Novel precision-type high-pressure-resistant rotary compensator

A rotary compensator, a precise technology, applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, adjustable connections, etc. problems such as large investment and pressure loss, to achieve the effect of safe pipeline operation, small pressure loss and strong pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

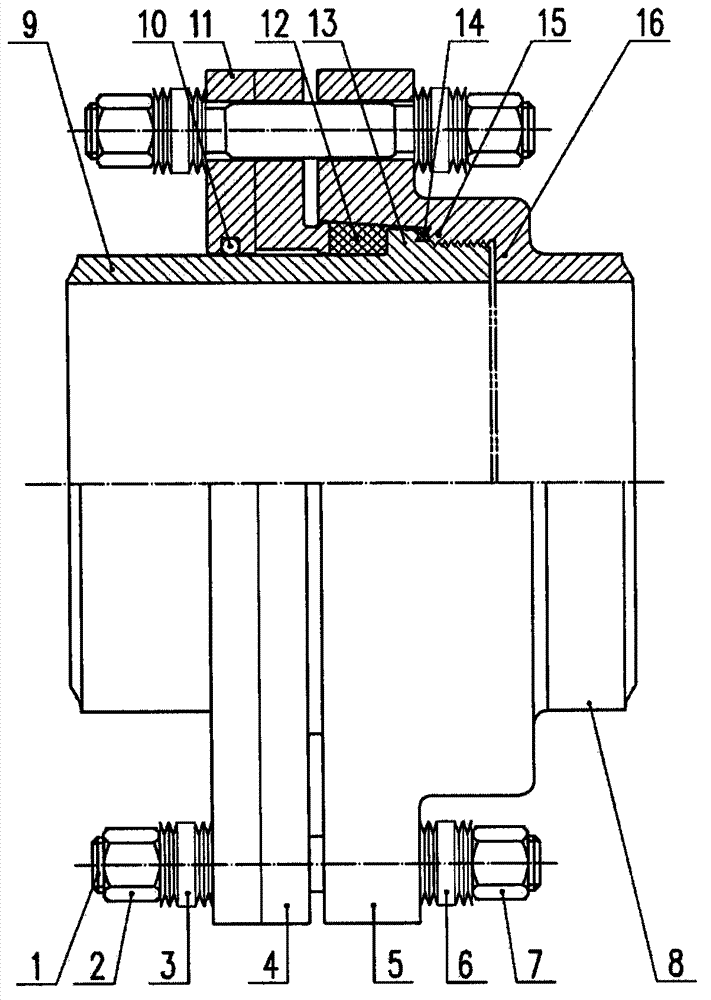

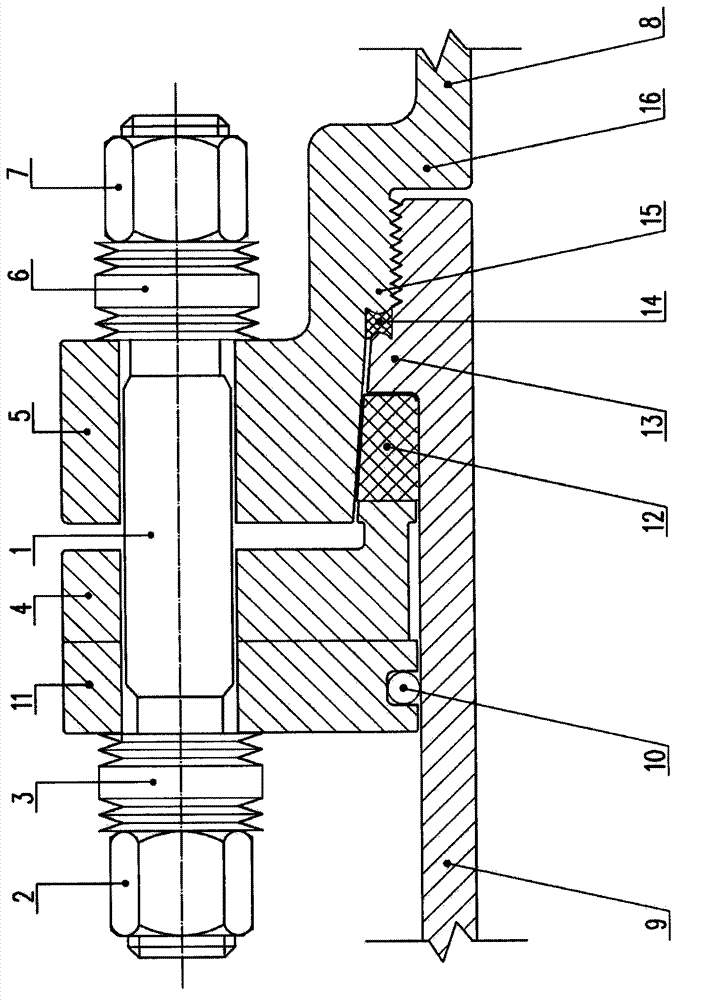

[0048] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] Such as figure 1 , figure 2 Shown; a new type of precision high-pressure rotary compensator, including: stud bolt 1, nut A2, disc spring A3, seal compression flange 4, reducer flange 5, disc spring B6, nut B7, Reducer tube 8, inner tube 9, steel ball 10, outer gland flange 11, graphite seal 12, inner tube convex outer ring 13, metal winding gasket 14, reducer inner cap B15 and reducer inner cap A16;

[0050] The internal diameter of the inner tube 9 is the same as that of the reducer tube 8, and the inner end is coaxially inserted; the detailed description is as follows: figure 1 As shown, that is, the inner tube 9 is a columnar tube structure, arranged horizontally, one end (or right end) is the inner end, and the other end (or left end) is the outer end; the reducing tube 8 is a columnar tube structure, arranged horizontally, O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com