Laboratory self-control pile sinking device

A self-controlled, laboratory technology, applied in the direction of sheet pile wall, foundation structure test, construction, etc., can solve the problems of unsatisfactory test results, limited model pile size, obvious size effect, etc., to ensure reliability and installation Correctness, ensuring verticality, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

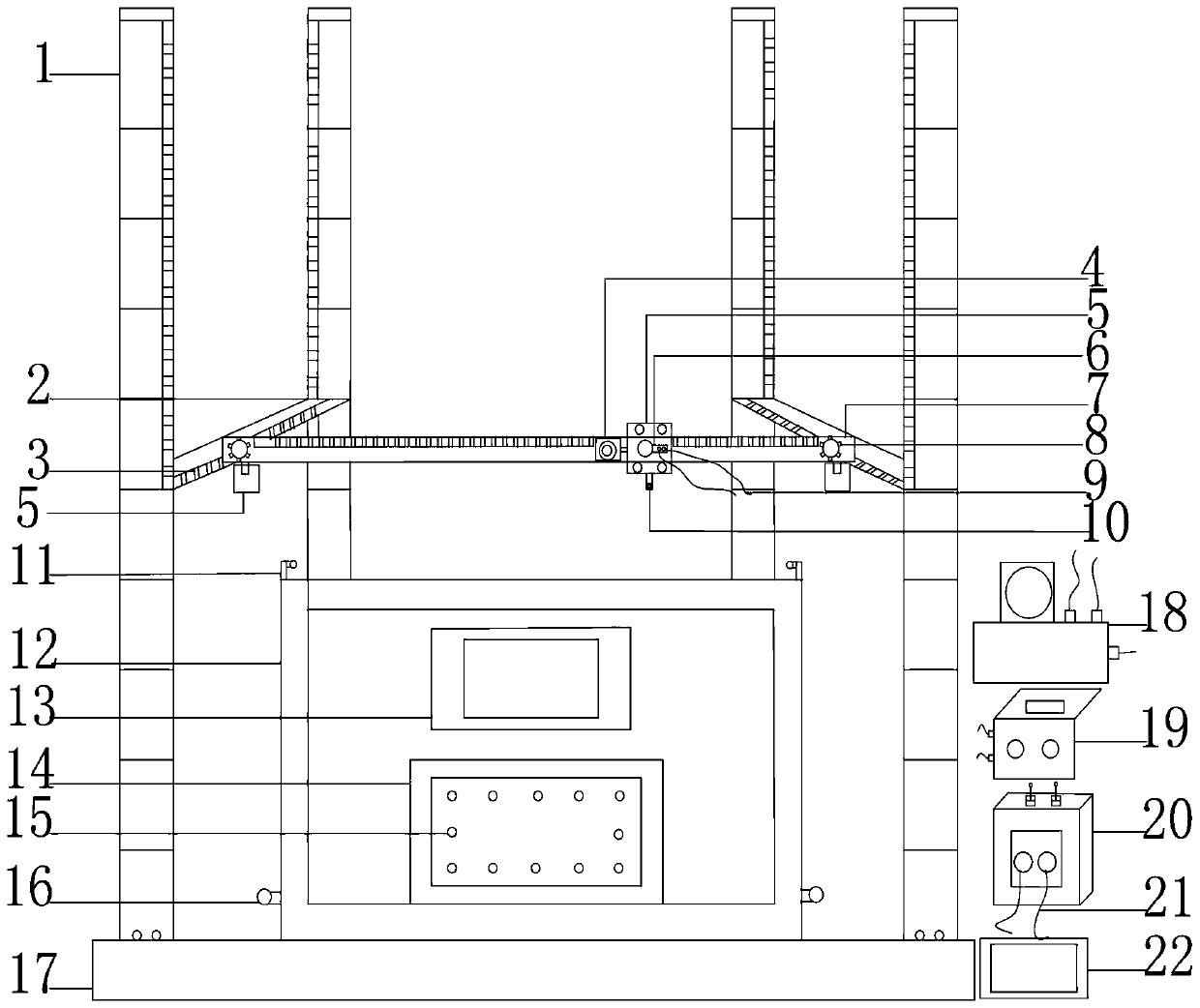

[0013] The main structure of the laboratory self-controlled pile sinking device described in this embodiment includes five functional parts: a model box system, a loading system, a laser displacement acquisition system, a verticality monitoring system, and a control system. The model box system includes a model box 12, a visual Window 13, drainage outlet 16, sand discharge outlet 14, model box 12 with a size of 3000mm×3000mm×2000mm (length×width×height), the bottom plate of model box 12 is a steel plate with a thickness of 14mm, and the surrounding frame is made of channel steel with a cross section of 100mm square It is welded; the visible window 13 is to change the steel plate into a transparent plexiglass in the upper part of the model box 12; the drain 16 is to open four 30mm round holes on the four corners of the bottom plate of the model box 12, and use a ball-type The steel pipe of the valve is welded with the round hole; the sand discharge port 14 is a convenient dismou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com