Method for processing reducer pipe by integral cold drawing molding

A processing method and a technology for reducing the diameter of the tube, which are applied in the processing field of the non-cutting and drawing-forming reducer, and can solve the problems of poor connection sealing and electrical conductivity, poor electrical performance of the reducer, and difficulty in adjusting the capacitance value. The electrical properties are convenient, the processing equipment requirements are not high, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated in the following examples, which are only used to illustrate the present invention and not to limit the present invention.

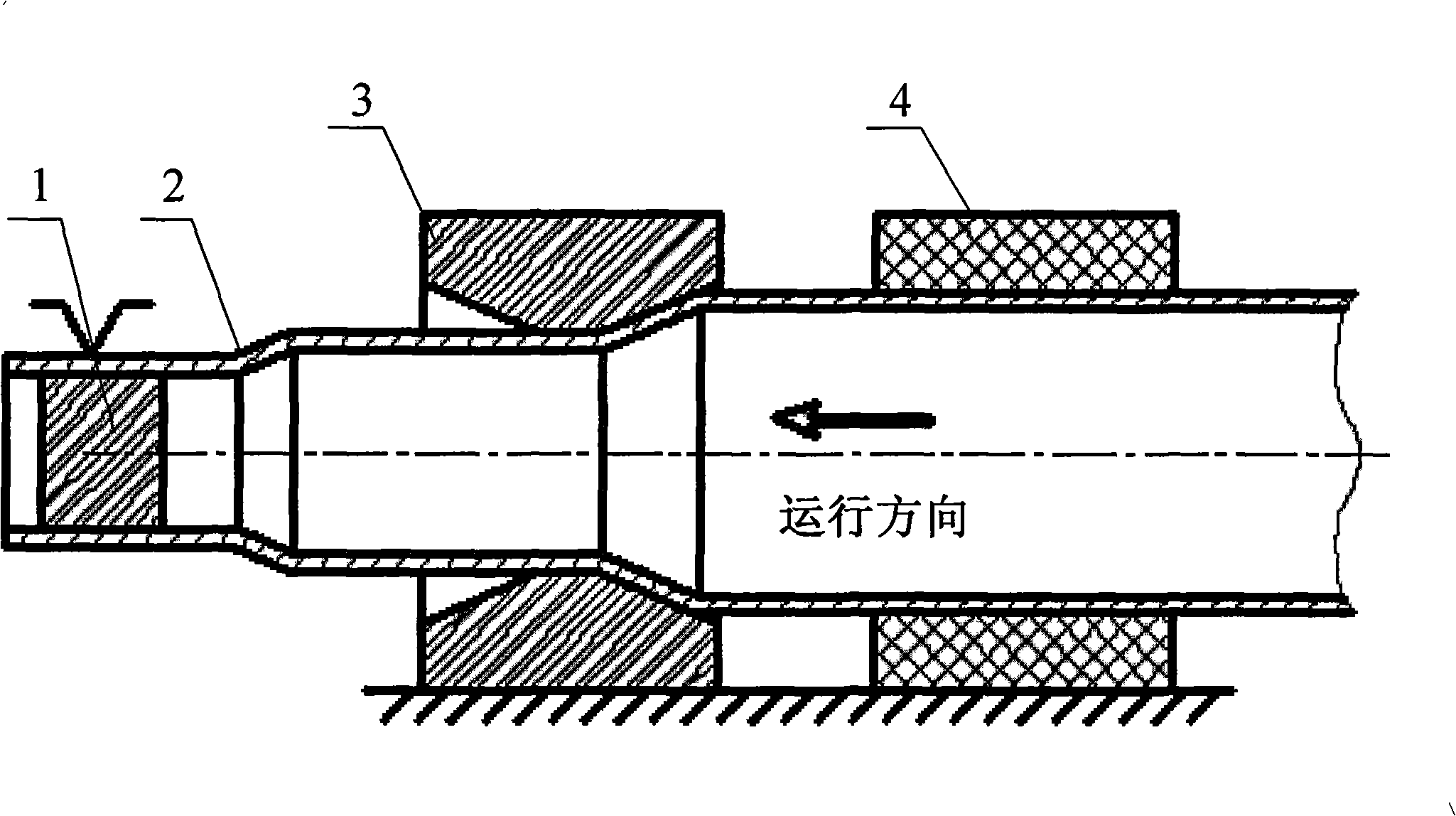

[0020] Referring to Fig. 1, according to the present invention, a machining aid tool mandrel 1 is prepared. The mandrel 1 is a cylindrical solid body matched with the inner diameter of a section of the process tube of the tube blank 2 . Fix the stretching die 3 and the support sleeve 4 with stretching transition surfaces at one or both ends on the working platform of the stretching machine tool to form a stretching process equipment with the same centerline. The tube blank material is preferably 3A21H24, the wall thickness is preferably 0-2mm, and the diameter reduction range is preferably 0-50%.

[0021] At one end of the tube blank 2, a small section of process tube smaller than the diameter of the above-mentioned tube blank 2 is formed by extrusion or trimming, and then the pre-prepared cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com