Directly-buried maintenance-free axial conjointed sleeve compensator

A sleeve compensator, maintenance-free technology, applied in the direction of pipeline protection, pipeline protection through thermal insulation, thermal insulation, etc., can solve the problems of inability to meet the structure, limited compensation amount, complex working conditions, etc., and achieve a simple axial connection structure , Reduce the cost of matching, the effect of high coaxial accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to accompanying drawing.

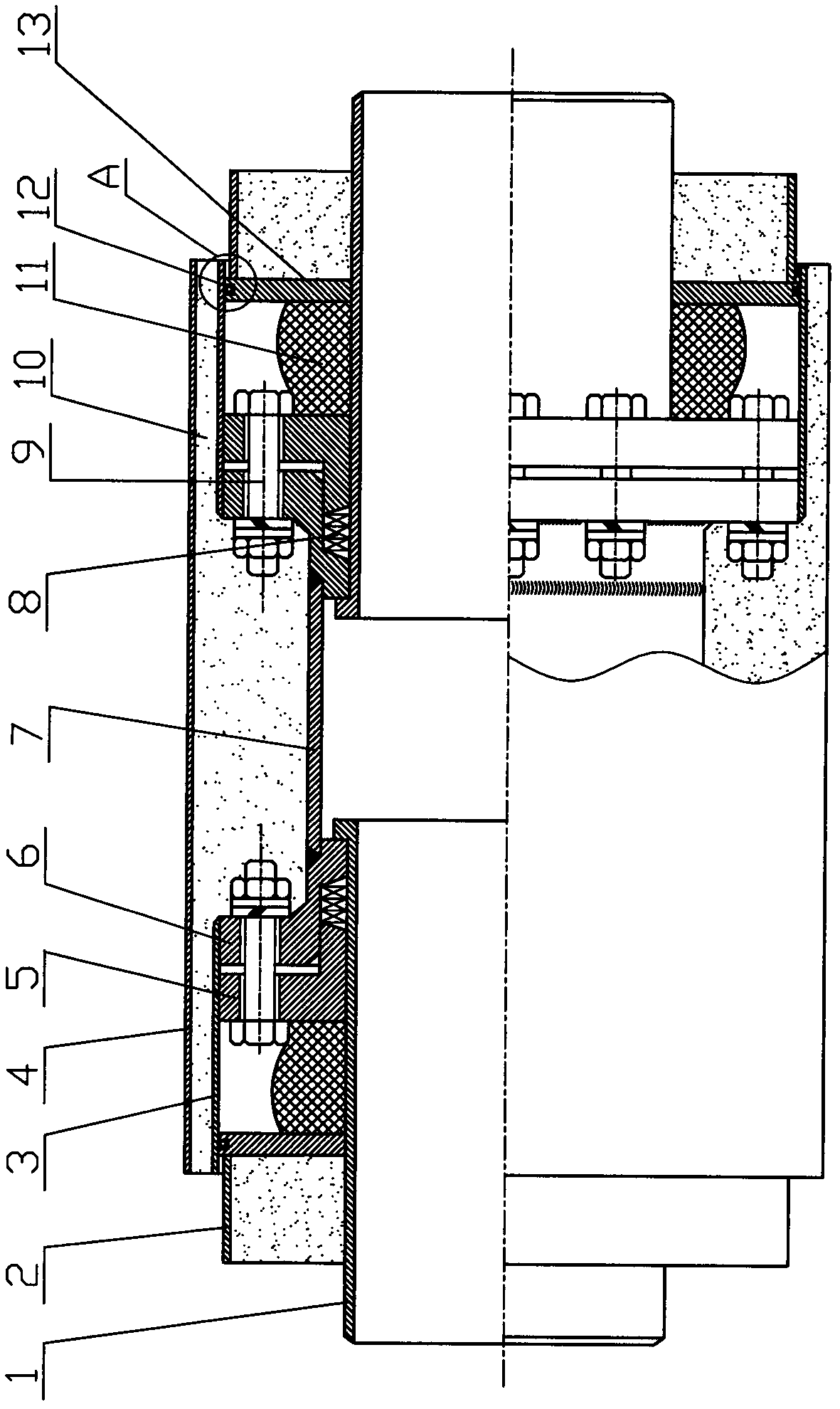

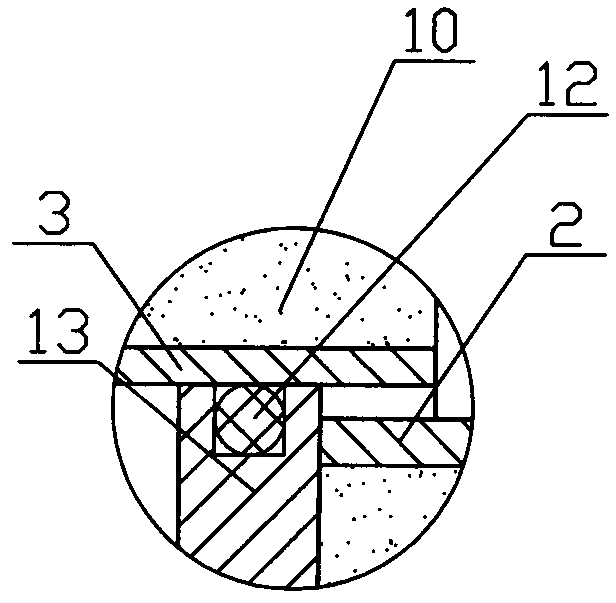

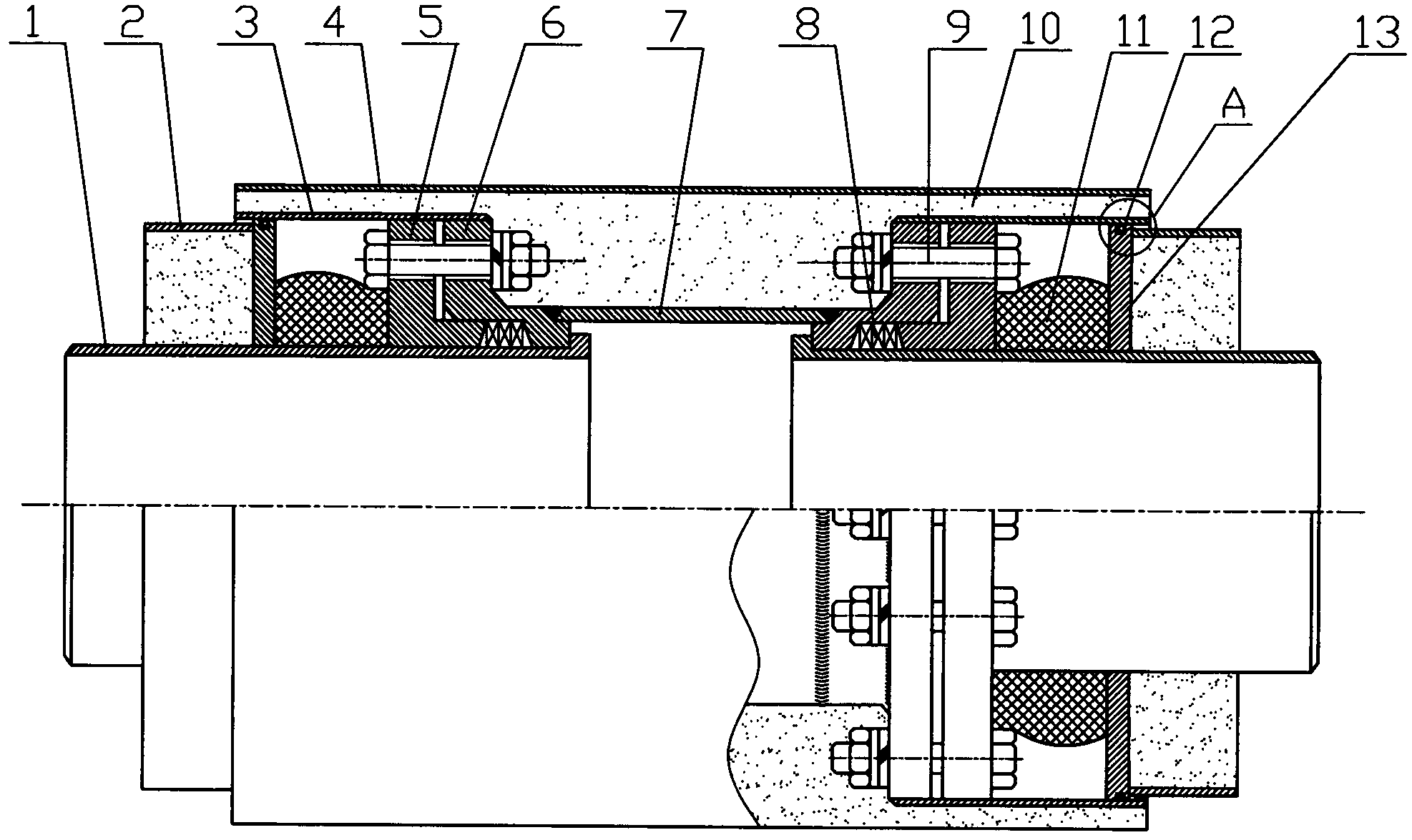

[0014] figure 1 The direct-buried maintenance-free axial joint sleeve compensator shown in the figure includes two identical sleeve compensators arranged in the same axial direction and a matching heat preservation structure. The sleeve compensator includes an inner tube 1 , a casing 2 , a guide tube 3 , a gland 5 , a sealing seat 6 , a packing 8 , a bolt assembly 9 and an end plate 13 . The inner tube 1 is a straight tube structure, and the outer wall is sequentially fitted with a sealing seat 6, a packing 8 and a gland 5, and a bolt assembly 9 is connected in series with the sealing seat 6 and the gland 5 to form a sealing adjustment structure, so that the inner tube 1 is axially sealed under the sealed condition. Move or rotate and combine movements. The outer wall of the inner tube 1 located outside the gland 5 is coaxially connected to the end panel 13, and the outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com