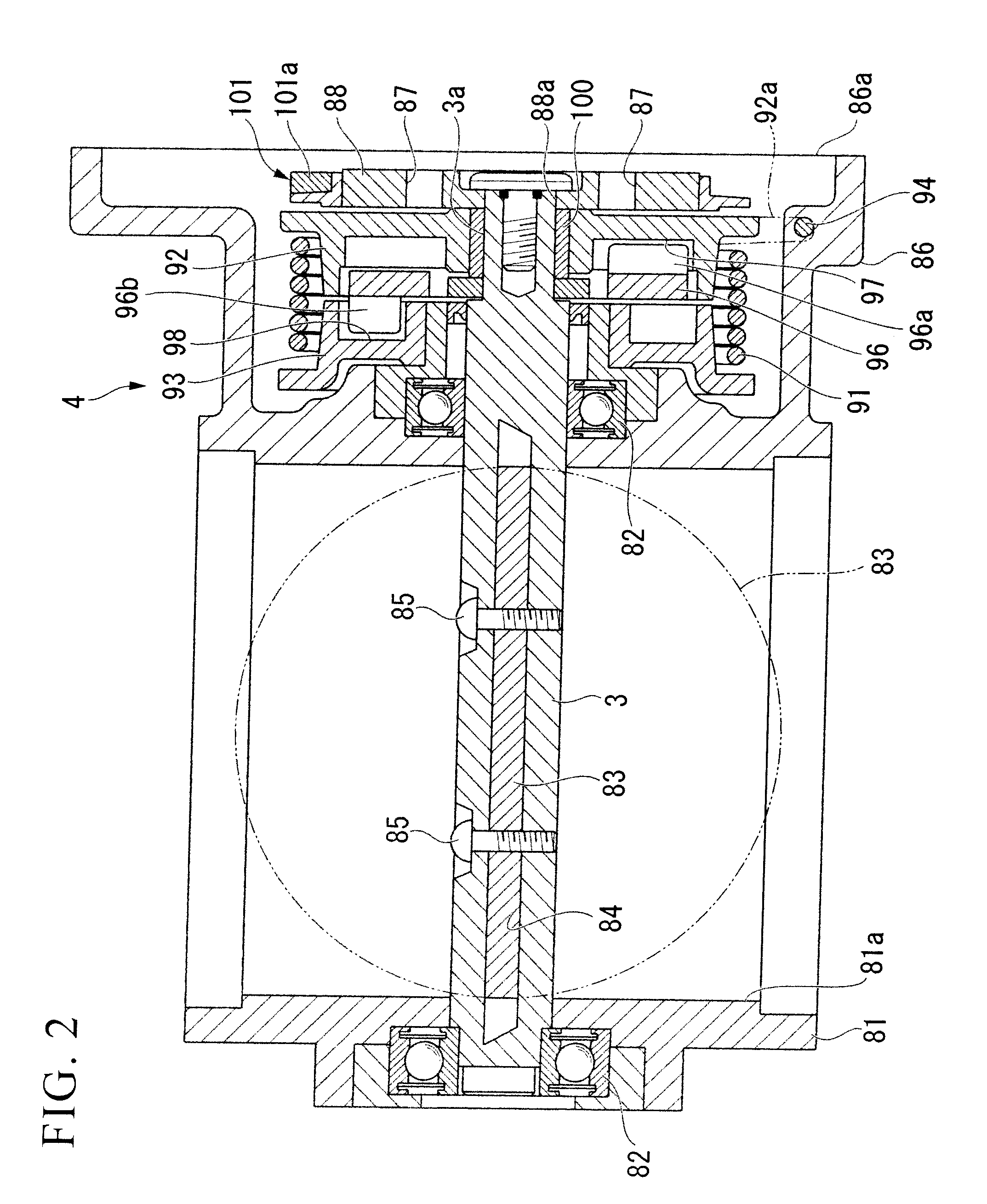

Rotation angle detection device

InactiveUS20070108968A1Shorten the length of the axial directionImprove layout flexibilityUsing electrical meansEngine controllersMagnetic fluxSynchronism

Yoke plates (3a, 3b) of magnetic material adapted for rotation in synchronism with a rotary shaft (2) are installed. An axially magnetized magnet (5) is disposed through the yoke plates (3a, 3b) and an air gap (G1). The outer diameter (R1) of the yoke plates (3a, 3b) is larger than the outer diameter (R2) of the magnet (5). The magnet (5) is fixed to a fixing plate (6) of magnetic material. Hall ICs (9a, 9b) are attached to the front ends of the pole pieces (8a, 8b) of the fixing plate (6). The Hall ICs (9a, 9b) are disposed in a magnetic circuit (M) formed by the magnet (5). When the rotary shaft (2) rotates, the opposed areas (S1, S2) between the magnet (5) and the yoke plates (3a, 3b) vary, so that the density of magnetic flux passing through the Hall ICs (9a, 9b) in the magnetic circuit (M) linearly varies in proportion to the rotation angle. The Hall ICs (9a, 9b) catch this variation and detect the rotation angle of the rotary shaft (2). Thereby, the cost of production of the rotation angle detection device is reduced without deteriorating the detection accuracy.

Owner:MITSUBA CORP

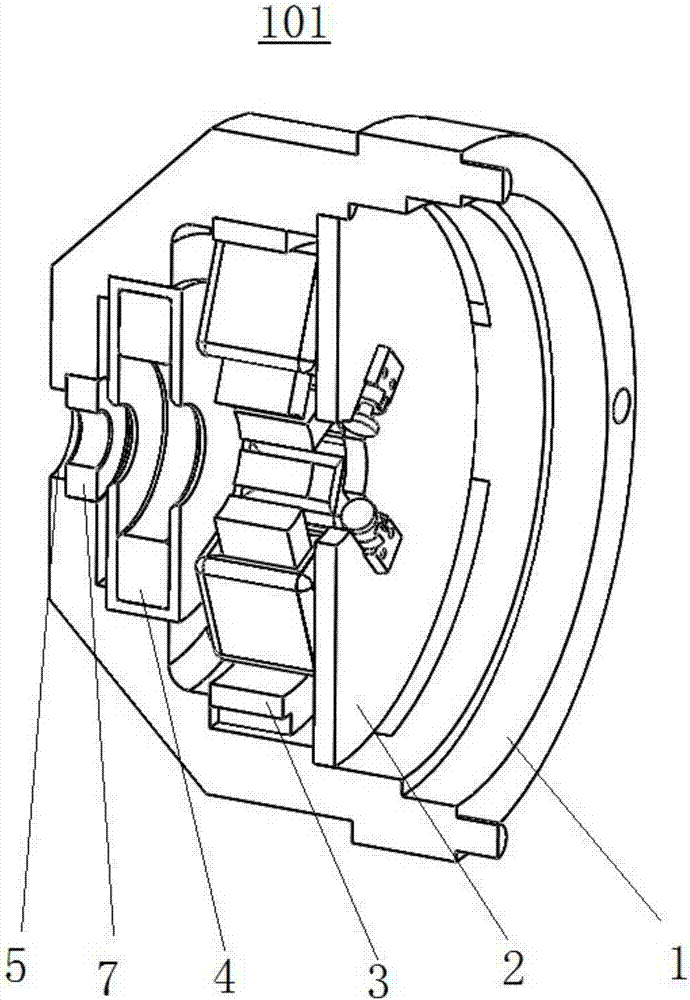

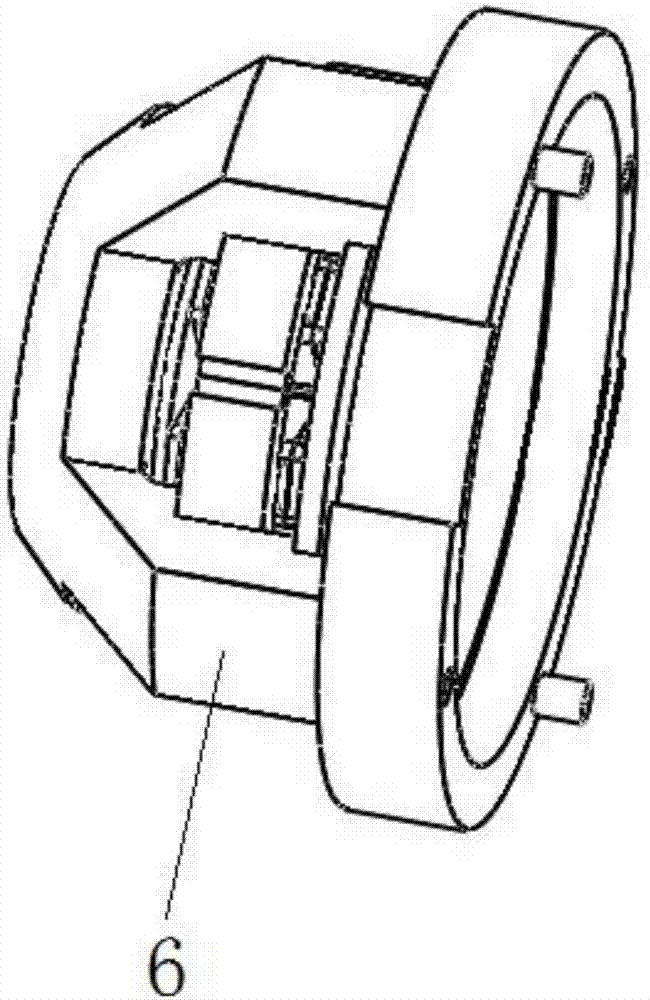

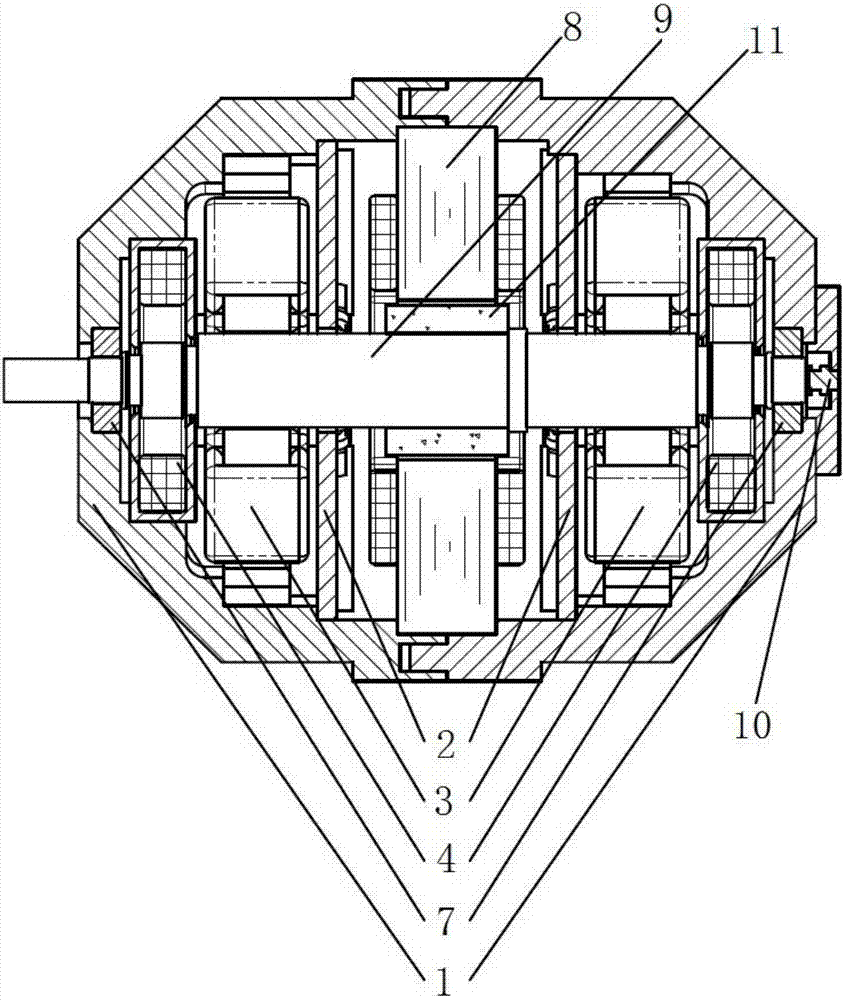

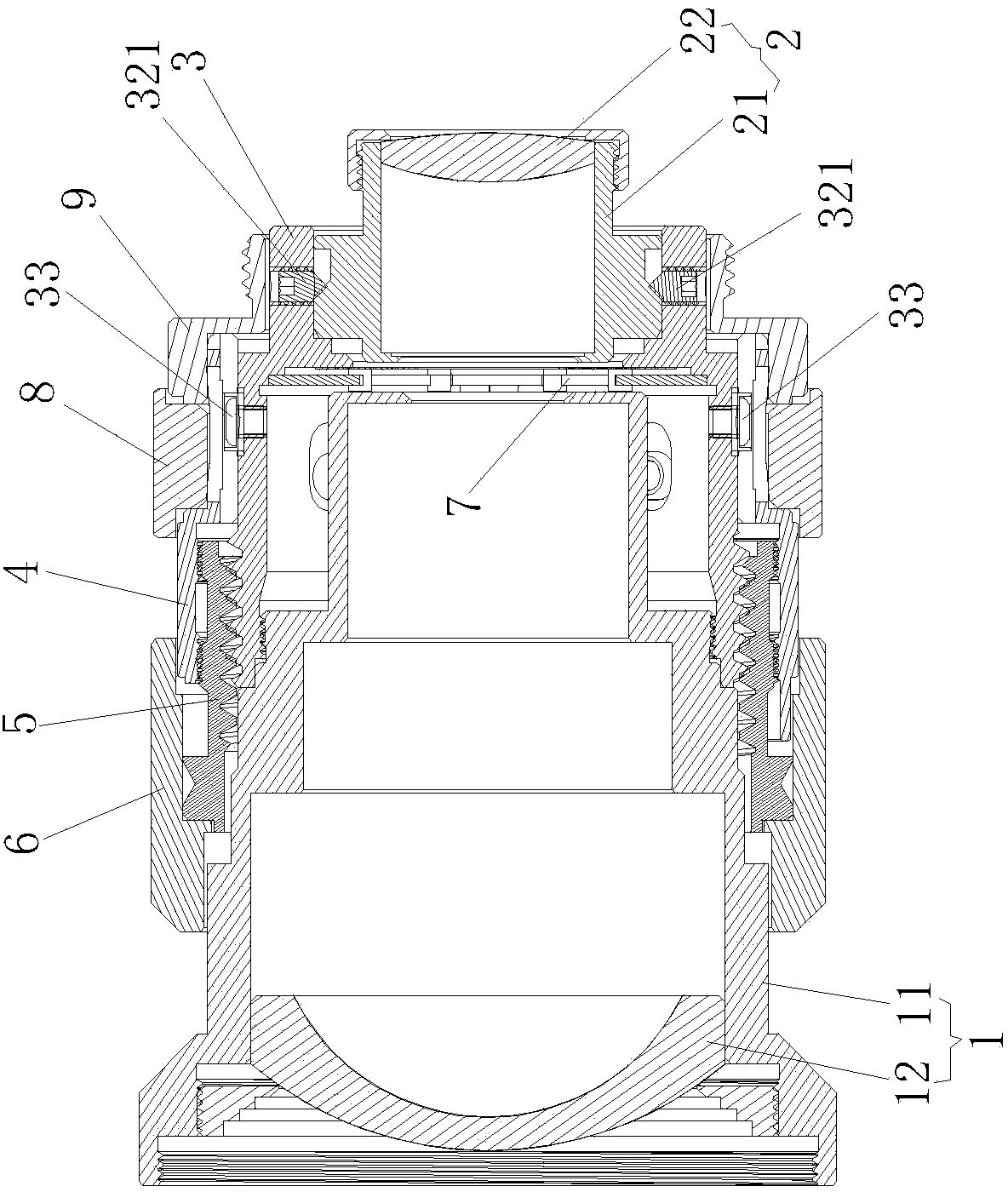

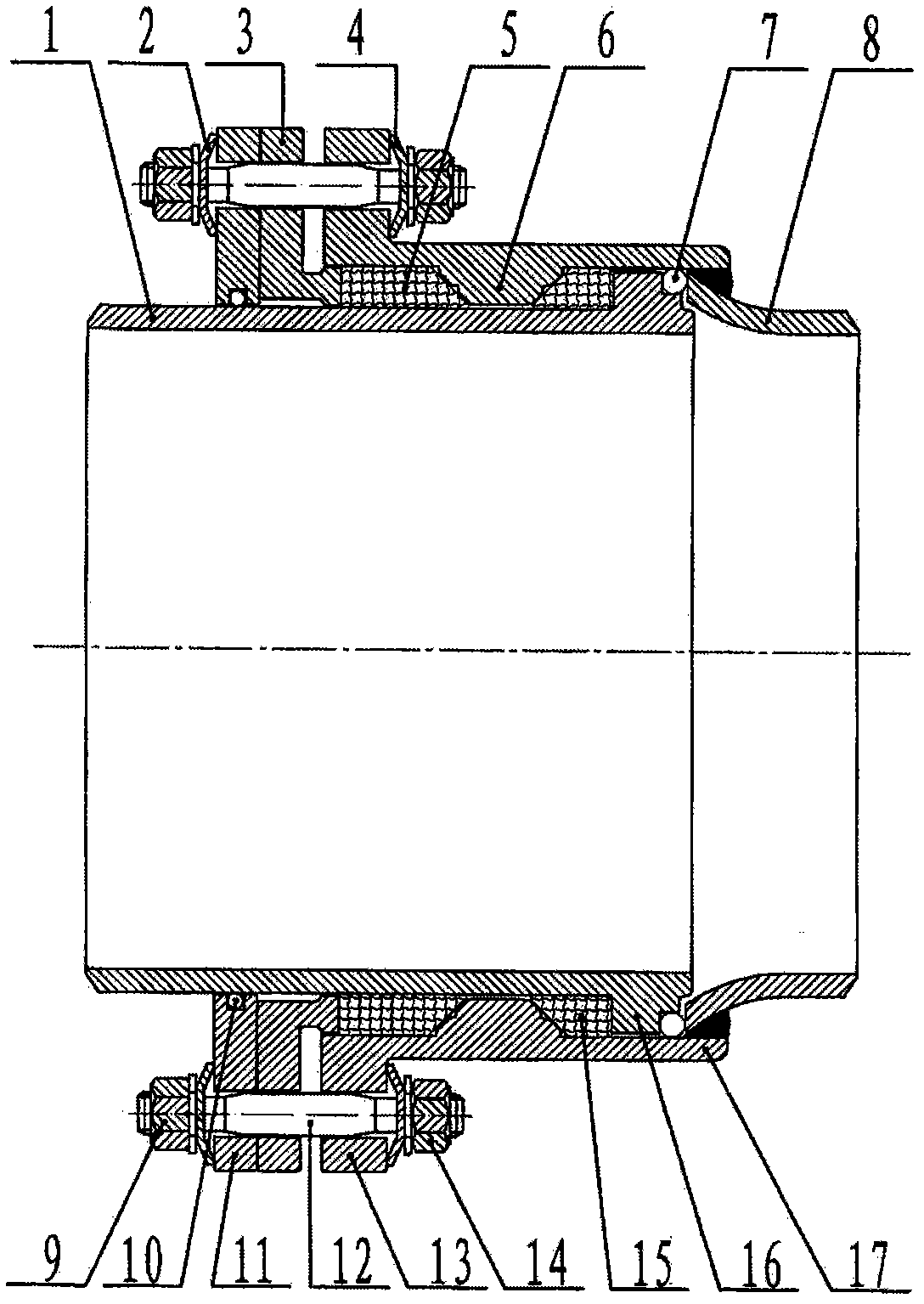

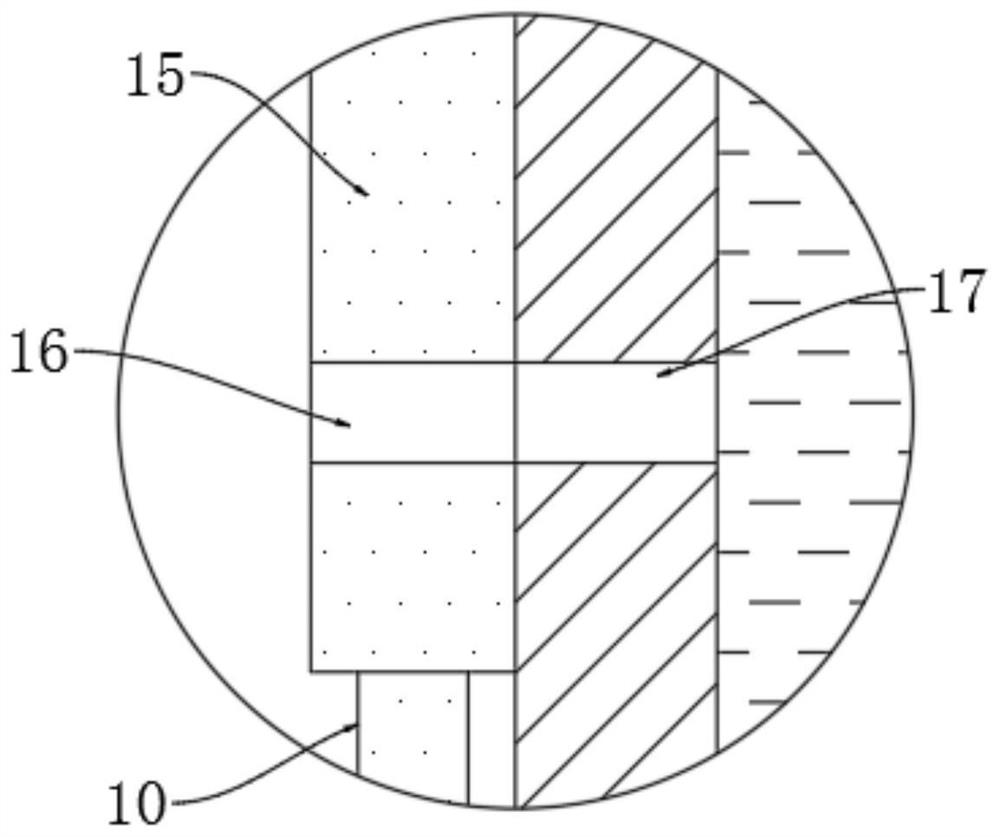

A magnetic suspended rotor support system, a magnetic suspension motor and a dust collector

PendingCN107124069AHigh coaxial precisionReduce in quantityMechanical energy handlingStructural associationSupporting systemMagnetic bearing

The invention relates to the technical field of motors, and especially relates to a magnetic suspended rotor support system, a magnetic suspension motor and a dust collector provided with the motor. The magnetic suspended rotor support system includes a shell, a radial displacement sensor, a radial magnetic bearing and an axial magnetic bearing; the radial displacement sensor, the radial magnetic bearing and the axial magnetic bearing are all coaxially arranged in the shell; the shell is provided with an opening at one end in the direction of arrangement of the radial displacement sensor, the radial magnetic bearing and the axial magnetic bearing to receive a motor stator core; and the other end of the shell is provided with a shaft hole for a rotor shaft to extend to the outside. The structure is compact, and the invention is applicable to production of miniature motors. The modularization production of the motor is realized; the quantity of parts is relatively small in the modularization production; the coaxiality of the parts in the magnetic suspended rotor support system can be firstly guaranteed; the raise of the coaxiality precision of the whole motor can be facilitated; the production efficiency can be raised; and the cost can be reduced.

Owner:北京昆腾迈格技术有限公司

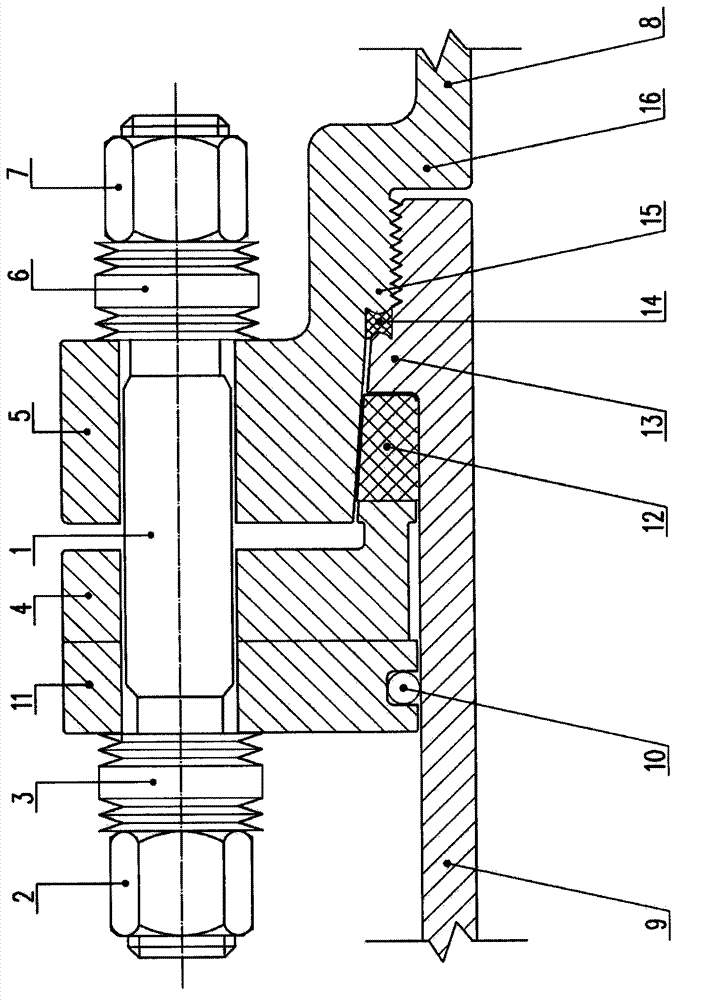

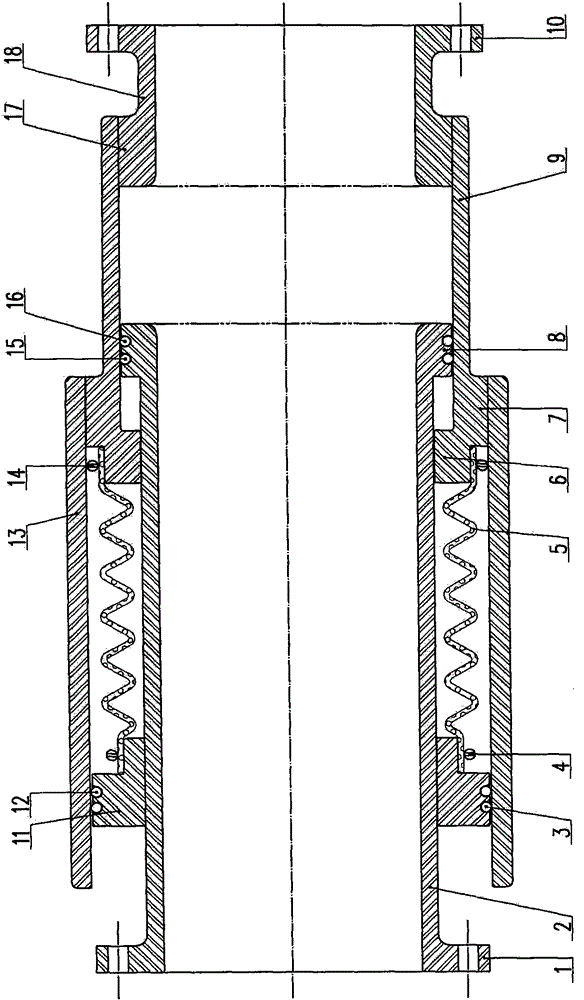

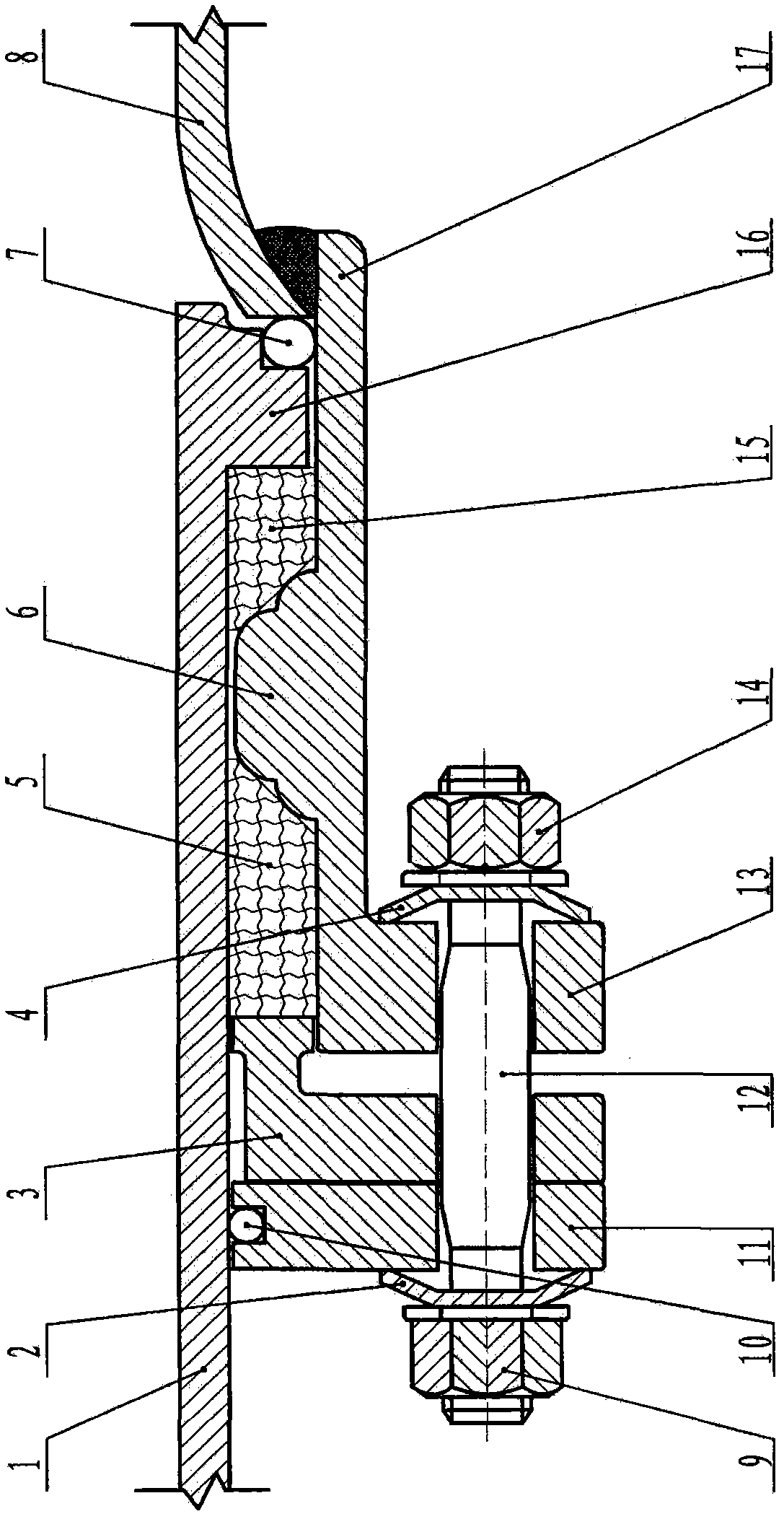

Novel precision-type high-pressure-resistant rotary compensator

InactiveCN104329529AGuaranteed uptimeEasy maintenancePipeline expansion-compensationAdjustable jointsReducerHigh pressure

The invention discloses a novel precision-type high-pressure-resistant rotary compensator and belongs to the technical field of heat power pipeline compensation device structures. The novel precision-type high-pressure-resistant rotary compensator comprises an outer pressing cover flange, a sealing piece pressing flange and a reducer pipe, wherein the outer pressing cover flange is integrated by fixing a stud, a nut A and a nut B; an inner pipe with an inner pipe convex outer ring is inserted into the reducer pipe and is spirally connected with the reducer pipe; a structure that the reducer pipe, the outer pressing cover flange, the sealing piece pressing flange and the inner pipe can coaxially, synchronously, entirely, relatively and rotatably move along the radial direction by virtue of the rotation of a threaded area when being pushed by radial heat expansion force is formed, and the reducer pipe, the outer pressing cover flange and the sealing piece pressing flange are fixed integrally. With the structure, the novel precision-type high-pressure-resistant rotary compensator has the advantages that the coaxial accurate is high, the pressure bearing capacity is higher, the flowing direction of a medium is not limited, and a pipeline is safer to operate and convenient to maintain.

Owner:陈墅庚

Electric motor, rotary actuator and rotary apparatus

InactiveUS20100176666A1High precisionSimple structureAssociation with control/drive circuitsMagnetic circuit characterised by insulating materialsControl theoryRotary actuator

A rotary actuator including: a housing that rotatably supports thereinside a rotor shaft of an electric motor; an eccentric shaft portion that is provided on a protruding end portion of the rotor shaft that protrudes outside the housing; an external gear that is rotatably supported on the eccentric shaft portion via a bearing; an internal gear that is fixed to an outer surface of the housing and meshes with the external gear; and a transmitting portion that is provided on the external gear, and transmits rotation force to an external output shaft.

Owner:KEIHIN CORP

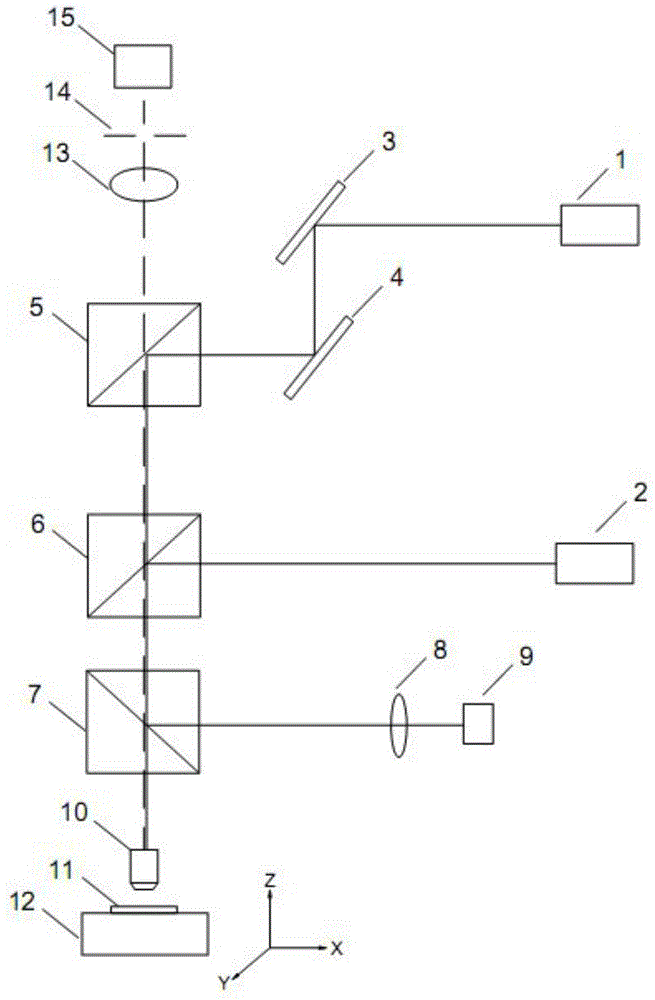

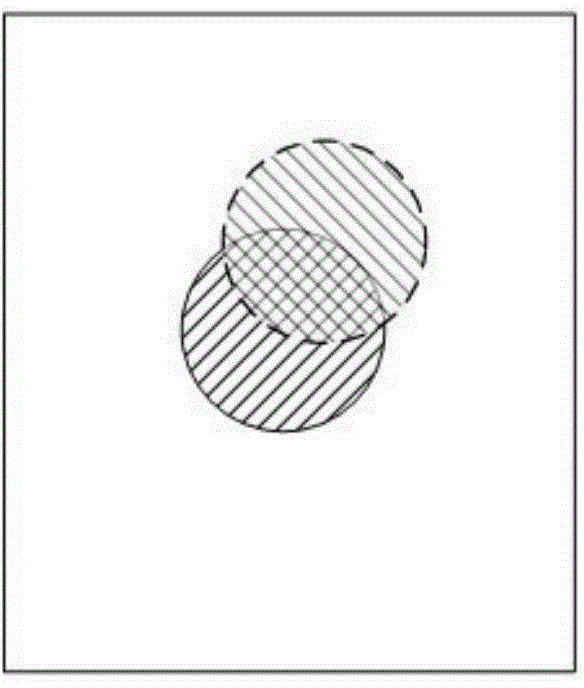

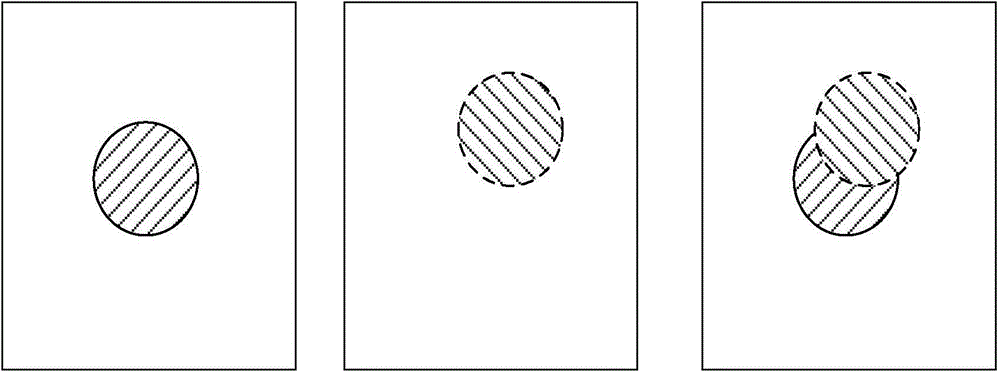

Coaxiality detection and adjusting method of multiple beams

ActiveCN104535296AReduce addReduce complexityOptical apparatus testingConfocal laser scanning microscopeParticulates

The invention discloses a coaxiality adjusting method of multiple beams. The method comprises the following steps that: step (1), a plurality of reflectors or beam splitters are arranged at light paths of a plurality of laser light sources, so that light emitted by the multiple laser light source is combined into one beam of light that can not be distinguished by naked eyes; step (2), a particulate matter that can reflect laser is selected, wherein the particle size of each particle of the particulate matter is less than the diameter of the light spot of the light beam that can not be distinguished by naked eyes; step (3), with an imaging device arranged at a confocal laser scanning microscope, scanning imaging is carried out on the particulate matter by the light beam that can not be distinguished by naked eyes; and step (4), if the obtained image contains a double image, the light beam that can not be distinguished by naked eyes is not a coaxial one, and the reflectors or beam splitters are adjusted and the step (3) is carried out again; and if no double image exists in the obtained image, the light beam that can not be distinguished by naked eyes is the coaxial one and thus adjustment is completed.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Direct-connected integrated gear pump

InactiveCN102102667AIncrease the required lifeHigh coaxial precisionRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention relates to a direct-connected integrated gear pump which is mainly characterized in that the device comprises a front end cover connection body and a back end cover pump body, wherein the front end cover connection body and the back end cover pump body are fixedly connected; an oil outlet, an oil outlet one-way valve and an overpressure protection valve are arranged on the back end cover pump body; the oil outlet one-way valve and the overpressure protection valve are integrally communicated; an antifriction alloy casting is inlayed in an inner chamber of the back end cover pump body; and the front end cover connection body, the back end cover pump body, an oil inlet, the oil outlet one-way valve and the overpressure protection valve are casted into an integral communication structure. In the invention, the back end cover pump body and the front end cover connection body are integrally assembled; therefore, the direct-connected integrated gear pump has the advantages of high coaxial precision, simple structure and convenience for assembling, and can enhance the cumulative tolerance of the combination of the components and parts of the gear pump, lighten the total weight, enhance the volumetric efficiency and prolong the life by 2 times.

Owner:浙江奥力电机股份有限公司

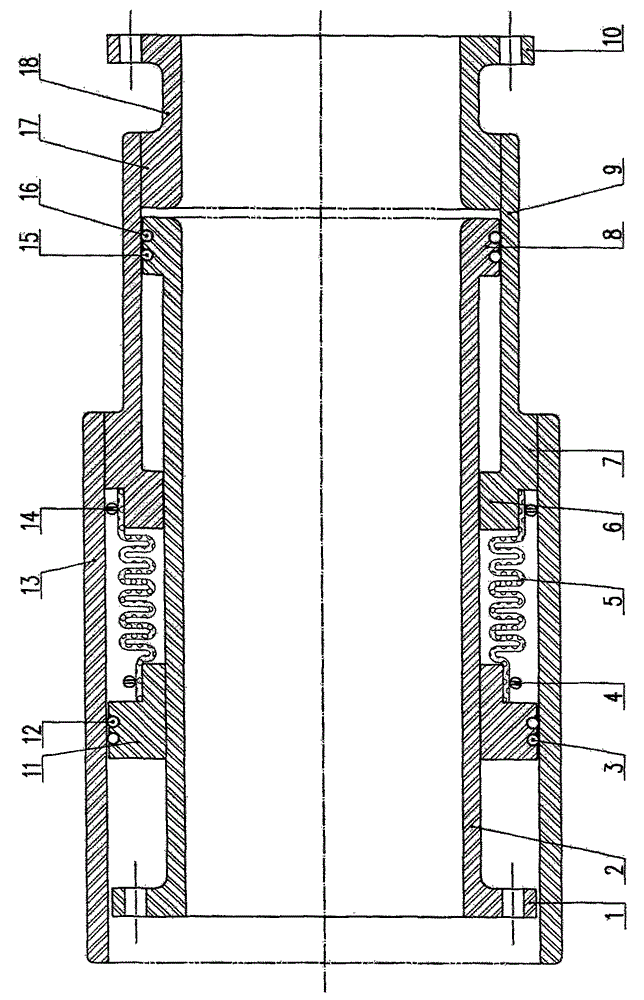

New Plastic Pipe Compensator

InactiveCN103968179BGuaranteed uptimeHigh coaxial precisionPipeline expansion-compensationPlastic pipeworkEngineering

The invention discloses a novel plastic pipeline compensator and belongs to the technical field of heat distribution pipeline compensation devices. A pipe A combination structure is formed by an external connection flange B, a pipe A, a sealing framework and a pipe A protruding outer ring, a pipe B combination structure is formed by an external connection flange A, a pipe B, a pipe B protruding outer ring, a core pipe, a core pipe protruding outer ring, a pulling and disengaging preventing limit ring and an outer casing pipe, and when being squeezed by axial heat expansion force, the pipe A combination structure and the pipe B combination structure can integrally move relative to each other axially, coaxially and synchronously through flexible deformation of a corrugated pipe. With the structure, the novel plastic pipeline compensator has the advantages of being high in coaxial precision, smaller in friction efficient, self torque and pressure loss, higher in bending resisting capability and loading capability, reliable in sealing, good in performance and convenient to maintain, the medium flowing direction is not limited, and pipeline operation is safer.

Owner:陈墅庚

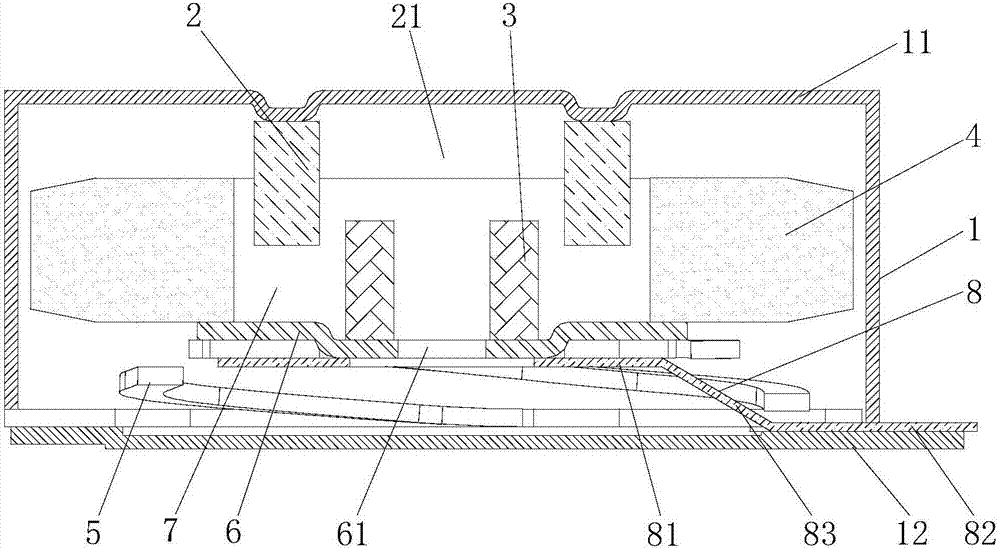

Linear vibration motor

InactiveCN107317454AEnhanced Electromagnetic DriveIncrease effective bandwidthDynamo-electric machinesForce linesLinear vibration

The invention discloses a linear vibration motor which comprises a stator assembly, a vibrator assembly and an elastic supporting part, wherein the stator assembly comprises a shell with an accommodating cavity and a magnet positioned in the accommodating cavity and combined and fixed with the shell; the magnet comprises a hollow part; the vibrator assembly comprises a coil arranged on a concentrating flux plate and mass blocks surrounding the periphery of the coil; the hollow part extends along a vibrating direction of the vibrator assembly; when the vibrator assembly vibrates, the coil vibrates along with the vibrator assembly and is inserted into the hollow part of the magnet; the elastic supporting part is configured to suspend the vibrator assembly in the accommodating cavity of the shell; and the concentrating flux plate further comprises a through hole which corresponds to an inner cavity of the coil and runs through the upper surface and the lower surface of the concentrating flux plate. According to the linear vibration motor provided by the invention, the structure can utilize magnetism of the magnet to the greatest extent; utilization efficiency of the coil for magnetic force lines of the magnet is promoted; an electromagnetic driving force of the motor is promoted; and the assembling process is simple and convenient, and assembling accuracy is high, so that the motor can obtain better vibration performance.

Owner:GOERTEK INC

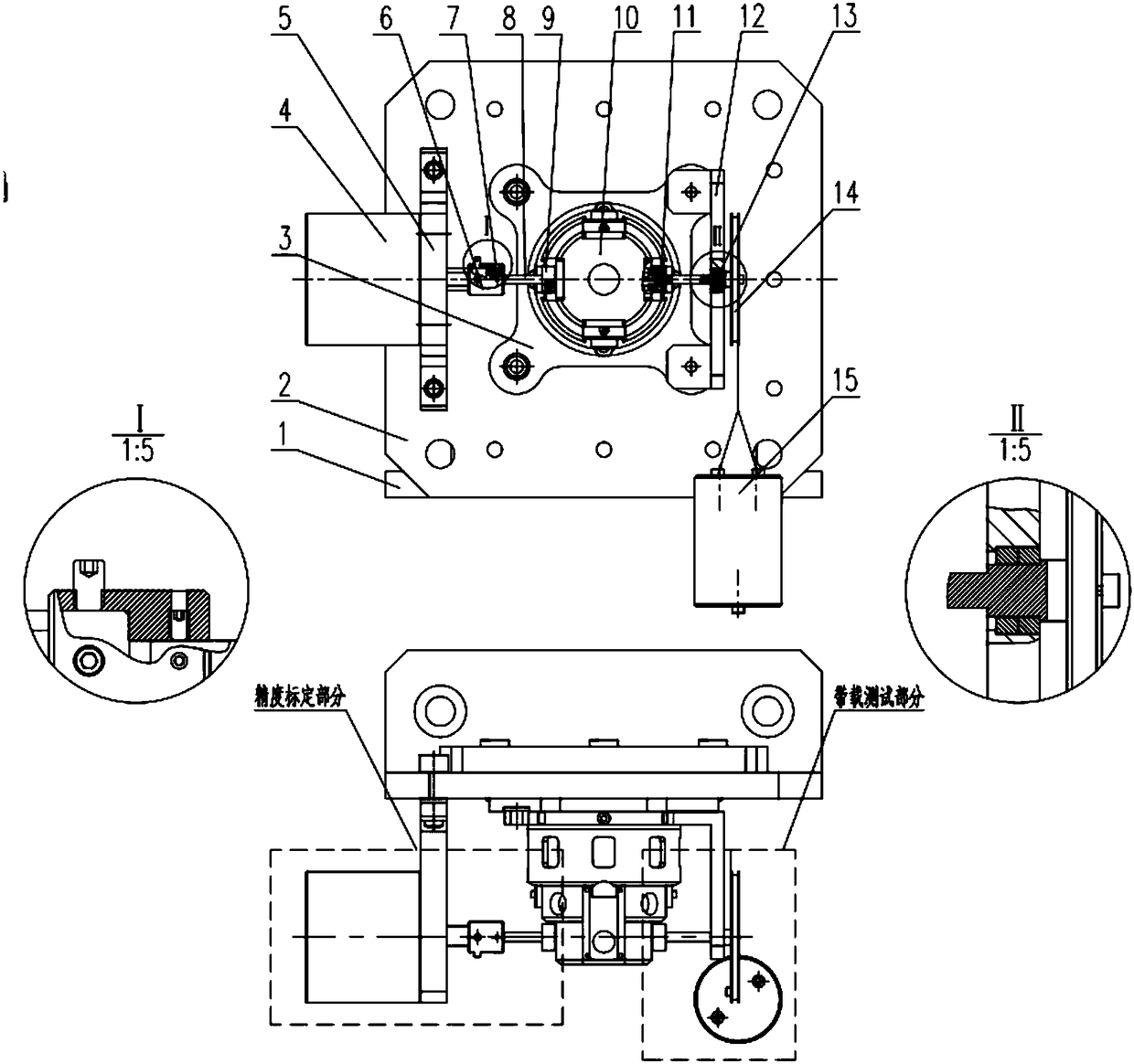

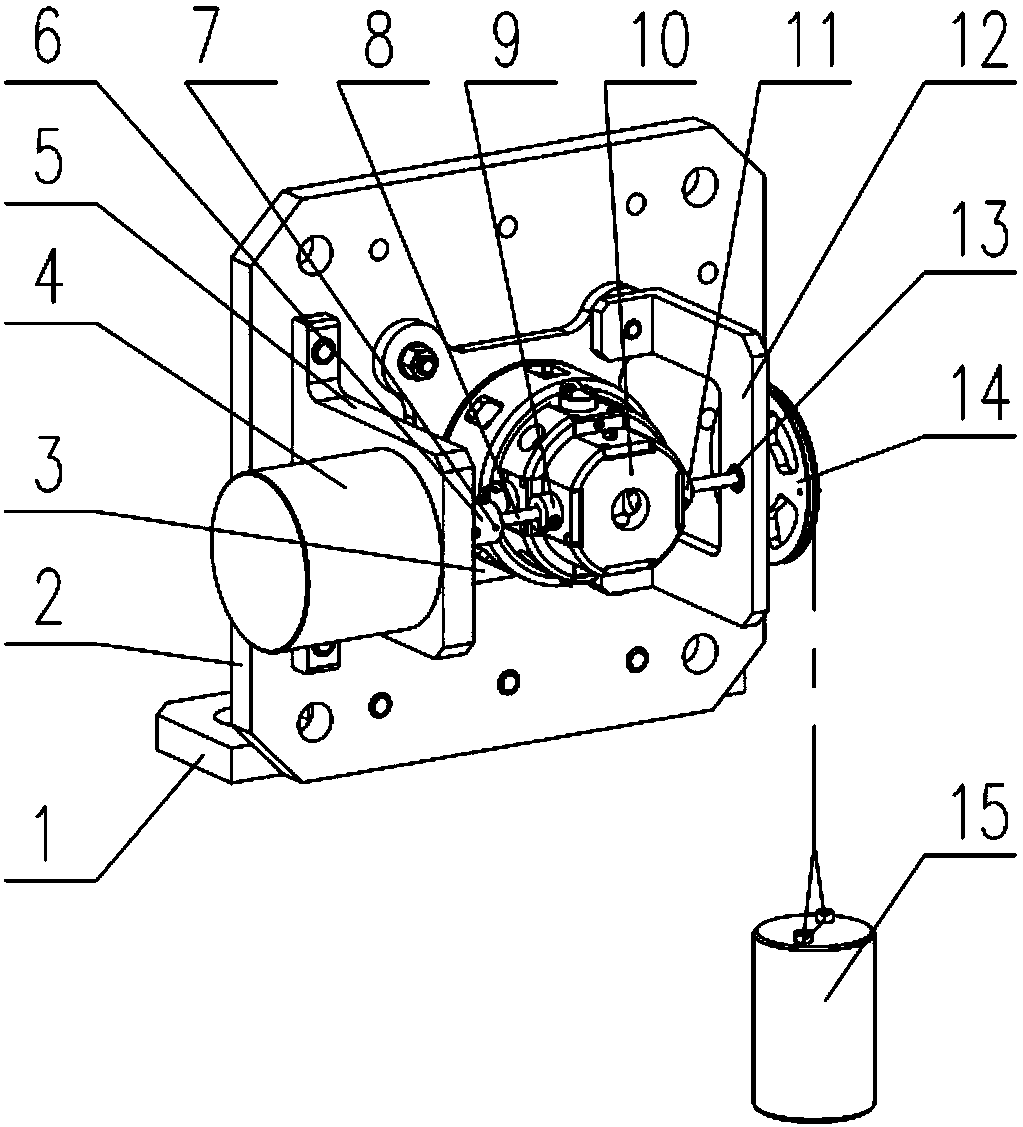

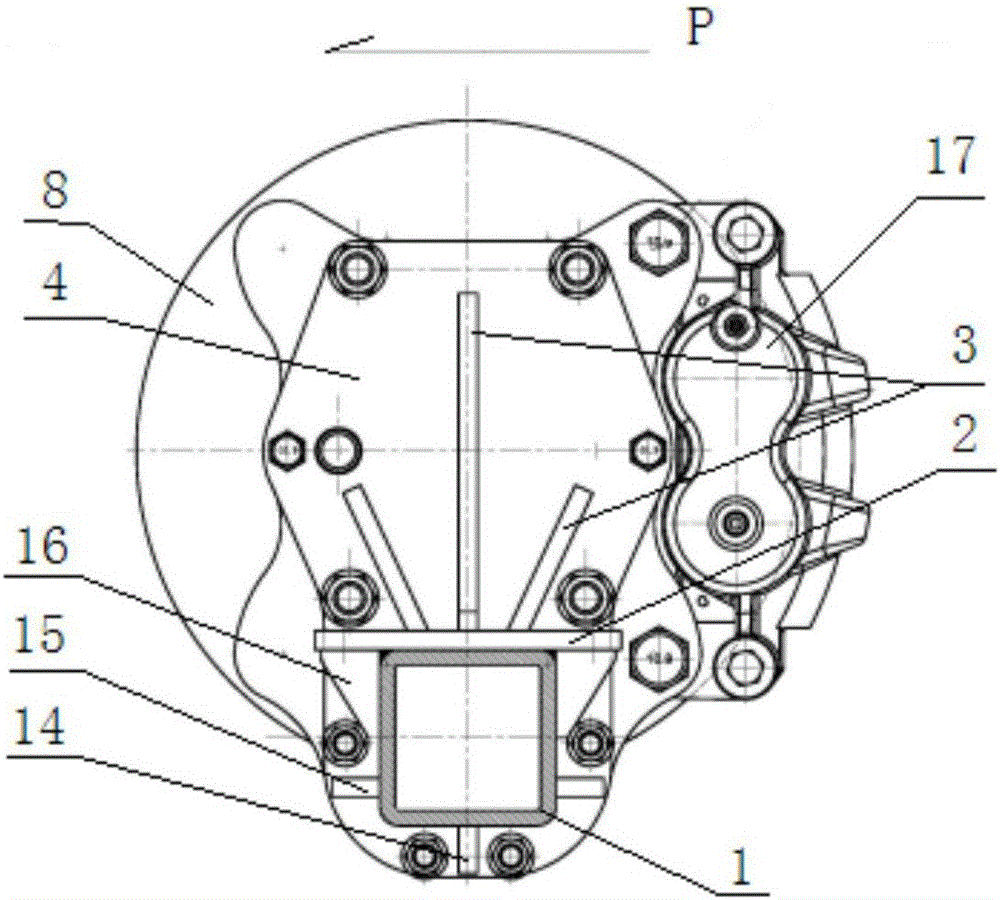

Device for on-load testing and precision calibration of steering engine component

ActiveCN108562452AAccuracy Calibration ImplementationHigh coaxial precisionStructural/machines measurementEngine testingControl theory

The invention relates to a device for on-load testing and accuracy calibration of steering engine component, and belongs to the technical field of high-precision steering engine testing. On the basisof the steering engine component and a substrate, the on-load testing part is coaxially connected with the output shaft of the one-way steering engine to test the rated load of the steering engine successfully; the precision calibration part is coaxially connected with the output shaft of the side one-way steering engine and achieves high coaxial precision, high-precision transmission angle and torque, so that the precision calibration of the steering engine is realized; the whole device can simultaneously realize the on-load testing and precision calibration of the steering engine component,has the advantages of simple structure, high integration level and convenient operation.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

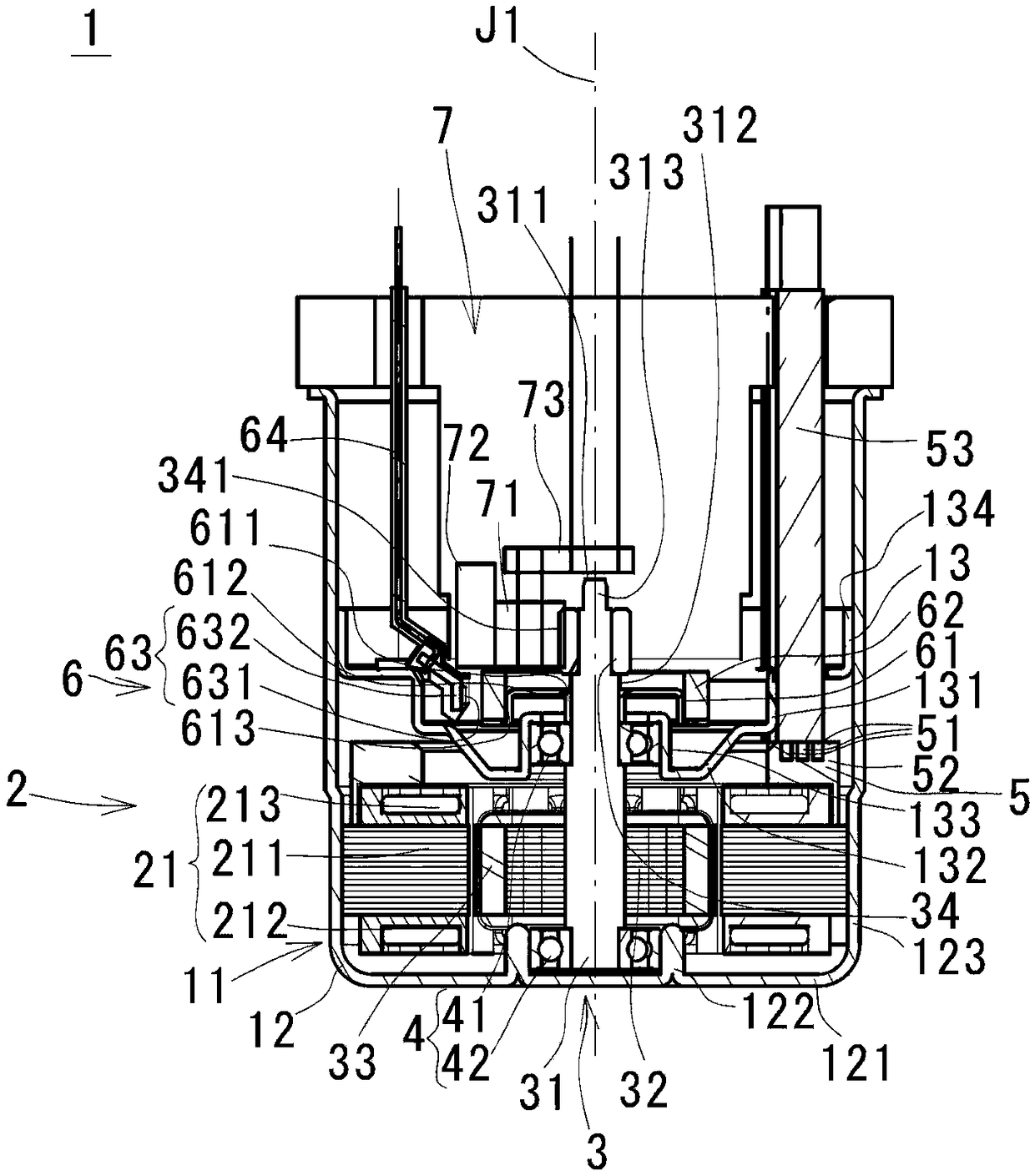

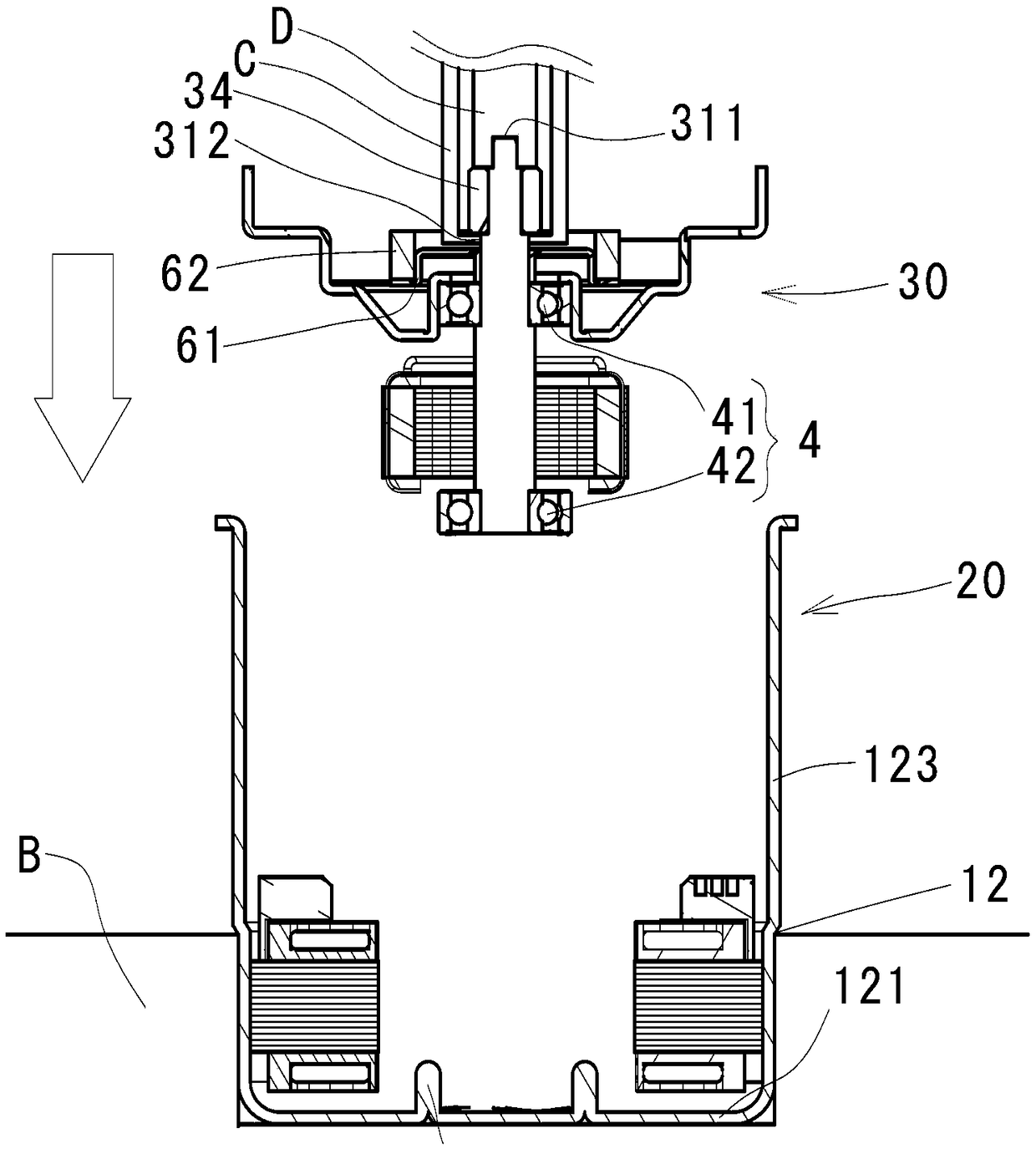

Motor

ActiveCN108702078AHigh coaxial precisionMechanical energy handlingStructural associationRotor magnetsGear wheel

An electric motor provided with: a rotor part having a shaft, a rotor magnet, a sensor yoke positioned axially upward from the rotor magnet, a sensor magnet supported by the sensor yoke, and an inputgear having a gear part for transmitting torque to outside; an armature positioned radially outward of the rotor magnet; a bearing mechanism for rotatably supporting the rotor part; a housing for covering the armature, the rotor part, and the bearing mechanism; and a rotary detection sensor facing the sensor magnet, the rotary detection sensor detecting rotation of the rotor part. The housing hasa bottom part, and includes a housing main unit that supports the armature, and a bearing holder that supports a first bearing. The rotary detection sensor is arranged on the upper part of the bearingholder. The shaft has a top surface positioned axially upward and radially inward from the gear part, and has an exposed part that is exposed in regions axially downward from the gear part, and axially upward from the senor yoke.

Owner:NIDEC CORP

Water outgoing device capable of forming hollow water curtain

ActiveCN105983490ALarge bath areaIncrease graininessMovable spraying apparatusDomestic plumbingWater flowEngineering

The invention discloses a water outgoing device capable of forming a hollow water curtain. The water outgoing device comprises a hollow shell and a diversion column inserted into the shell, an annular runner is formed between the shell and the diversion column, a plurality of arc-shaped water incoming grooves are formed in the shell and are in an annular array taking the annular runner as a center, the inner end of each arc-shaped water incoming groove is communicated with the annular runner, and water flows into the annular runner along the arc-shaped water incoming grooves to form the hollow annular water curtain with centrifugal force. When tangential centrifugal force of the water guided along a lower-portion flowing section is greater than surface tension of the water, the water is broken after certain length of the water curtain is maintained to be granularly scattered to form continuous water sprays within a certain range, the water sprays are wide in shower range, and a single granular water spray is good in granular sensation.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

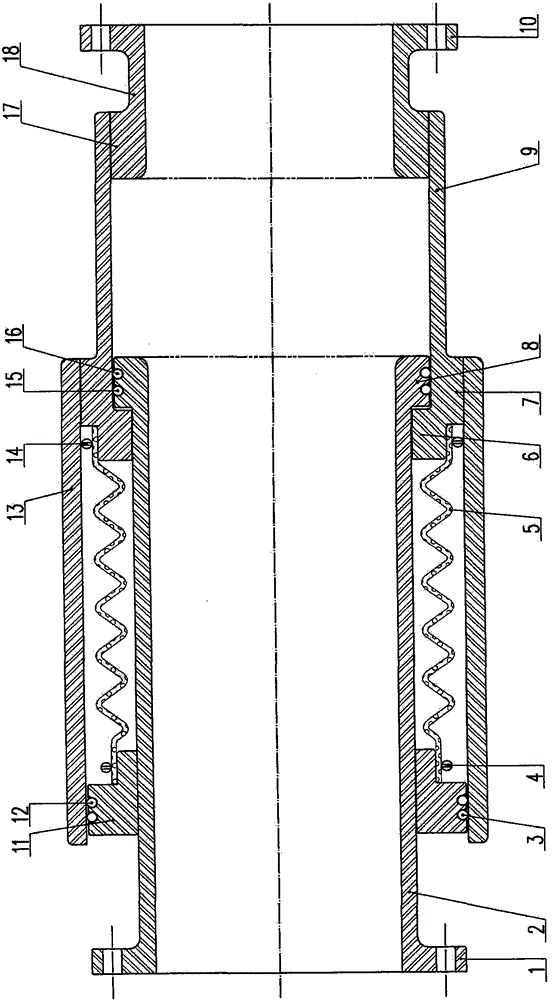

Novel torch pipeline compensator

ActiveCN104197143AGuaranteed uptimeEasy maintenancePipeline expansion-compensationAdjustable jointsTorchEngineering

The invention discloses a novel torch pipeline compensator, and belongs to the technical field of heat distribution pipeline compensation device structures. The novel torch pipeline compensator comprises a pipe B with the end provided with a countersunk head concave cavity and a pipe A inserted into the pipe B. Corrugated pipes are fixed to the outer ring of the pipe B and the outer ring of the pipe A. The pipe B is provided with prestretching jackstay, a sealing piece gland flange, a sealing piece structure and a prestretching positioning structure, wherein the prestrethicng jackstay is used for adjusting the prestretching amount of the corrugated pipes. By means of the structure, the novel torque pipeline compensator has the advantages of being high in coaxial precision, small in friction coefficient, self-torque and pressure loss, high in bending resistance and loading capacity, reliable in sealing, good in performance, safe in pipeline operation and convenient to maintain.

Owner:陈墅庚

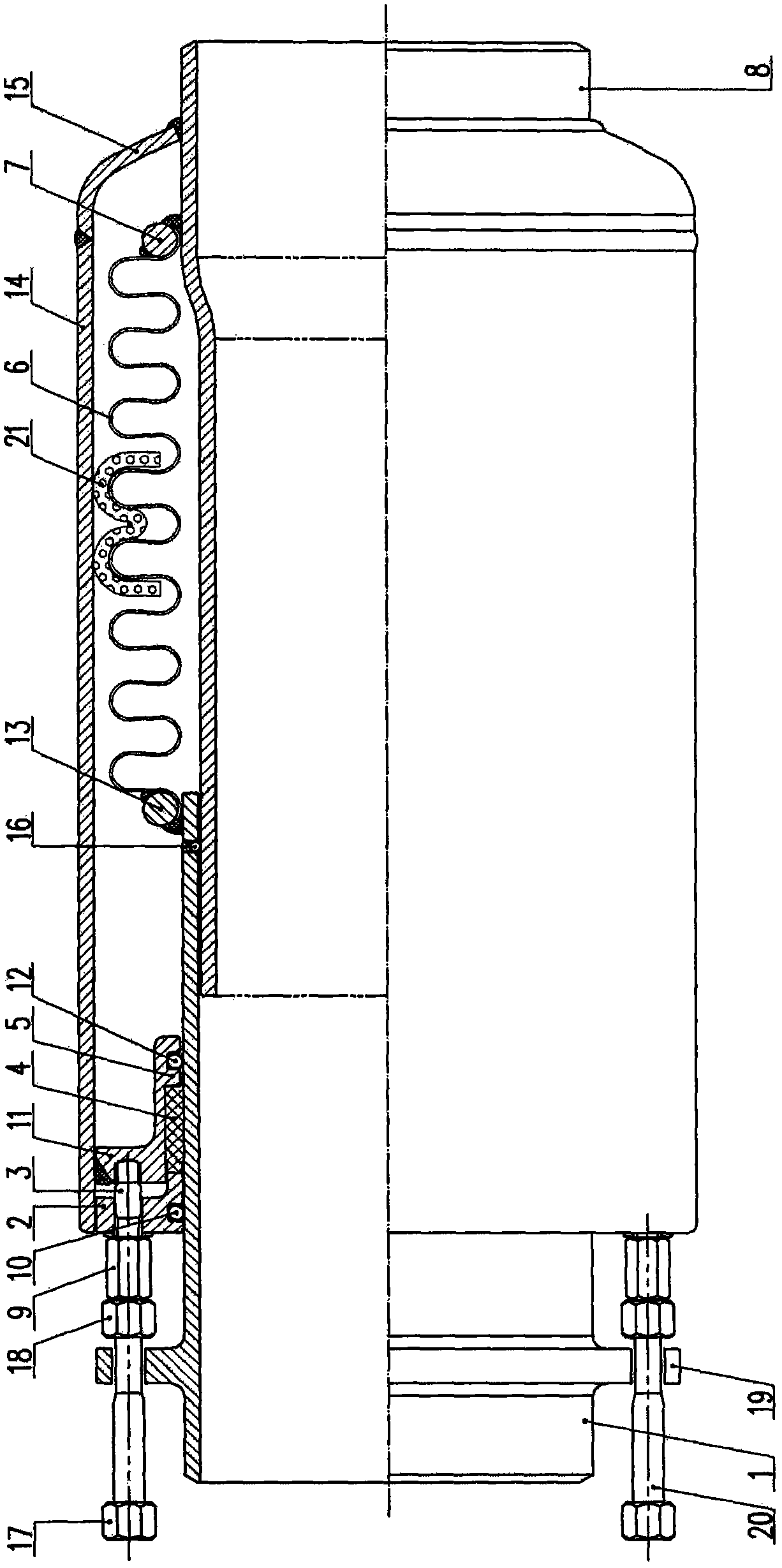

Method for processing reducer pipe by integral cold drawing molding

The invention provides a method for processing a reducer pipe by integral cold drawing molding. Firstly, a small section of process pipe is formed on one end of a pipe blank (2) by the mode of extrusion or pruning, and the pipe blank (2) on which the process pipe is produced is arranged in concentric holes of a supporting sleeve (4) and a stretching die (3) provided with a stretching transition face; secondly, a cylindrical mandrel (1) which is prepared beforehand is arranged in the process pipe, and the process pipe thereof is gripped on the gripping head of a machine tool; and thirdly, the process pipe is moved along with the gripping head of the machine tool in the movement direction, and then can be formed by stretching. The reducer pipe produced by the method has the advantages of smooth surface, no flash burr, favorable airtightness and electrical conductivity, stable and reliable stretching, high efficiency and easy control of reducing size, and avoids the disadvantages of hard guarantee of straightness and coaxiality of parts, low production efficiency, complex connection structure, high production cost, poor connection airtightness and electrical conductivity, and the like of the common method for processing the reducer pipe. The method is suitable for processing the controllable stoke reducer pipe and can meet the special requirements of measurement products on fuel oil for aviation and motor cars.

Owner:四川泛华航空仪表电器厂

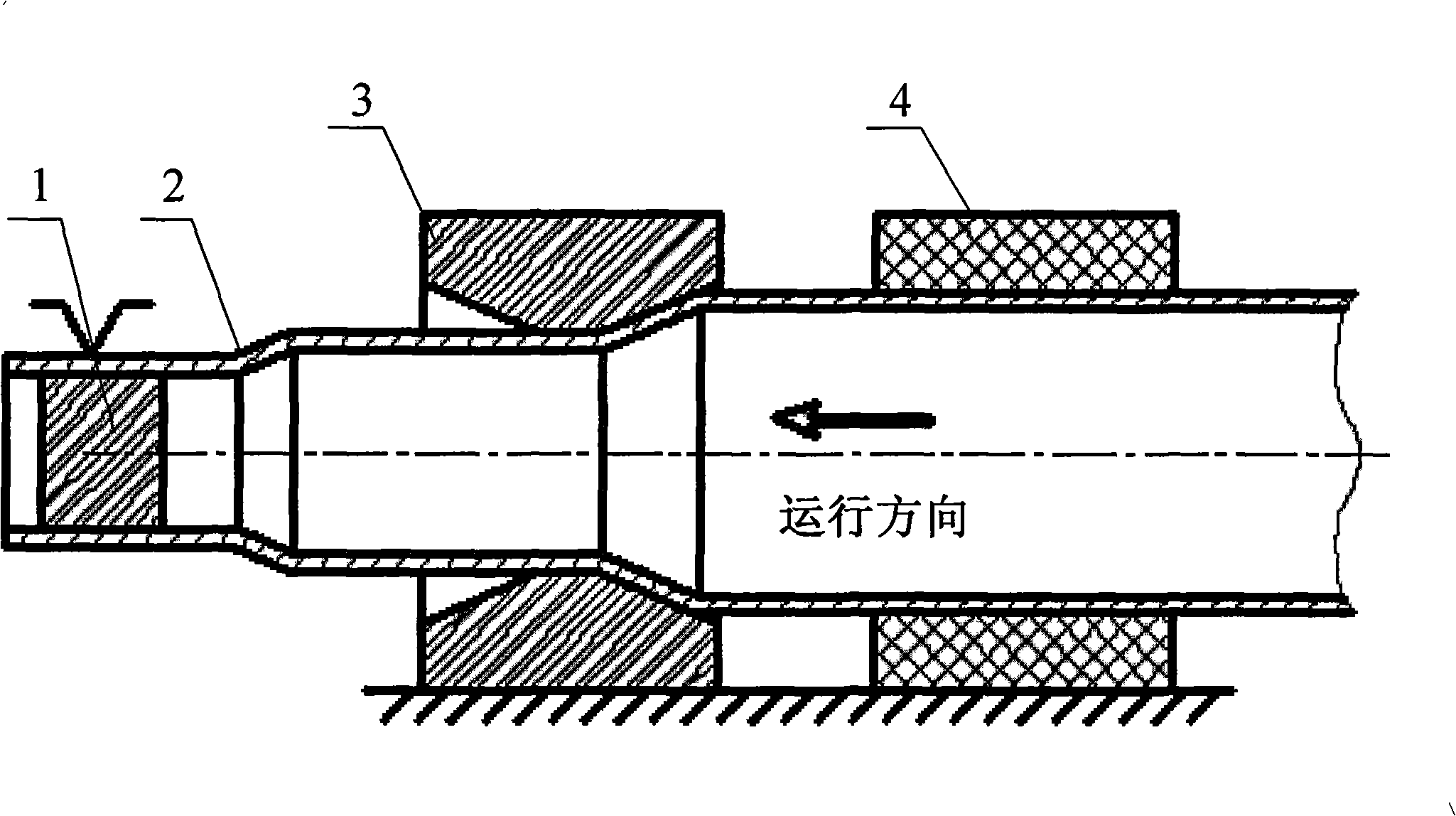

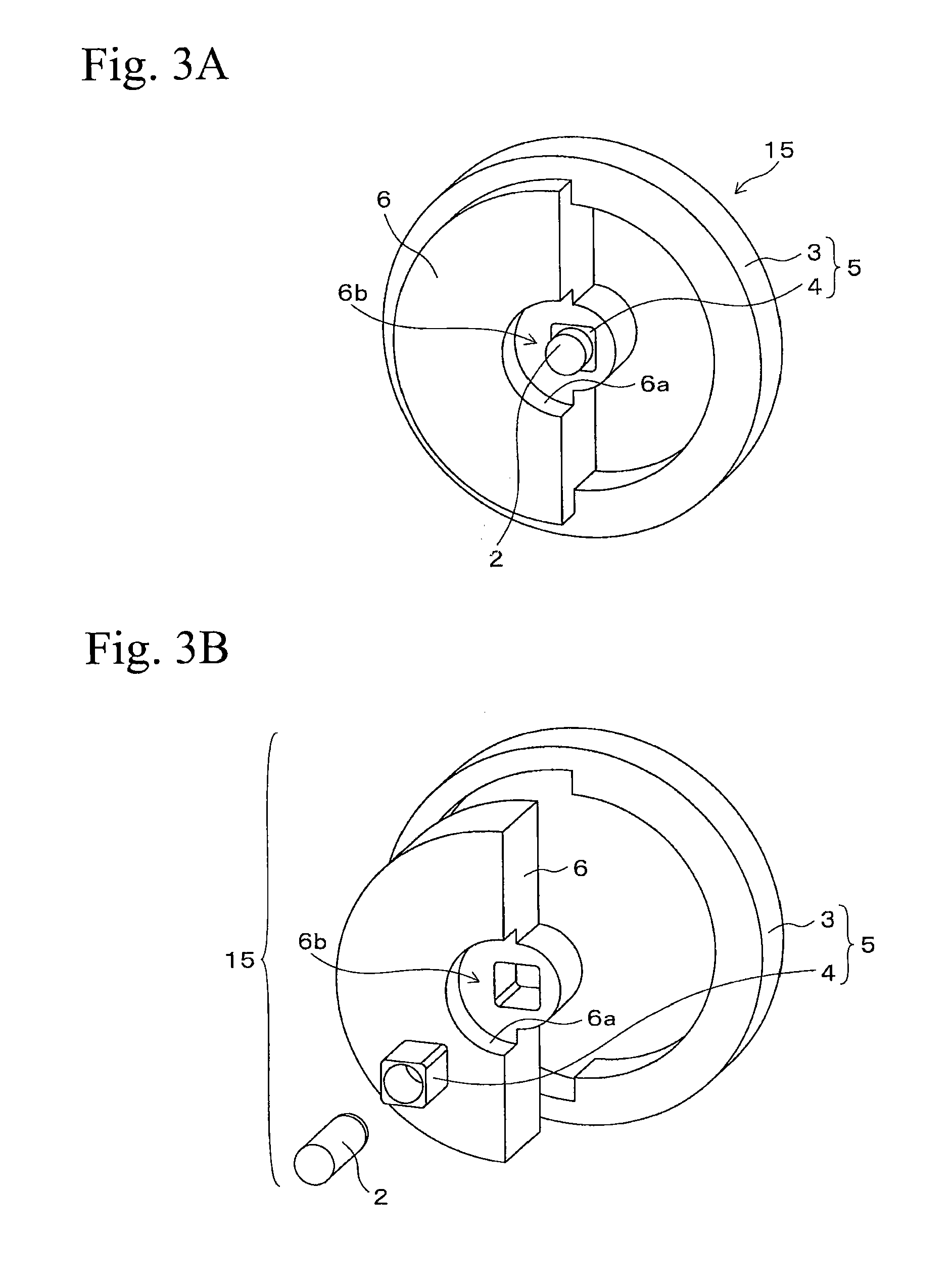

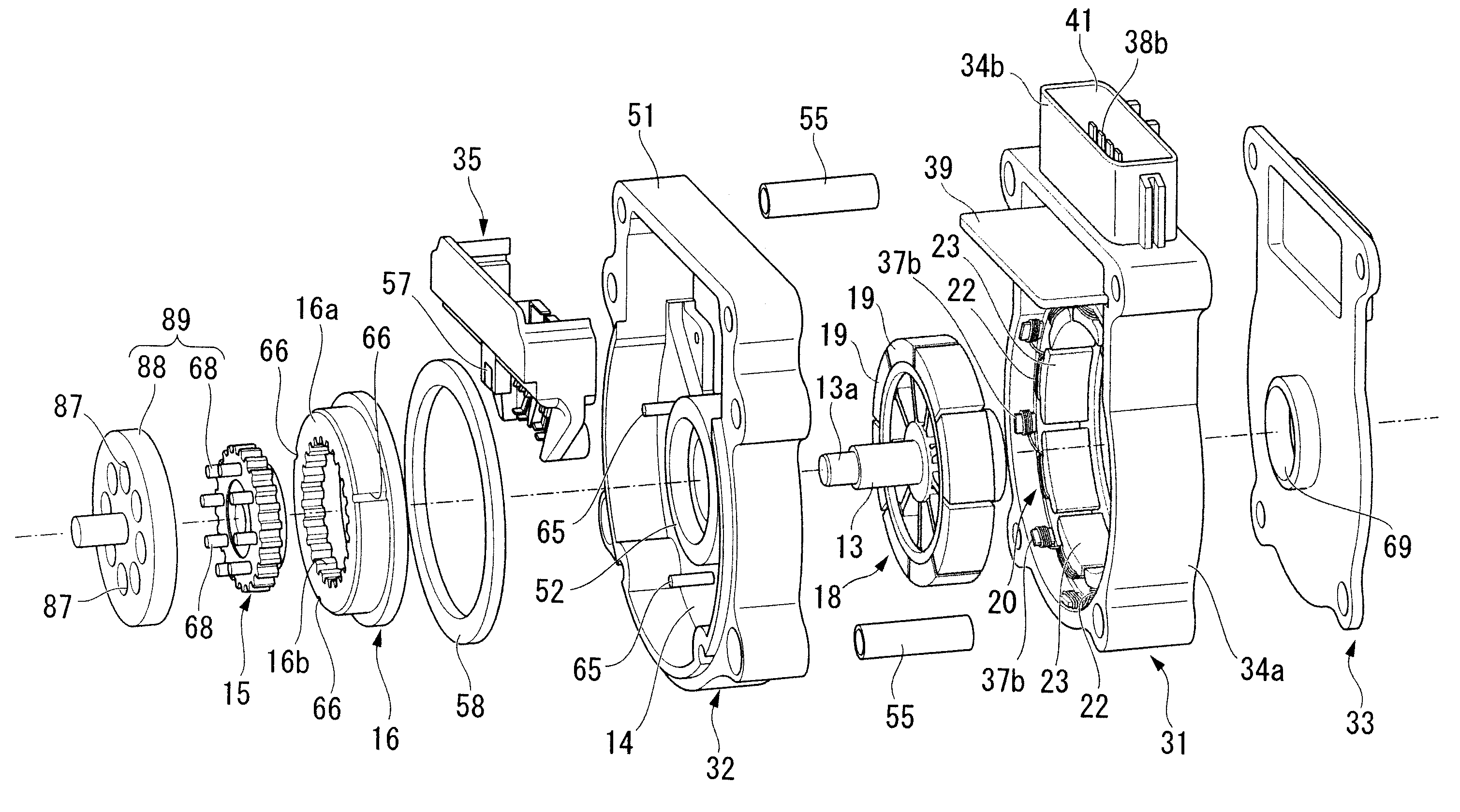

Production method of vibrating motor and rotor for vibrating motor

ActiveUS8405266B2High coaxial precisionIncrease the number ofManufacturing stator/rotor bodiesMagnetic circuit characterised by insulating materialsEngineeringMagnet

A vibrating motor has a shaft, a stator including a yoke having pole teeth extending toward an axis of the shaft from an inner circumference and coils wound around the pole teeth, a rotor including an eccentric weight formed on a radially outer surface of the shaft, and a permanent magnet integrally formed with the eccentric weight, and a bearing device rotatably supporting the rotor maintaining clearance between the inner circumference of the pole teeth and the rotor. The rotor has a structure in which the shaft, the eccentric weight, and the permanent magnet are integrally formed with each other by a thermoplastic magnetic material composing the permanent magnet.

Owner:MINEBEAMITSUMI INC

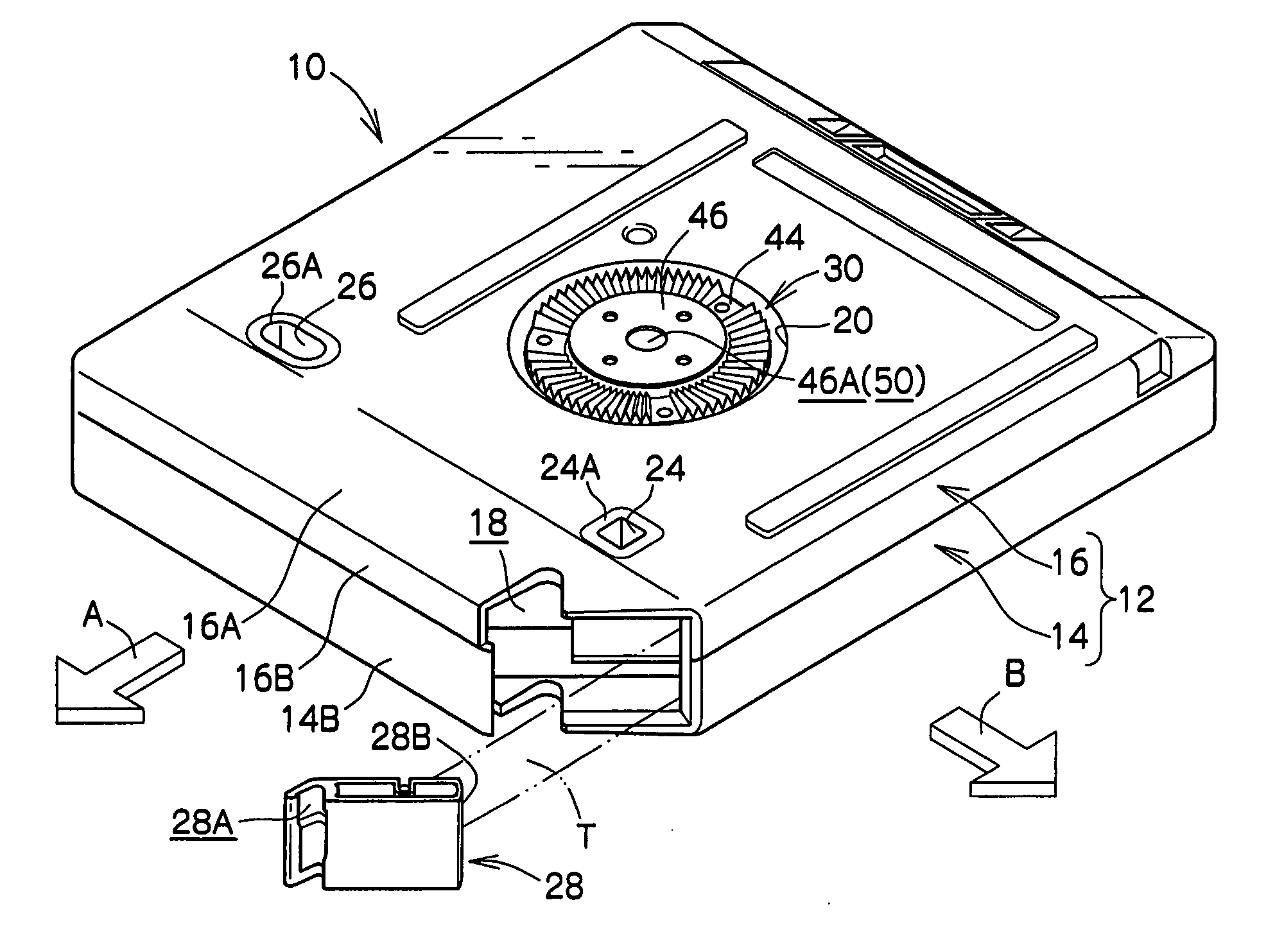

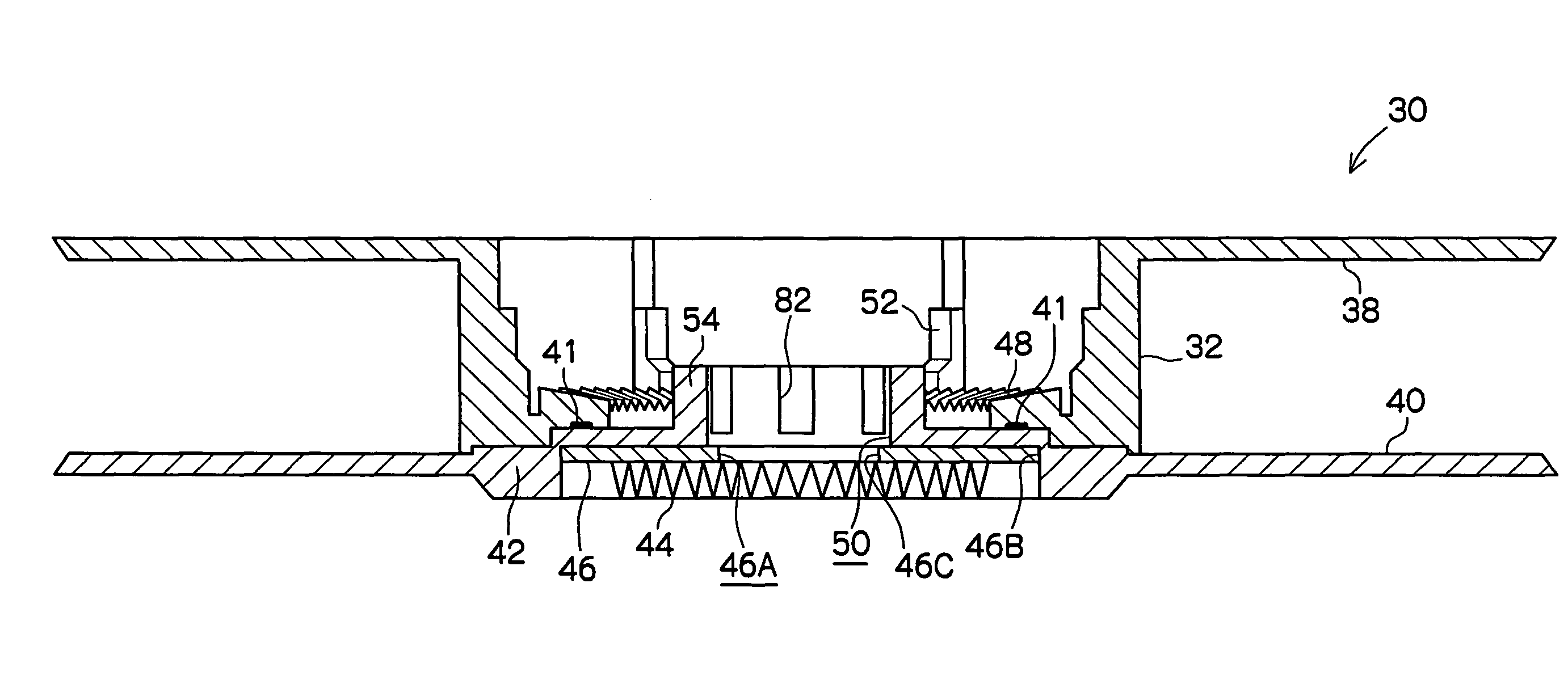

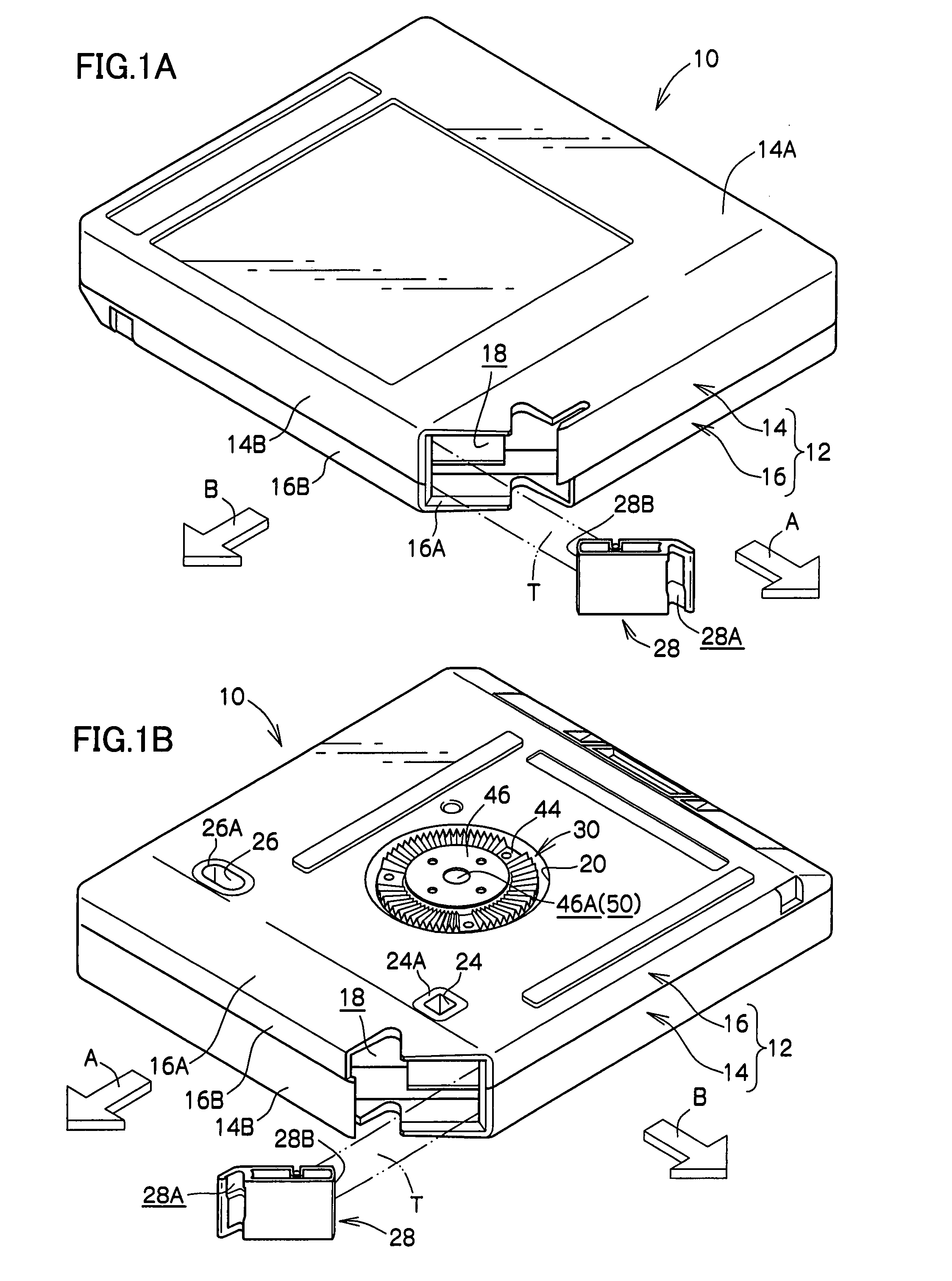

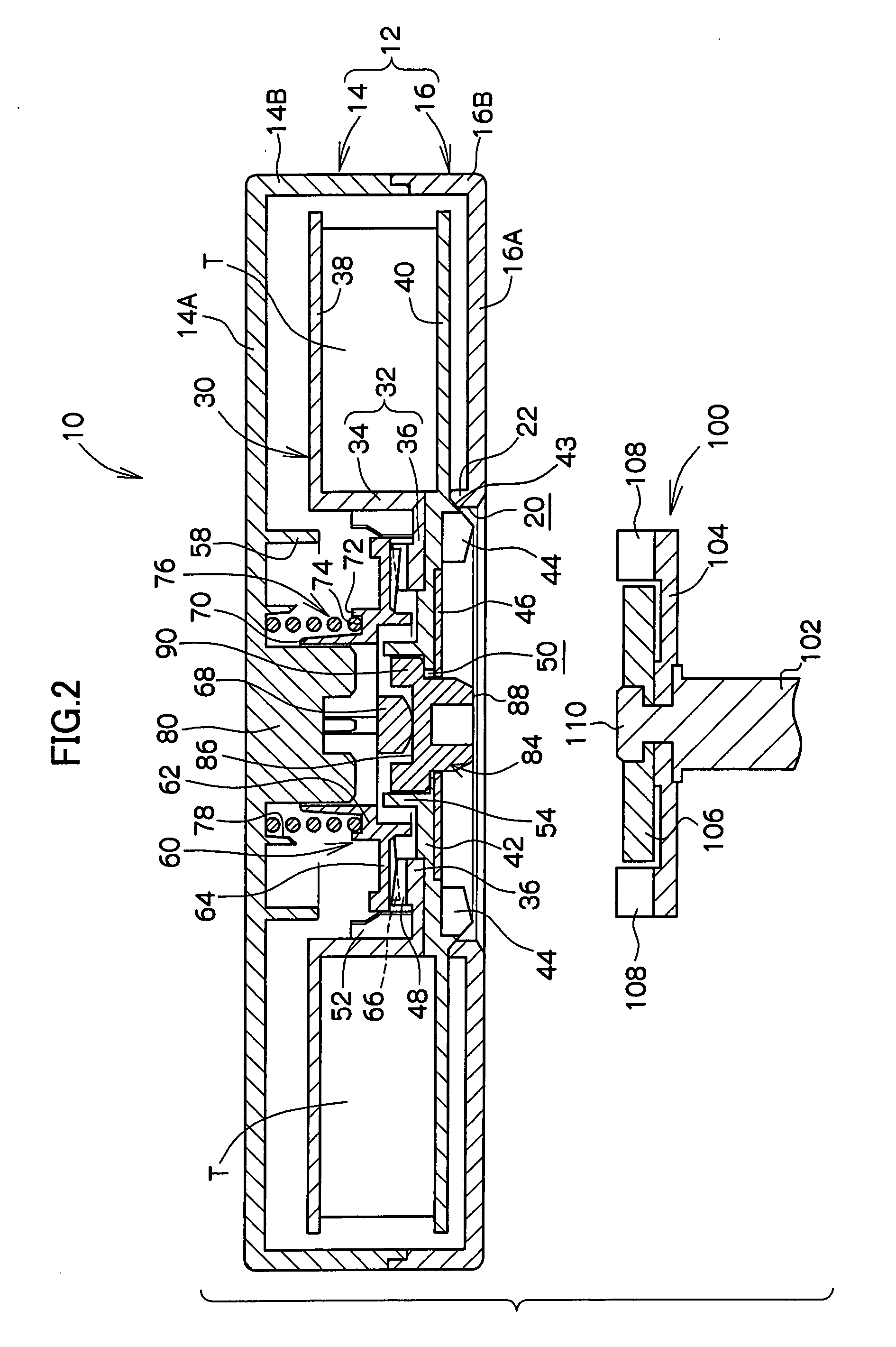

Reel

ActiveUS20080277519A1Improve rigiditySuppression of deformationPicture changing apparatusRecord information storageFlangeEngineering

A reel is provided that may raise the rigidity of the hub, and suppress flange deformation that is caused by winding tension of recording tape. The reel is provided with: a cylindrical hub on which recording tape may be wound; a top flange extending integrally to the hub from a peripheral edge at one end portion of the hub; a bottom flange, including a bottom wall that has had a reel plate fixed thereto, the bottom flange being welded to a portion of the hub at the opposite end of the hub to the end of the top flange, the welding site being within the region where the reel plate is fixed.

Owner:FUJIFILM CORP

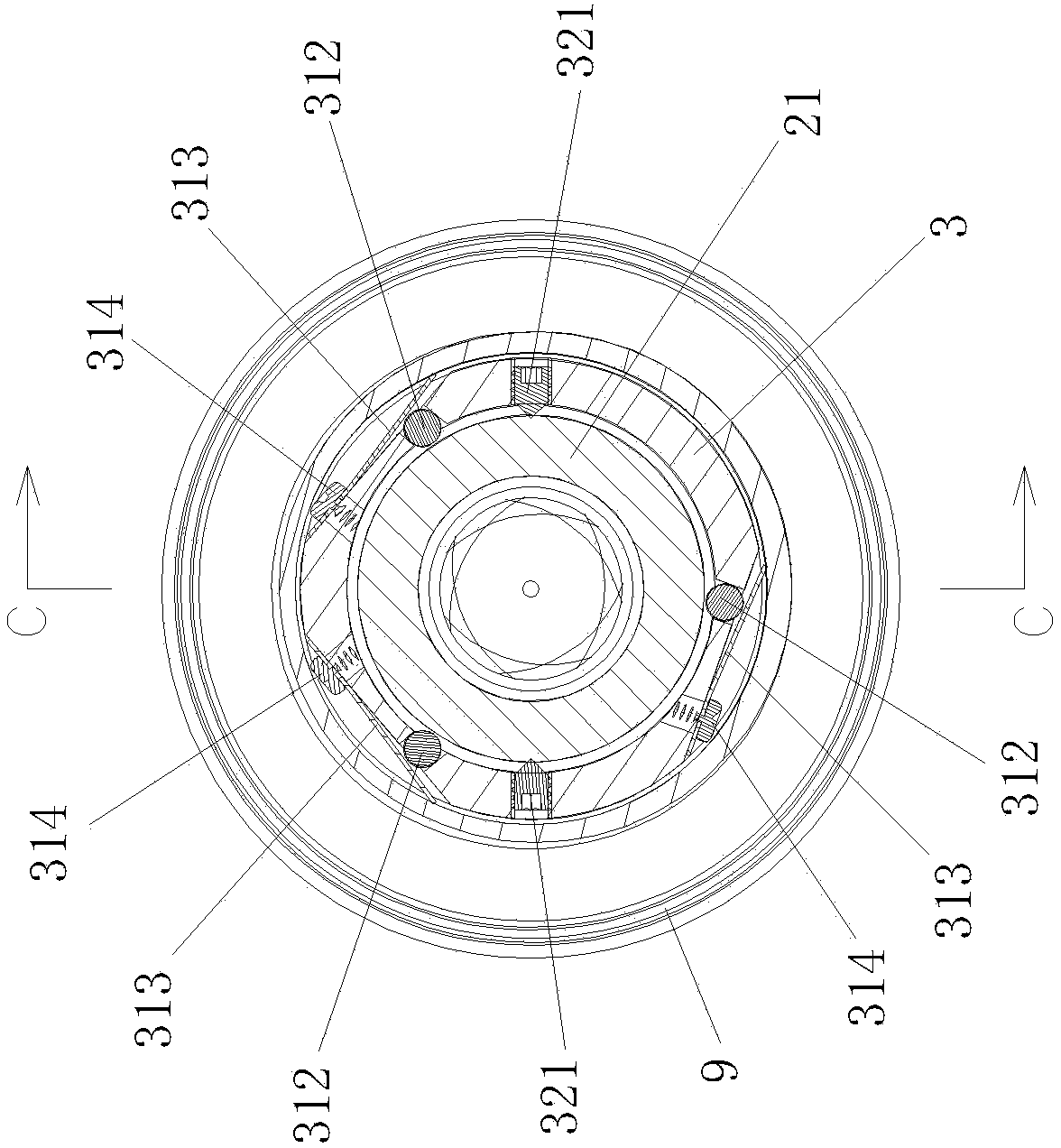

Lens adjustable in coaxiality of front lens group and rear lens group

ActiveCN103901579AImprove image qualityHigh coaxial precisionMountingsImaging qualityOptoelectronics

The invention discloses a lens adjustable in the coaxiality of a front lens group and a rear lens group. The lens comprises the front lens group, the rear lens group and a first main cylinder. The front lens group comprises a front lens cone and a lens sheet, a rear lens group comprises a rear lens cone and a lens sheet, the front lens cone is fixedly connected to the front portion of an inner hole of the main cylinder, the rear lens cone is arranged on the rear portion of the inner hole of the first main cylinder in a sleeved mode, and a shoulder matched with the end face of the front portion of the rear lens cone is arranged in the middle of the inner hole of the first main cylinder. Three first radial holes with the same diameter are formed in the outer circumference of the rear portion of the first main cylinder at a 120-degree interval, three grooves are formed in the positions, located on the peripheries of the three first radial holes, on the outer circumference of the first main cylinder, steel balls with the same diameter are installed in the three first radial holes respectively, one end of each of three elastic sheets is pressed on the corresponding steel ball, the other ends of the three elastic sheets are locked on the bottom surfaces of the three grooves through screws respectively, an annular groove corresponding to the three first radial holes is formed in the outer circumference of the rear lens cone, and the front side face of the annular groove is a conical surface and meanwhile is matched with the three steel balls. The lens can improve the coaxial accuracy of the front lens group and the rear lens group, and the imaging quality of the lens can be improved.

Owner:XIAMEN LEADING OPTICS

A water outlet device capable of forming a hollow water curtain

ActiveCN105983490BLarge bath areaIncrease graininessMovable spraying apparatusDomestic plumbingParticulatesWater flow

The invention discloses a water outlet device capable of forming a hollow water curtain, which comprises a hollow shell and a guide post inserted in the shell, an annular flow channel is formed between the shell and the guide post, the The casing is also provided with several arc-shaped water inlet grooves, which are arranged in a circular array around the annular flow channel. The inner ends of the arc-shaped water inlet grooves communicate with the annular flow channel, and the water flows along the arc. The water inlet groove flows into the annular channel to form a hollow annular water curtain with centrifugal force. When the tangential centrifugal force guided by the lower flow section of the water flow is greater than its surface tension, it will break open, so that the water flow will break apart into particles and disperse after maintaining a certain length of the water curtain. After dispersing, a certain range of continuous splashes will be formed. The bathing area is large, and the single granular water splash has a good grain feeling.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Electric motor, rotary actuator and rotary apparatus

InactiveUS20100176672A1High precisionSimple structureAssociation with control/drive circuitsMechanical energy handlingEngineeringControl theory

Owner:KEIHIN CORP

Novel double-gland precision type pipeline compensator

ActiveCN102913707AGuaranteed uptimeUnrestricted medium flowPipeline expansion-compensationHigh pressureNozzle

The invention discloses a novel double-gland precision type pipeline compensator, and belongs to the technical field of structures of thermal pipeline compensation devices. The novel double-gland precision type pipeline compensator comprises a core pipe, a sealing pressure sleeve flange, a variable-diameter nozzle, a gland flange, an outer sleeve pipe flange, an outer sleeve pipe, and the like, wherein the inner end of the core pipe is oppositely propped against a variable-diameter end of the variable-diameter nozzle; the gland flange, the sealing pressure sleeve flange and the outer sleeve pipe are annularly sleeved on the outer annular surface of the core pipe in sequence; and the sealing pressure sleeve flange is positioned between the gland flange and the outer sleeve pipe. By adopting the structure, the novel double-gland precision type pipeline compensator has the advantages of non-limit on the flow direction of media, high coaxial precision, smaller friction coefficient, smaller personal torque, higher bending resistant ability, higher pressure bearing ability, more excellent sealing performance, longer service life and safer and more reliable pipeline operation, and has a feasible emergency plan structure.

Owner:陈墅庚

Directly-buried maintenance-free axial conjointed sleeve compensator

InactiveCN102359682AAxial connection structure is simpleSimple structureThermal insulationAdjustable jointsPerseverationBack-to-back connection

The invention discloses a directly-buried maintenance-free axial conjointed sleeve compensator, which comprises two coaxial sleeve compensators and heat preservation structures, wherein the two sleeve compensators are opposite to one end of a sealing seat and hermetically and coaxially connected through an intermediate connecting pipe to form an external heat perseveration structure which is formed by winding a heat perseveration layer on the outer wall after conjoint connection and wrapping by a shell, an end-face heat perseveration structure which moves along with an inner pipe and is formed by filling a heat perseveration layer in a cavity between a sleeve and the inner pipe, and an inner heat perseveration structure which is formed by winding a heat perseveration material on the outer wall of the inner pipe between a gland and an end face plate. According to the invention, through the coaxial connection between the two sleeve compensators and one end of the sealing seat, the coaxial precision is guaranteed, the two sleeve compensators can independently bear to absorb or compensate the axial movement and rotation of a connecting pipeline and can do an equidirectional action simultaneously. Because the two coaxially-connected sleeve compensators cooperatively act in the same structure, the directly-buried maintenance-free axial conjointed sleeve compensator has large compensation amount and flexibility and can meet difference compensation requirement of a heat supply piping network. According to the invention, because the back-to-back connection is adopted, the axial size is short, and the mating cost is greatly reduced.

Owner:JIANGYAN GAOGE PIPELINE EQUIP FACTORY

Shooting nail gun

The invention discloses a shooting nail gun, belonging to auxiliary equipment in shooting nail fastening technology. The shooting nail gun comprises a connection handle, a sliding sleeve, an outer sleeve pipe and a nail sleeve pipe which are sequentially connected, and is characterized in that the sliding sleeve and a triggering spring and a triggering device in the sliding sleeve are pushed by the connection handle; gun powder at the head of a shooting nail in the nail sleeve pipe is impacted to explode, so that the shooting nail is fixed on a base body; and reset is realized through counterforce after explosion. The shooting nail gun has the advantages that by adopting the triggering device and design of the sliding structure of the triggering device, triggering force is high enough; the coaxial degree is high; no pin breaking phenomenon is caused; the triggering success rate is higher than 99.8%; assembly and disassembly for cleaning are convenient; the shooting nail gun is soundproof, environment-friendly, heat-dissipating and quality-guaranteeing; the service life is long; and operation is safer due to a limiting safety device.

Owner:LINHAI MICRO ABILITY CASTING MACHINE CO LTD

Method for manufacturing automotive bevel gear shaft

The invention discloses a method for manufacturing an automotive bevel gear shaft. The method is performed according to the following sequence: firstly, manufacturing a workpiece blank by means of die forging, machining central holes in the both ends of the workpiece, positioning the workpiece by virtue of the central holes, then turning a tooth blank section according to design dimensions; secondly, still positioning by virtue of the central holes of the workpiece, implementing tooth forming by means of cutting, and performing conventional heat treatment on the workpiece which finishes tooth-cutting machining; finally, positioning and installing a tooth die in a clamp and the bevel gear of the workpiece, and then performing finish turning until each shaft neck on the shaft section of a cantilever beam shaft to achieve design dimensions. The method disclosed by the invention is short in process route, high in production efficiency, capable of avoiding external damages and internal stress generated on the surface of the workpiece, and beneficial to improve the inherent quality of the workpiece. Most of all, each shaft neck on the shaft section of the workpiece is positioned by teeth and subjected to finish turning, and due to the positioning structure, the superposition of a machining positioning reference and an installation reference is realized, thus greatly improving the coaxial accuracy of the teeth and the shaft necks, and contributing to improve the transmission quality of the workpiece after being installed.

Owner:JIANGSU AIRSHIP GEAR

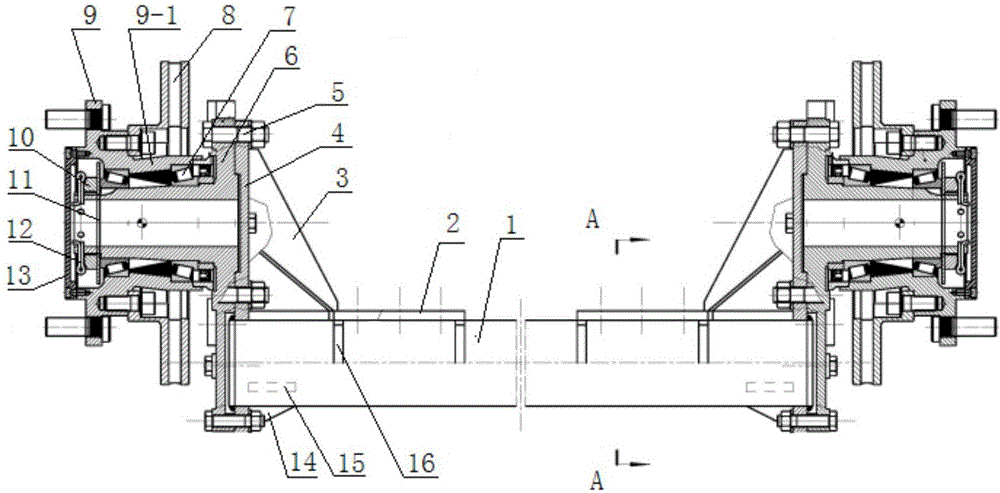

Independent suspension type front drive rear axle assembly

InactiveCN106183632ABig spaceImprove battery lifeBraking element arrangementsAxle unitsGravity centerEngineering

The invention discloses an independent suspension type front drive rear axle assembly. The two ends of a rear axle cross beam are welded and fixed to the lower portions of the inner sides of flange discs respectively. Rear shaft heads are fastened on the outer sides of the upper portions of the flange plates through bolts respectively. The distance between the center of each rear shaft head and the axis of the rear axle cross beam ranges from 130 mm to 160 mm. The rear shaft heads support rear wheel hubs, the rear wheel hubs are provided with shaft sleeves corresponding to the rear shaft heads, and paired single-row tapered roller bearings for bearing positive and reverse axial force are arranged between the shaft sleeves and the rear shaft heads. Locknuts in threaded connection with the rear shaft heads and gaskets of the locknuts are arranged at the ends of the rear shaft heads, the gaskets are jointed with the inner rings of the single-row tapered roller bearings on the outer sides, and stop cotter pins are arranged at the ends of the locknuts and the ends of the rear shaft head. The rear axle cross beam is a square steel pipe, brake discs are fixed to the inner sides of the rear wheel hubs, brake assemblies in friction joint with the brake discs are symmetrically arranged at the transverse front and back positions of the brake discs, and brakes are hydraulic drive brakes. The gravity center of a finished automobile is lowered, and the driving stability can be improved. The independent suspension type front drive rear axle assembly is more beneficial for the arrangement of electrical apparatus elements such as battery packs of purely electric large and medium buses and buses, and therefore the higher speed per hour and the larger endurance mileage can be achieved.

Owner:通天汽车桥(天津)有限公司

Cold rolling mill roller surface treatment device

InactiveCN111791101AHigh coaxial precisionHigh surface finishRevolution surface grinding machinesGrinding work supportsReciprocating motionElectric machinery

The invention discloses a cold rolling mill roller surface treatment device. The device comprises a grinding box, a liquid storage cavity is formed in the side wall of the grinding box, a motor is fixedly arranged on the side wall of the grinding box, an output shaft of the motor extends into the grinding box, chucks are arranged at the tail end of an output shaft of the motor and the inner wall,right opposite to the output shaft of the motor, of the grinding box, and reciprocating lead screws are rotationally connected between the inner walls, located above and below the chucks, of the grinding box. According to the device, through the arrangement of a driving mechanism, a liquid pumping mechanism, an elastic film, a through hole and a liquid outlet hole, a grinding ring horizontally moves in a reciprocating manner, and a roller rotates so that the surface of the roller can be stably and evenly ground, and the coaxiality precision and the surface smoothness of the roller are improved; and cooling liquid can be automatically sprayed for cooling and heat dissipation, the spraying time is fixed, the manual control is not needed, the precision is high, and the cooling liquid can be recycled, so that the environment is protected, and the cost is saved.

Owner:柳友香

Vertical multifunctional friction-wear testing machine

PendingCN108507895AAvoid job instabilityHigh coaxial precisionInvestigating abrasion/wear resistanceEngineeringMultiple function

The invention discloses a vertical multifunctional friction-wear testing machine. The vertical multifunctional friction-wear testing machine comprises a testing machine body, wherein a main shaft tankis arranged at the upper part of the testing machine body, a rotating disc, a grinding wheel and a fixed disc are arranged on the main shaft tank, the rotating disc is detachably arranged, the main shaft is driven by a steering device in a bearing so as to rotationally arrange the rotating disc in the main shaft tank, and a detachable vibrator and a detachable heater are arranged on the rotatingdisc; the grinding wheel is detachably arranged; the fixed disc is fixed at the top end of the main shaft tank; and the friction block is arranged on the rotating disc or the fixed disc, and a detachable testing device is arranged on the friction block. According to the vertical multifunctional friction-wear testing machine by utilizing a new-form friction pair, namely that the rotating disc is mounted in the bearing, the rotating disc and the fixed disc have relatively high coaxial precisions, so that the coaxiality between the rotating disc and the fixed disc is well guaranteed, the rotatingdisc can smoothly rotate along the axial direction, and the situations that the contact among a suspending and rotary swing head at the shaft end of the rotating disc, the friction block and the friction disc (fixed disc or rotating disc) is poor, and the friction pair cannot work stably are avoided.

Owner:JILIN UNIV

Electromotor overspeed preventer

InactiveCN101577414ALimit the maximum speedAchieve normal operationEmergency protective circuit arrangementsStructural associationCouplingShort circuit protection

The invention relates to an electromotor overspeed preventer, and the main design of the preventer comprises that: a coupling shaft is connected with a main shaft of an electromotor; a coder and an overspeed switch are arranged on a coupling; the coder and the overspeed switch have the characteristics of small volume, high coaxial precision, accurate action, convenient mounting, adaptability to environmental temperature variation and high protection level; the coder adopts the photoelectric effect and measures the length, the position, the speed, the angle or other physical quantities; a sensor for converting mechanical displacement quantity into an electrical signal has high-quality signals, antifatigue compensation, temperature compensation, short-circuit protection, impact resistance and vibration resistance; and the overspeed switch limits the maximal rotational speed of the electromotor, achieves the aims of rapidly breaking the circuit and ensuring the safe operation of equipment and has the bidirectional protective function of positive rotation and reverse rotation.

Owner:魏秋湘

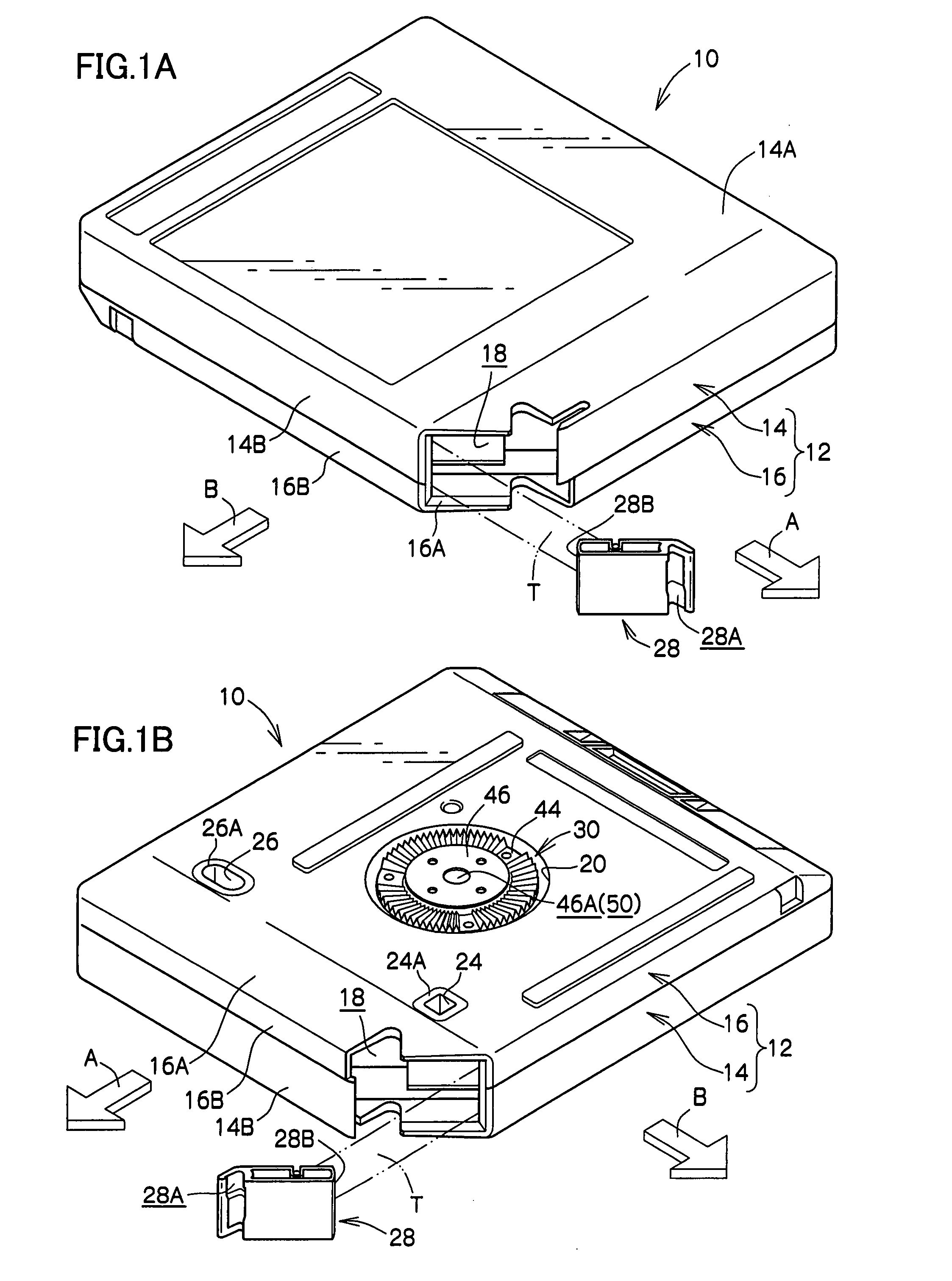

Reel

ActiveUS8006930B2Improve rigiditySuppression of deformationPicture changing apparatusRecord information storageEngineeringFlange

A reel is provided that may raise the rigidity of the hub, and suppress flange deformation that is caused by winding tension of recording tape. The reel is provided with: a cylindrical hub on which recording tape may be wound; a top flange extending integrally to the hub from a peripheral edge at one end portion of the hub; a bottom flange, including a bottom wall that has had a reel plate fixed thereto, the bottom flange being welded to a portion of the hub at the opposite end of the hub to the end of the top flange, the welding site being within the region where the reel plate is fixed.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com