Shooting nail gun

A nail gun and nail storage technology, which is applied in the field of nail guns, can solve problems such as troublesome replacement, nail scrapping rate, easy deviation, etc., and achieves the effects of convenient assembly, disassembly and cleaning, long service life and high coaxial precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

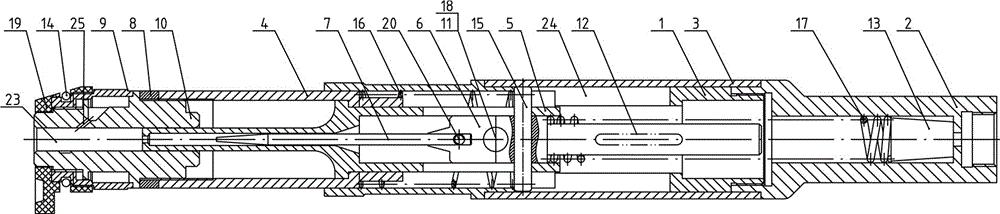

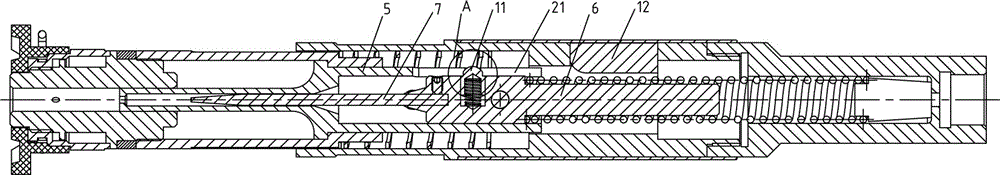

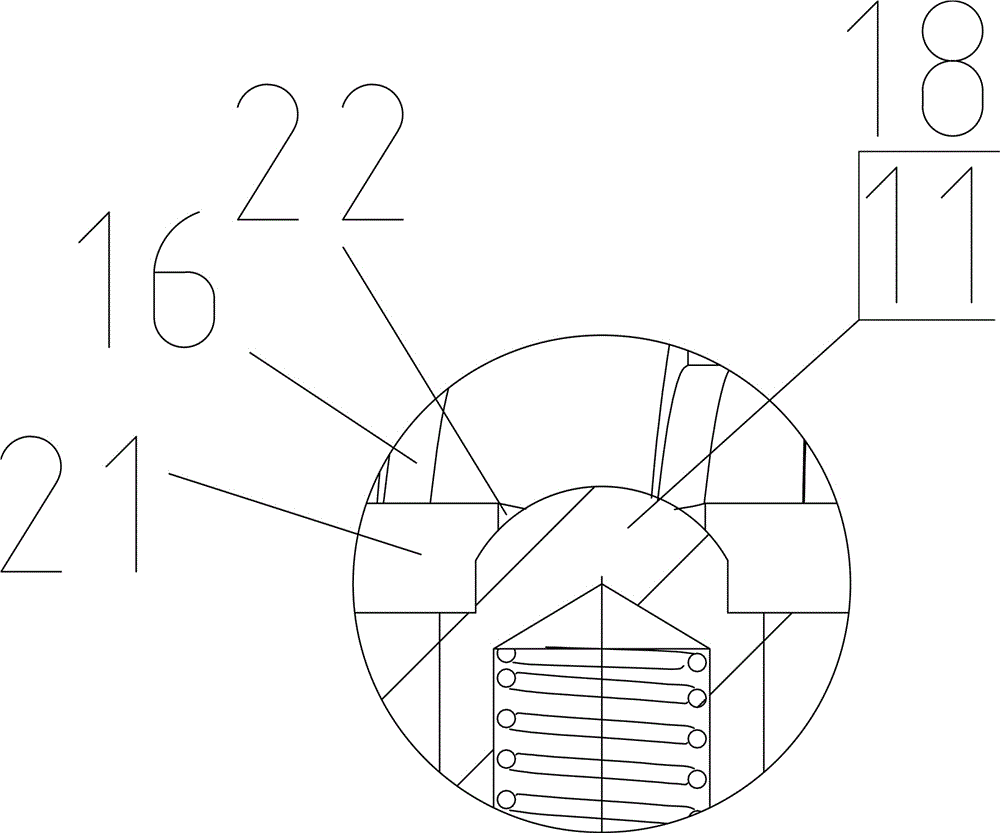

[0022] The present invention will be further described and explained below in conjunction with the accompanying drawings.

[0023] The nail gun includes a connecting handle 2, a sliding sleeve 1, an outer sleeve 4 and a nail sleeve 10 that are connected in sequence. The connecting handle 2 is provided with two cavities, and the first cavity is connected to the external booster rod to adapt to various For high use, a nylon pad 13 is placed in the second cavity to provide cushioning during firing, and a firing spring 17 is placed on the nylon pad 13. The sliding sleeve 1 is screwed and fixed with the connecting handle 2, and a limit groove 24 that is symmetrical up and down is arranged in the middle of the sliding sleeve. The limit groove 24 is inserted into the return pin 15, and the return pin slides back and forth in the limit groove ; The sliding sleeve 1 is slidingly matched with the outer sleeve 4, and there is a cavity between the outer sleeve and the return pin, and a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com