Non-magnetic sheet clamping and positioning tool and manufacturing method thereof

A technology for clamping and positioning and manufacturing methods, which is applied to positioning devices, clamping, manufacturing tools, etc., can solve the problems of non-magnetic thin plates that cannot be clamped and positioned, and achieve the effects of simple structure, easy operation, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

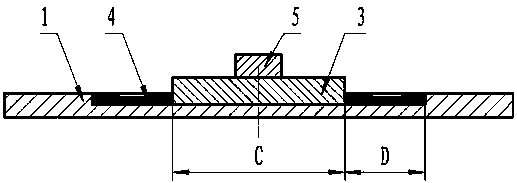

[0023] image 3 The shown non-magnetic thin plate clamping and positioning tool includes a base plate 1 and a plate material 3. A groove 2 is opened on the base plate 1, and the plate material 3 is placed in the groove 2. Between the edge of the plate material 3 and the inner wall of the groove 2 A gap area is provided, and the alloy material filling layer 4 is filled in the gap area, and a counterweight 5 is pressed on the side of the plate 3 away from the bottom surface of the groove 2 .

[0024] Preferably, the above-mentioned alloy material used as the alloy material filling layer 4 is tin-bismuth alloy, and the mass fraction of bismuth element in the tin-bismuth alloy is 58%. The base plate 1 is made of magnetic steel, which can meet the installation requirements of magnetic workbenches such as grinding machines, milling machines, and machining centers, and can also meet the installation requirements of traditional non-magnetic workbenches, which is convenient to use.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com