A fast-clamping and self-aligning grinding wheel flange for precision grinding machines

A technology of precision grinding machine and grinding wheel, which is applied in the direction of grinding machine parts, devices for fixing grinding wheels, grinding/polishing equipment, etc. Eccentricity error, simplified structure, improved damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

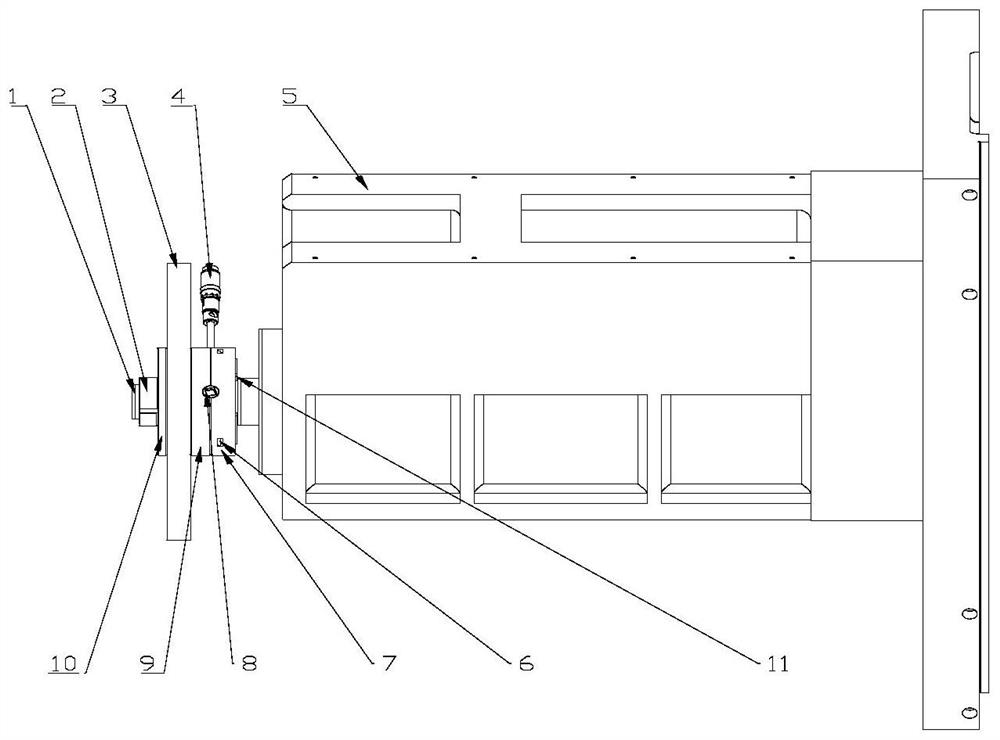

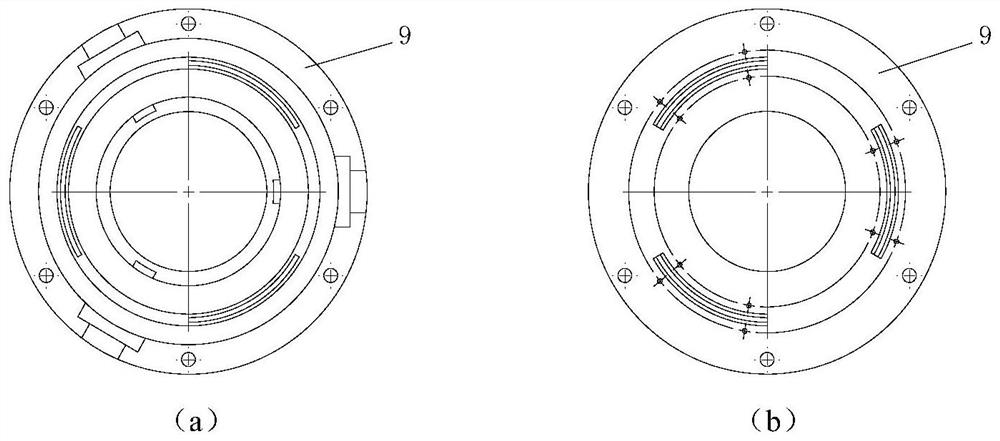

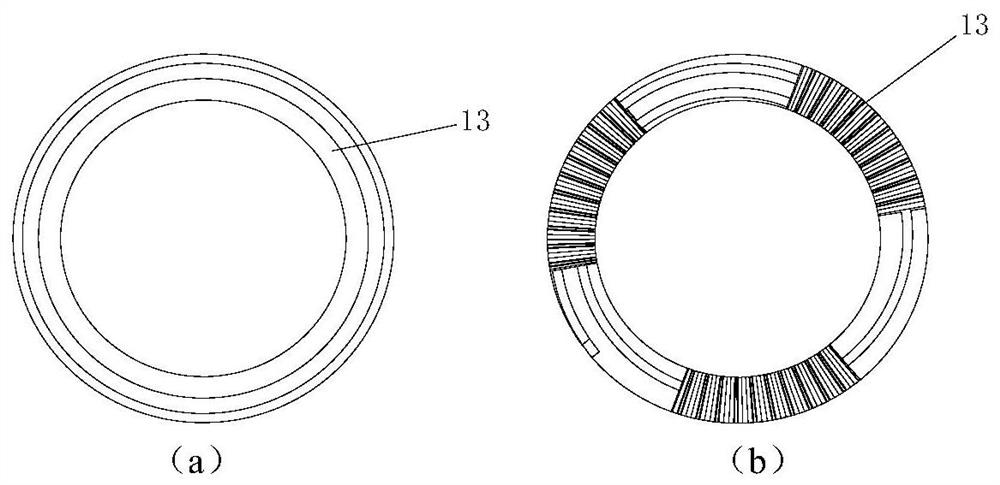

[0022] see Figure 1-9 The embodiment of the present invention is provided with a machine tool spindle 1, a grinding wheel fixing nut 2, a grinding wheel 3, an aligning wrench 4, a claw 6, an aligning device rear cover rear end 7, a small bevel gear 8, an aligning device rear cover front end 9, Centering device front end cover 10, ball cover 11, bearing 12, bevel gear 13 and ball 14.

[0023] The grinding wheel 3 is pre-tightened by the grinding wheel fixing nut 2, and the grinding wheel 3 is installed on the stepped shaft of the front end 9 of the back cover of the centering device. The self-aligning wrench 4 is inserted into the centering hole of the grinding wheel flange, and the self-aligning wrench 4 drives the large bevel gear 13 to rotate through the gear transmission of the small bevel gear 8 and the large bevel gear 13, and the plane thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com