Motor

一种马达、传感器的技术,应用在马达领域,能够解决不能电动马达薄型化等问题,达到同轴精度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A motor 1 according to an embodiment of the present invention is mounted in, for example, an electric brake booster 1 . The electric brake booster 8 is used for braking operations of vehicles such as automobiles.

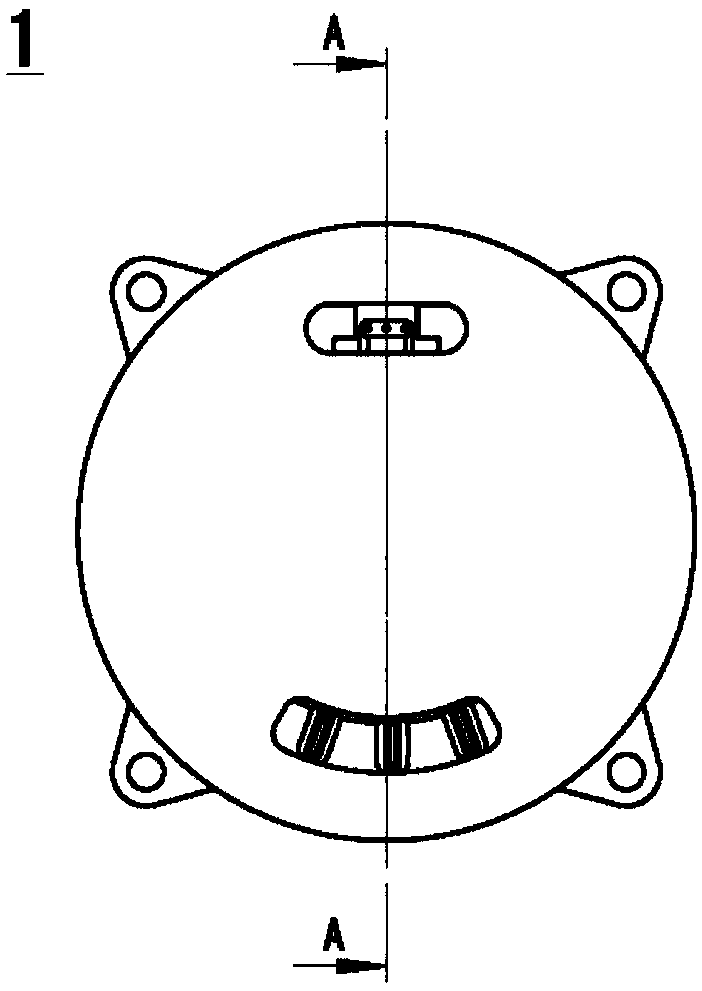

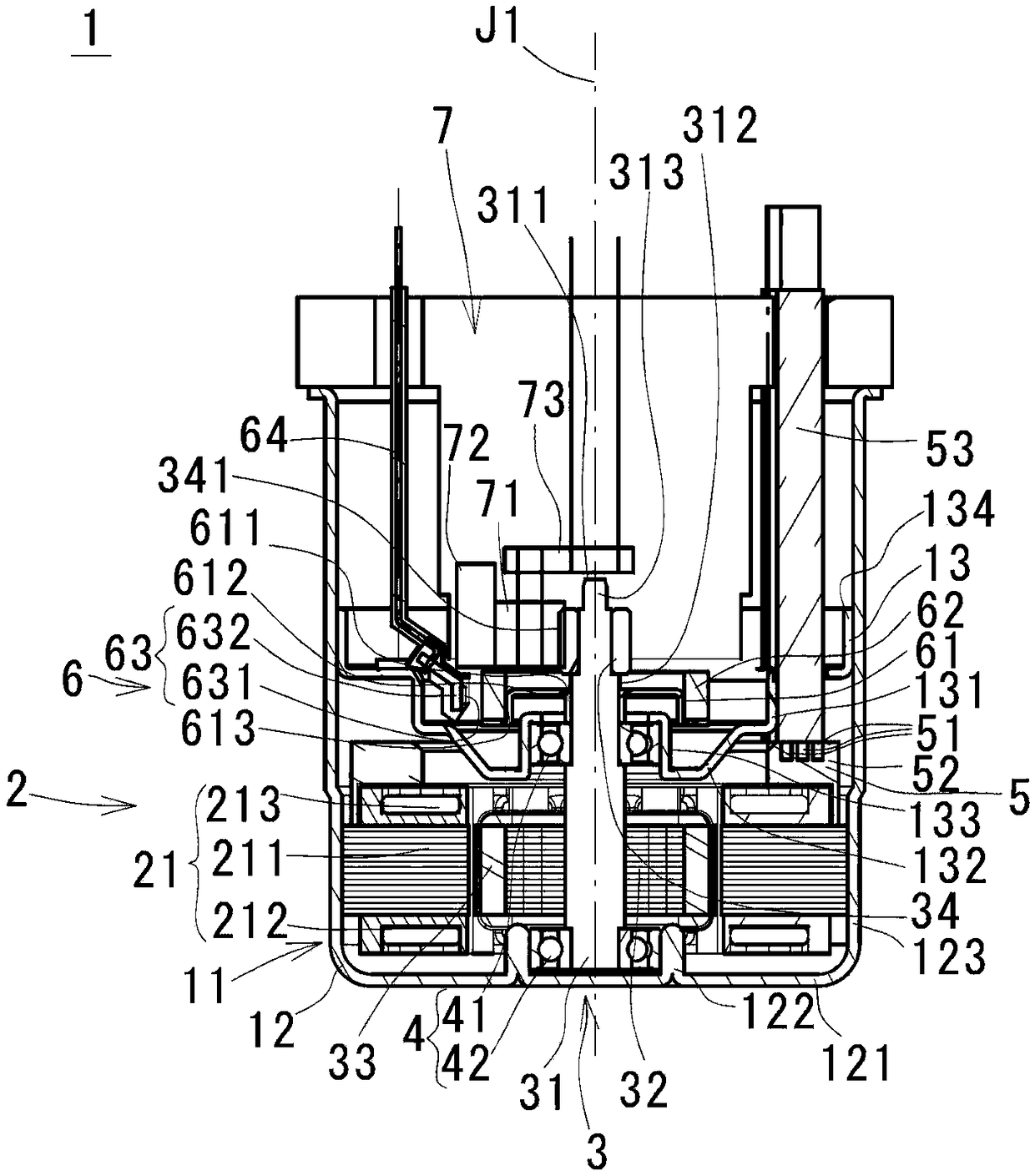

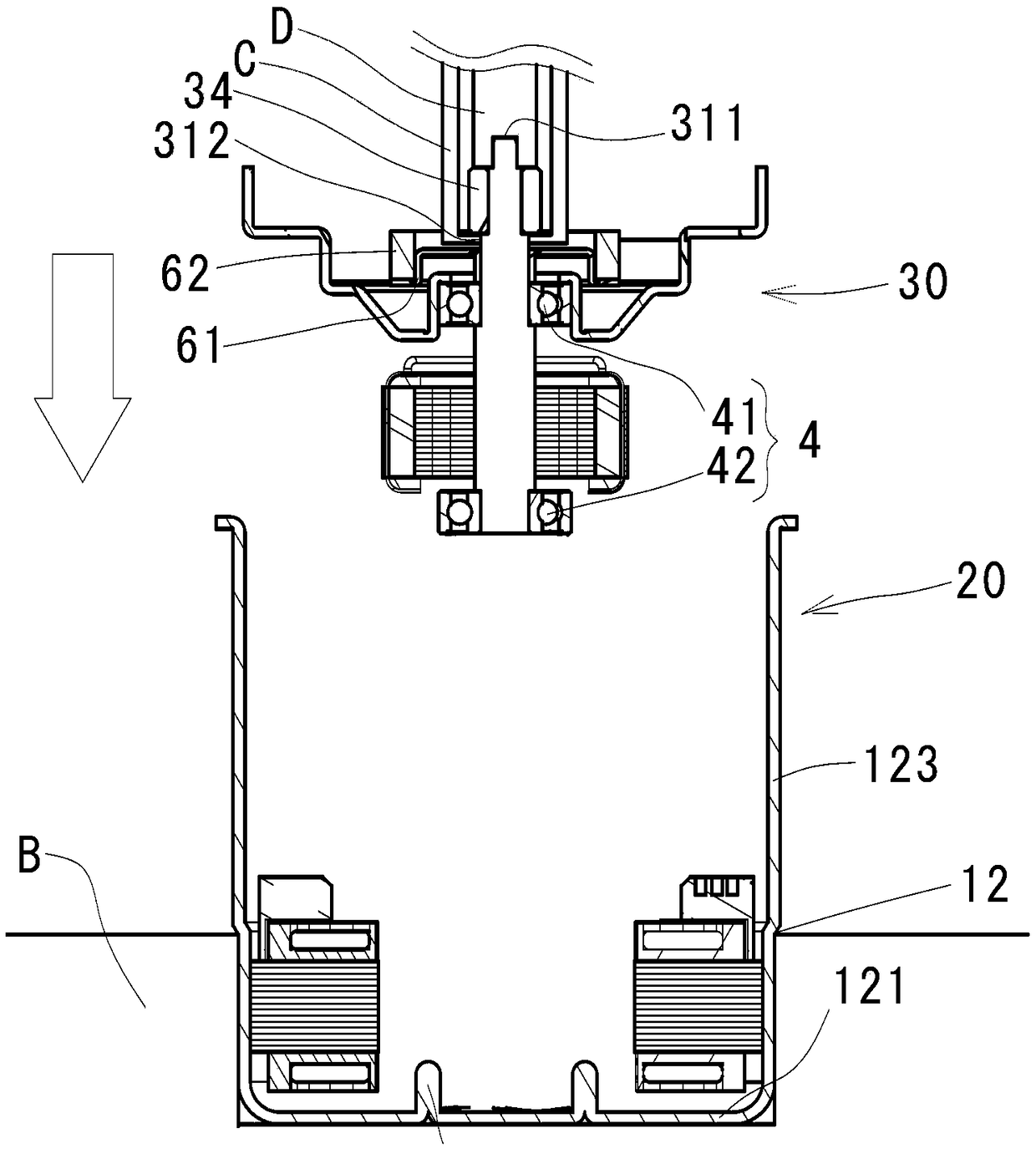

[0014] figure 1 is a plan view showing the motor 1, figure 2 is in figure 1 The longitudinal sectional view of the motor 1 is cut at the position of A-A. exist image 3 In , a cross section on a plane including the central axis J1 of the motor 1 is shown. The motor 1 is a 3-phase AC motor driven by 3-phase AC current.

[0015] Such as image 3 As shown, the motor 1 is an inner rotor type motor, which includes: a stator part 2; a rotor part 3; a bearing mechanism 4, which supports the rotor part 3 so as to be rotatable around the central axis J1 relative to the stator part 2; unit 5 that connects the coil 213 of the stator part 2 with an external power source; and a sensor 6 that magnetically detects the angular position of the rotor core 32 of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com