New Plastic Pipe Compensator

A technology of plastic pipes and compensators, which is applied to expansion compensating devices, pipe elements, pipes/pipe joints/fittings, etc. for pipelines, which can solve a single sealing form, increase the cost and pressure loss of the pipe network, and increase the pressure of the fluid medium. Loss and other problems, to achieve the effect of unrestricted medium flow, safe pipeline operation and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

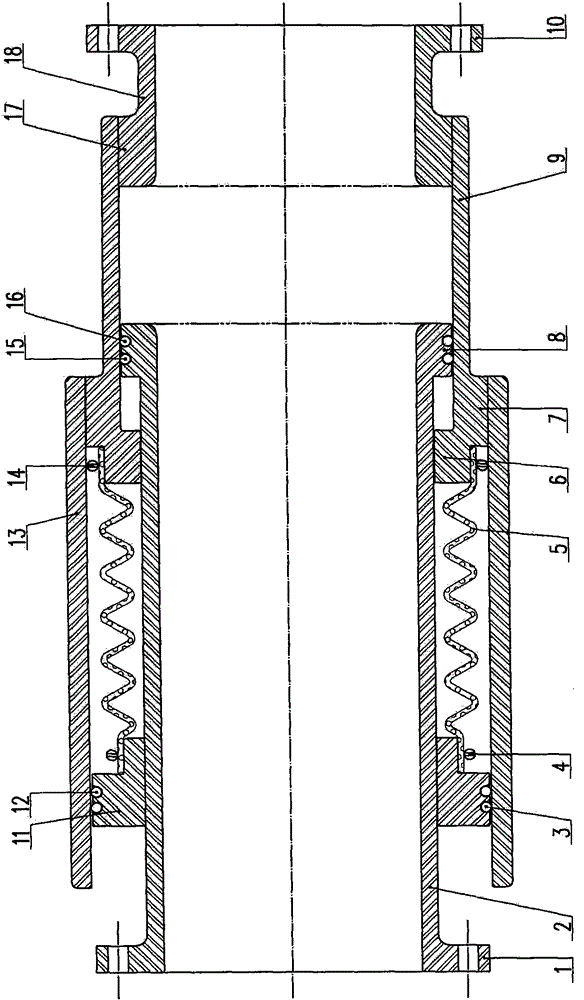

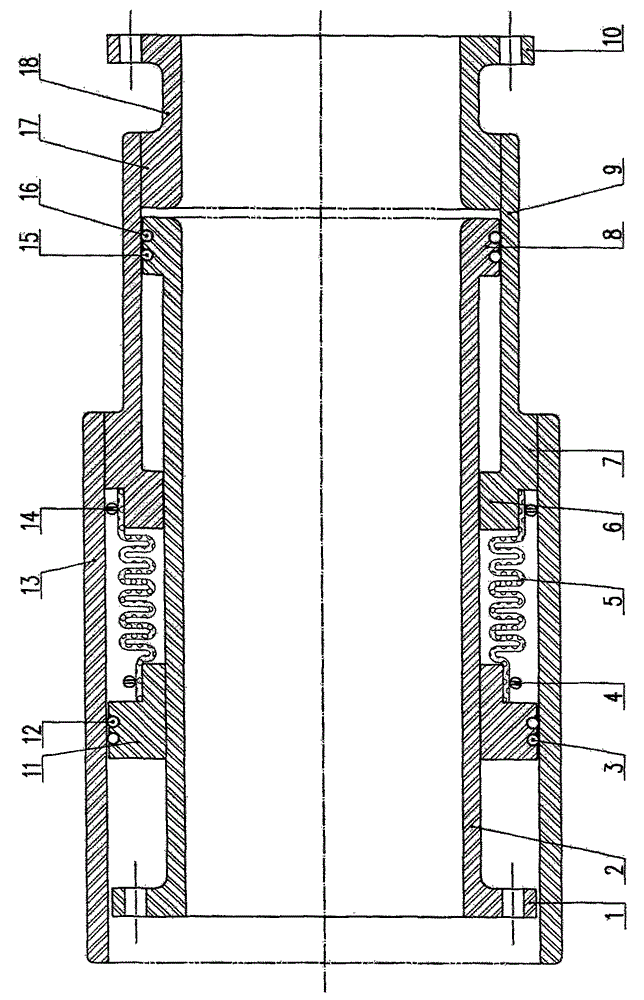

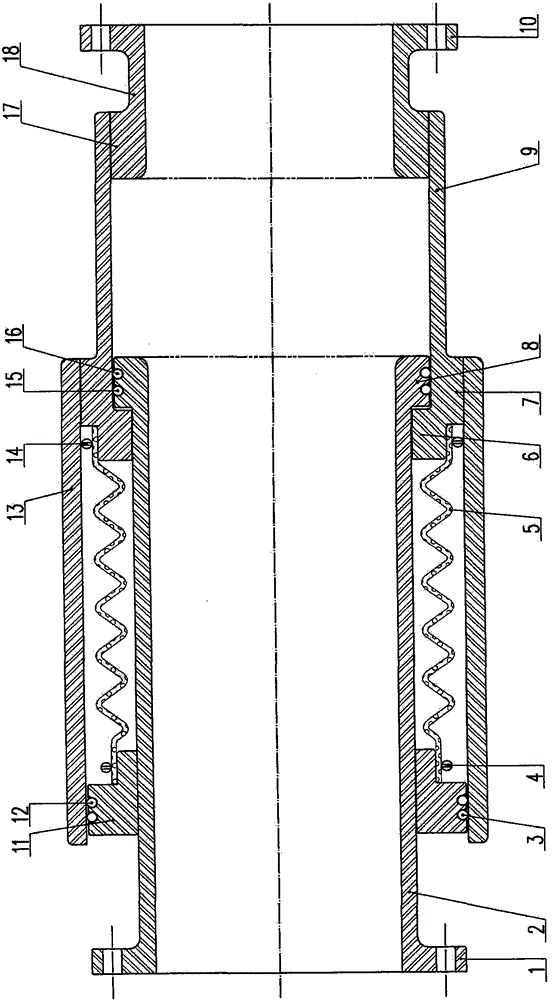

[0046] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] Such as figure 1 , figure 2 with image 3 shown. A new type of plastic pipe compensator, including external connection flange B1, pipe A2, O-ring D3, throat clamp B4, bellows 5, anti-pull stop ring 6, core pipe convex outer ring 7, pipe A convex Outer ring 8, core tube 9, outer connecting flange A10, sealing structure 11, O-ring C12, outer casing 13, throat clamp A14, O-ring B15, O-ring A16, pipe B convex outer ring 17 , pipe B18;

[0048] The pipe A2 and the core pipe 9 form a structure in which the pipe A2 is coaxially inserted into the core pipe 9;

[0049] Described pipe A2 is cylindrical rigid structure, one end or inner end (as figure 1 , figure 2 with image 3 The right end in the middle) along the surface of the outer ring integrally formed protruding setting section is the rectangular pipe A protruding outer ring 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com