Cantilever erection of large-span railway steel truss girder bridge with flexible cushioning device for ultra-high load-bearing brackets

A steel truss bridge and long-span technology, which is applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of high construction cost, uneven pad steel plate, harsh use conditions, etc., and achieves high safety and cost. Low, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be described clearly and completely below. Obviously, the described implementation

[0036] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention

[0037] In addition, in the present invention, such as the description related to "first", "second", etc. are only for the purpose of description, and should not be construed as

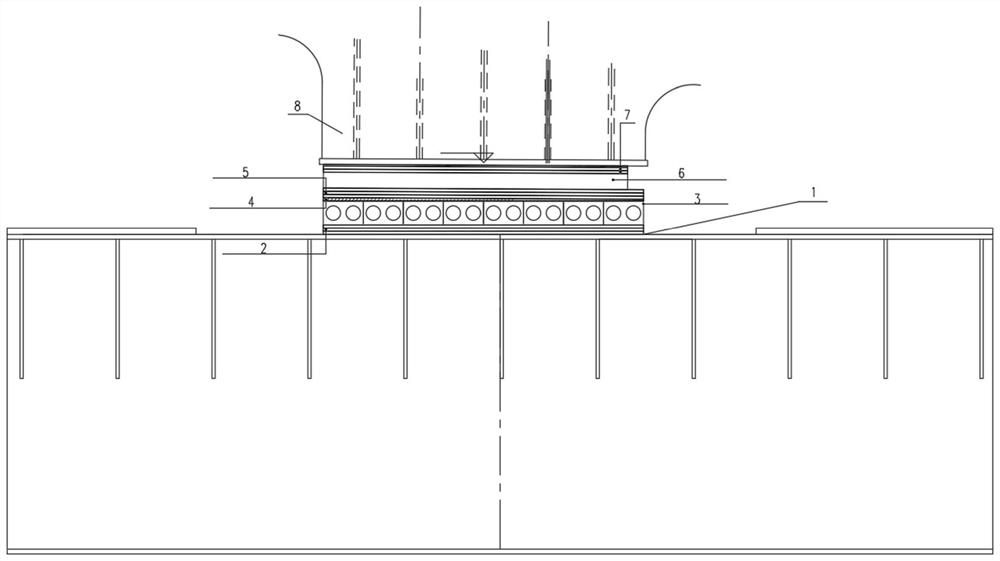

[0039] The present invention will now be further described with reference to the accompanying drawings.

[0043] The plate type rubber bearing should give a suitable plane size (the length and width of the rubber bearing) before processing to make it fully covered

[0045]

[0047] Wedge-shaped steel plate: The wedge-shaped steel plate is a local "fine-tuning" structure of the flexible pad device. Due to the actual erection process and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com