Patents

Literature

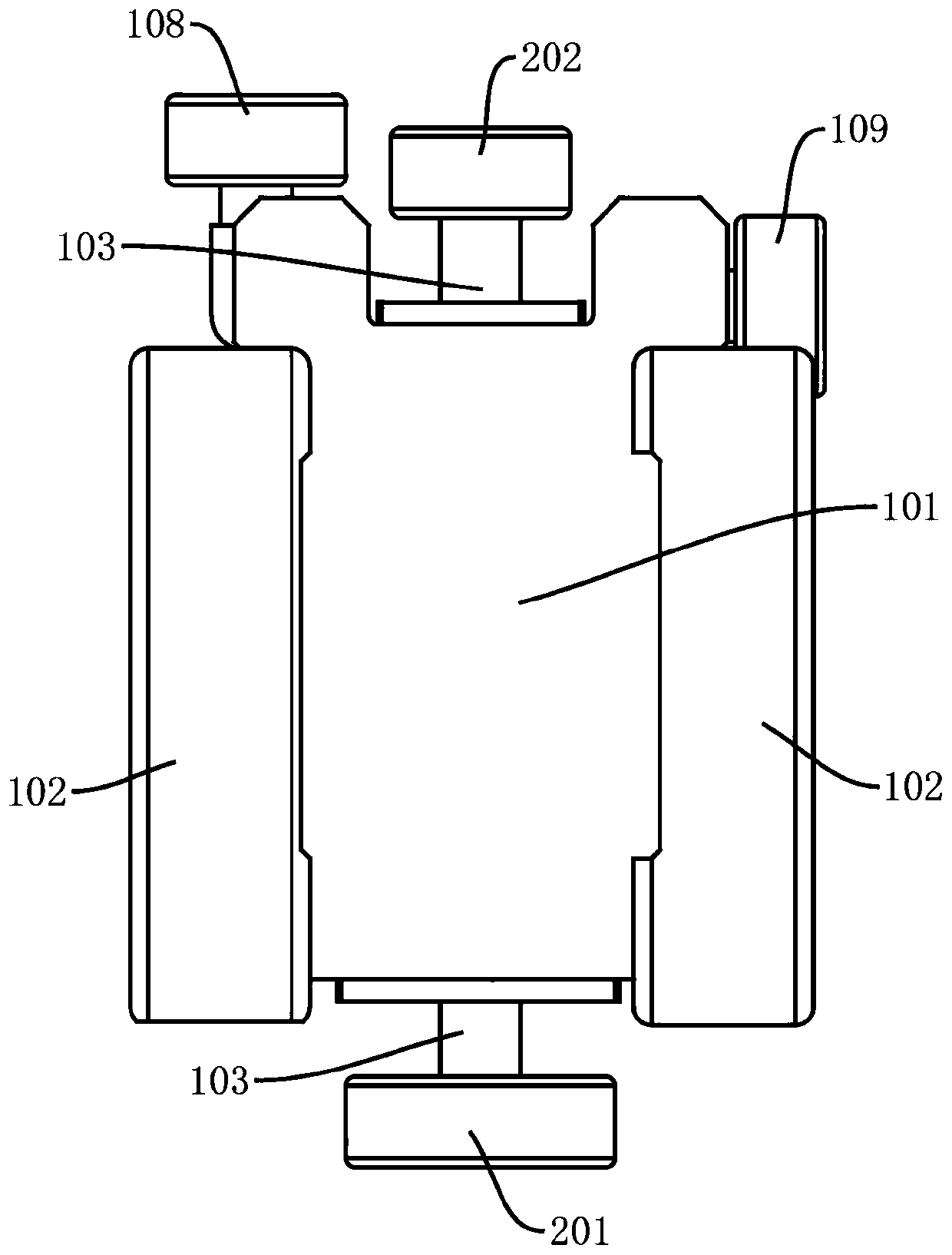

46results about How to "Solve the problem of eccentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

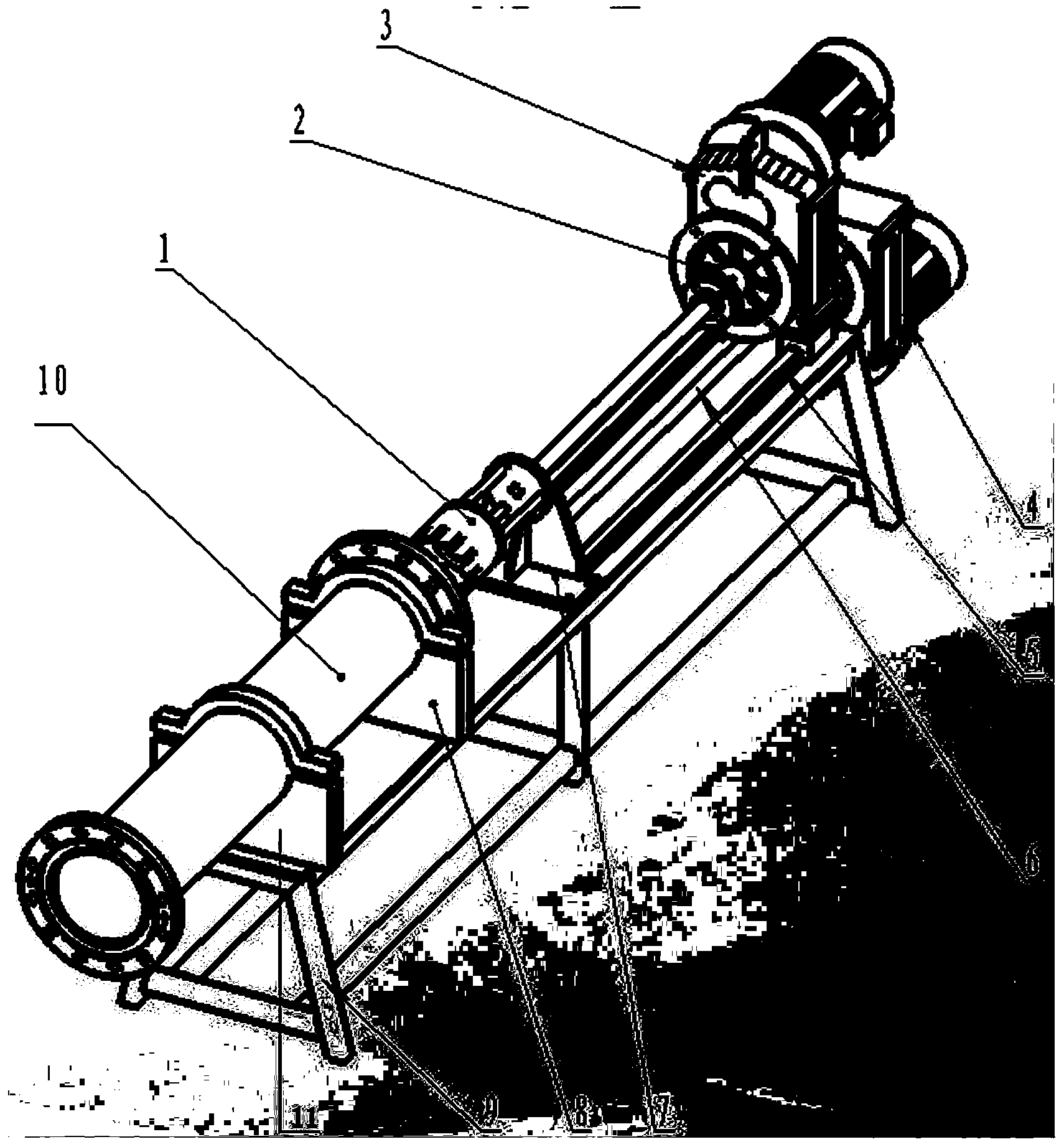

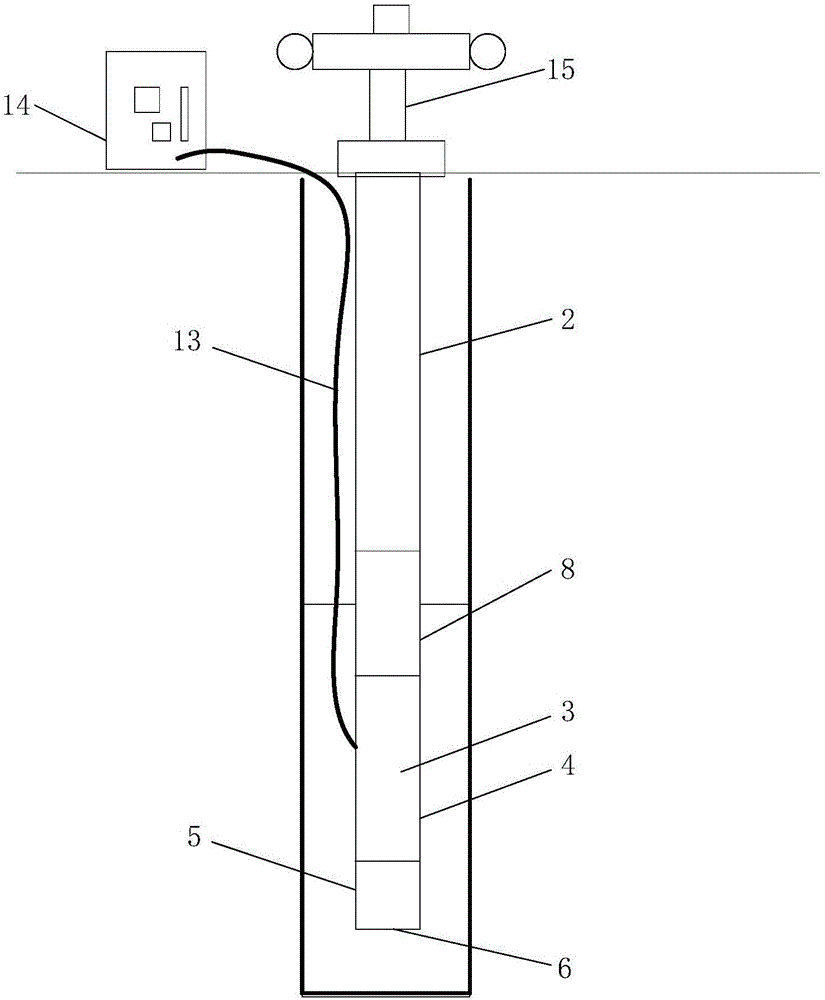

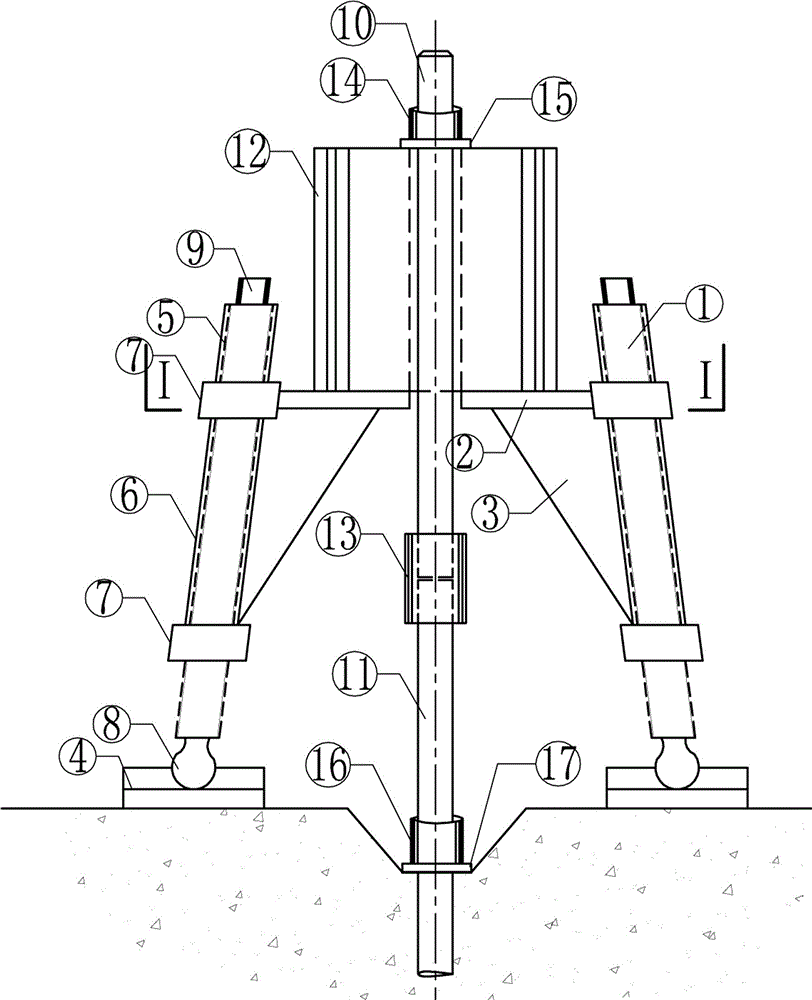

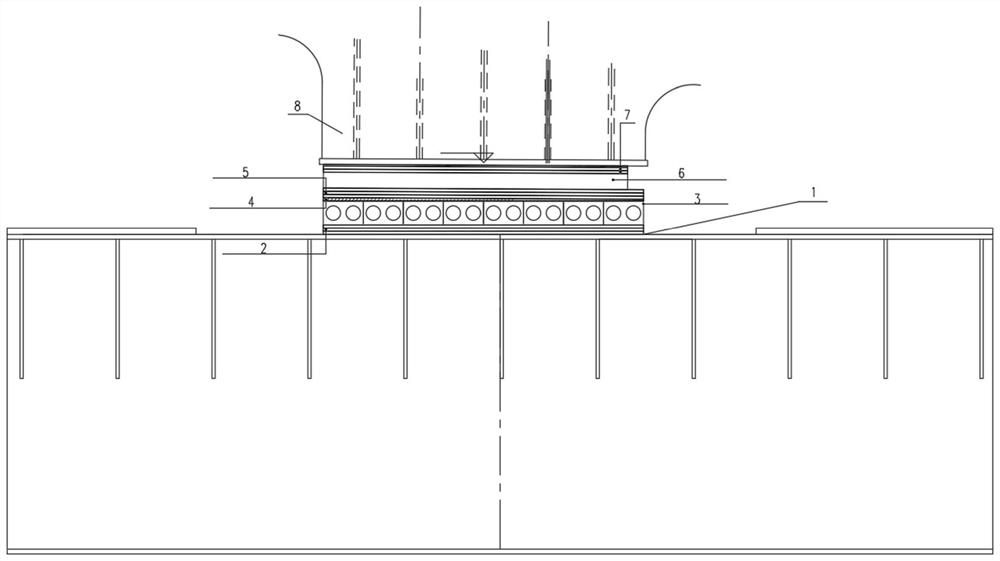

Construction process of open sea fan foundation rock-socketed pile

ActiveCN106120839ASolve the problem of eccentricityImprove the immunityFoundation testingBulkheads/pilesOpen seaEngineering structures

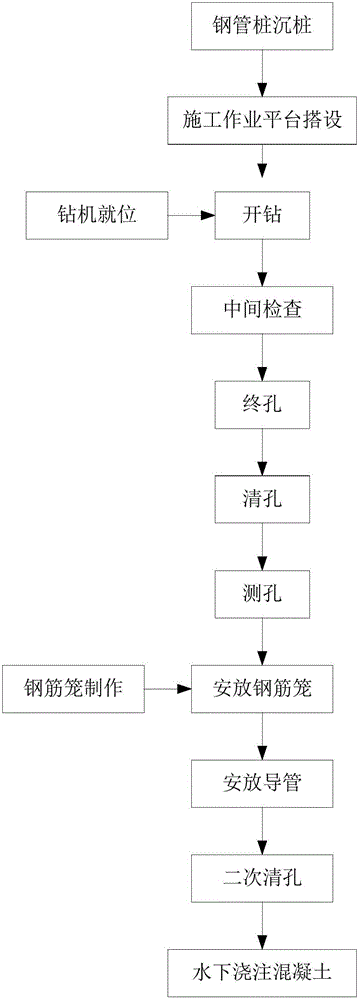

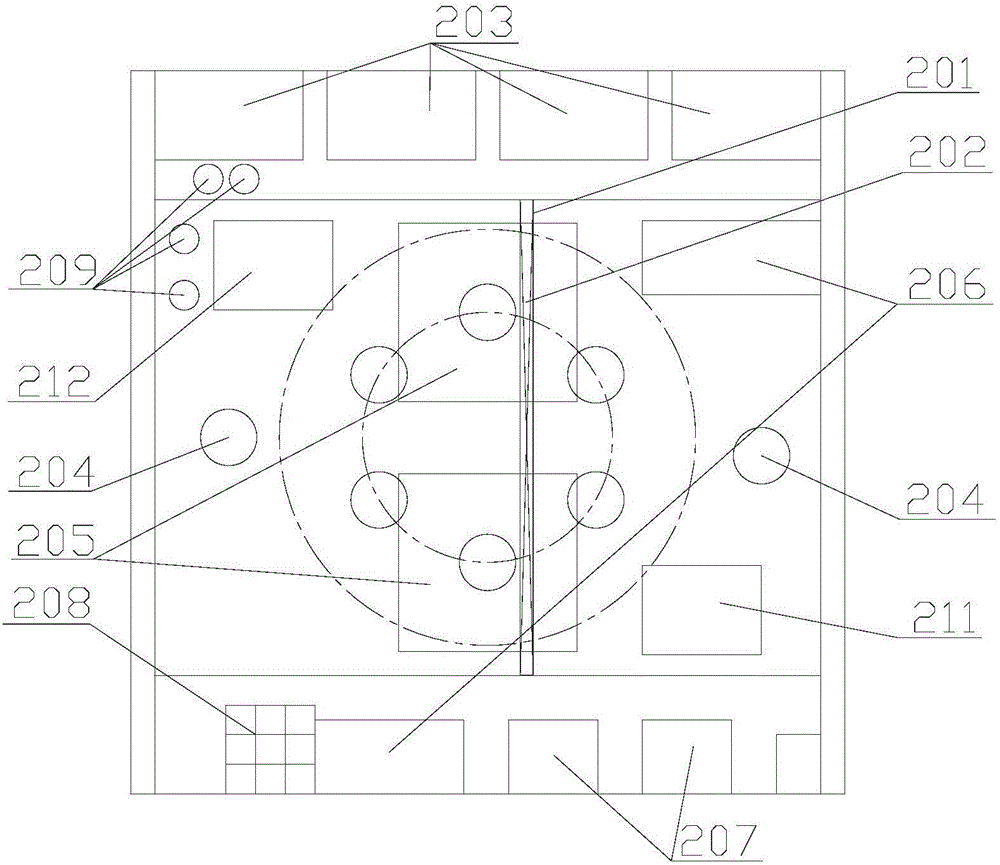

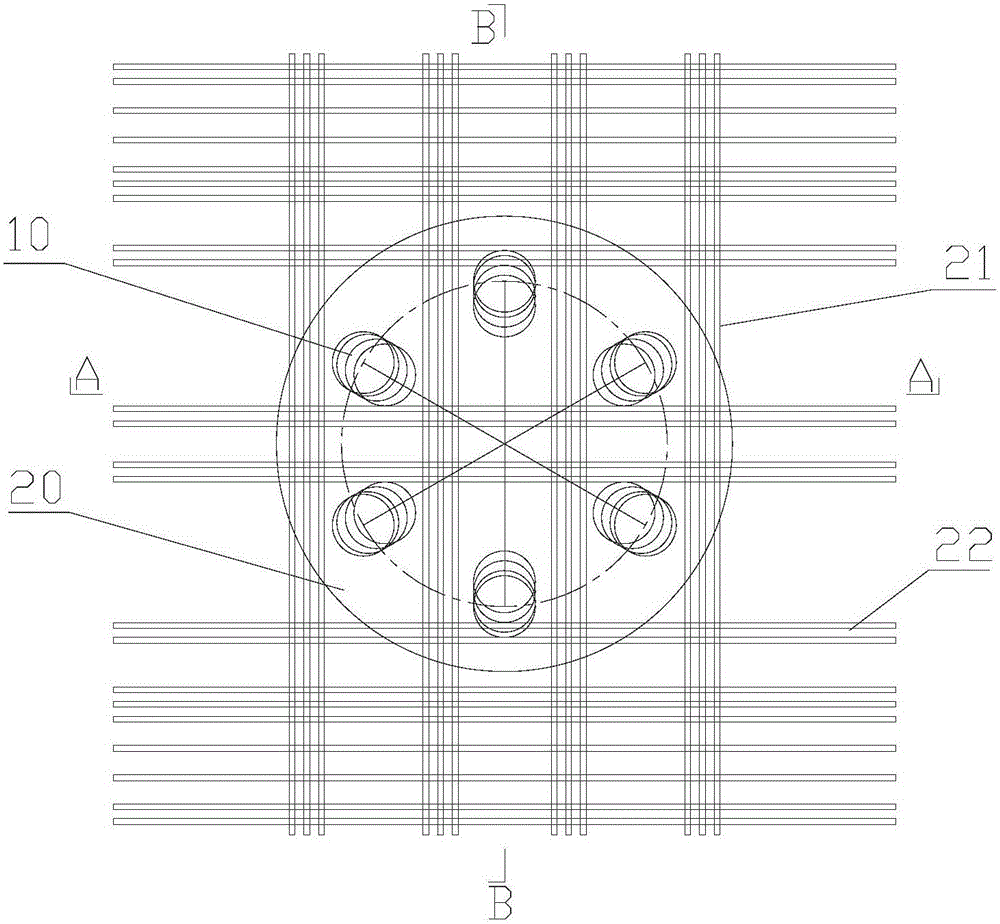

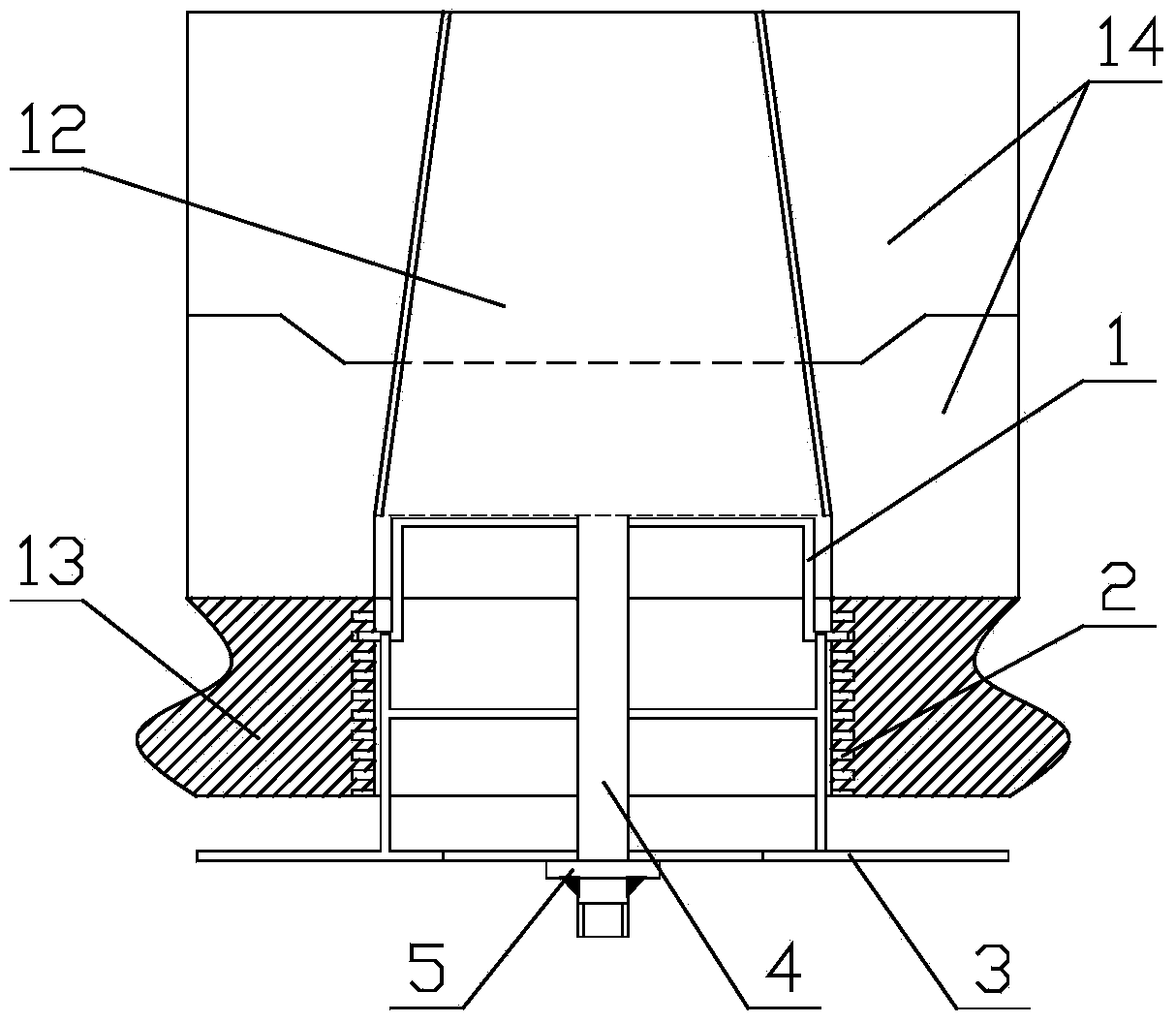

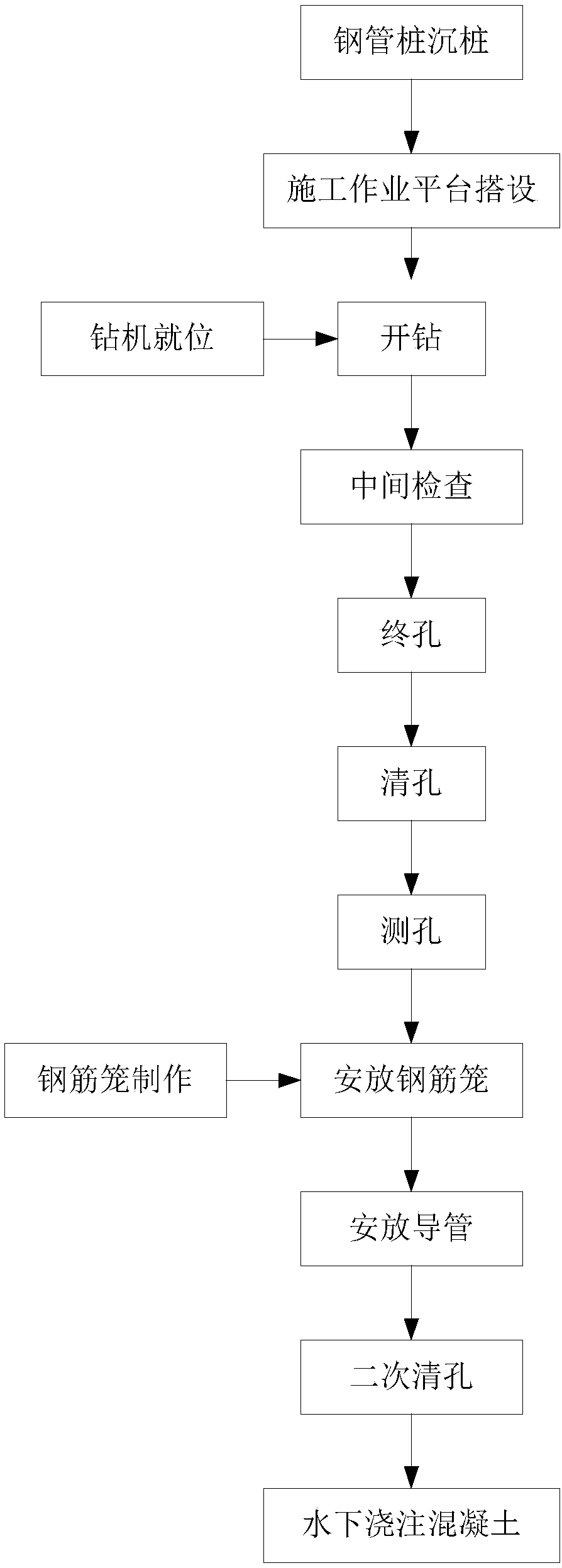

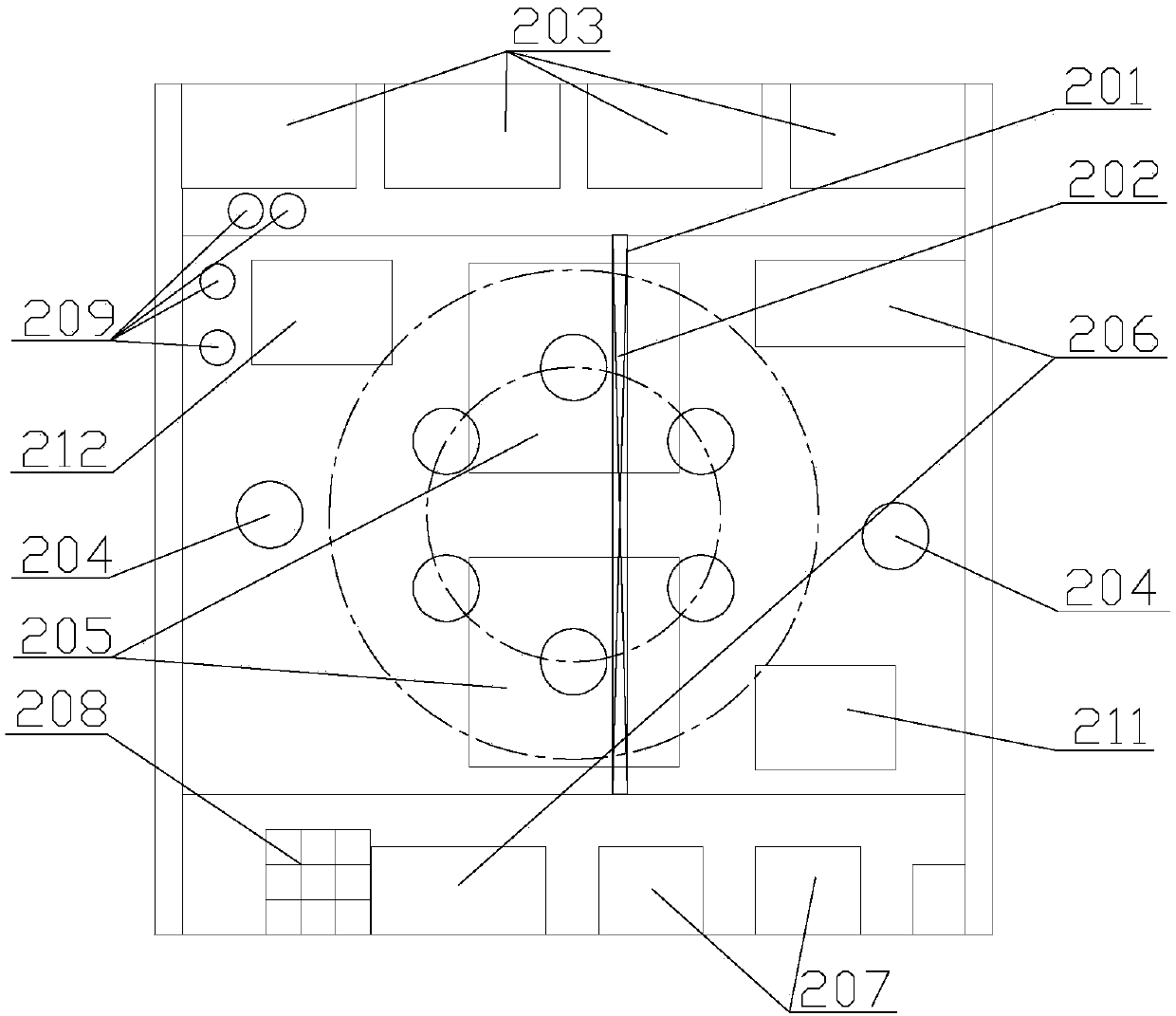

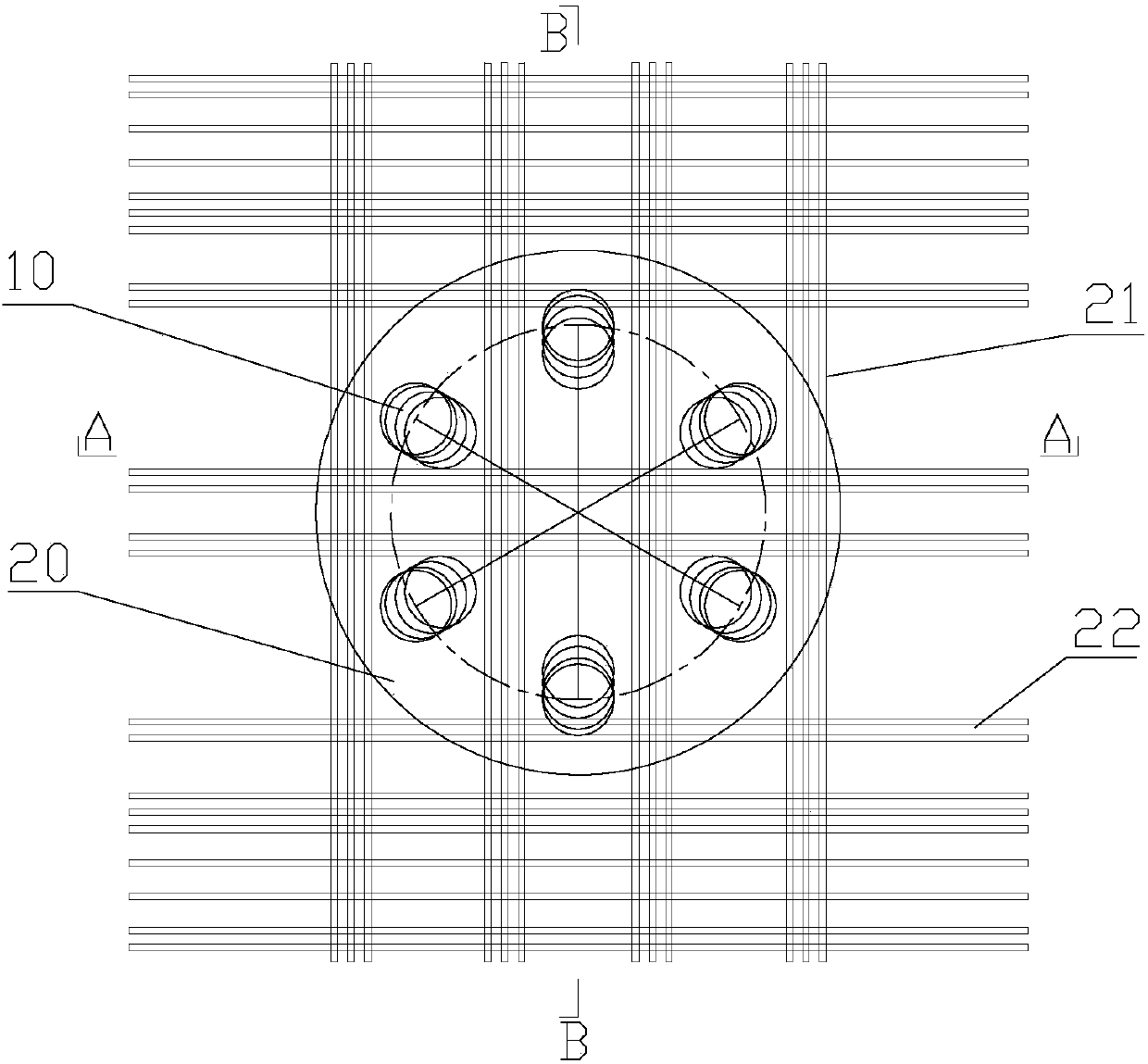

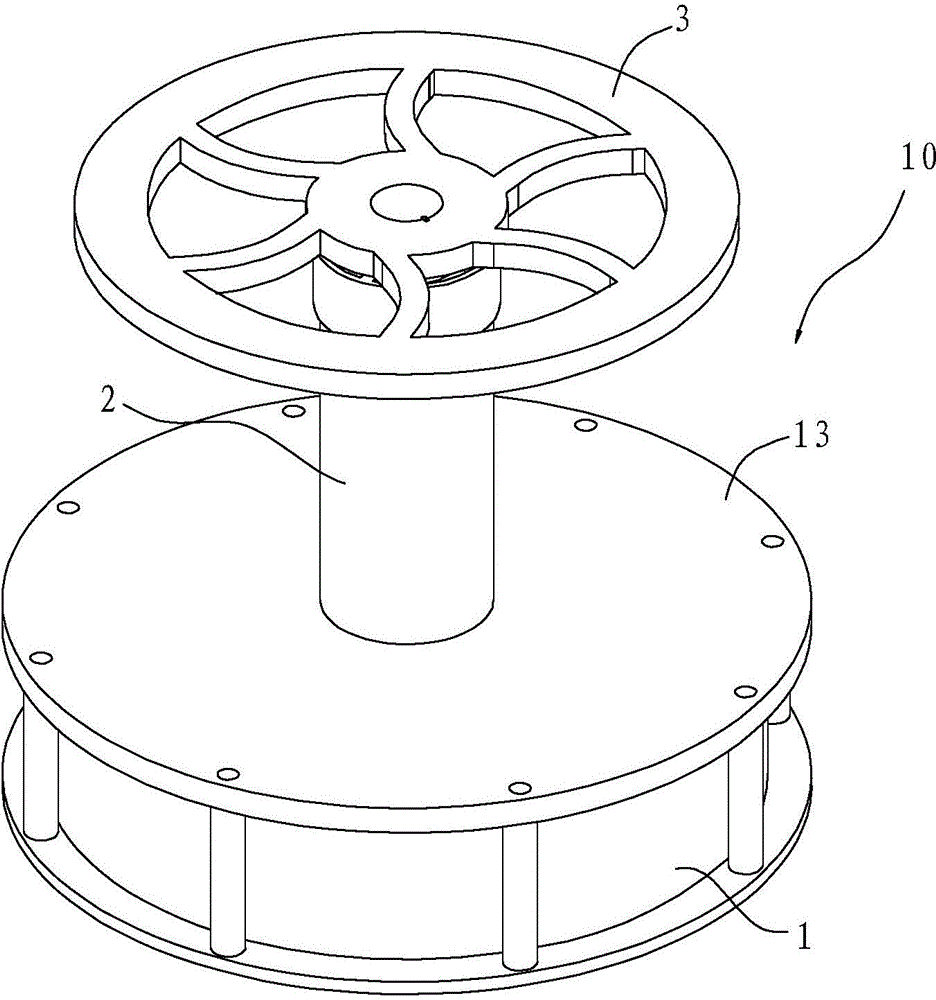

The invention discloses a construction process of an open sea fan foundation rock-socketed pile. The construction process comprises the steps of pile sinking of a steel pipe pile, setting a construction operation platform, drilling, performing intermediate inspection, finishing a drilled hole, clearing the hole, measuring the hole, placing a steel reinforcement cage, placing a guide pipe, clearing the hole for the second time and performing underwater concrete pouring procedure. In the pile sinking procedure of the steel pipe pile, six steel pipe piles with the inclination of 5:1 which are uniformly distributed on the circular track curve are sunken into the foundation in the pile driving way by a special pile driving boat; in the setting procedure of the construction operation platform, the construction of a bearing platform bottoming concrete layer is performed and the construction operation platform is erected on the bearing platform bottoming concrete layer; the concrete of the bearing platform bottoming concrete layer is performed by the steel pipe piles; the construction operation platform is square and comprises an upper bailey frame, a lower bailey frame, a steel platform panel and a safety fence. According to the construction process, the construction efficiency of the pile socketing into rock can be improved, the horizontal resistance and the anti-shifting capability of the rock-embedded piles can be effectively improved, and the requirements of engineering structure design and construction are met.

Owner:CCCC THIRD HARBOR ENG +2

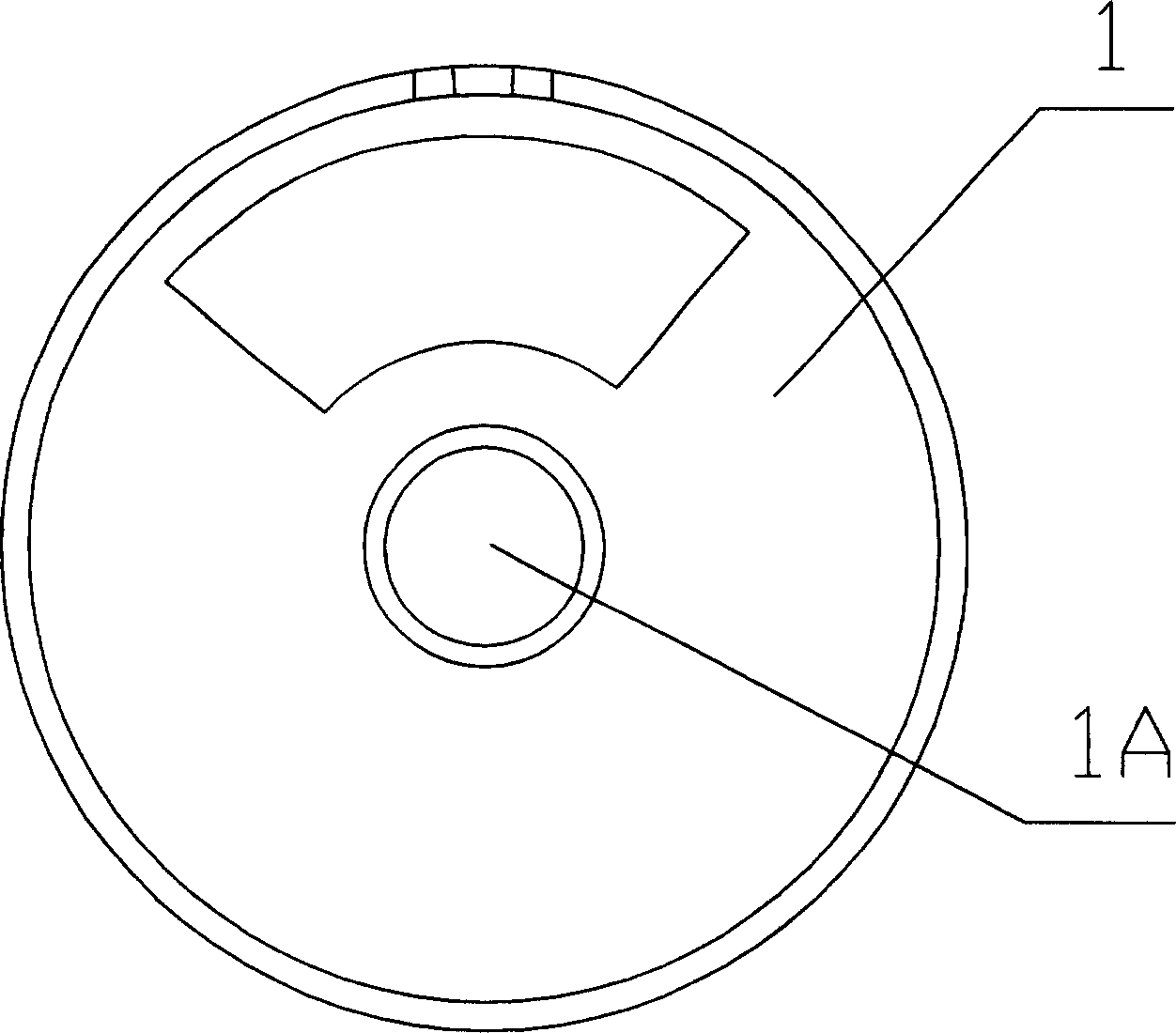

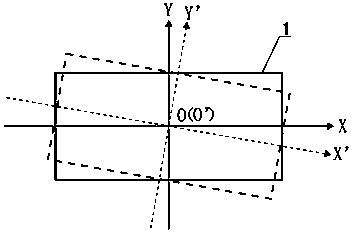

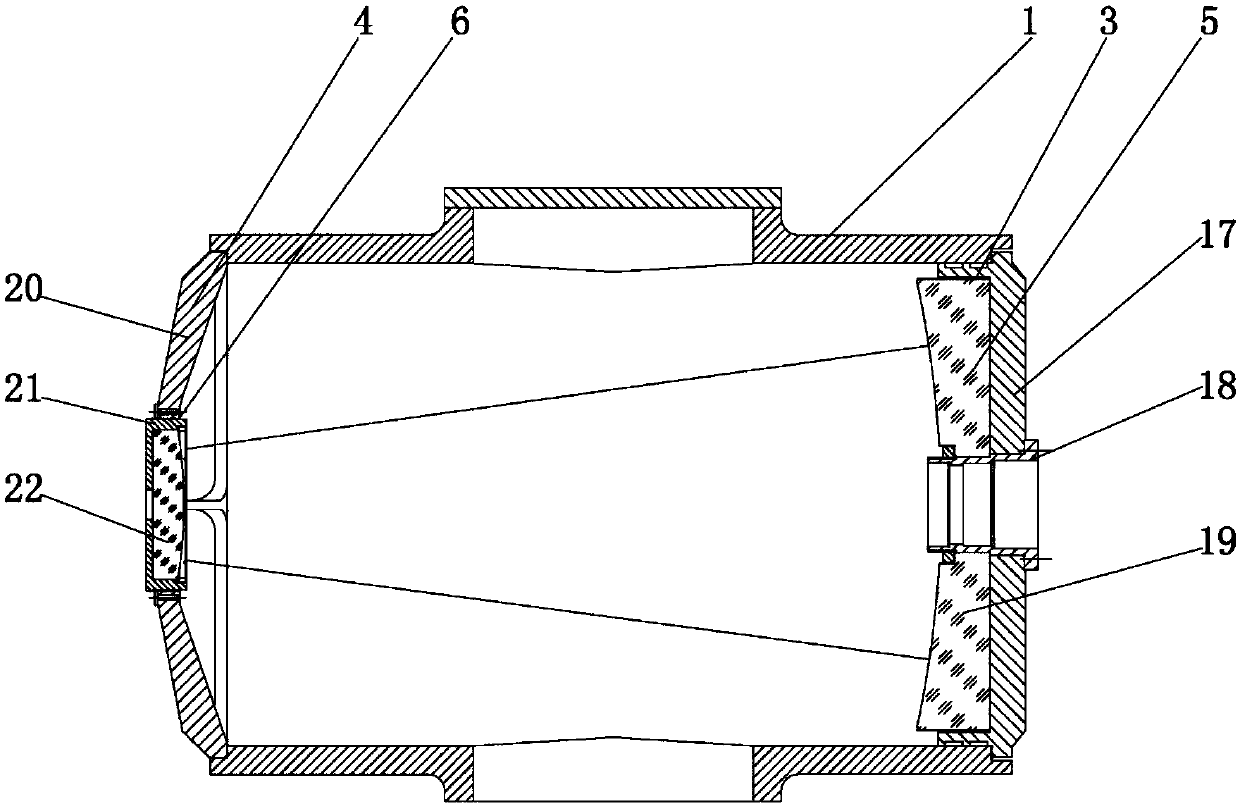

Lens module production device and method of manufacture thereof

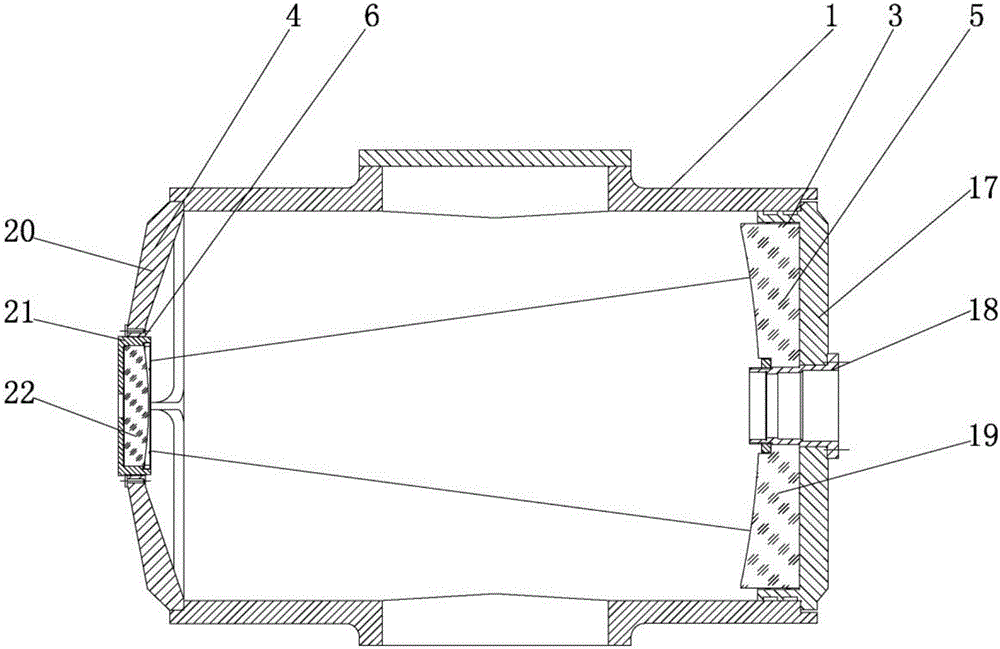

InactiveCN101105570ASolve the problem of eccentricitySolve lens skewGlass pressing apparatusMountingsCushioningCamera lens

The invention relates to a lens module manufacture device and the manufacture method thereof; the lens module manufacture device comprises a lens (a separating cushion piece can be selected to match with the lens), a forming mould and moulding processes; wherein the lens can be the lenses in various catalogs; the separating cushion piece is equipped between the lenses; the forming mould comprises a mould cavity; the mould cavity consists of an upper film kernel, a lower film kernel, a left sliding block film kernel and a right sliding block film kernel (or the film kernel in other direction); cushioning devices can be equipped on the film kernel and under the film kernel; the cushioning devices are used to cushion the lens and the separating cushion piece and regulate the tolerances of the lens and the separating cushion piece; stop sliding blocks can be equipped on the front ends of the left and the right sliding block film kernels, which avoids the migration or the transplacement of the center line of the lens when the lens module is formed. The invention makes at least one lens and more than one separating cushion piece selected to match with the lens pass through a thermohardening or a thermoplastic forming mould and be processed into the lens module through an integral forming processing procedure.

Owner:HORNIX OPTICAL TECH

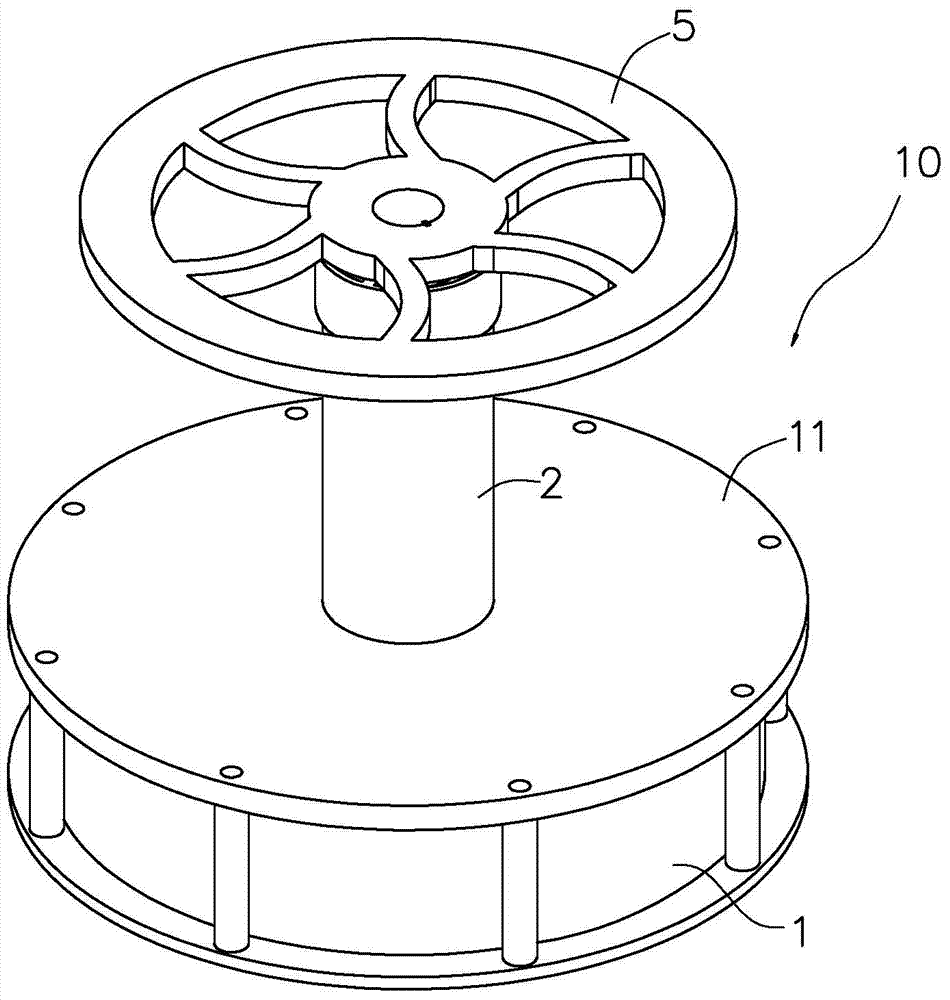

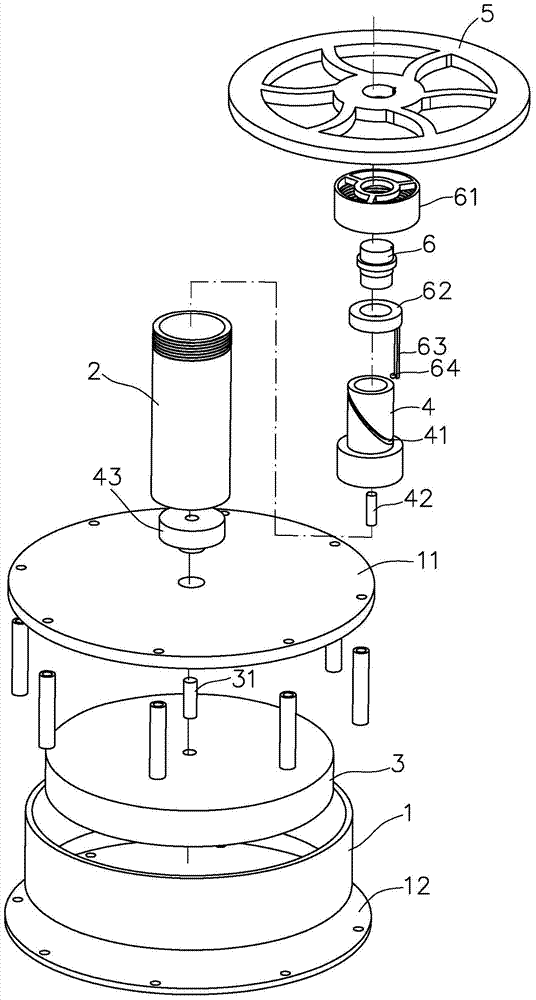

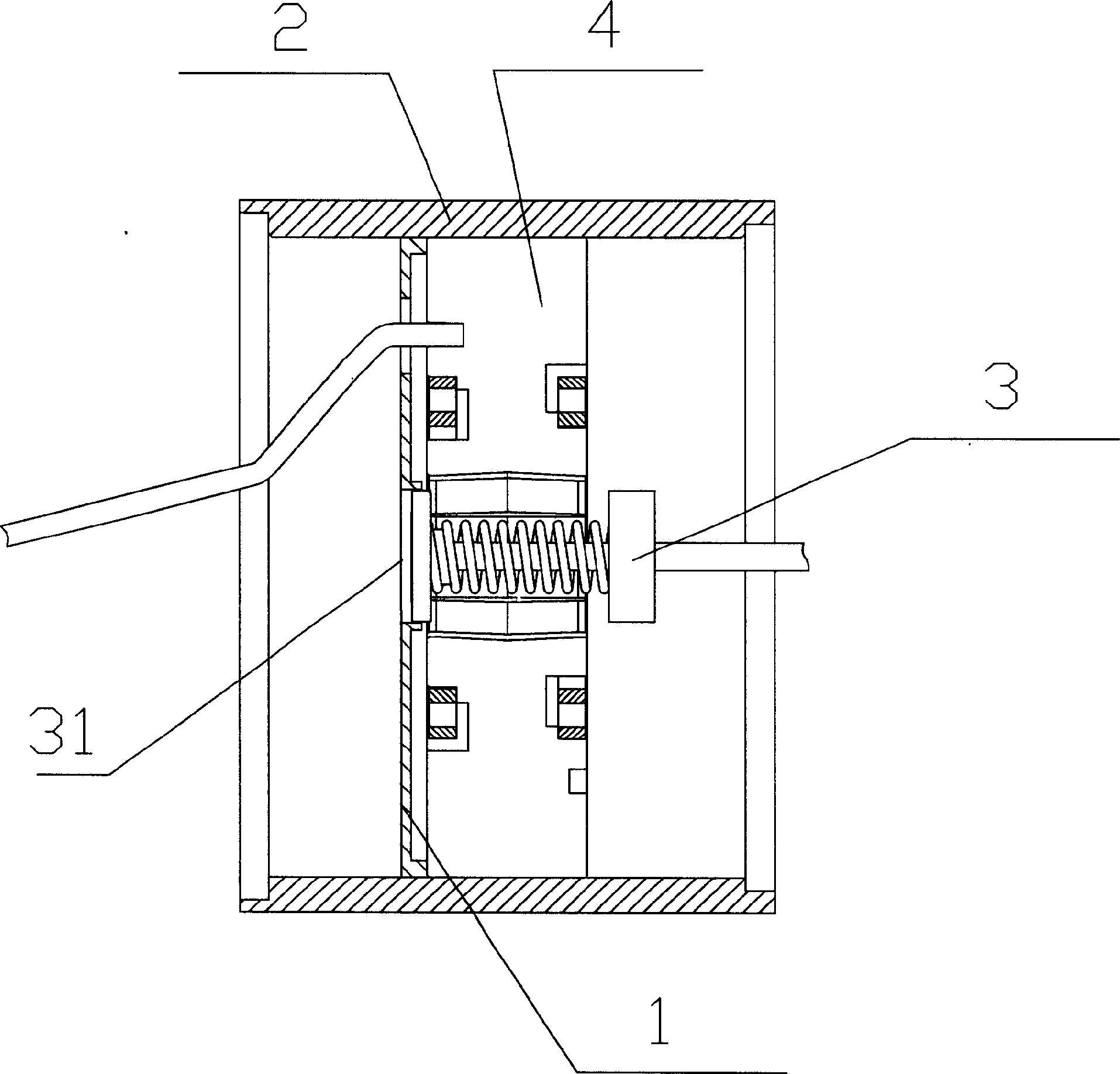

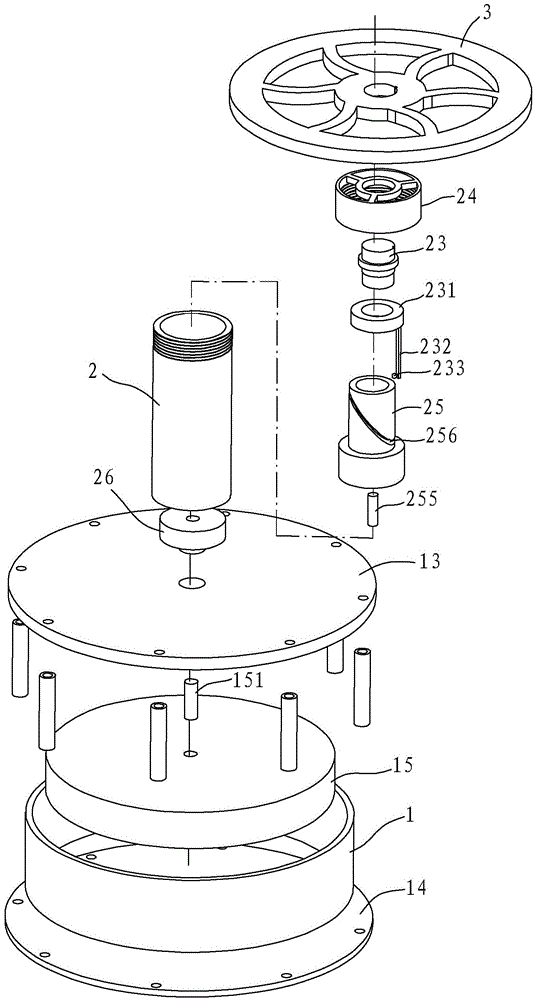

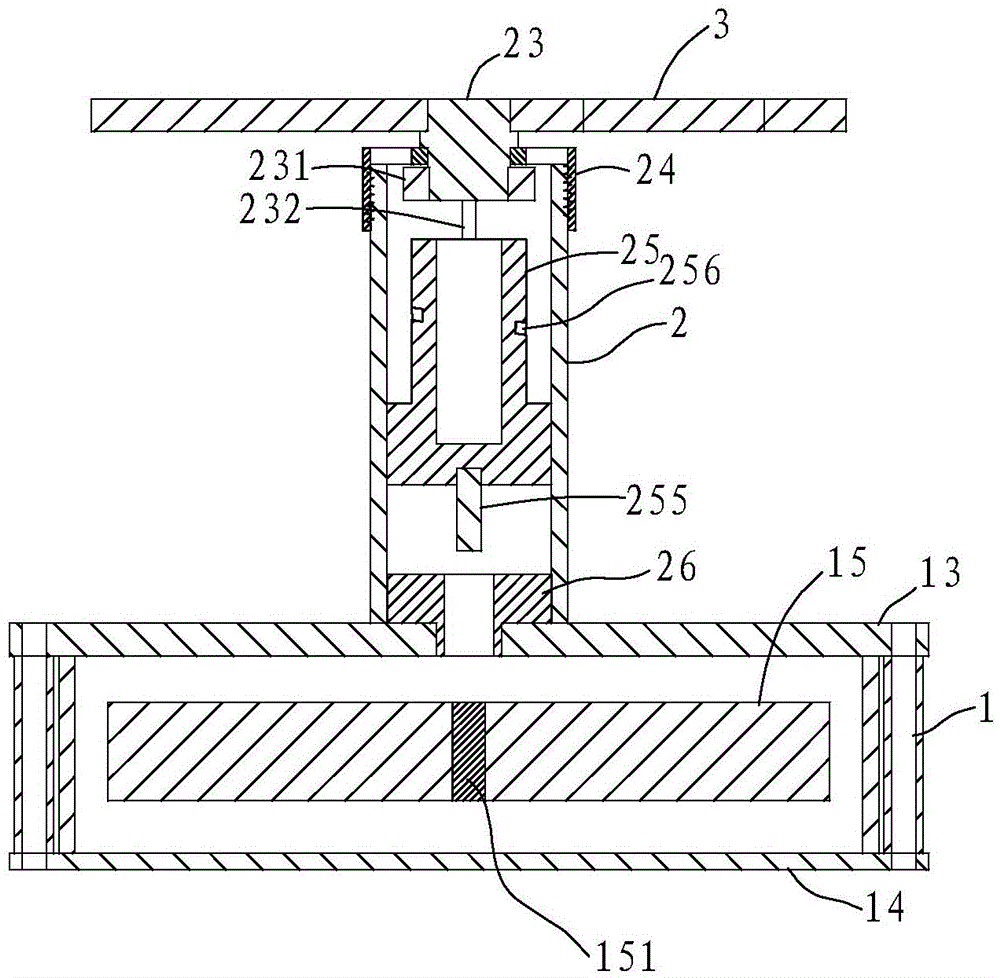

Stirling engine and cup cover and cup with same

The invention provides a stirling engine. The stirling engine comprises a first cylinder, a second cylinder, an air moving piston and a power piston. The stirling engine is characterized in that the bottom end of the power piston is arranged to a magnet, and a guide groove is obliquely formed in the periphery or the inner wall of the power piston; a driving block which is in match with the magnet by magnetic attracting through a clearance manner is arranged on the air moving piston; a flywheel is arranged on the top end of the second cylinder through a rotating shaft; the rotating direction of the flywheel is perpendicular to the moving direction of the power piston; the rotating shaft is downwards connected with a driving rod; the end part of the driving rod is arranged in the guide groove and can move along the guide groove. The invention further discloses a cup cover and a cup which are both provided with the engine. Compared with the prior art, the stirling engine has the advantages that the power piston drives the flywheel through the driving rod to rotate in the horizontal direction, so that the structure and type of the existing stirling engine model is enriched; the whole structure is compact, and the design is nice.

Owner:NINGBO XIAYUAN TECH +1

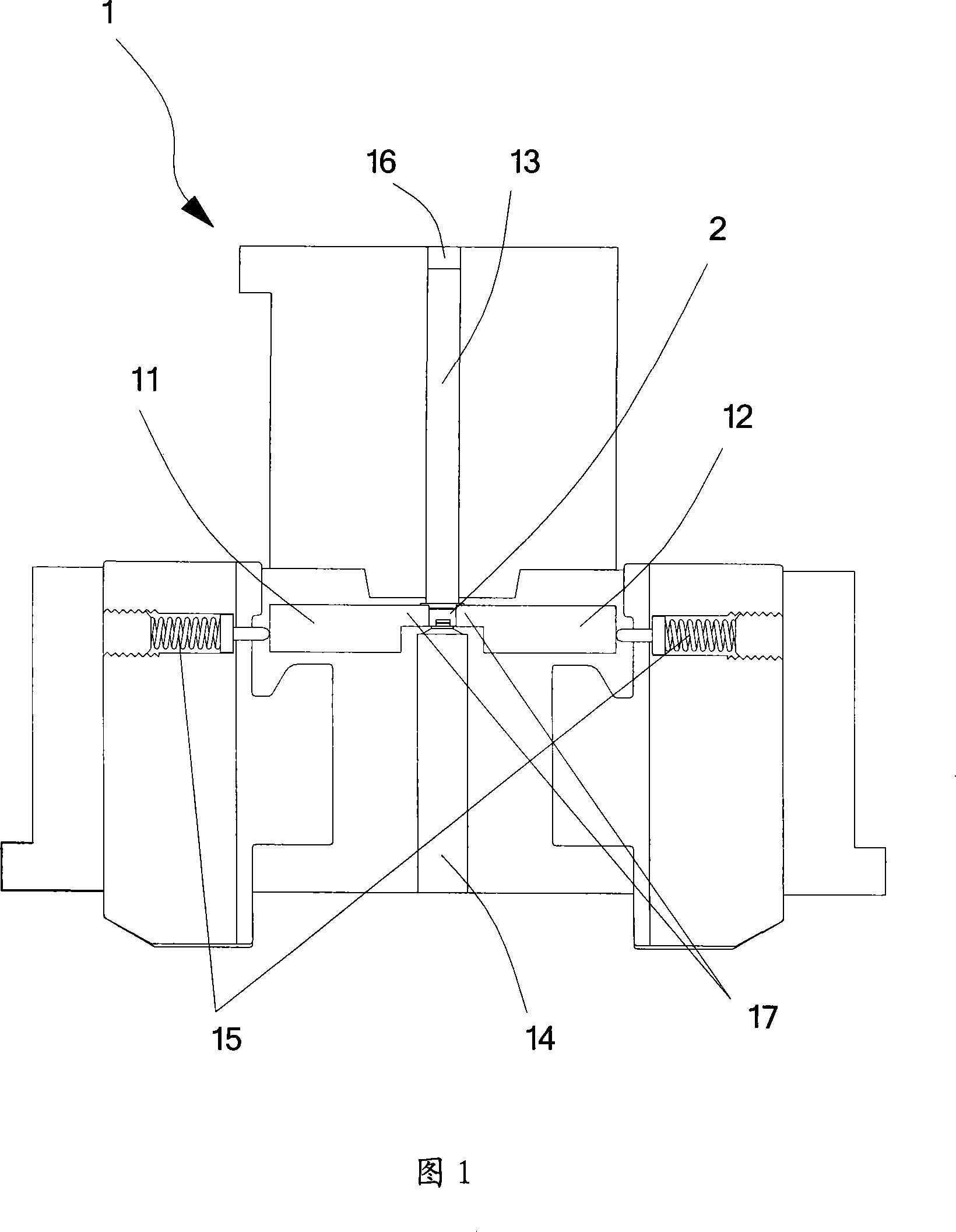

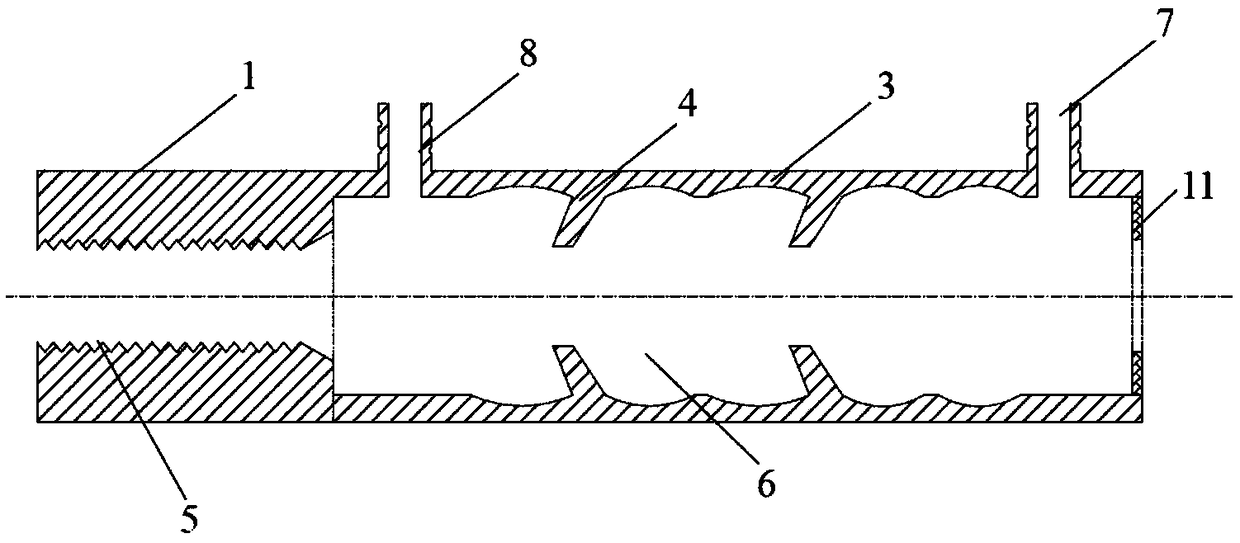

Self-locking steel bar connecting grouting sleeve

The invention discloses a self-locking steel bar connecting grouting sleeve which comprises a sleeve body. The sleeve body is provided with a grouting hole and a grout outlet hole, a grouting cavity communicated with the grouting hole and the grout outlet hole is formed in the sleeve body, the inner wall of the grouting cavity is provided with ribs or corrugations, and the inner wall of the grouting cavity is also provided with multiple clamping tongues. On one hand, when steel bars are inserted into the self-locking steel bar connecting grouting sleeve, a mechanical anchoring force can be effectively provided through the self-locking effect between the steel bars and threaded steel bar ribs; on the other hand, when connected steel bars inserted into prefabricated members have deviations,and when the steel bars are inserted into the grouting sleeve, the situation of wall attachment or eccentricity occurring during connection of the self-locking steel bar connecting grouting sleeve canbe effectively avoided through appropriate position correction of the steel bars due to the vertical radial effect of the clamping tongues.

Owner:SOUTHEAST UNIV

Method of mounting and fixing purging plug brick on outer upper portion of ladle

The invention relates to a method for mounting and fixing a purging plug brick on outer upper portion of a ladle. The method includes the steps of firstly, fixing a spiral slideway on the inner side of a reference ring of the purging plug brick, fixing a bolt at the bottom of the purging plug brick, sleeving a screwing slider on the outer side of the bolt, and inserting the top end of an automatic torque wrench to the screwing slider; secondly, starting the power of the automatic torque wrench, and allowing rotation torque to drive the screwing slider to be screwed into the purging plug brick along the spiral slideway; thirdly, demounting a nut and the automatic torque wrench, embedding a support brick with ash into a groove of the screwing slider, mounting support iron, a cover plate and the nut, and tightening the nut and the bolt to fix the cover plate and the support iron. The method has the advantages that due to the fact that mounting is performed through the automatic torque wrench, accurate mounting of the purging plug brick is achieved, the purging plug brick defects such as air channels, eccentricity, position difference, large seam and twin brick raising during purging plug brick mounting are overcome, the purging plug brick can be replaced conveniently, and ladle leakage accidents caused by purging plug brick mounting mistakes are avoided.

Owner:ANGANG STEEL CO LTD

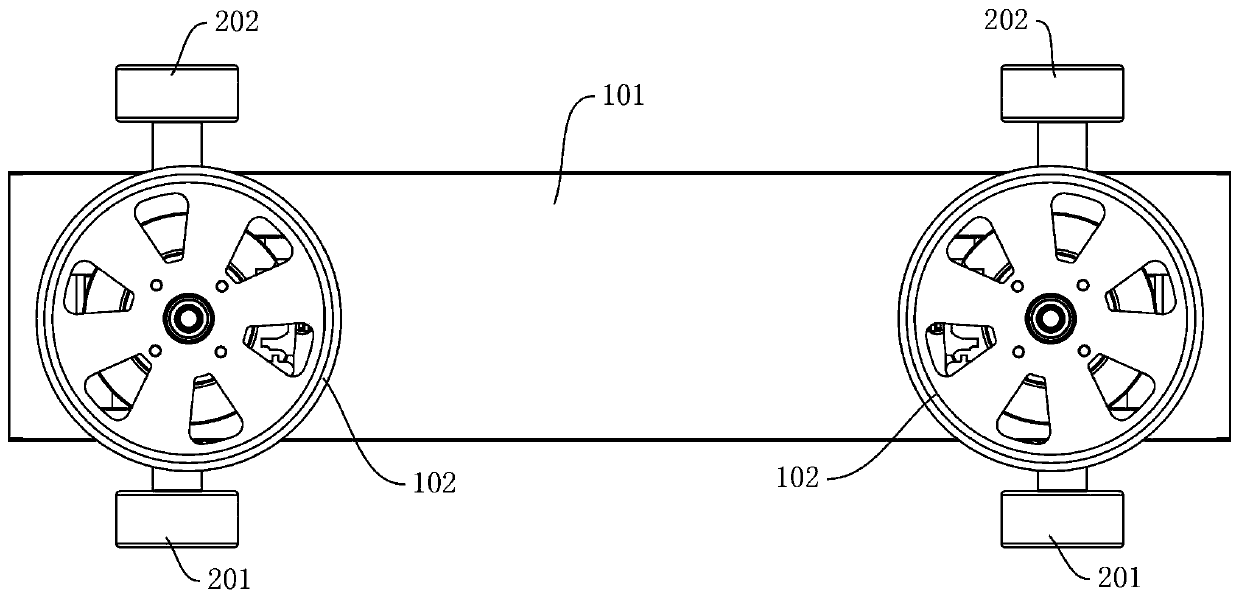

Locomotive for individual rapid transport system, and individual rapid transport system

The invention relates to a locomotive for an individual rapid transport system, and the individual rapid transport system. The locomotive comprises a locomotive body, a first stabilizing wheel used for stabilizing the locomotive is arranged on the lower part of the locomotive body, the rotary axis of the first stabilizing wheel is perpendicular to the length direction of the locomotive body, and the first stabilizing wheel is used for rolling along with a rail of the locomotive. The individual rapid transport system is simple and compact in structure and low in cost, stable operation is facilitated, resonance is prevented, noise is reduced, the problem of eccentricity of the locomotive during monorail operation can be effectively solved, and force balance of the locomotive is facilitated.

Owner:JIANGSU FLYING SHUTTLE INTELLIGENT CO LTD

Automatic decoking equipment

InactiveCN103846260ATo achieve the purpose of decokingLow costHollow article cleaningAutomatic test equipmentCoupling

The invention relates to automatic decoking equipment. The automatic decoking equipment comprises a hollow bit, a coupling, a motor reduction gearbox, a stepping motor, a linear sliding rail, a ball screw, a feeding support frame, a first fixing piece, a decoking equipment support, a coke tower and a second fixing piece; the linear sliding rail is arranged above one side of the decoking equipment support, and the feeding support frame, the first fixing piece and the second fixing piece are arranged above the other side of the feeding support frame; the stepping motor is arranged at the right end part of the decoking equipment support and is connected with the motor reduction gearbox and the coupling; the hollow bit is connected in the axial direction of the coupling and is axially butted with the coke tower; the ball screw is arranged between the motor reduction gearbox and the feeding support frame; the hollow bit is fixedly arranged on the feeding support frame and a sliding block of the linear sliding rail; the coke tower is arranged on the first fixing piece and the second fixing piece. The automatic decoking equipment has the advantages that the labor intensity of operators can be greatly reduced, the working efficiency can be improved and the testing cost is reduced.

Owner:KYMSON LUOYANG PETROCHEM EQUIP

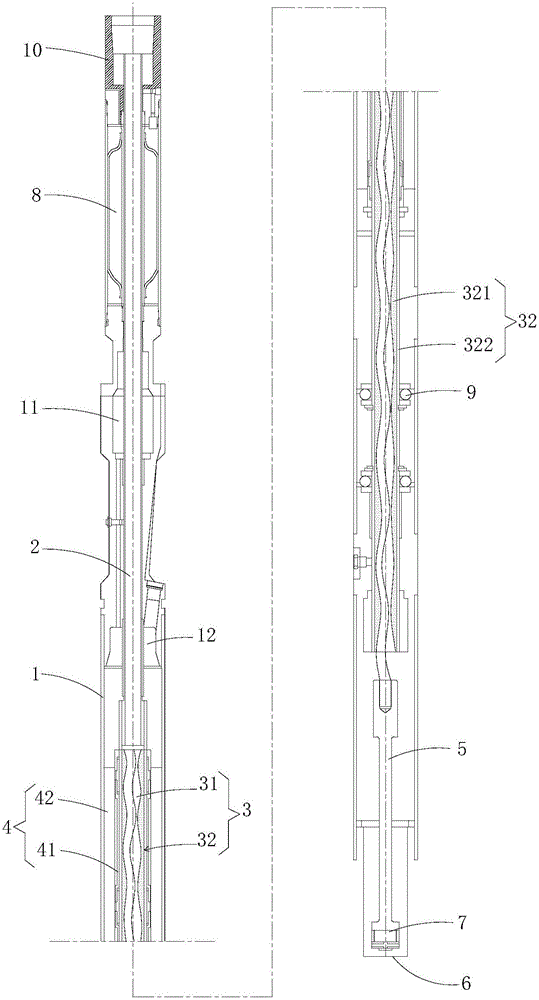

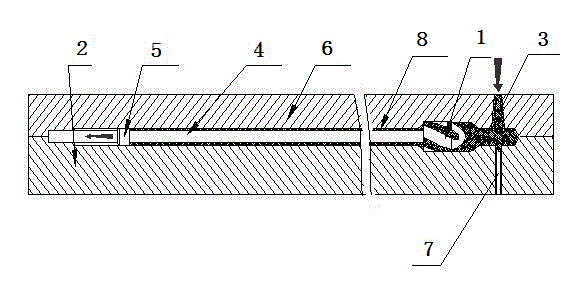

Integrated rod-free lifting tubing string

InactiveCN106812503AGuaranteed uptimeEliminate vibrationPump componentsFluid removalEngineeringStops device

The invention provides an integrated rodless lifting string, which includes: an outer cylinder and an oil pipe pierced in the outer cylinder; a screw pump, which is arranged in the outer cylinder, and the screw pump is connected to the Below the oil pipe, and includes a screw and a screw pump stator sleeved outside the screw, an oil delivery chamber communicated with the oil pipe is formed between the screw pump stator and the screw; the submersible motor is located at In the outer cylinder, it includes a motor rotor connected to the stator of the screw pump, and a motor stator sleeved outside the motor rotor and connected to the outer cylinder, and the motor rotor can drive the screw pump The stator rotates; the flexible shaft is arranged in the outer cylinder and connected under the screw rod; the thrust device is fixed in the outer cylinder and connected under the flexible shaft. The invention can reduce the length of the tool string of the lifting pipe string and improve the passability of the inclined well section.

Owner:PETROCHINA CO LTD

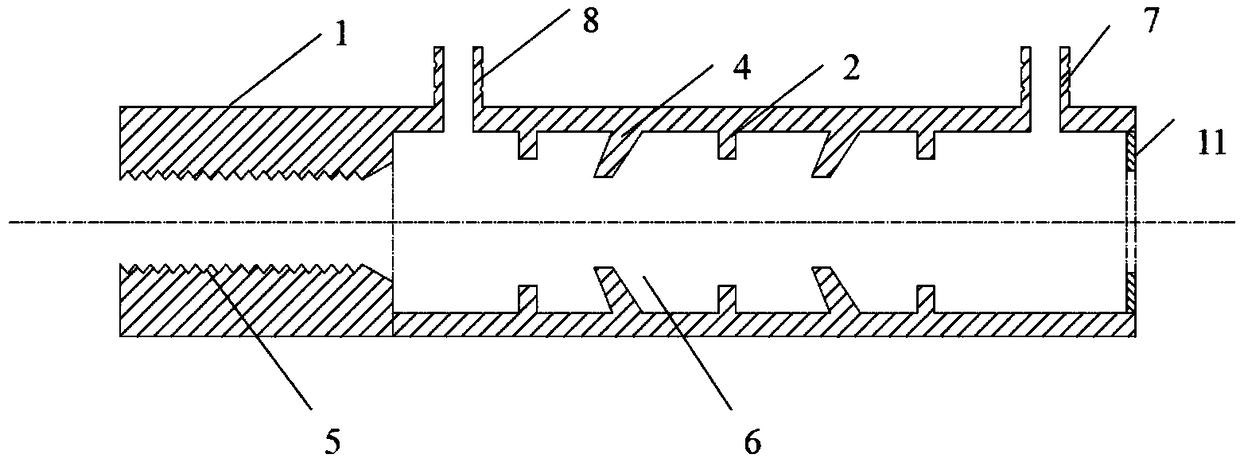

Method and die for eccentricity prevention of injection molding and rubber coating of slender rod

InactiveCN102717478ASolve the problem of eccentricityEffectively fixedCoatingsEngineeringInjection molding machine

The invention discloses a method and a die for eccentricity prevention of injection molding and rubber coating of a slender rod. A shunting shuttle which is of a bullet shape is arranged at the front end of a slender rod workpiece, the surface of the shunting shuttle is provided with a plurality of spiral shunting trenches, and the shunting shuttles are arranged at one ends of the die cavities of a moving die core and a fixed die core and communicated with the runner of the fixed die core; a guide ring capable of moving is sleeved on the body of the slender rod is sleeved by the guide ring capable of moving, and the guide ring isthe body of the slender rod and arranged in the die cavities of the moving die core and the fixed die core and can move in the die cavities; and then, the shunting shuttles, the guide ring and the slender rod workpiece are placed into the die cavity for injection molding production, then, the die is opened after injection molding is finished, and the shunting shuttles, the guide ring and the slender rod workpiece are taken out and separated. The top of the slender rod is additionally provided with the shunting shuttle, so that sol rubber uniformly enters the die cavity of the die after being shunted by the shunting shuttle. Thus, not only the top end of the slender rod is fixed effectively, but also rubber is uniformly introduced in the rubber introduction process. The problem that the slender rod is eccentric can be effectively solved in the slender rod rubber coating process, and the rejection rate of plastic injection parts can be greatly reduced.

Owner:SHANDONG HORAN SUPER ENG PLASTICS

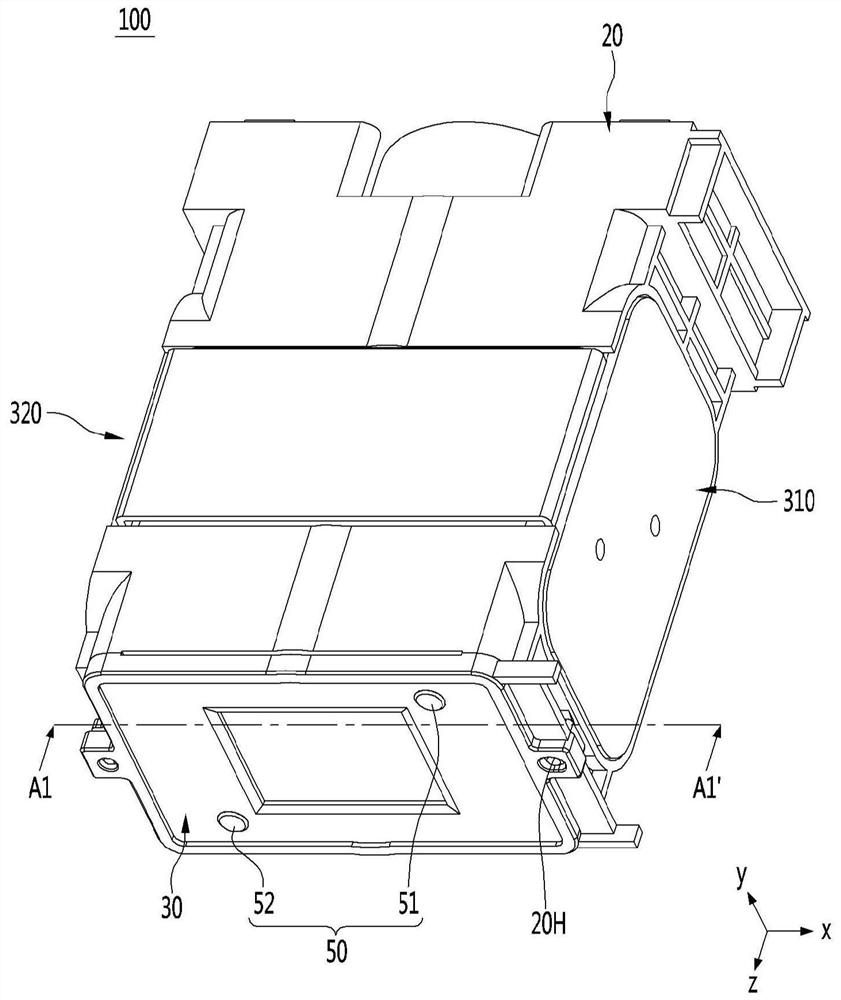

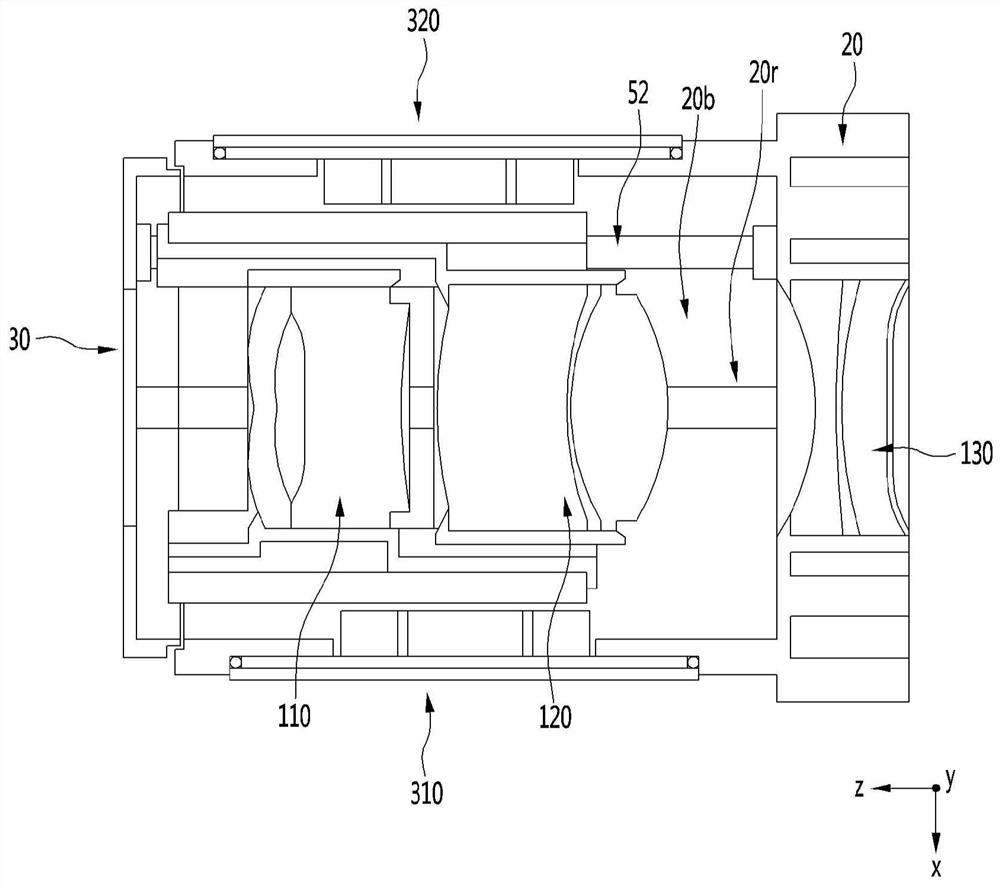

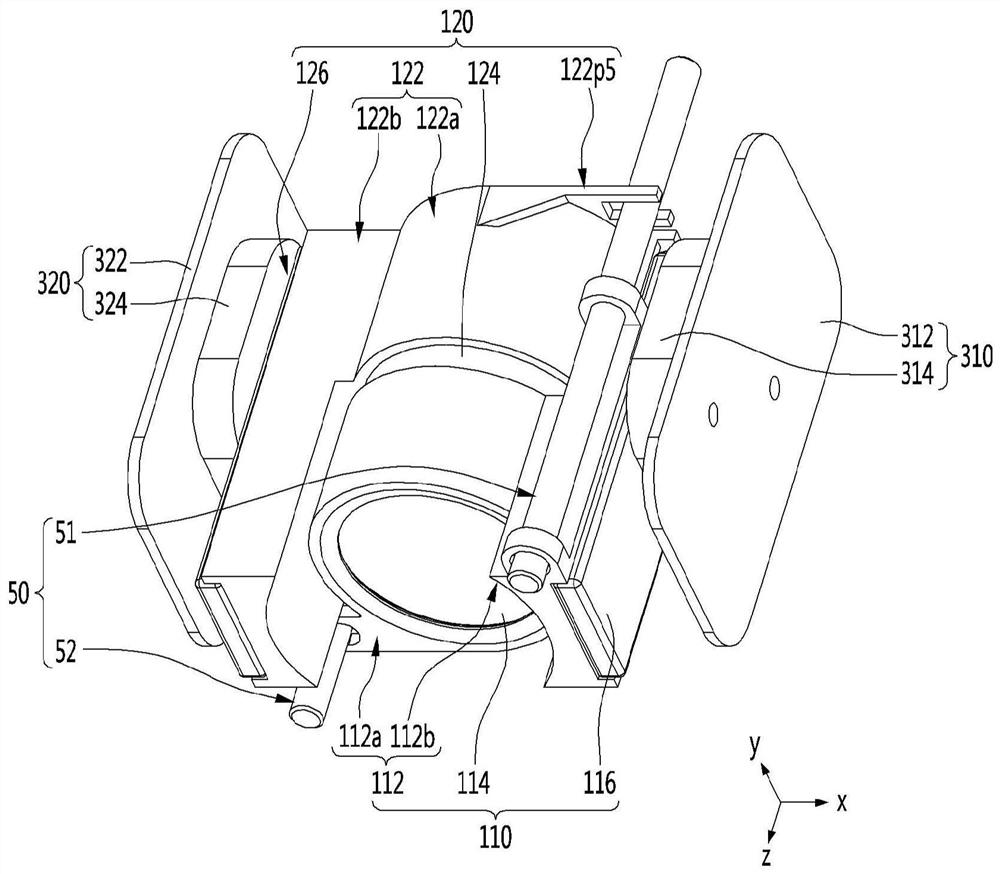

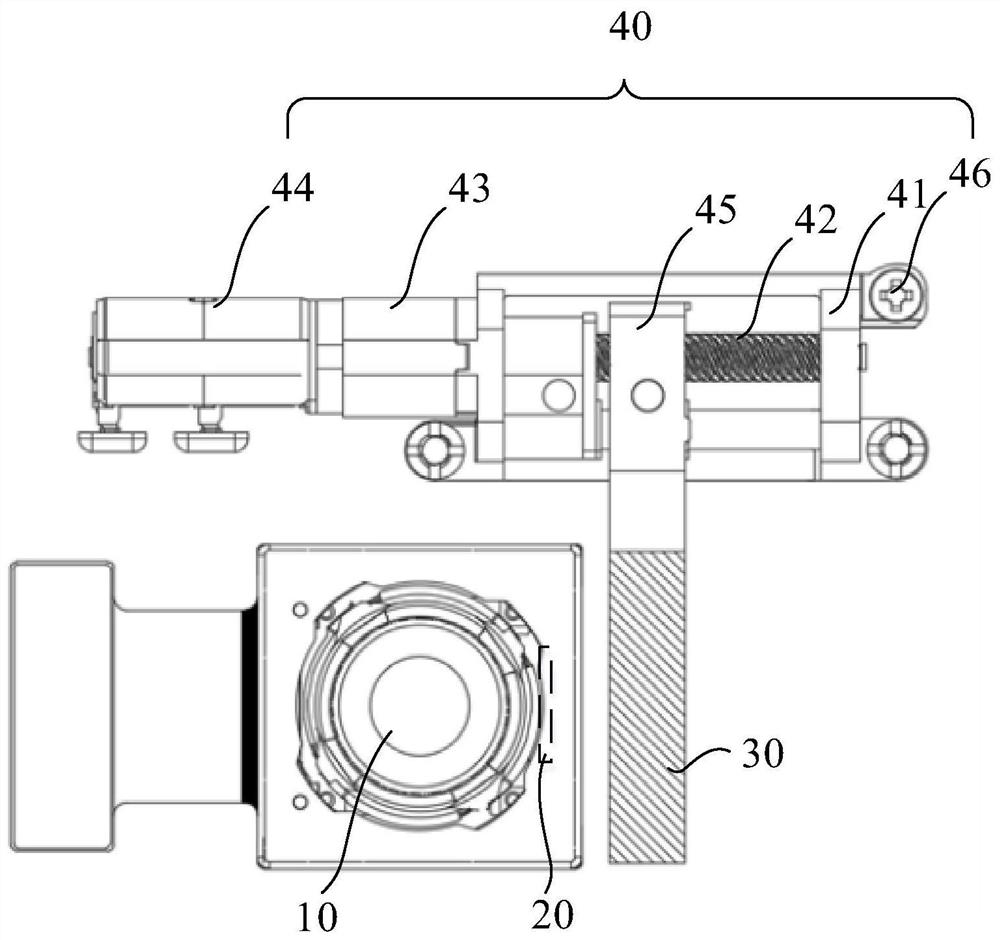

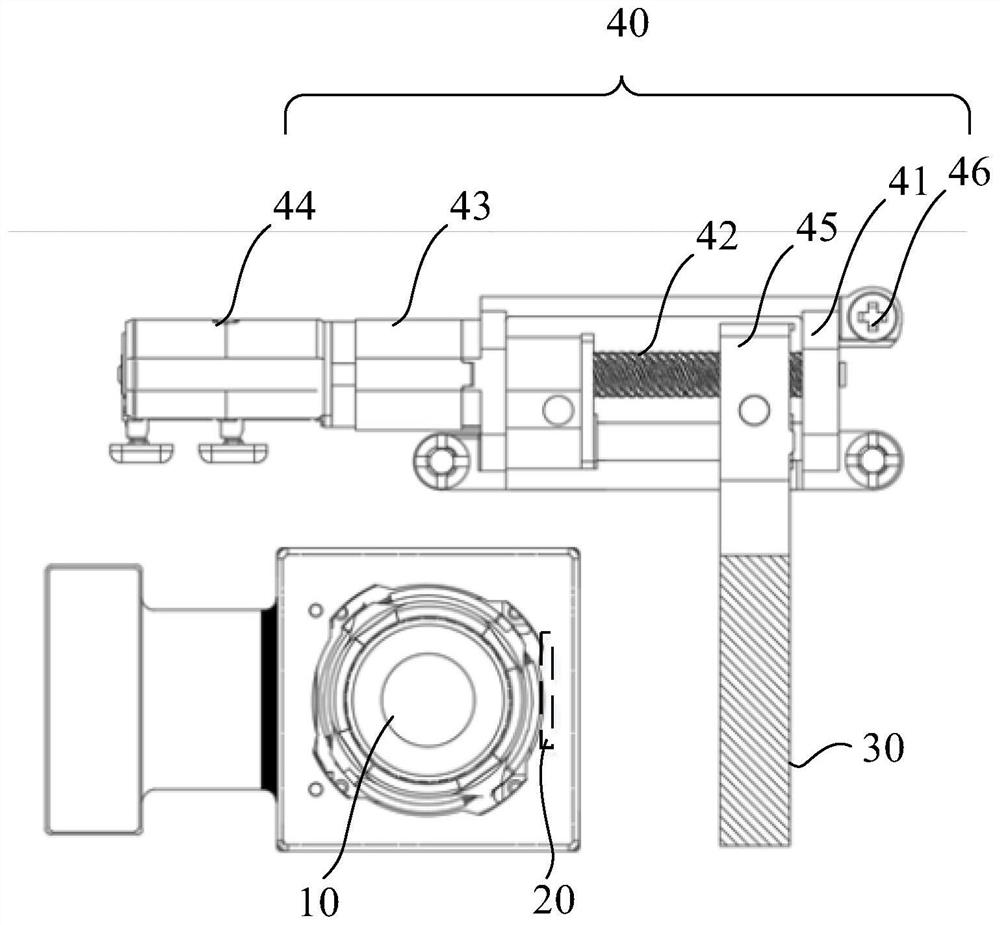

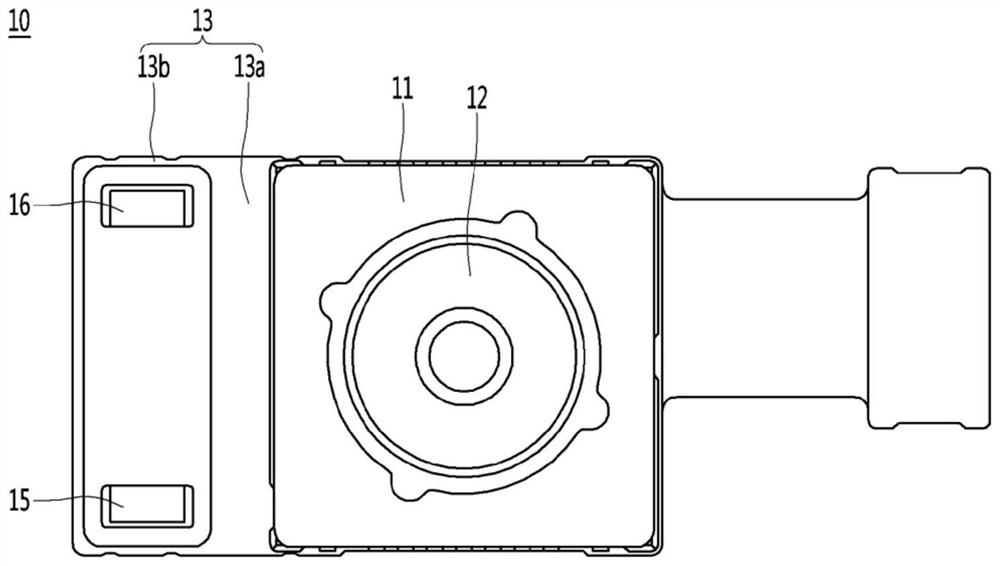

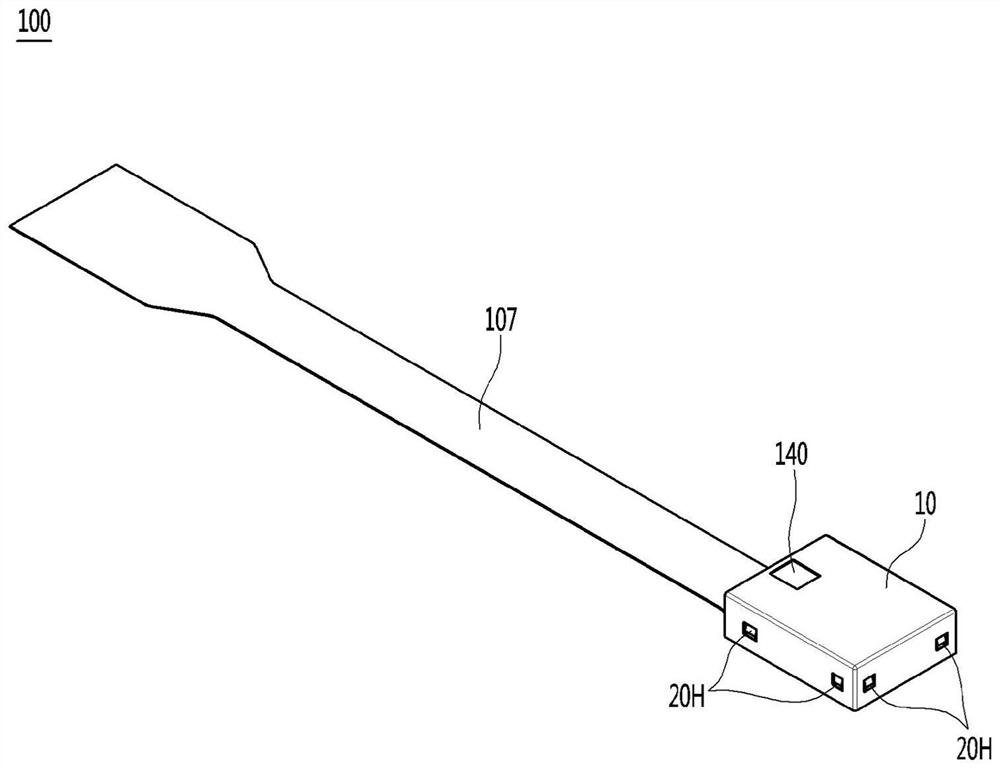

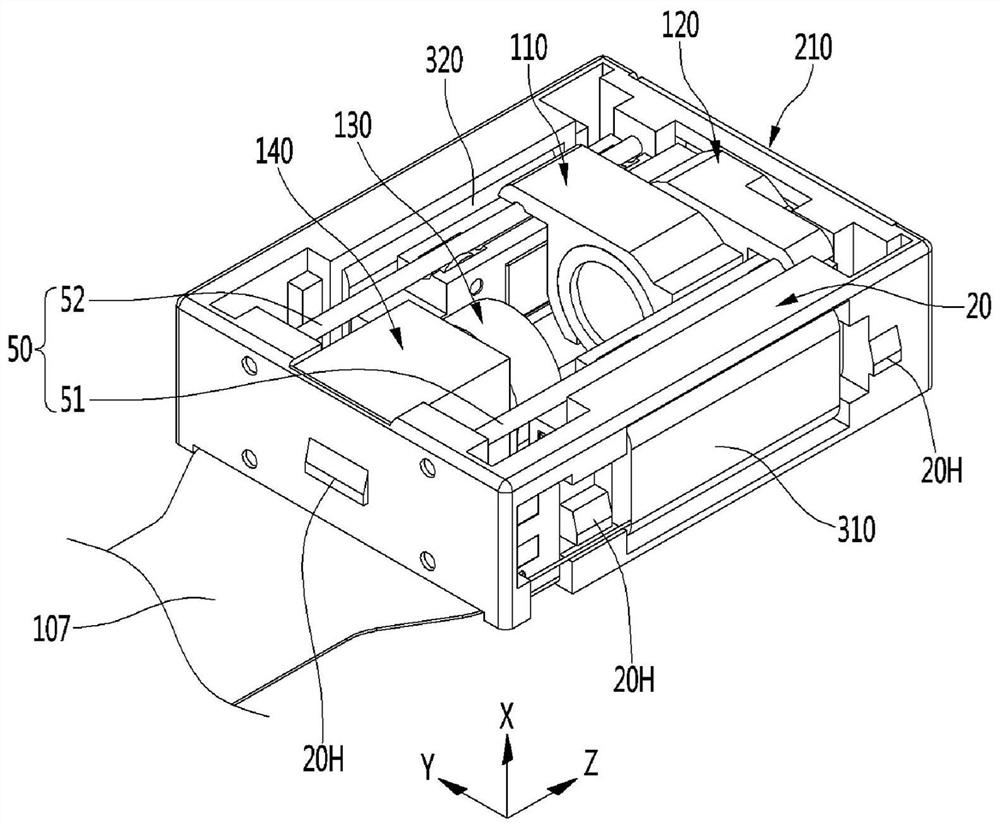

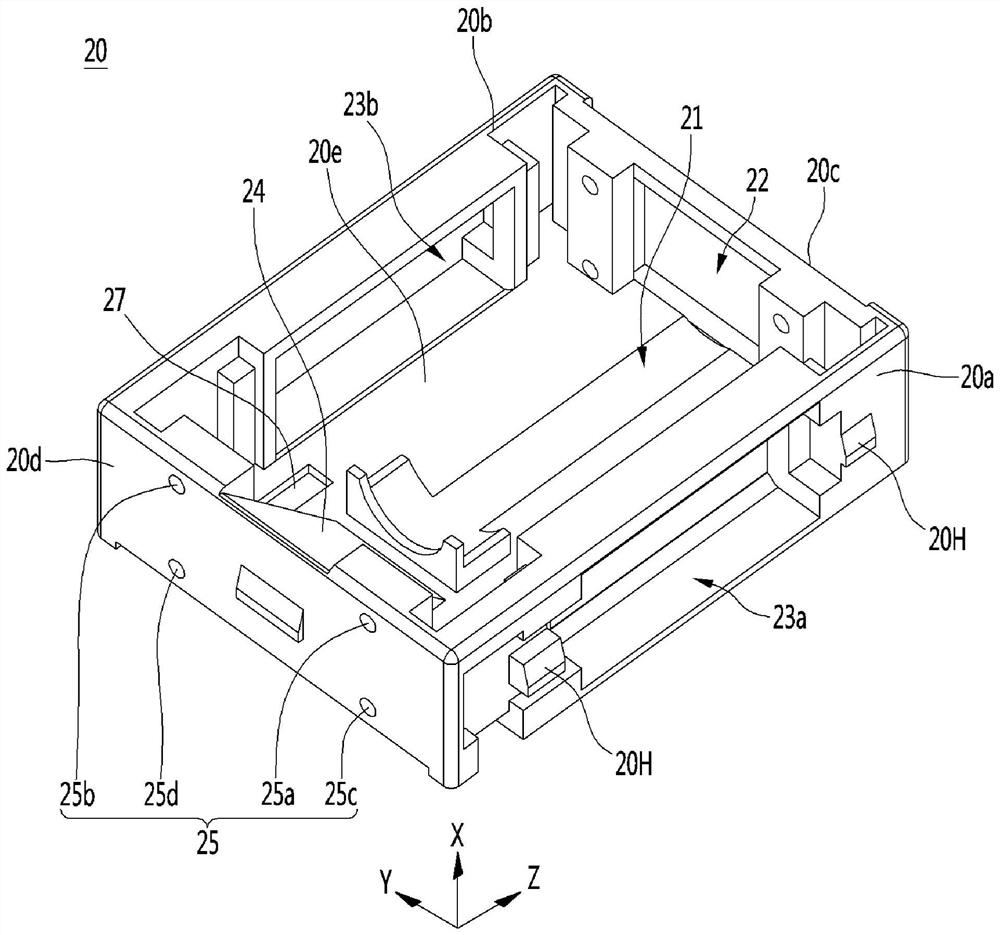

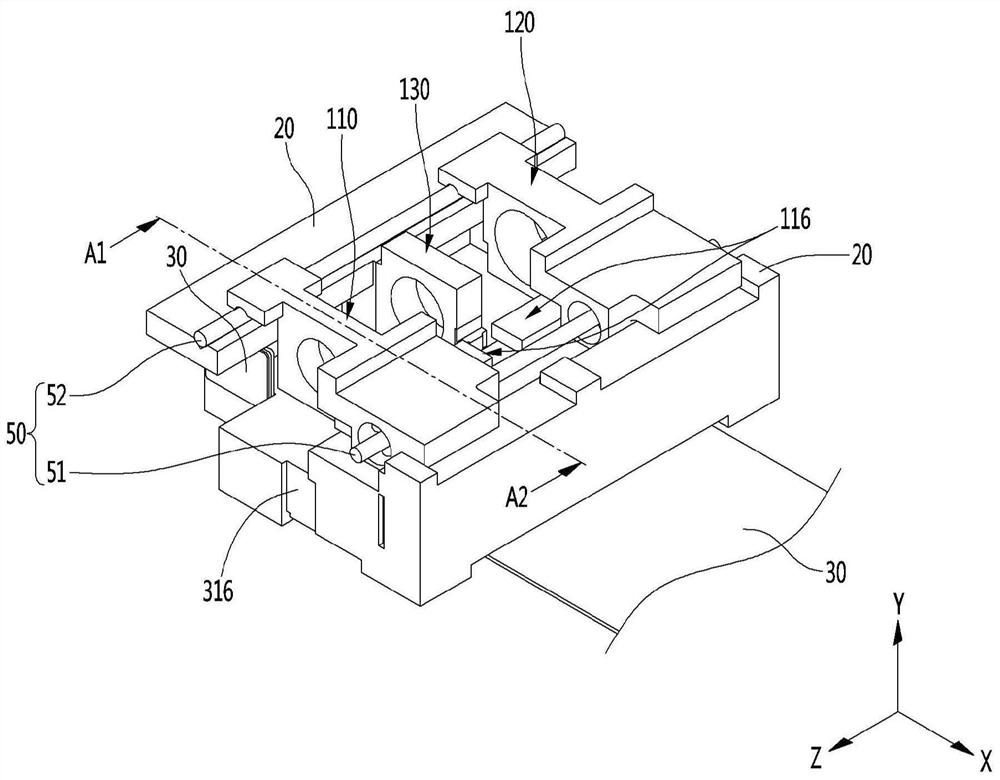

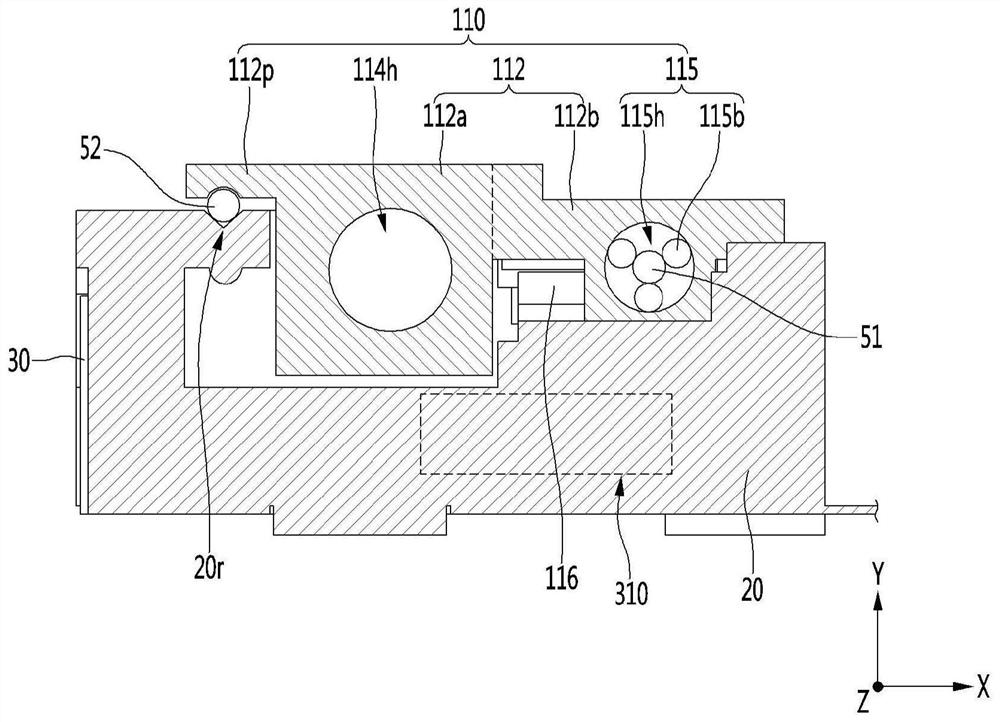

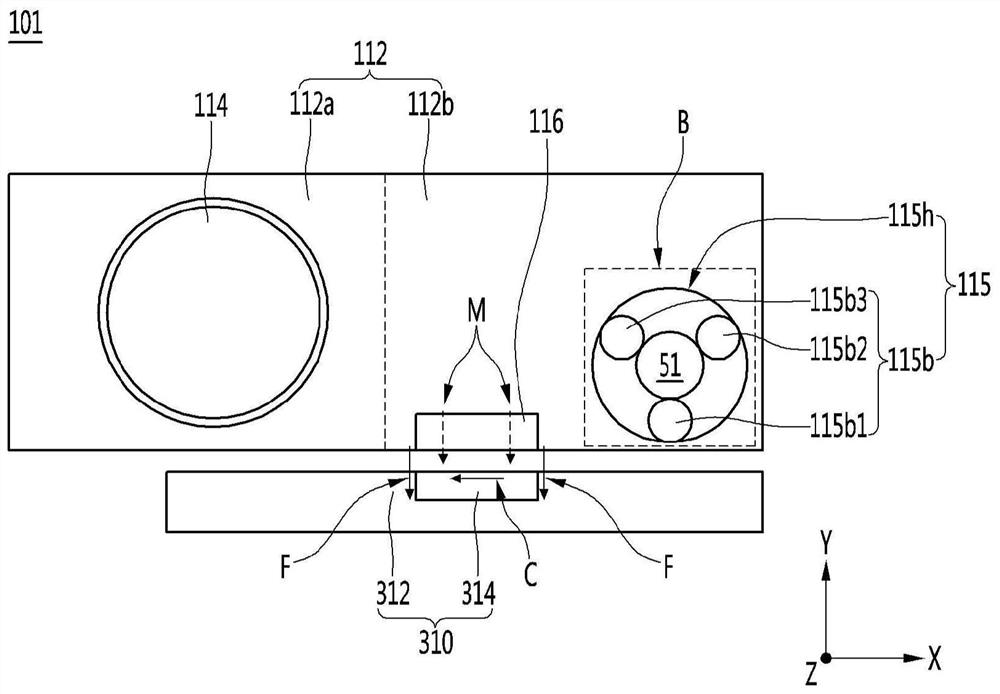

Lens driving device

ActiveCN111788519ASolve the problem of eccentricitySolve the tiltProjector focusing arrangementCamera focusing arrangementOptical axisEngineering

An embodiment relates to a lens driving device and a camera module including same. A lens driving device according to an embodiment may comprise: a base; a pin coupled to the base; a housing includinga group of lenses to be moved along the pin in an optical axis direction; a magnet disposed on one side of the housing; a yoke spaced apart from the magnet; and a coil disposed between the magnet andthe yoke. The housing may include a guide hole disposed at one side thereof and a guide groove disposed at the other side thereof. The pin may include a first pin disposed in the guide hole, and a second pin disposed in the guide groove. An attractive force may be applied between the yoke and the magnet.

Owner:LG INNOTEK CO LTD

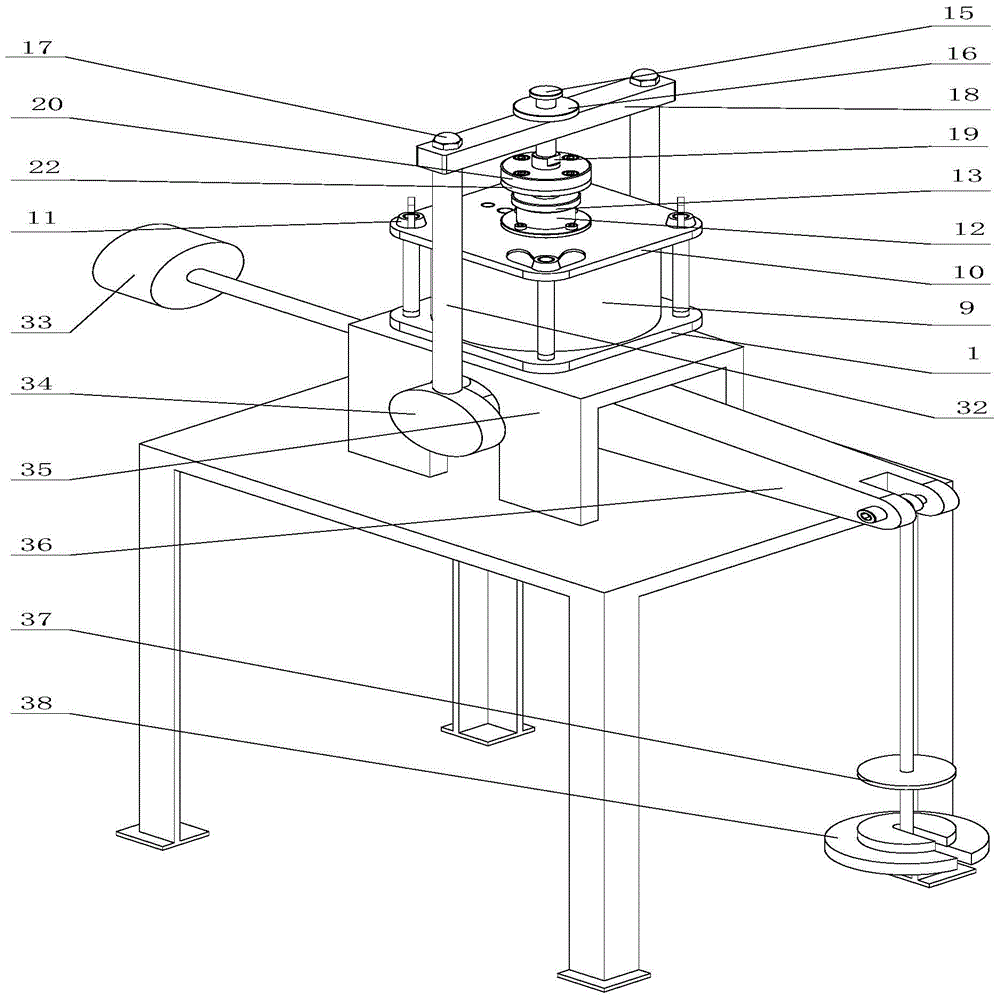

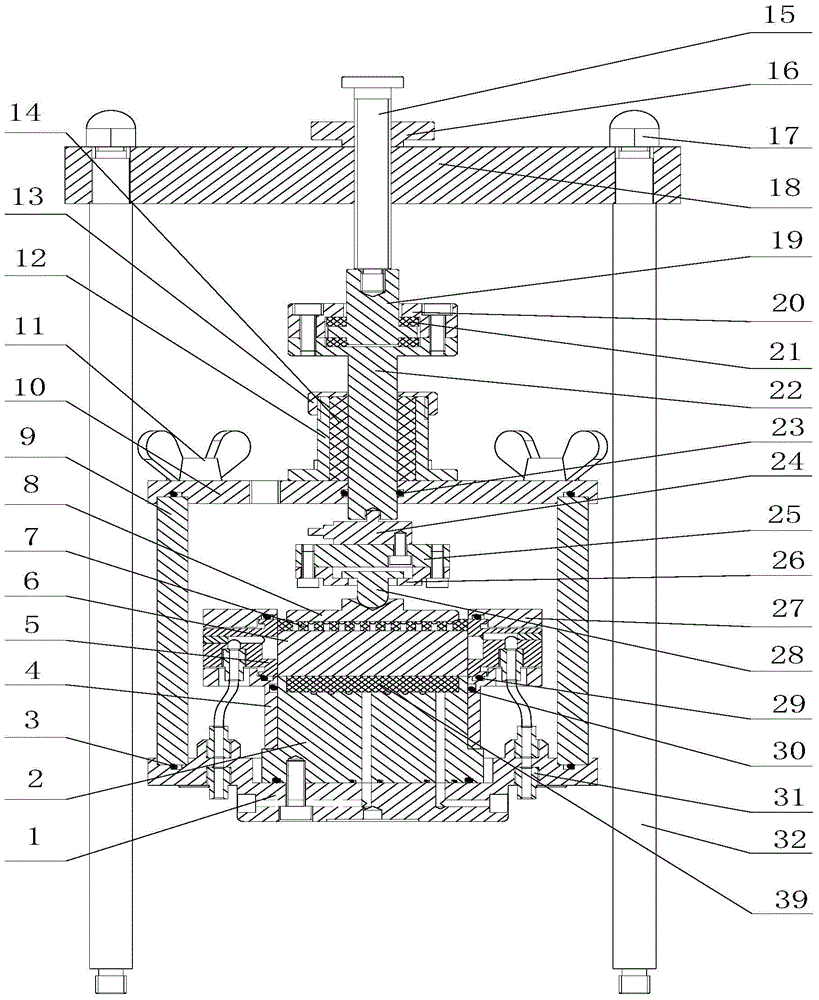

A multifunctional unsaturated soil consolidation instrument and testing method

InactiveCN104458430BReduce preloadVersatileMaterial strength using tensile/compressive forcesSoil scienceAxial pressure

A multifunctional unsaturated soil consolidation instrument and a testing method belong to the field of geotechnical testing instruments. The built-in methods of thrust bearings, linear bearings, self-aligning parts and axial pressure sensors are used on the loading rod of the test platform of the cementation instrument to eliminate the influence of friction during loading, and the design of rotating rigid connection components reduces the impact on the sample. The design of the self-aligning component solves the problem of eccentricity of the loading rod and the sample due to processing and installation. At the same time, the optimized design of the structure enables it to adapt to various loading platforms, ensuring that it can be tested on the existing saturated soil consolidation instrument, and can also be tested on the triaxial compression test instrument.

Owner:DALIAN UNIV OF TECH

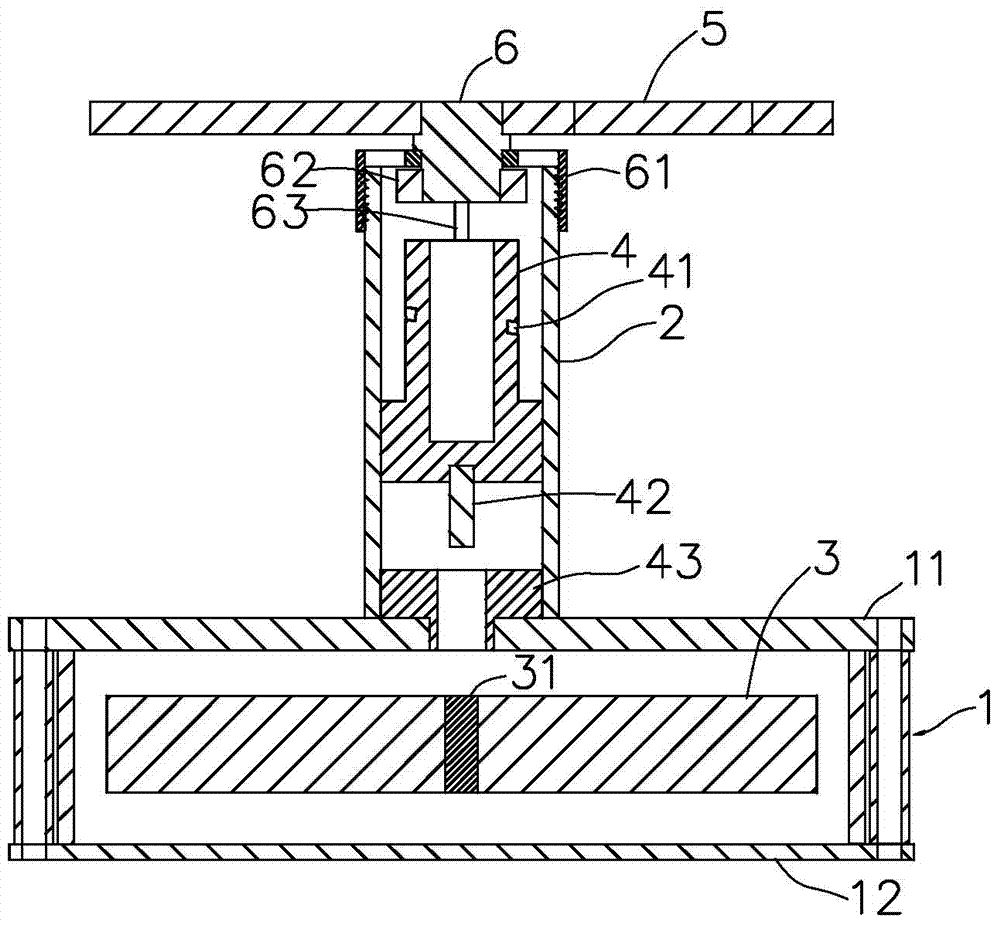

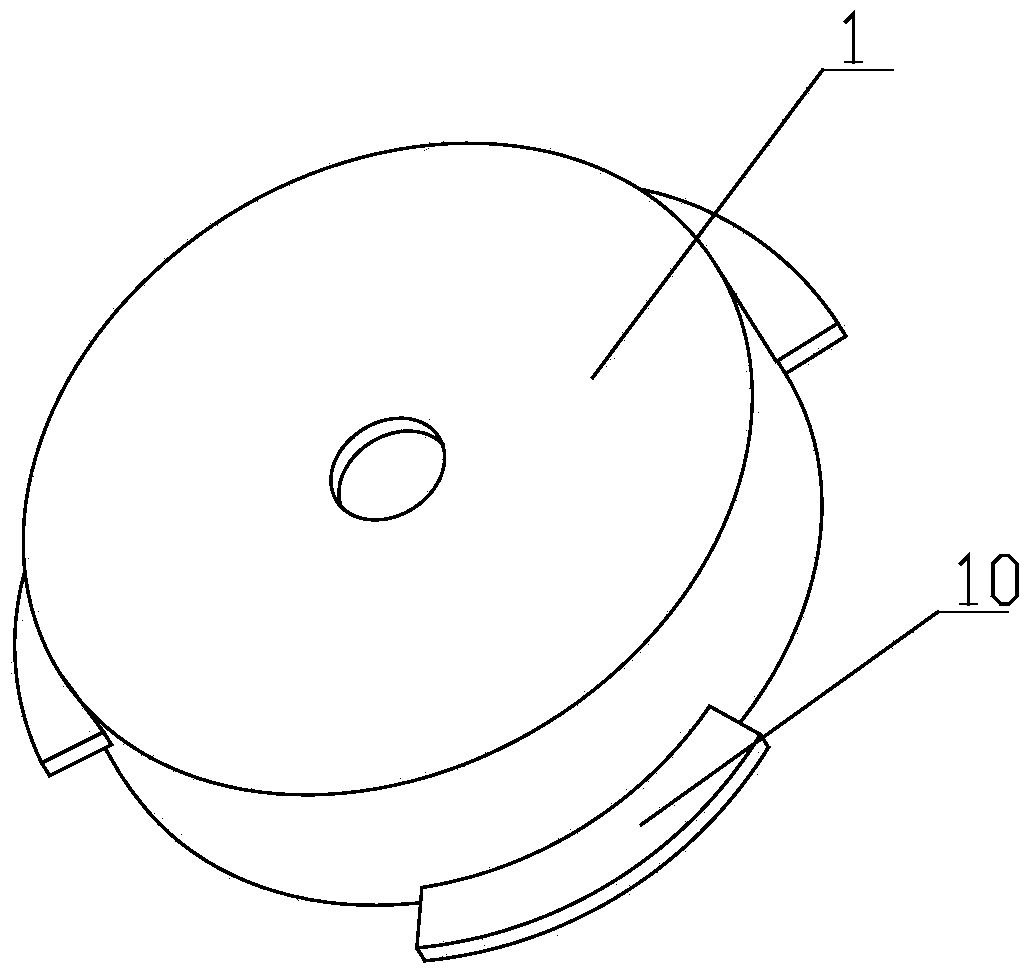

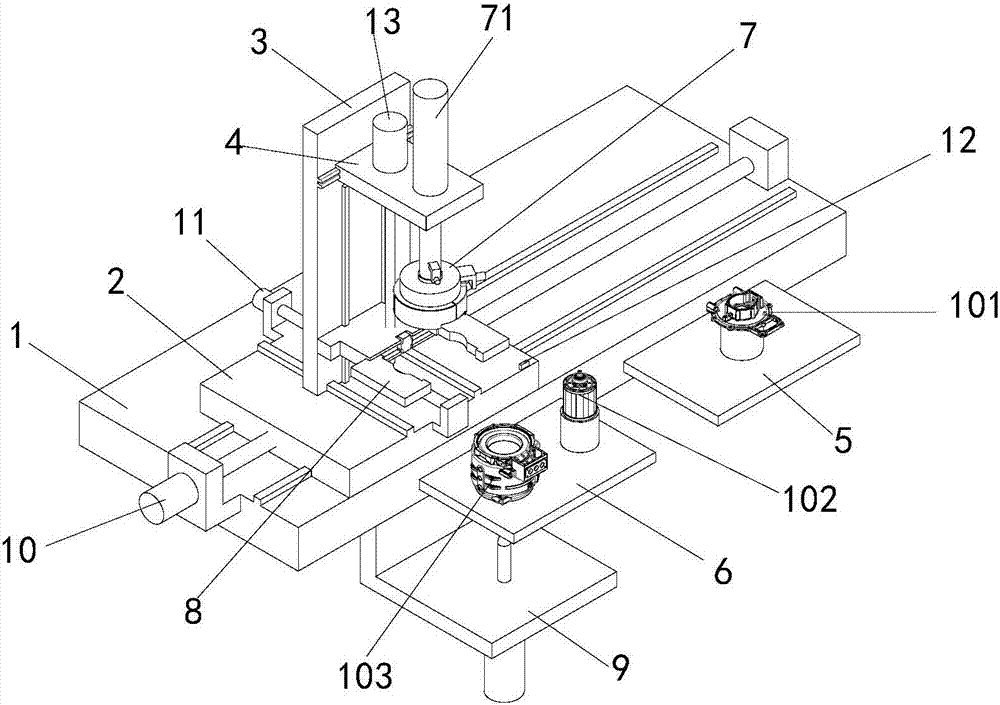

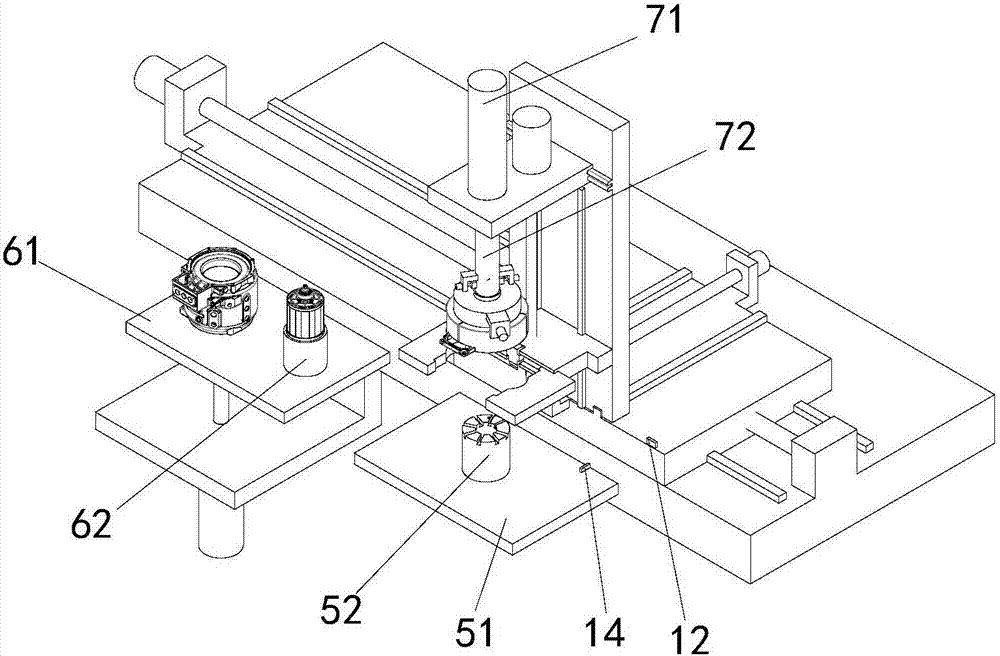

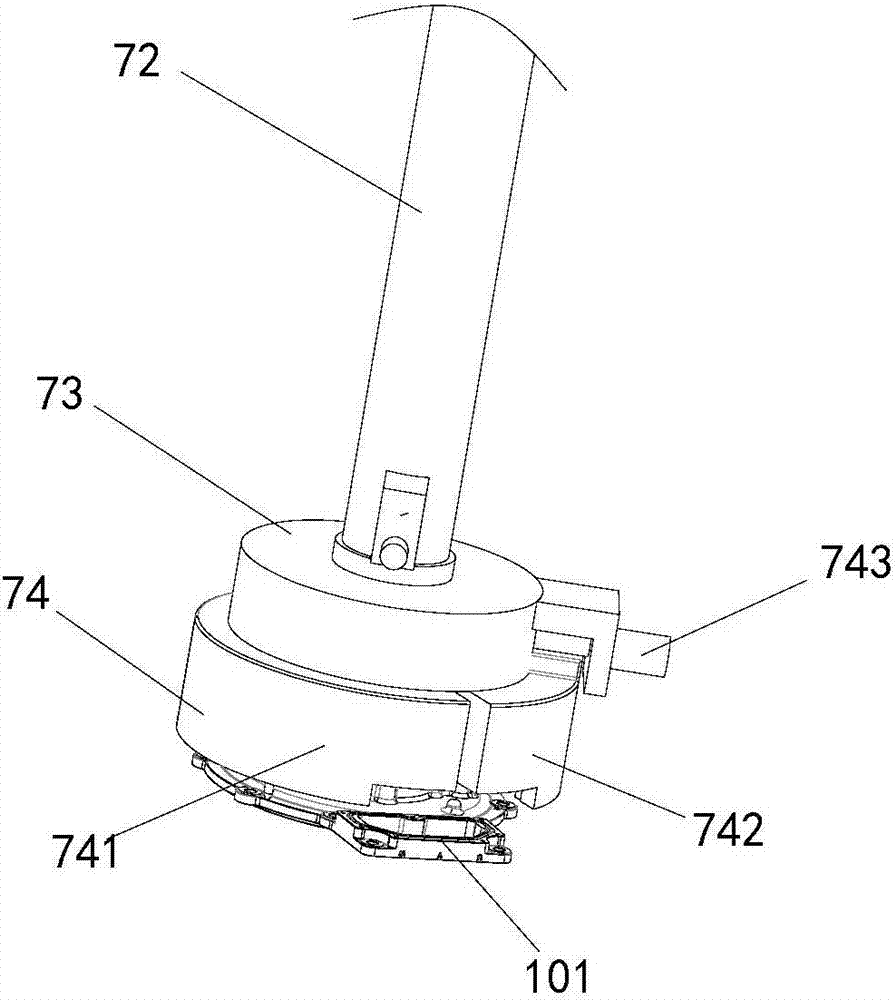

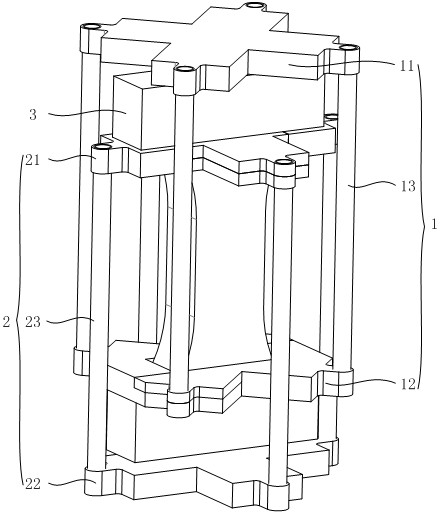

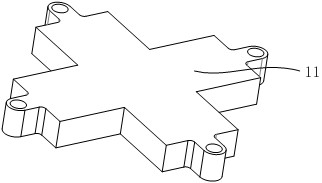

Automatic assembling device of rotor and end cover of permanent magnet synchronous motor

ActiveCN107317440ASolve the deformationSolve for uniformityCentering/balancing rotorsElectric machinesElectric machinePermanent magnet synchronous motor

The invention provides an automatic assembling device of a rotor and an end cover of a permanent magnet synchronous motor. The automatic assembling device comprises a fixed platform, a horizontal moving platform, a radical moving platform, a supporting platform, an end cover transferring platform, a rotor and case transferring platform, an end cover gripping assembly, a rotor gripping assembly and an ejector rod assembly, wherein the end cover gripping assembly comprises a pushing cylinder, a pushing rod assembly, an end cover gripper fixing platform and an end cover gripper; and the rotor gripping assembly comprises a rotor gripper fixing platform, a rotor gripper and a bidirectional cylinder. The working process of the device provided by the invention comprises the steps of firstly gripping the end cover of the motor, then gripping the rotor of the motor, and finally completing the assembling of the rotor and the end cover of the motor, so that the problem of rotor displacement generated by magnetic force attraction with the inner wall of a stator in the process that the rotor of the permanent magnet synchronous motor is pressed is solved, and the problems that the end cover is deformed and the cooperation is non-uniform caused by knocking when the end cover of the permanent magnet synchronous motor is mounted are solved.

Owner:SHANGHAI EDRIVE +2

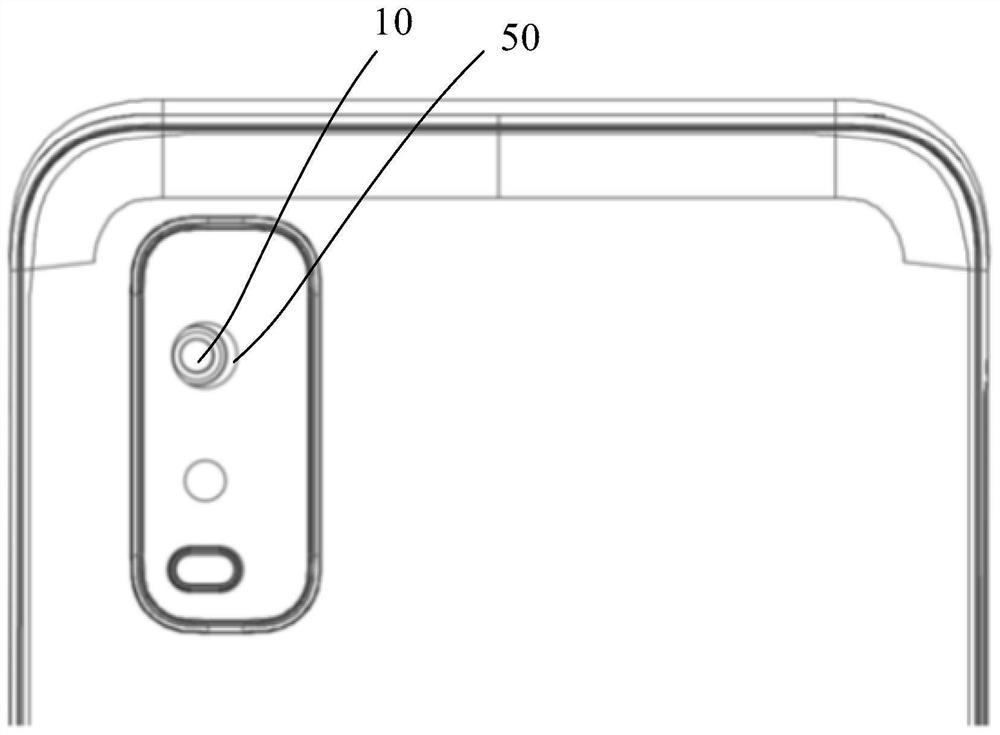

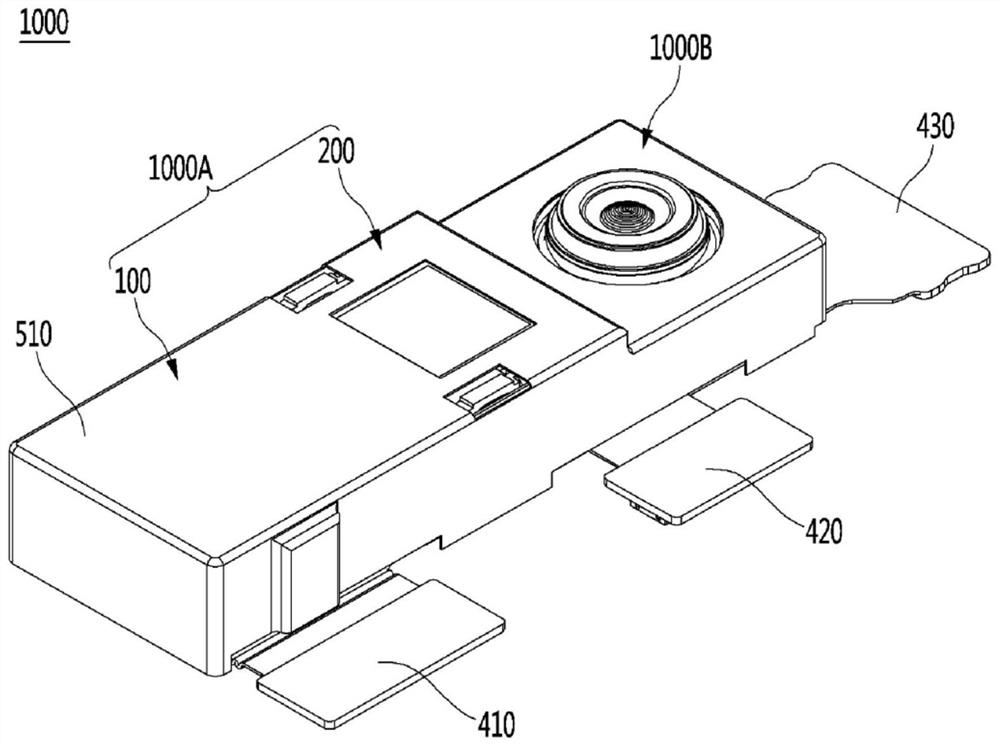

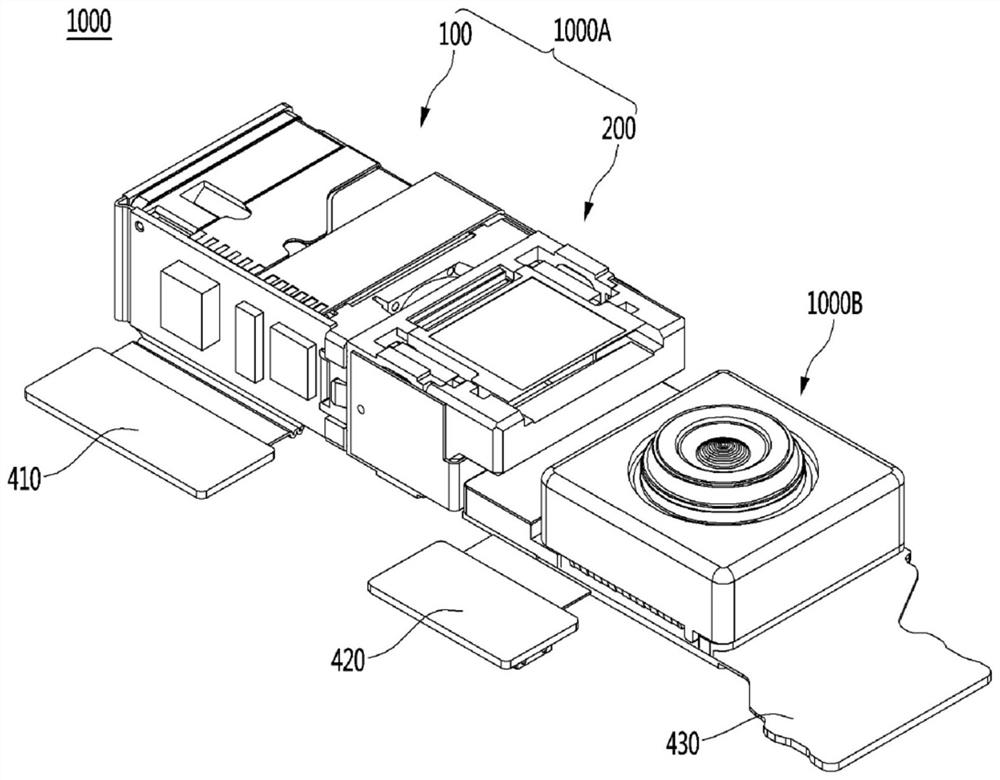

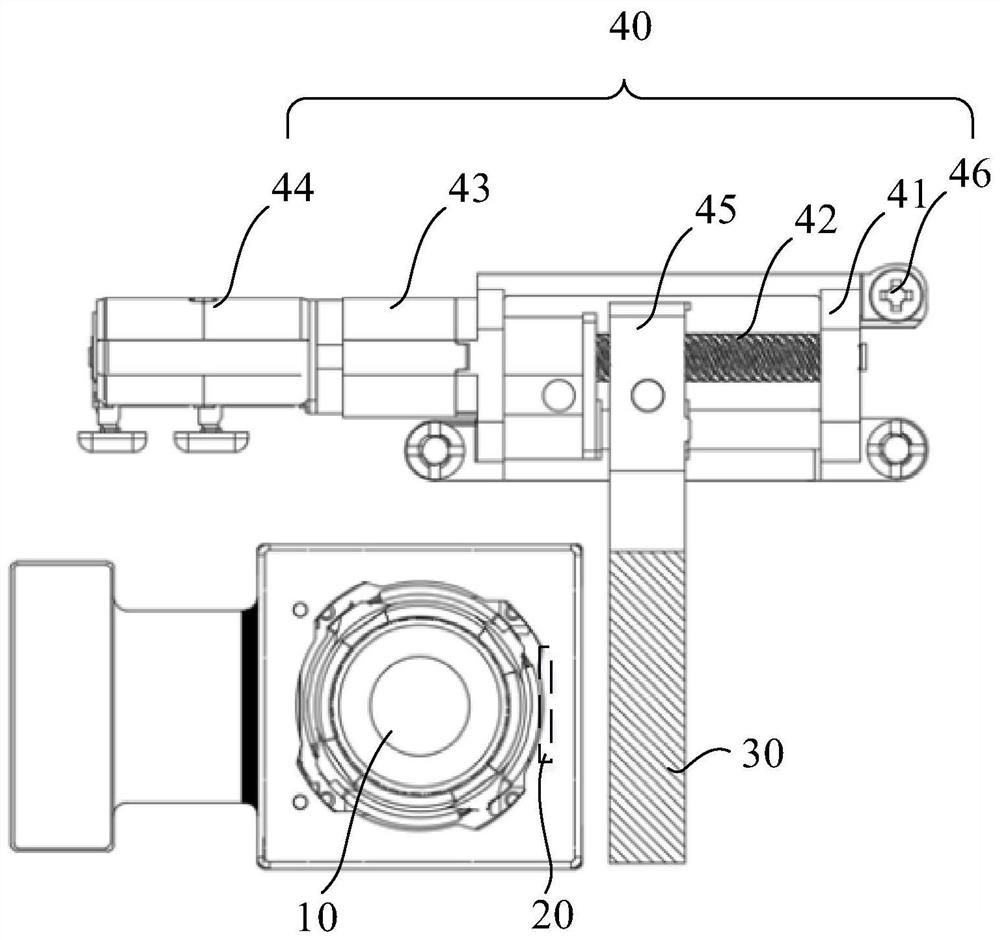

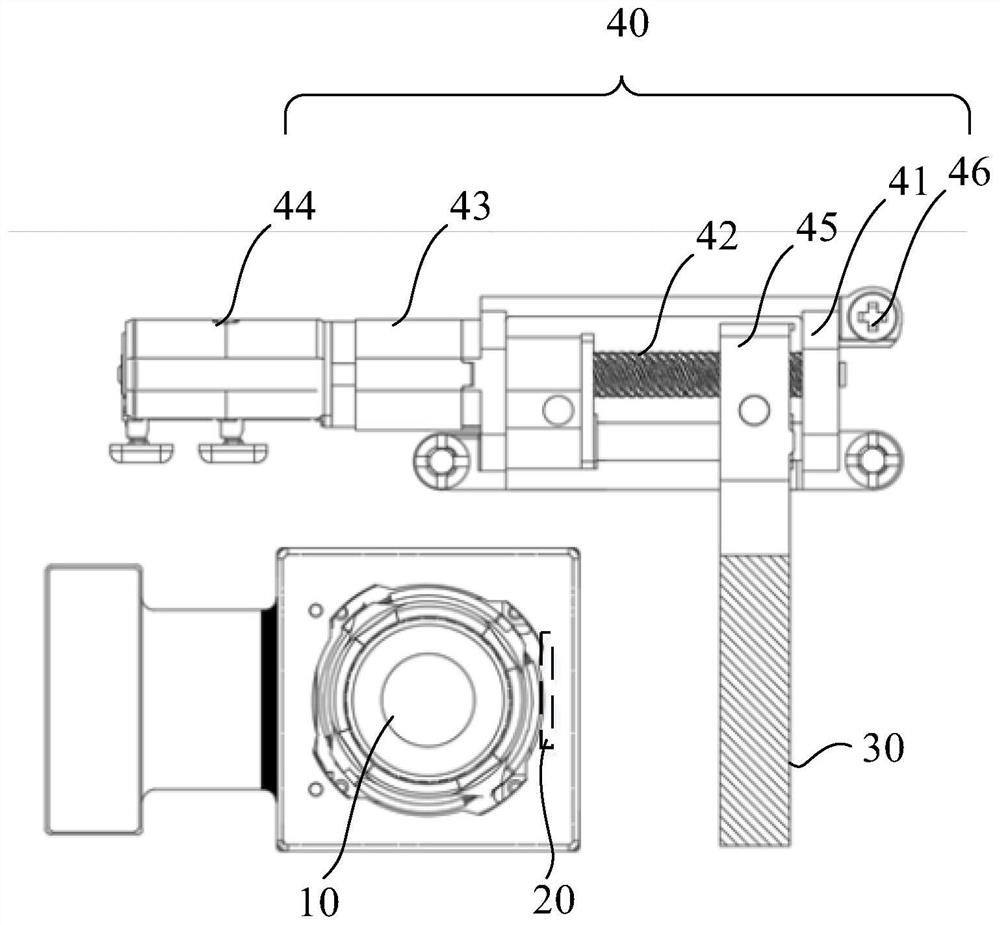

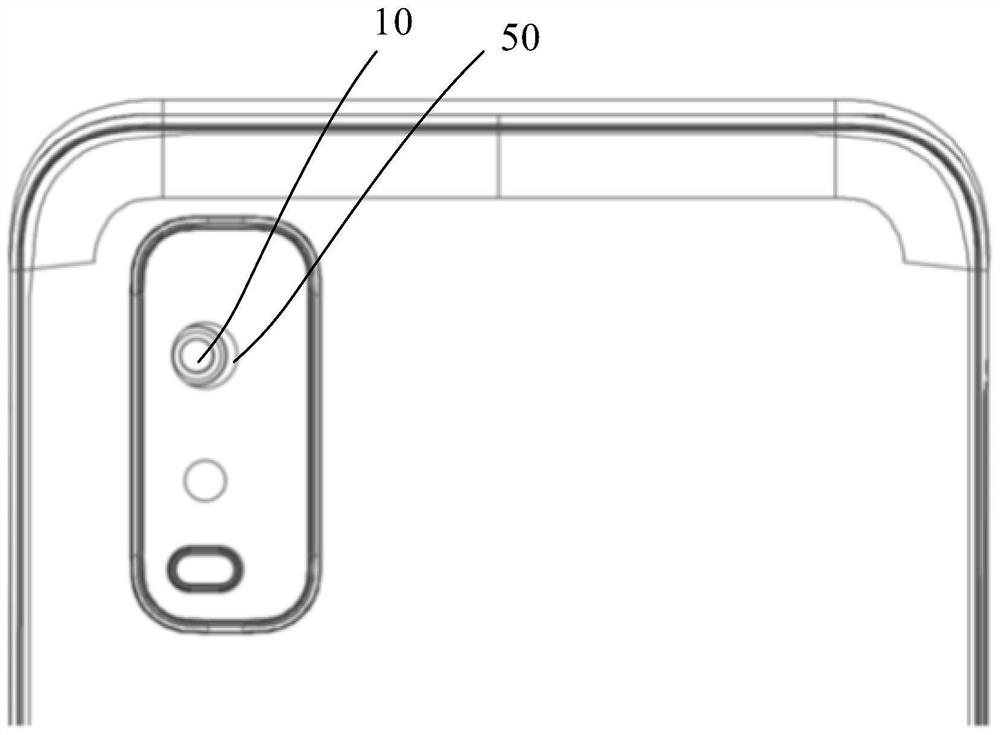

Camera module, shooting control method and electronic equipment

ActiveCN112311988APrevent free movementAchieve freedom of movementTelevision system detailsColor television detailsEngineeringCamera module

The invention discloses a camera module, a shooting control method and electronic equipment, belongs to the technical field of electronics, and aims to solve the problem of eccentricity of openings ofa lens and a decorative part caused by movement of the lens. The camera module comprises a lens; a first magnet connected with the lens; a second magnet opposite to the first magnet, wherein the first magnet and the second magnet are located on the same side of the lens; a driving mechanism connected with the second magnet; a control mechanism connected with the driving mechanism, wherein the control mechanism is used for controlling the driving mechanism to drive the second magnet to be away from the first magnet under the condition that the camera module starts a shooting mode until the lens is in an active state. Under the condition that the camera module closes the shooting mode, the driving mechanism is controlled to drive the second magnet to get close to the first magnet until thelens is in a static state. The camera module disclosed in the application is applied to the electronic equipment.

Owner:VIVO MOBILE COMM CO LTD

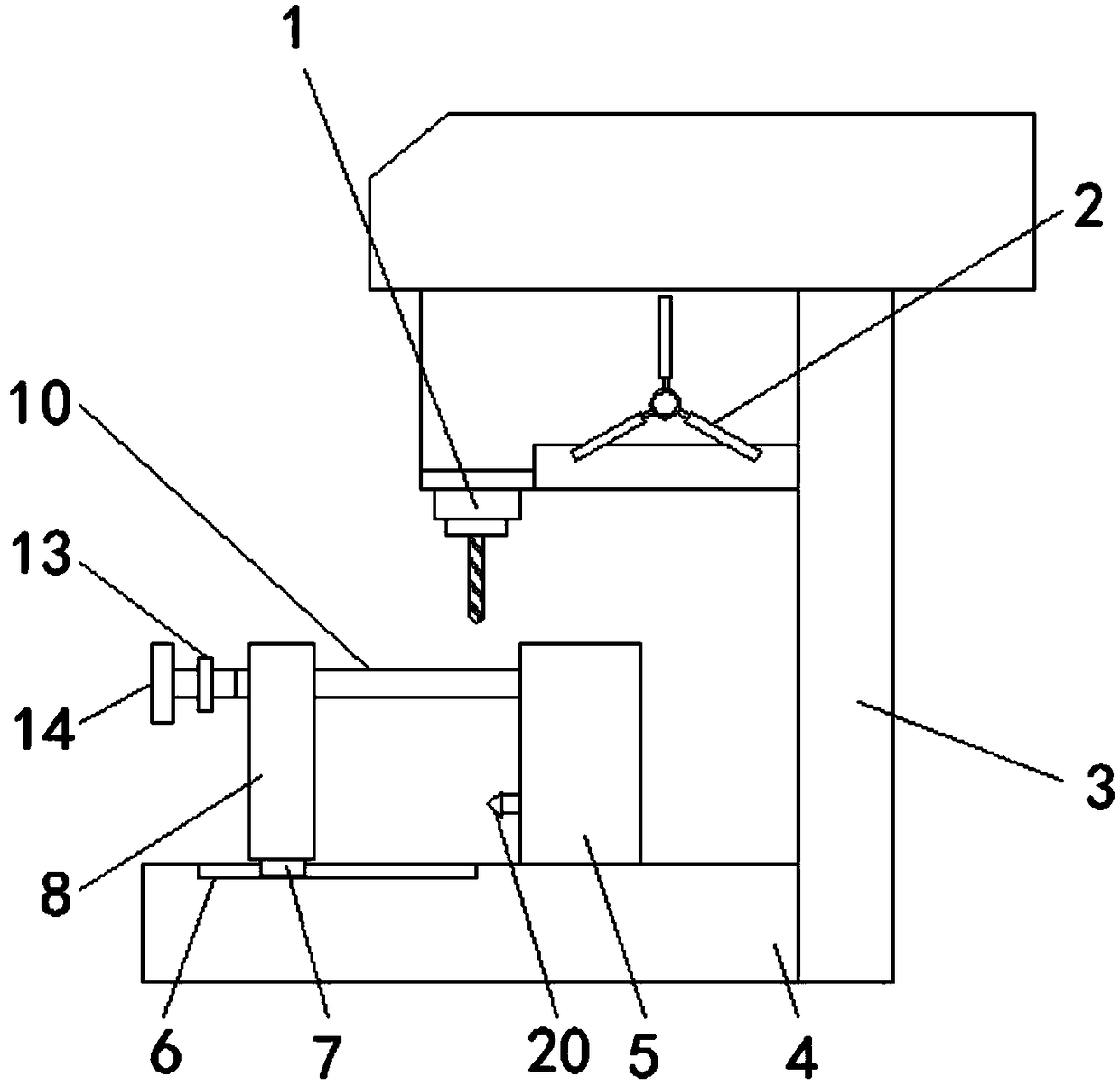

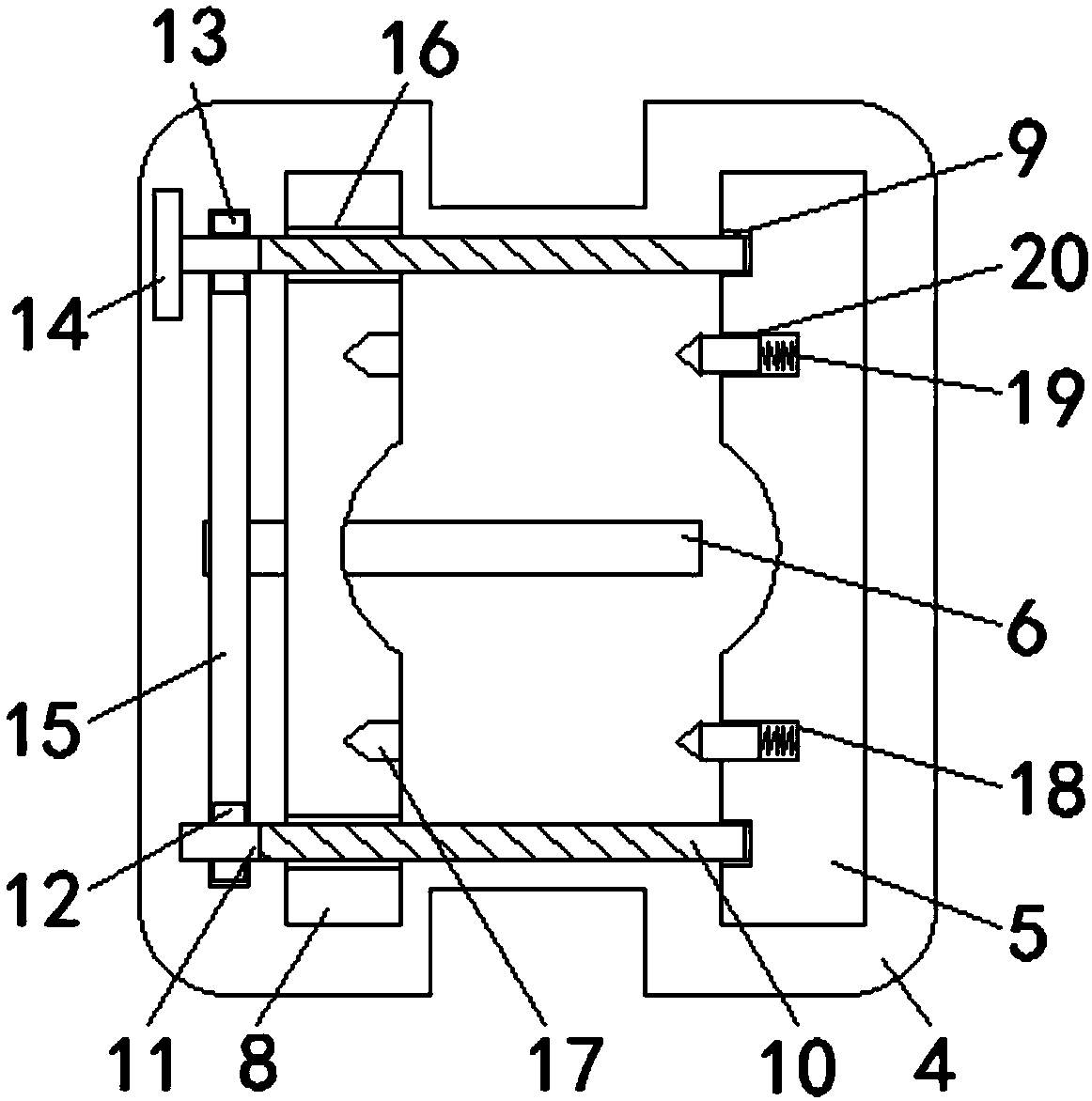

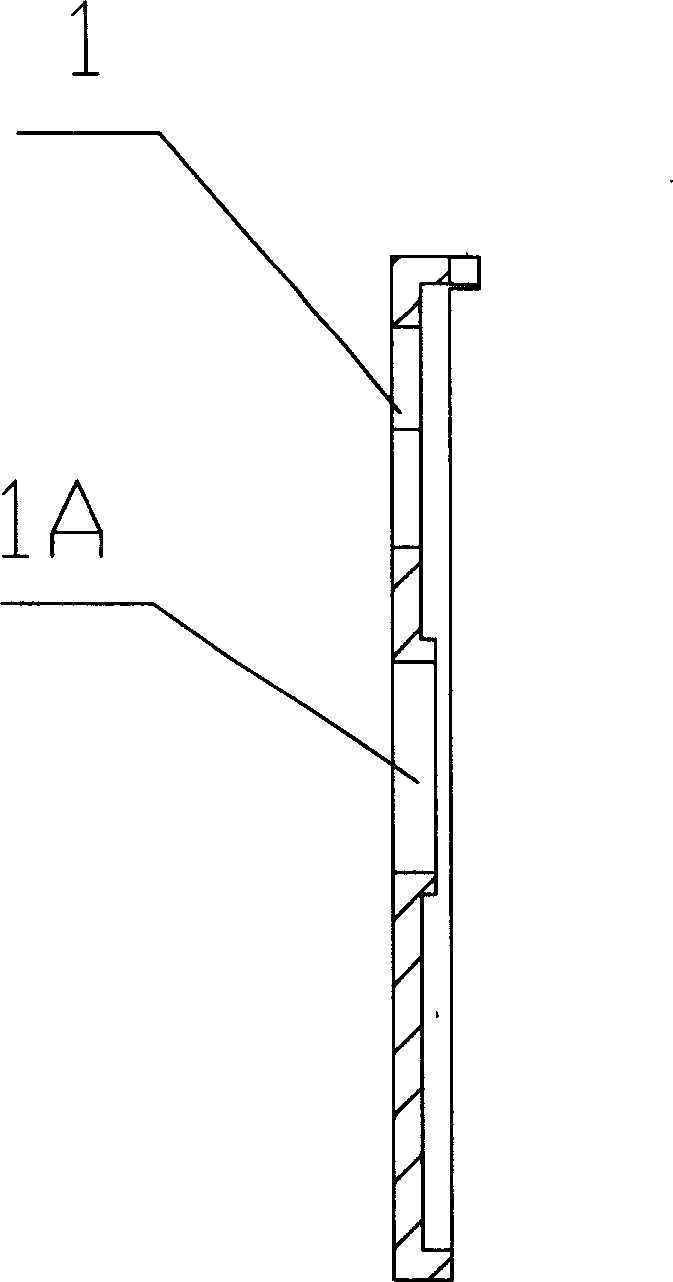

Machining device for door furniture axial central holes for civil defense

InactiveCN108372320AClamp firmlySolve the problem of eccentricityPositioning apparatusMetal-working holdersDrill bitDeclination

The invention relates to the technical field of civil defense protection equipment and discloses a machining device for door furniture axial central holes for civil defense. The machining device includes a drill bit, a lifting rod is fixedly installed on the front surface of the drill bit, a supporting plate is fixedly connected to the portion, on the right side of the lifting rod, of the bottom of the drill bit, a worktable is fixedly connected to the portion, at the bottom of the drill bit, of the left side of the supporting plate, and a fixed clamping plate is fixedly connected to the portion, at the bottom of the drill bit, of the top of the worktable. According to the machining device for the door furniture axial central holes for civil defense, through arrangement of two triangular head anti-declination blocks, after a movable clamping plate and the fixed clamping plate are both in contact with an object to be machined, a turntable is still selected at that time, and the left ends of the triangular head anti-declination blocks can be clamped to the inner walls of anti-declination grooves. Since the two triangular head anti-declination blocks are symmetric and a left structureis triangular, the fixed clamping plate is relatively parallel to the movable clamping plate, and a problem that the axial central holes are eccentric since clamping is not stable is solved.

Owner:苏州荣盾人防工程防护设备有限公司

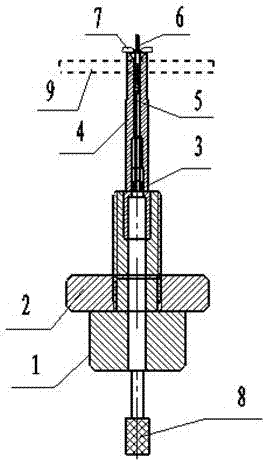

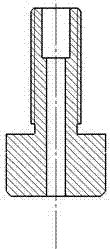

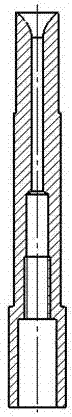

Welding fixture and welding method for vacuum tube

ActiveCN1772429ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesHeat conductingEngineering

The present invention relates to one kind of welding fixture and welding method for vacuum tube. The welding fixture made of heat conducting and electric insulating material has outer diameter equal to the inner diameter of the anode tube, and coaxial through hole in the middle part in the diameter equal to the outer diameter of the shielding cover of the filament assembly. The vacuum tube welding method with the welding fixture includes the following steps: 1. setting the fixture inside the anode tube; 2. setting the shielding cover of the filament assembly inside the through hole; and 3. welding the filament assembly coaxially with the anode tube. The fixture of the present invention has simple structure, and the welding method is simple, high in efficiency and low in cost, and can ensure the use performance of the vacuum tube.

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

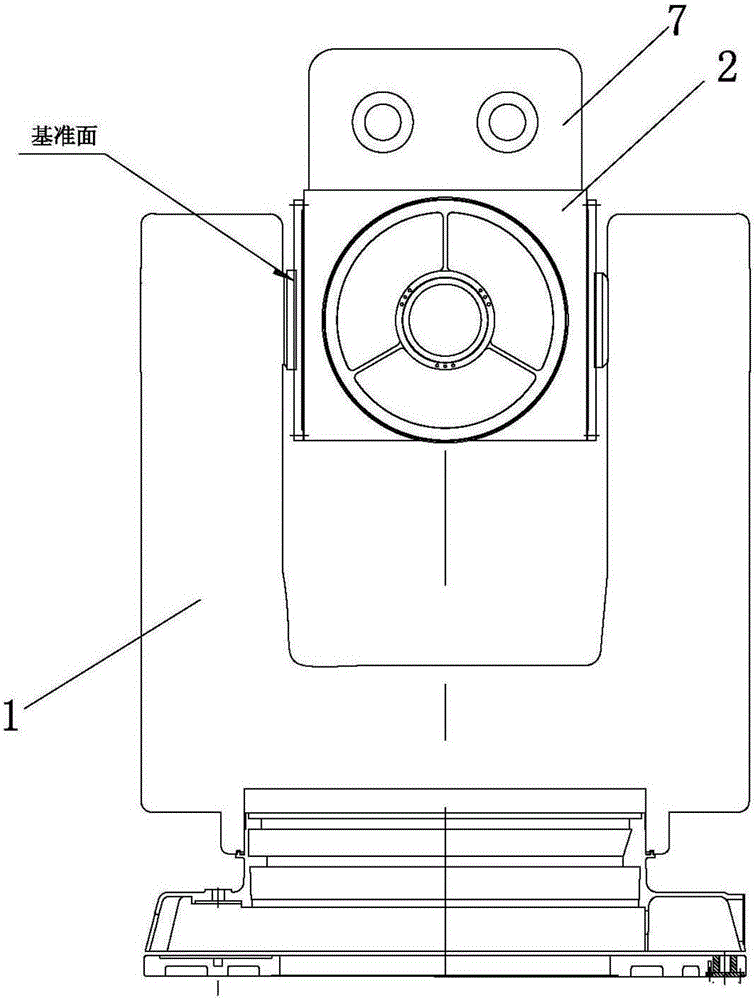

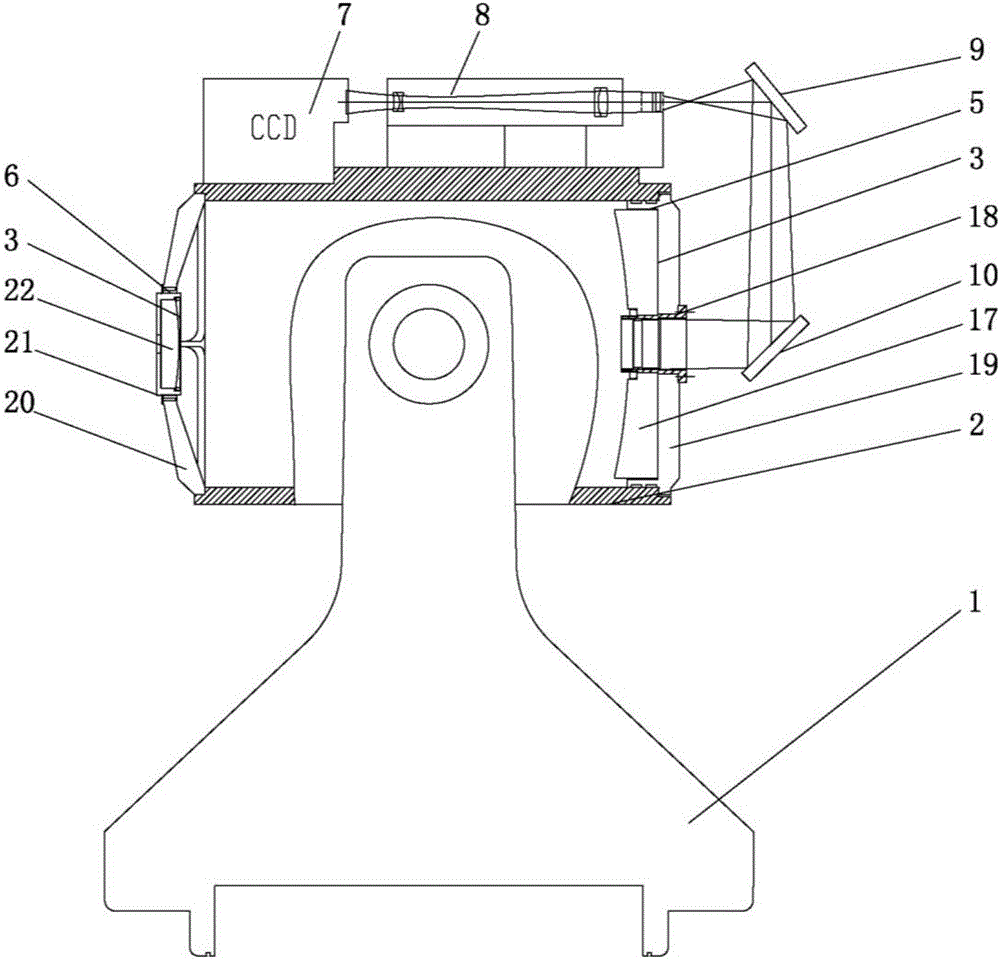

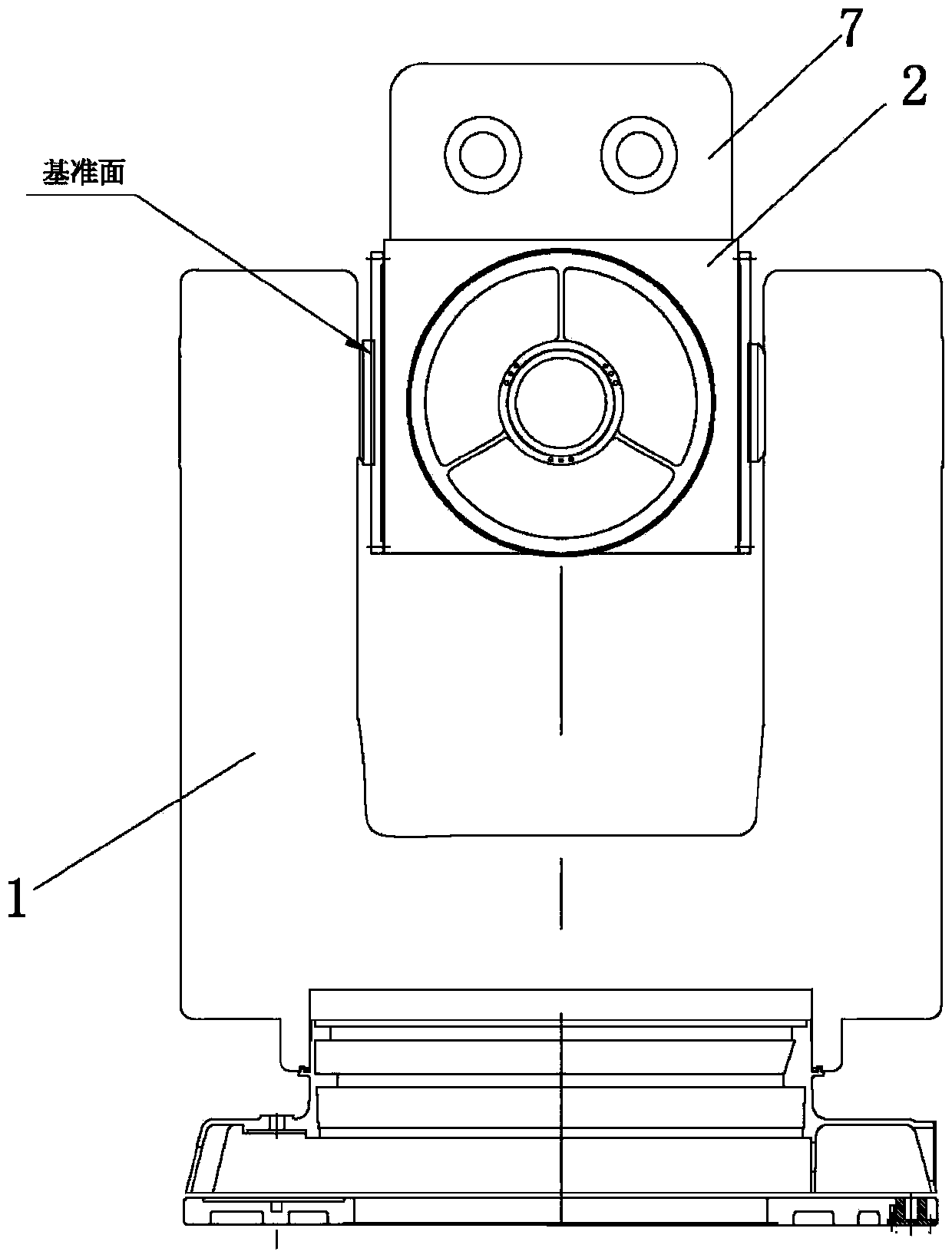

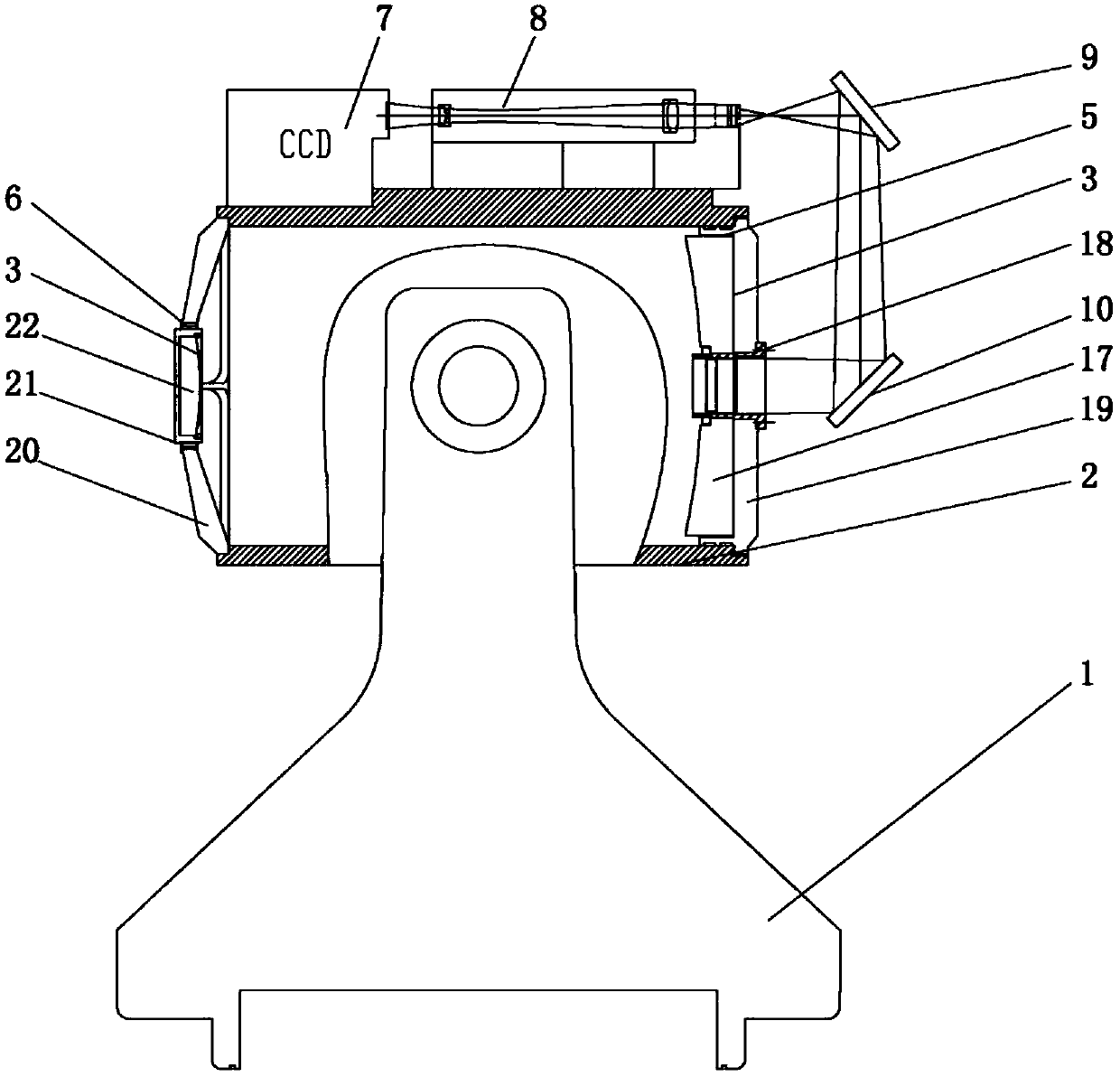

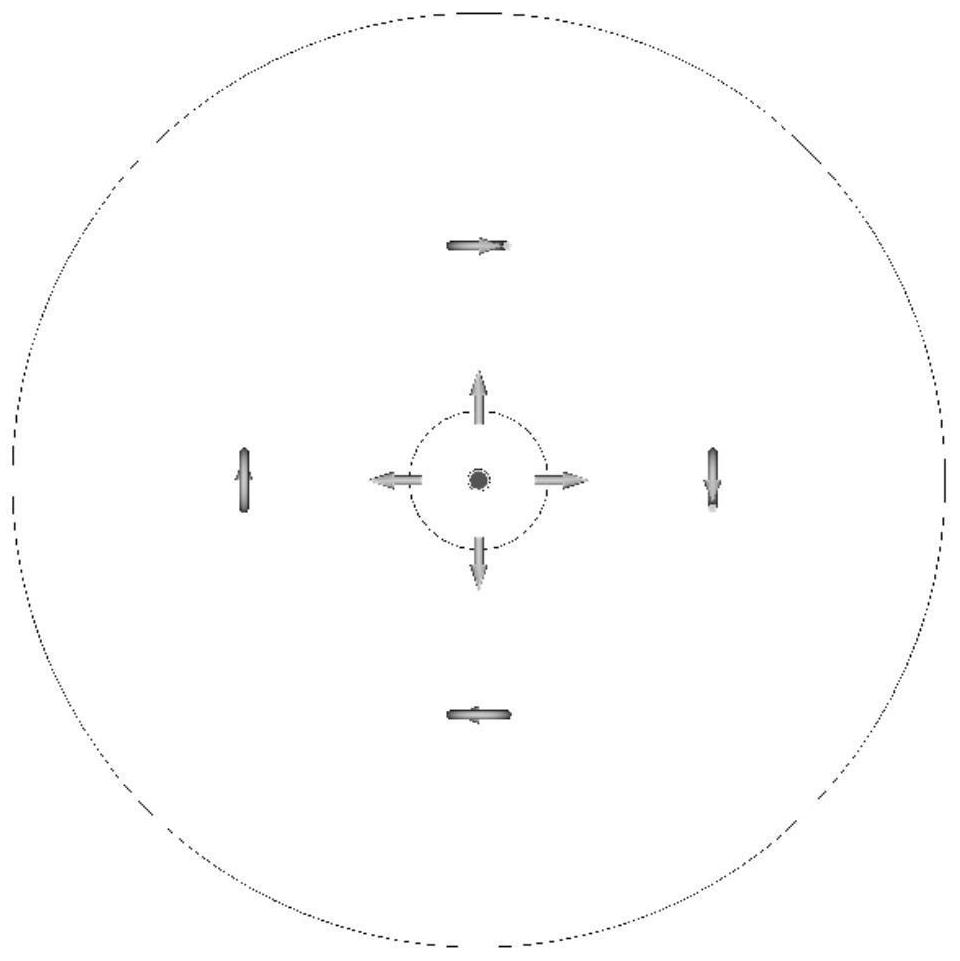

Horizon type theodolite collimation error adjustment method

The present invention belongs to the technical field of optics, and particularly relates to a horizon type theodolite collimation error adjustment method, which mainly comprises: 1) adjusting the auto-collimating centering of a main mirror; 2) adjusting the lens auto-collimating centering of a CCD; and 3) installing a sub-mirror assembly, eliminating the coma and the astigmatism between the main mirror assembly and the sub-mirror assembly, and ensuring that the spherical aberration and the focal distance of the main mirror system and the sub-mirror system meet the requirements. According to the present invention, the operation of the method is simple, and the problem that the processing precision of the mechanical structure member in the horizon type theodolite difficultly meets the optical system precision requirement so as to cause the inclination or decentration of the visual axis and the optical axis is solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Camera actuator and camera module comprising same

ActiveCN112840268ASolve the problem of eccentricitySolve the tiltTelevision system detailsProjector focusing arrangementOptical axisEngineering

Owner:LG INNOTEK CO LTD

Lens assembly

ActiveCN112041723ASolve the problem of friction torquePrevent frictional torqueProjector focusing arrangementCamera focusing arrangementRotational axisCamera module

Owner:LG INNOTEK CO LTD

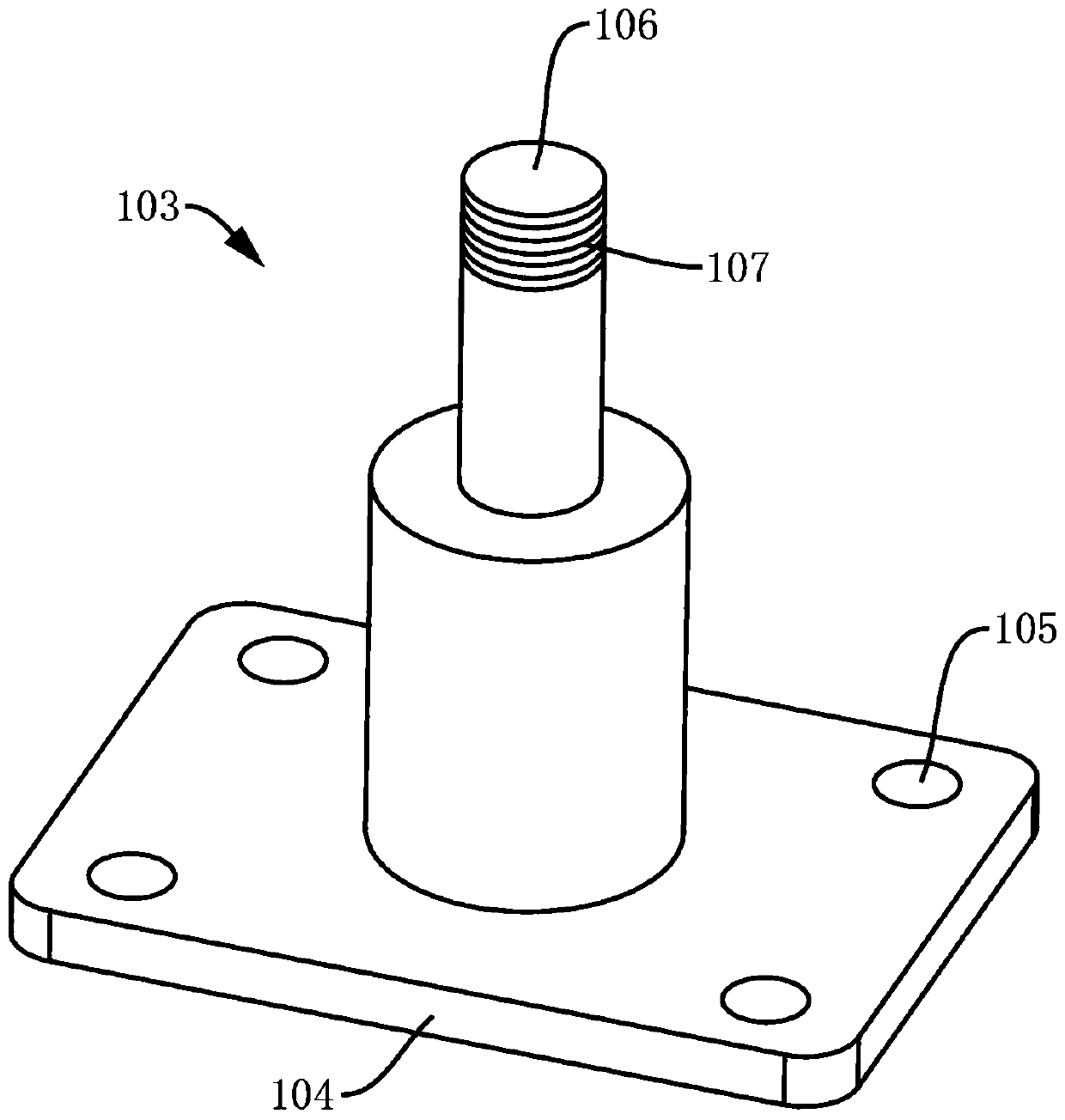

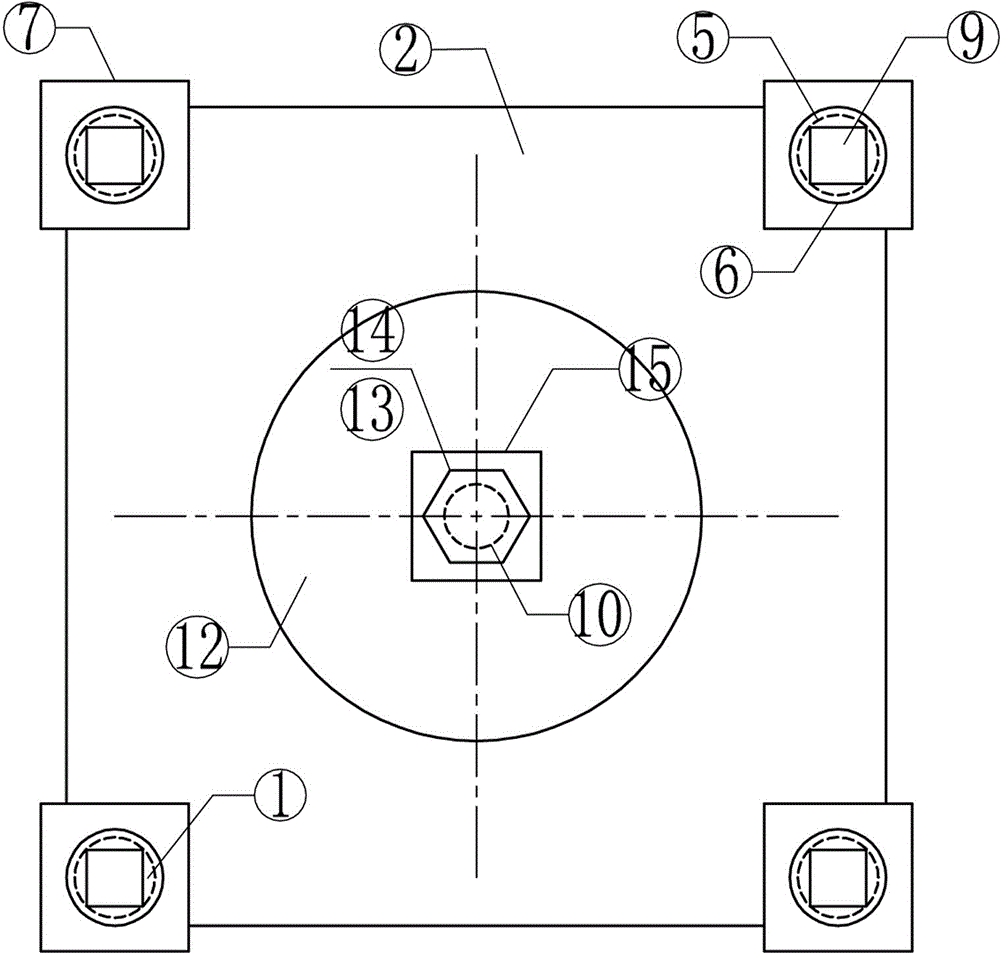

Adjustable center returning base of center penetrating jack

InactiveCN104695329AEasy to operateOperational securityBridge erection/assemblyBuilding material handlingFoot cushionJackscrew

The invention discloses an adjustable center returning base of a center penetrating jack. The base comprises adjustable legs, a bracket baseplate, a stiffened plate and a ground foot cushion plate, wherein the adjustable legs are connected through the bracket baseplate; the lower ends of the adjustable legs are mounted on the ground foot cushion plate; four adjustable legs are provided; each adjustable leg comprises an adjustable screw rod; screw rod casings are mounted outside the adjustable screw rods; and multiple square nuts are connected with the screw rod casings. The base has the advantages of simple structure, convenience for operation, safety and reliability; and the jack eccentricity problem can be solved only by manually adjusting the adjustable screw rods through a spanner, so that the problems of capability of performing the jack eccentricity adjustment through the fit of multiple persons, prevention of repeated adjustment, long adjustment time and inaccurate centering precision are solved.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Method for machining high-precision extrusion die

InactiveCN103658894AResolve twistSolve the problem of eccentricityExtrusion diesEngineeringMachining process

The invention discloses a method for machining a high-precision extrusion die. The extrusion die comprises a female die and a male die. Before the female die and the male die are subjected to workpiece standardization, an inward-contracting step face is machined under the surface of a workpiece, wherein the surface of the inward-contracting step face is in the shape of L, and the inward-contracting step face serves as a uniform leveling foundation of follow-up processes; the center point of the workpiece is found before machining and serves as the coordinate center of all the follow-up machining processes, and then positioning is carried out with the inward-contracting step face as the horizontal foundation to carry out machining according to uniform coordinate dimensions. Due to the adoption of the uniform leveling standard, a mold cavity and a mold core of the workpiece do not twist; due to the method that the center point of the workpiece serves as the coordinate center, the mold cavity and mold core of the workpiece will not be eccentric; in this way, the phenomena of twisting and being eccentric are avoided in the workpiece machining process, machining precision and efficiency are obviously improved, the female die and the male die can be matched with each other completely, and the rejection rate is obviously lowered.

Owner:XINGFA ALUMINUM CHENGDU

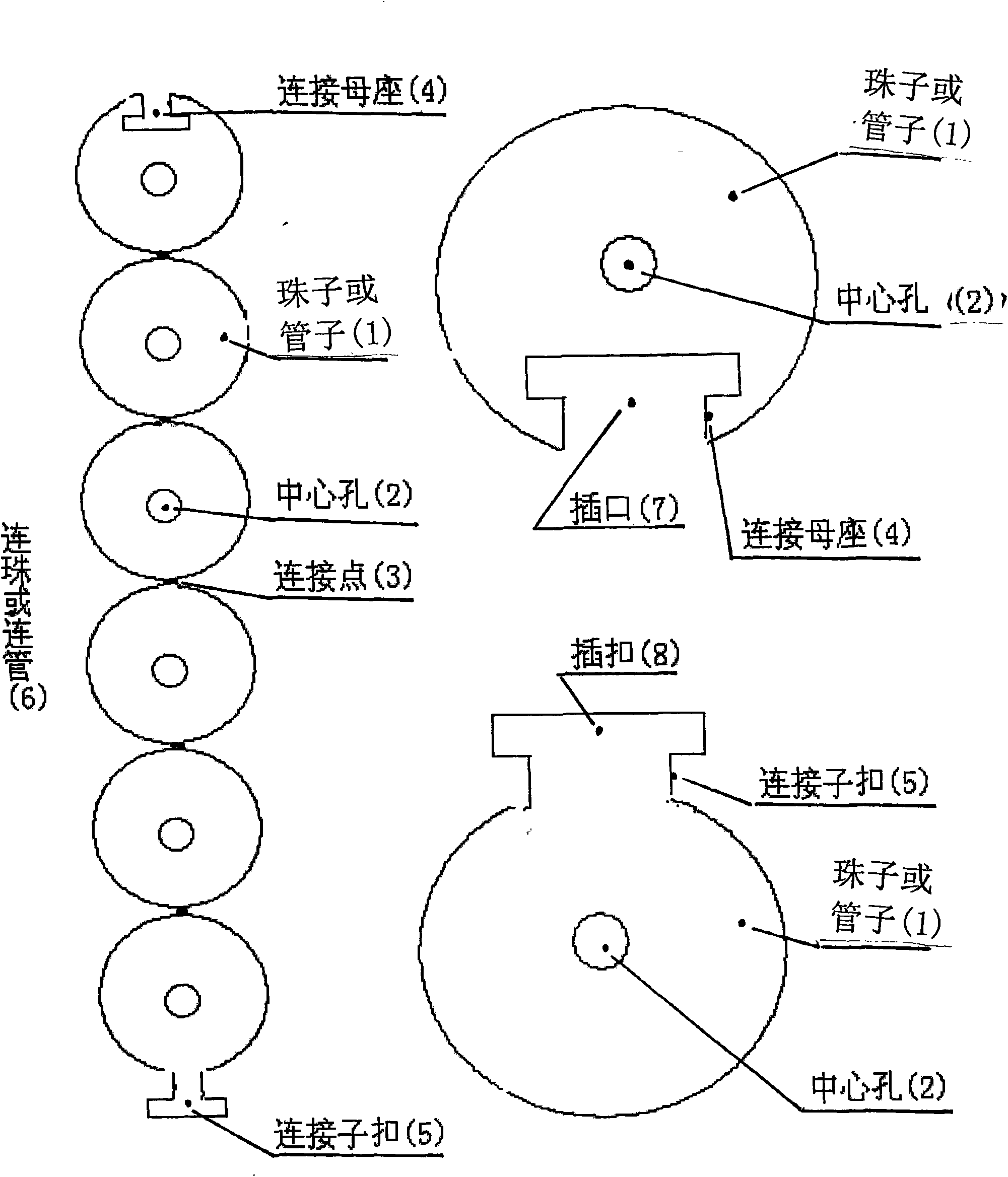

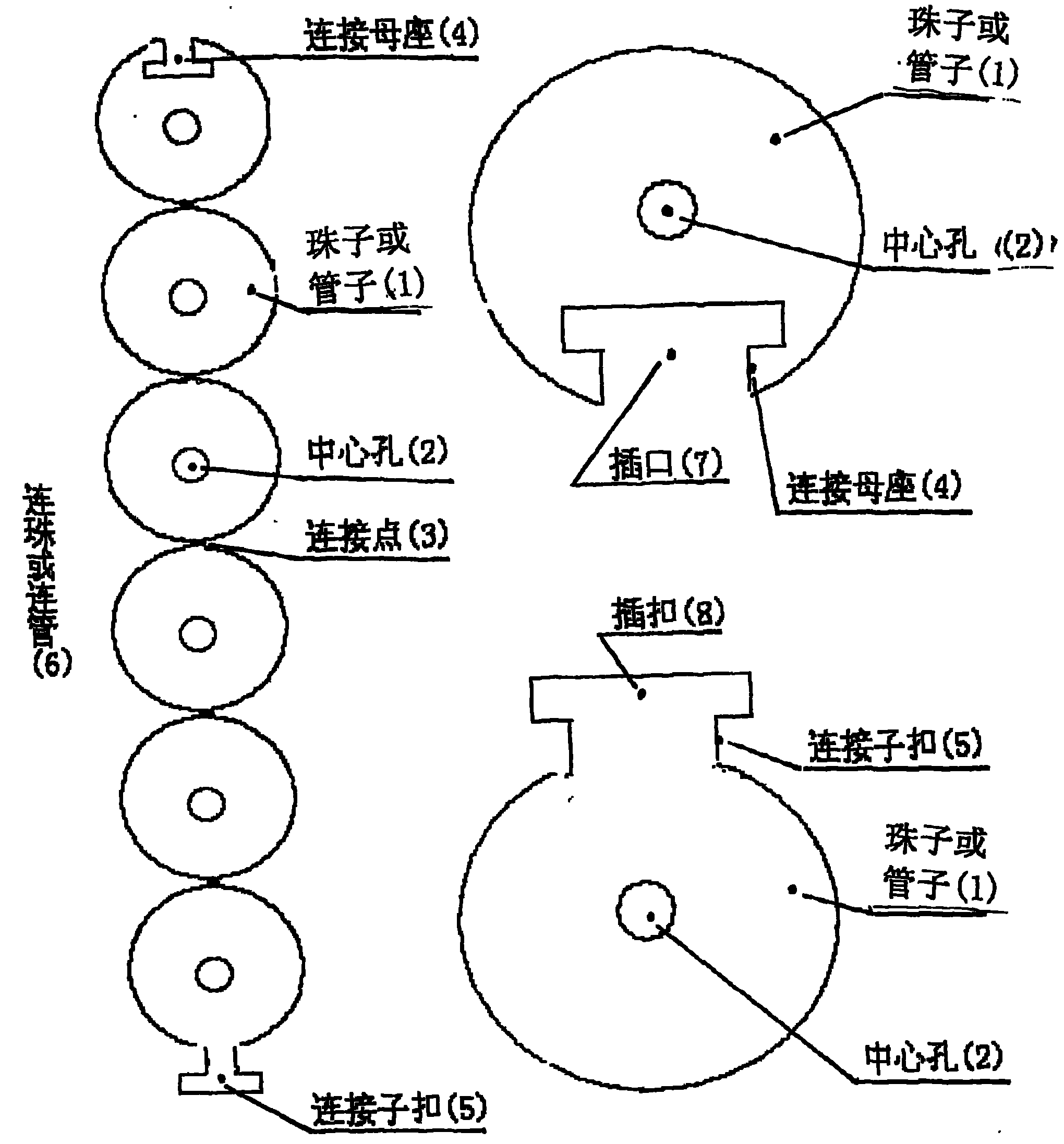

Connected bead and connected tube suitable for machine embroidery and manufacturing method

InactiveCN101892565ARaise the gradeEasy to viewEmbroidering machines apparatusContinuous useEngineering

The invention discloses a connected bead and a connected tube suitable for machine embroidery and a manufacturing method. The connected bead or connected tube comprises beads or tubes, centre holes, connection points, connection master seats and connection sub-fasteners. The beads or tubes are connected through the connection points to form the connected bead or connected tube with a certain length; the side faces of a first bead and a last bead of the connected bead or a first tube and a last tube of the connected tube are provided with the connection master seats and the connection sub-fasteners; the connection sub-fasteners are inserted into the connection master seats to form a longer connected bead or connected tube to be continuously used by an embroidering machine. The manufacturing method has great creativeness; the bulk beads or tubes are made into the connected bead or connected tube on the premise of keeping the original shape of the beads or tubes, and the beads or tubes are reembroidered on the fabric by machine embroidery instead of manual work, so that extremely convenient manufacturing is achieved; and due to the adoption of the supplementary material, the drop points of the beads or tubes in the patterns made by machine embroidery are very accurate and beautiful, so that the level and the ornamentality of the fabric are greatly improved and the effect is very obvious.

Owner:王仁坤

A method for adjusting the collimation error of horizon-type theodolite

ActiveCN106595703BSolve the tiltSolve the problem of eccentricityMeasurement devicesTheodoliteHorizon

The present invention belongs to the technical field of optics, and particularly relates to a horizon type theodolite collimation error adjustment method, which mainly comprises: 1) adjusting the auto-collimating centering of a main mirror; 2) adjusting the lens auto-collimating centering of a CCD; and 3) installing a sub-mirror assembly, eliminating the coma and the astigmatism between the main mirror assembly and the sub-mirror assembly, and ensuring that the spherical aberration and the focal distance of the main mirror system and the sub-mirror system meet the requirements. According to the present invention, the operation of the method is simple, and the problem that the processing precision of the mechanical structure member in the horizon type theodolite difficultly meets the optical system precision requirement so as to cause the inclination or decentration of the visual axis and the optical axis is solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

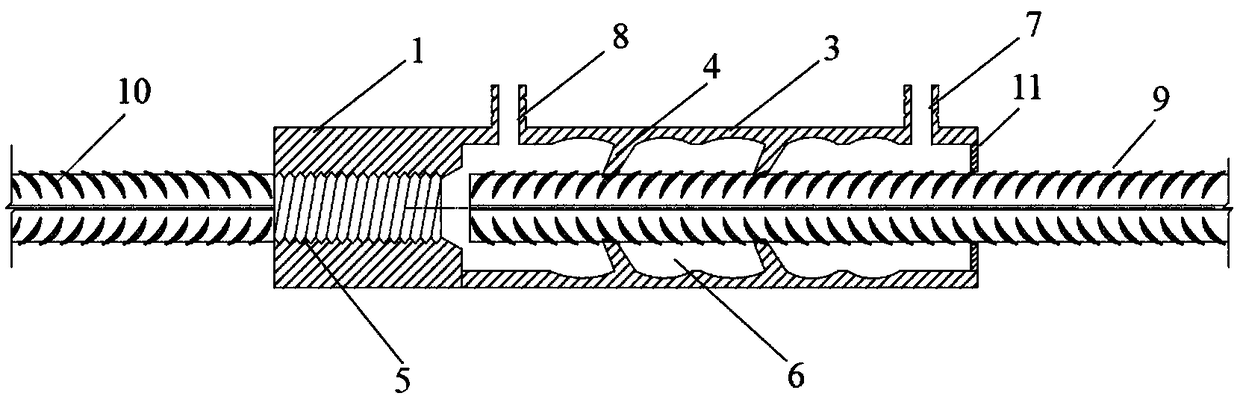

Lens driving device and camera module including same

ActiveCN111971619AFriction torque minimizationImproved drive powerTelevision system detailsPrintersOptical axisEngineering

One embodiment relates to a lens driving device and a camera module including same. The lens driving device according to the one embodiment can comprise: a base; a pin coupled to the base; and a housing including a lens group and moving in the optical axis direction along the pin. The housing can comprise, in one side thereof, a ball accommodation part and a plurality of balls arranged in the ballaccommodation part. The pin is arranged in the ball accommodation part so as to be capable of guiding the housing while coming in contact with the plurality of balls.

Owner:LG INNOTEK CO LTD

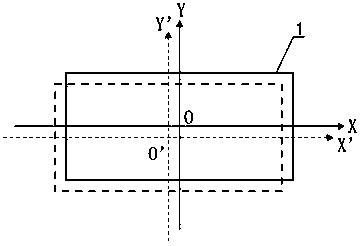

A Construction Technology of Rock-socketed Pile for Offshore Fan Foundation

ActiveCN106120839BSolve the problem of eccentricityImprove the immunityFoundation testingBulkheads/pilesEngineering structuresTurbine

The invention discloses a construction process of an open sea fan foundation rock-socketed pile. The construction process comprises the steps of pile sinking of a steel pipe pile, setting a construction operation platform, drilling, performing intermediate inspection, finishing a drilled hole, clearing the hole, measuring the hole, placing a steel reinforcement cage, placing a guide pipe, clearing the hole for the second time and performing underwater concrete pouring procedure. In the pile sinking procedure of the steel pipe pile, six steel pipe piles with the inclination of 5:1 which are uniformly distributed on the circular track curve are sunken into the foundation in the pile driving way by a special pile driving boat; in the setting procedure of the construction operation platform, the construction of a bearing platform bottoming concrete layer is performed and the construction operation platform is erected on the bearing platform bottoming concrete layer; the concrete of the bearing platform bottoming concrete layer is performed by the steel pipe piles; the construction operation platform is square and comprises an upper bailey frame, a lower bailey frame, a steel platform panel and a safety fence. According to the construction process, the construction efficiency of the pile socketing into rock can be improved, the horizontal resistance and the anti-shifting capability of the rock-embedded piles can be effectively improved, and the requirements of engineering structure design and construction are met.

Owner:CCCC THIRD HARBOR ENG +2

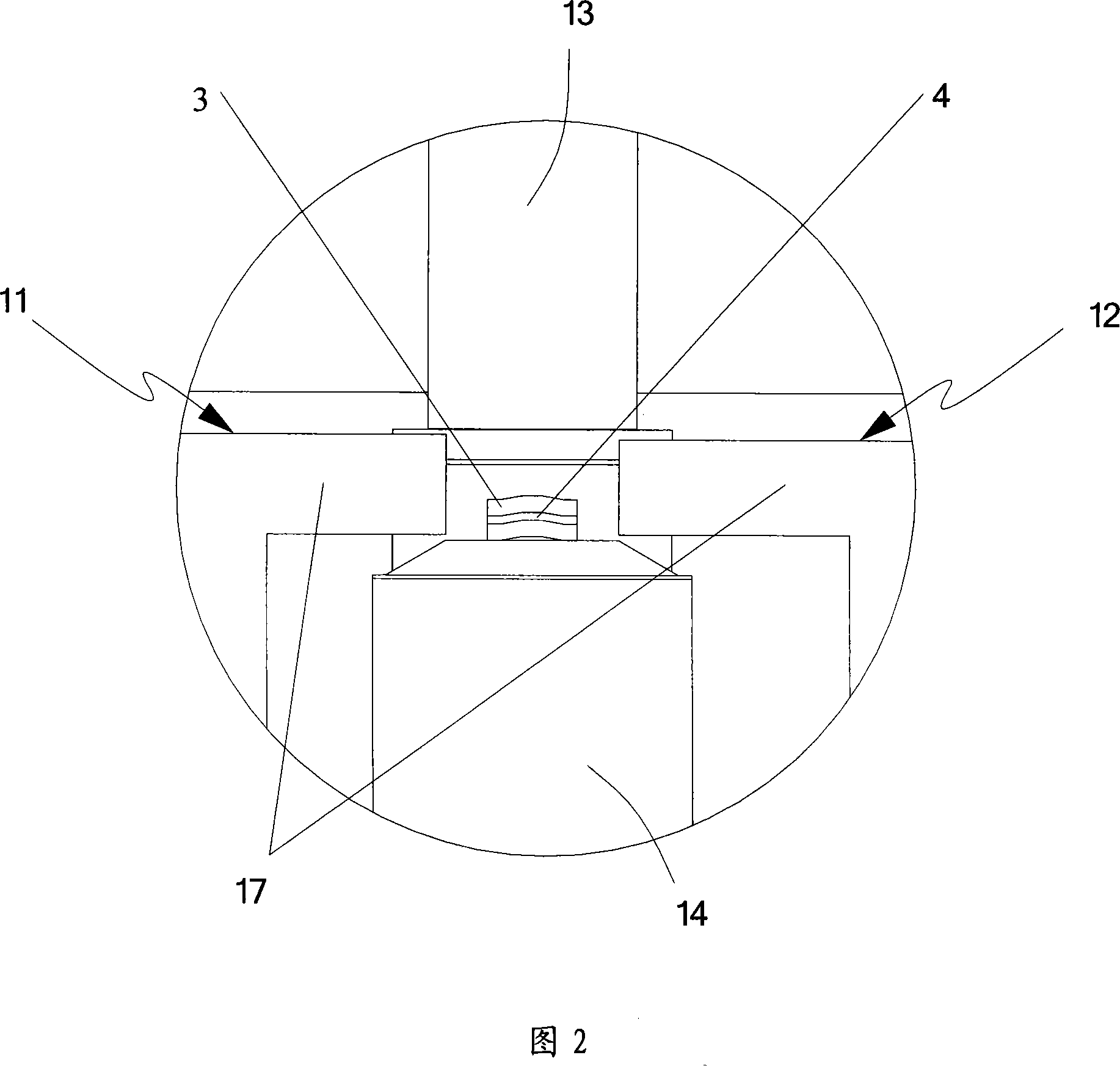

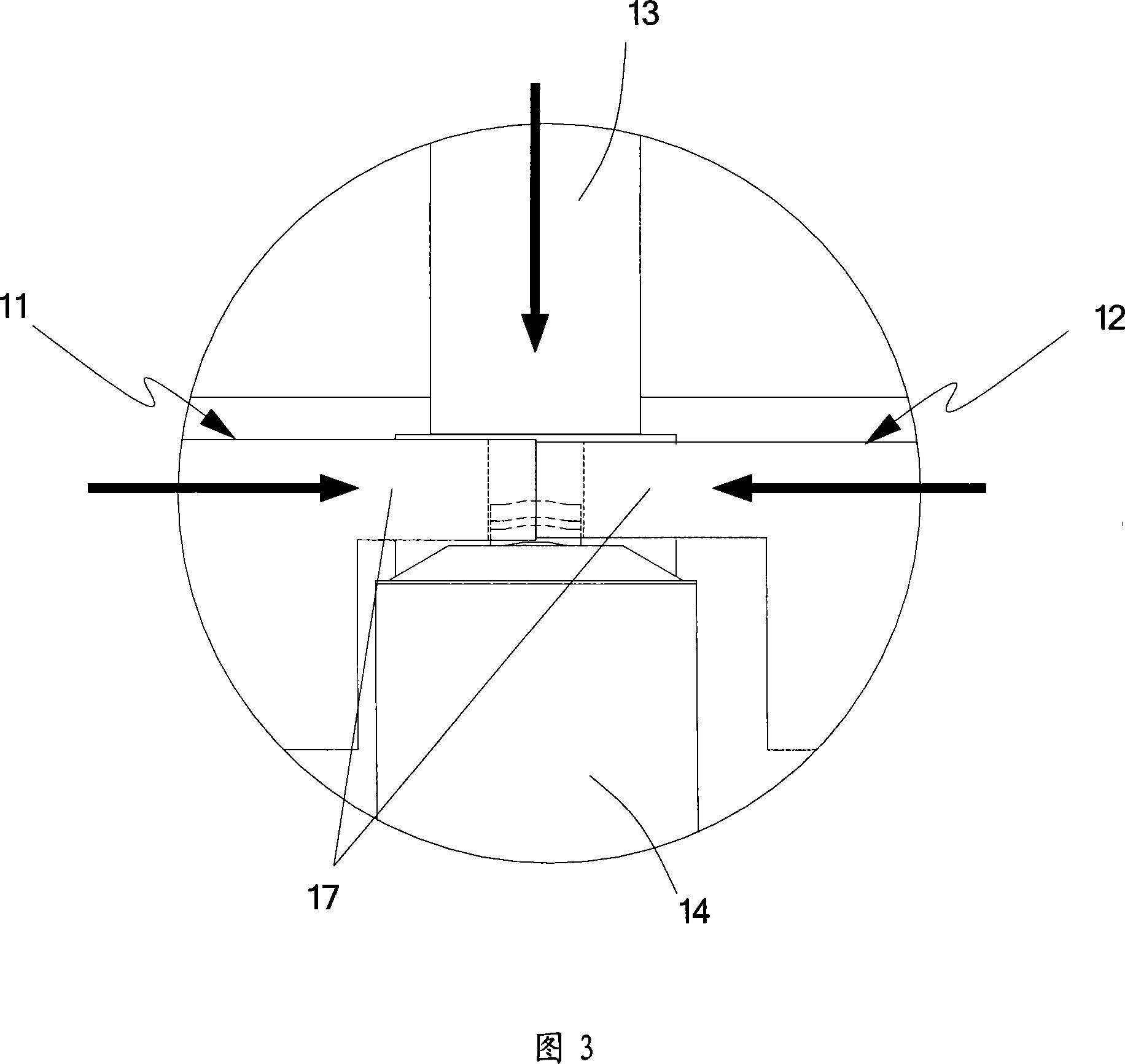

Stirling engine

The invention discloses a Stirling engine which comprises a first air cylinder, a second air cylinder, a first piston, a second piston and a flywheel. The first air cylinder and the second air cylinder are communicated with each other. The first piston is arranged in the first air cylinder and moves in a straight-line mode. The second piston is arranged in the second air cylinder and moves in a straight-line mode. The Stirling engine is characterized in that a magnet is arranged at the bottom end of the second piston, a driving block which is matched with the magnet in a gap-type-attracting mode is arranged on the first piston. The flywheel is arranged at the top end of the second air cylinder horizontally through a rotating shaft. The rotating shaft is driven to rotate by the second piston. A guiding groove is formed in the outer periphery or the inner wall of the second piston obliquely. A driving rod is connected below the rotating shaft. The end of the driving rod is arranged in the guiding groove and can move along the guiding groove. The flywheel is arranged horizontally, the overall height is greatly lowered, reasonable arrangement of other parts is convenient, special support arrangement is removed for the flywheel, the eccentric problem is solved, and overall attractiveness is improved.

Owner:苏州欣旺达创业服务有限公司

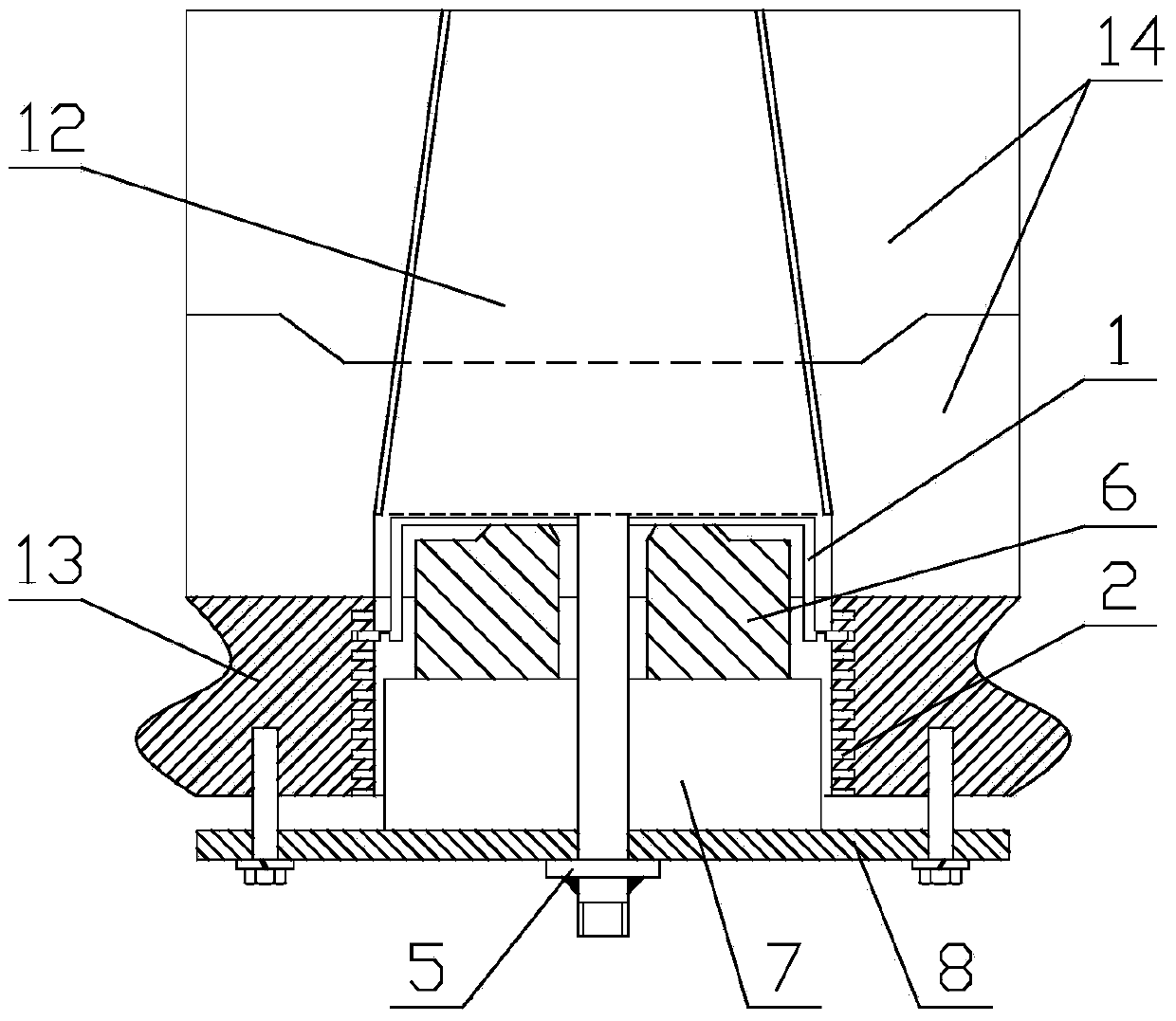

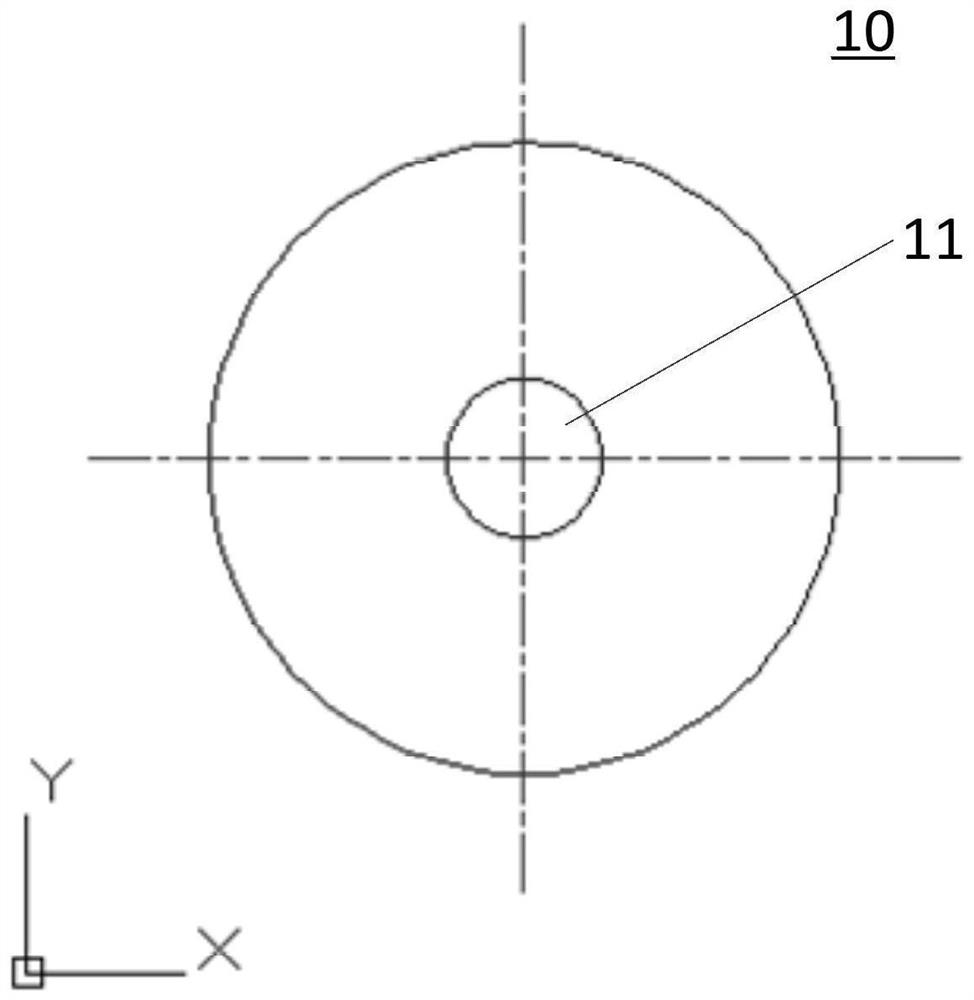

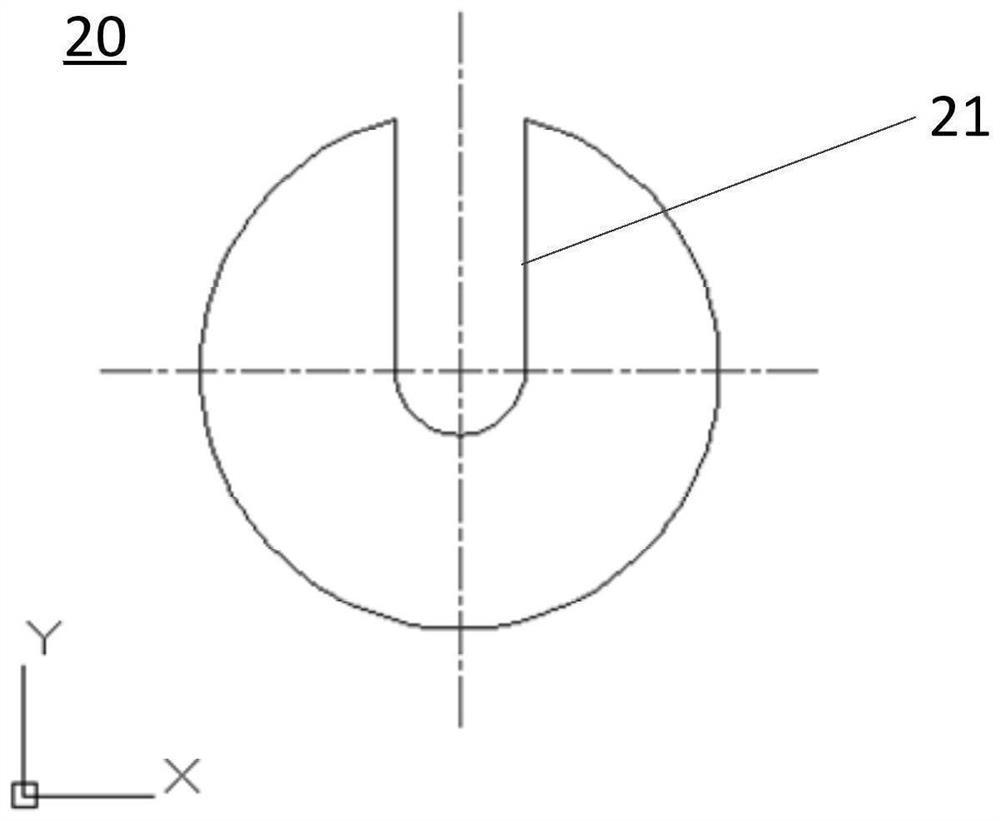

Magnetic steel sheet, magnetic focusing system and traveling wave tube comprising magnetic focusing system

The embodiment of the invention discloses a magnetic steel sheet, a magnetic focusing system and a traveling wave tube comprising the magnetic focusing system. The magnetic steel sheet comprises a first body with a first central through hole, and a U-shaped notch formed in the first body and penetrating through the upper side surface and the lower side surface of the magnetic steel sheet, whereinthe hole center of the first central through hole extends in the radial direction of the first central through hole to penetrate through the surface of the outer side wall of the first body to form the U-shaped notch, the magnetic steel sheet further comprises a first compensation notch, the first compensation notch and the U-shaped notch are arranged in the same center line, the opening directionof the first compensation notch is opposite to the opening direction of the U-shaped notch, the first compensation notch penetrates through the upper side surface and the lower side surface of the magnetic steel sheet, and the length of the first compensation notch is smaller than the radius length of the first body of the magnetic steel sheet. According to the invention, the magnetic steel sheetis simple to process and convenient to install, the asymmetry of the magnetic steel sheet is reduced, the eccentric distance of a magnetic induction line is shortened, and the passing rate of electron beams is improved.

Owner:NO 12 RES INST OF CETC

A needle body crimping positioning device for twist needles

ActiveCN105337135BQuick guideRapid positioningLine/current collector detailsLocking mechanismEngineering

Owner:遵义市飞宇电子有限公司

Camera module, shooting control method and electronic device

ActiveCN112311988BPrevent free movementAchieve freedom of movementTelevision system detailsColor television detailsEngineeringCamera module

Owner:VIVO MOBILE COMM CO LTD

Cantilever erection of large-span railway steel truss girder bridge with flexible cushioning device for ultra-high load-bearing brackets

ActiveCN112921828BSolve the problem of eccentricityImprove securityBridge erection/assemblyArchitectural engineeringLong span

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Device and method for testing tensile strength of mine filling body

ActiveCN111735704BImplementing Tensile Strength TestingTest coherenceMaterial strength using tensile/compressive forcesMechanical engineeringStrength testing

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com