End face sealing test device for liquid rocket engine turbine pump under low-temperature and high-speed

A liquid rocket, end-face sealing technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problem of no end-face sealing test device, etc., and achieve the effect of strong functionality, good test results, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

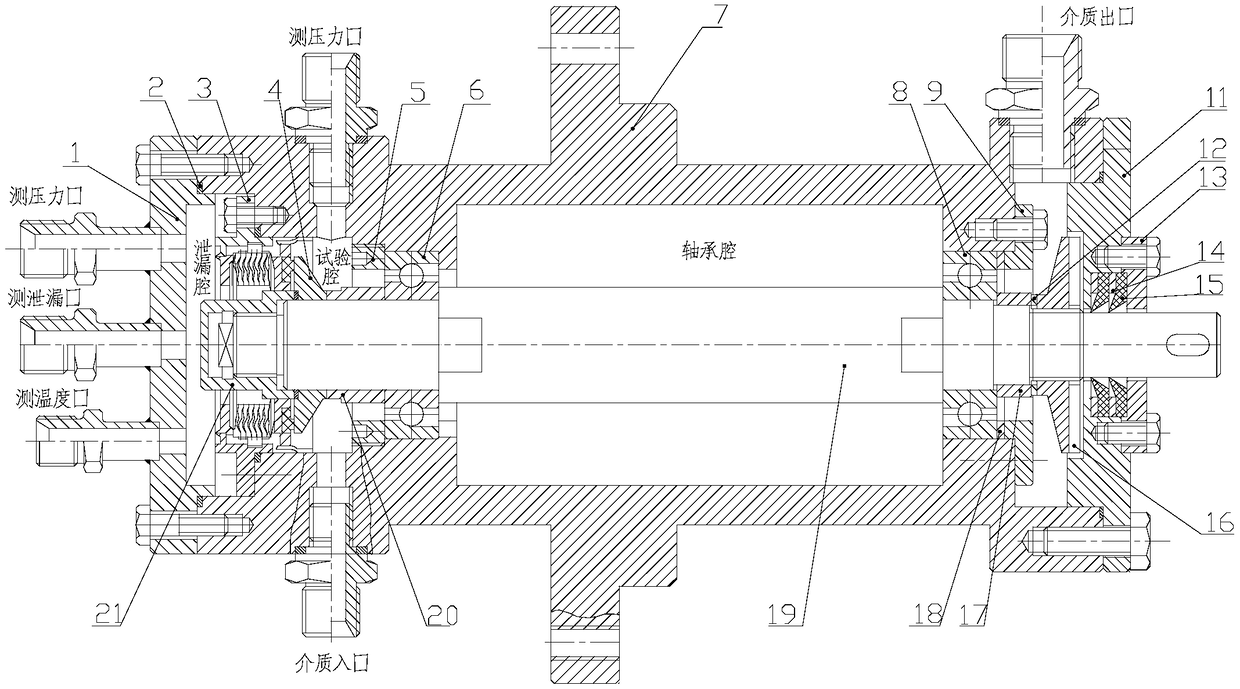

[0024] In order to carry out the low-temperature high-speed sampling test and running-in test of the end face seal of the turbo pump of the liquid rocket engine, and to detect the sealing performance between the static ring assembly and the moving ring of the turbo pump, a test device is designed in the present invention, and the device needs to meet the low temperature of -196 ℃ And the working conditions at 40000r / min speed, and no shrinkage deformation under low temperature environment, at the same time to ensure the dynamic stability of the stepped spindle and the requirements of low-speed dynamic balance and weight removal.

[0025] Assemble the end face seal products (engine static ring assembly and engine dynamic ring) into the test device of the present invention, simulate the working environment of the engine turbo pump, evaluate the sealing performance and structural rationality of the seal assembly products, and quantitatively detect the seal assembly products. It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com