Self-locking steel bar connecting grouting sleeve

A grouting sleeve and self-locking technology, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of less grouting sleeves, low shear bearing capacity, small construction space, etc., to solve eccentricity and sticking Wall problems, accurate radial positioning, and the effect of improving anchorage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

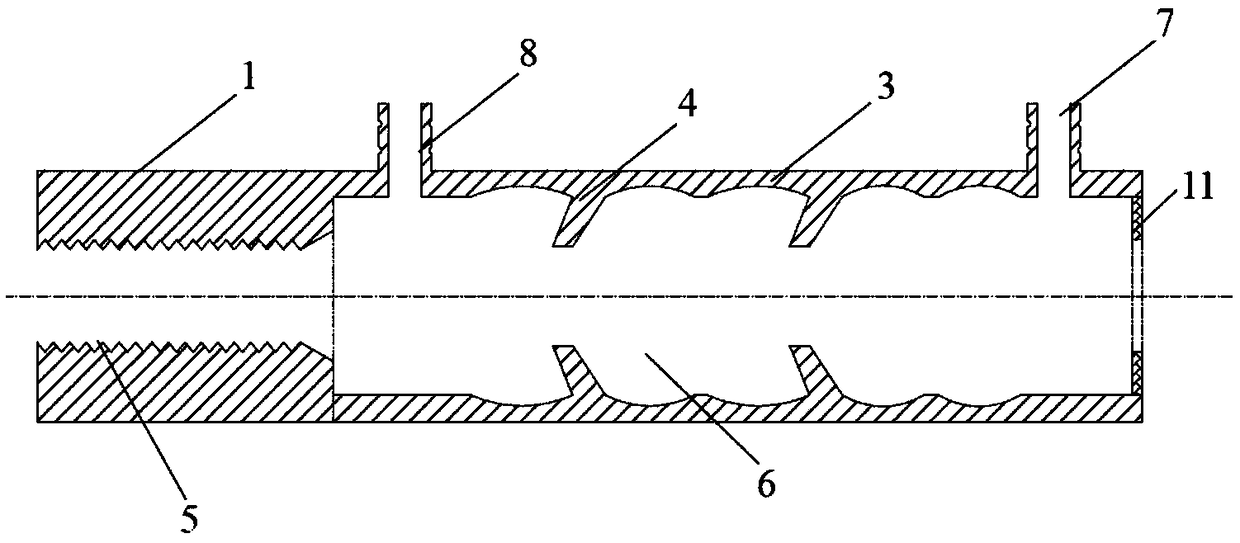

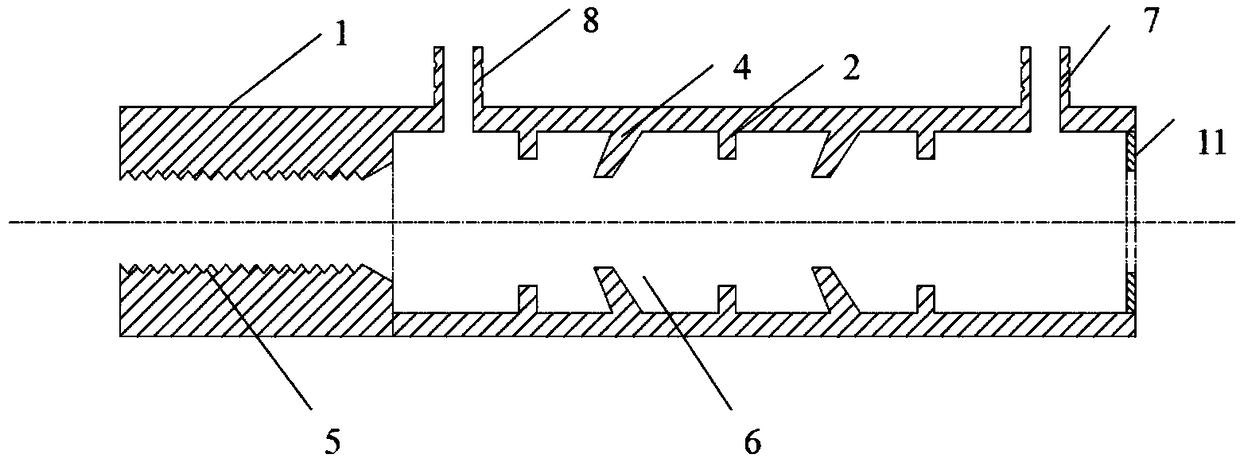

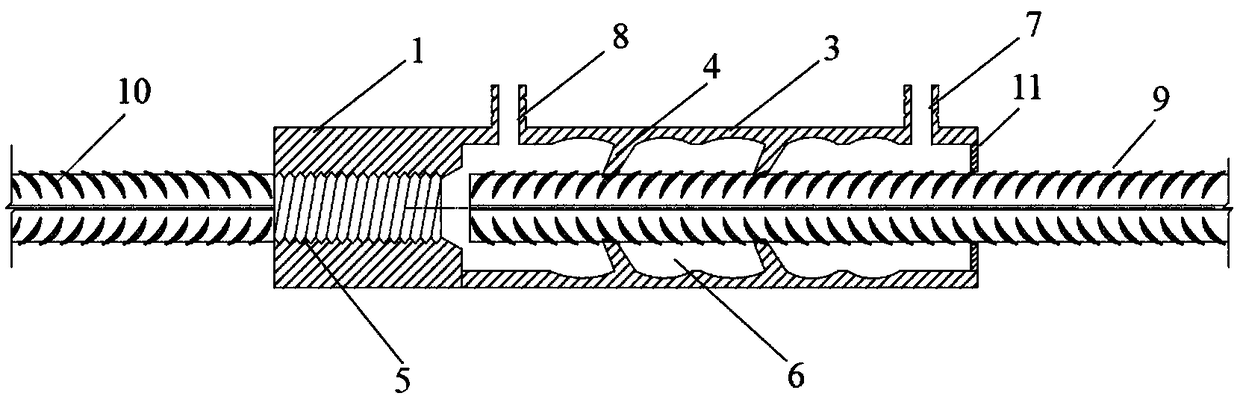

[0026] A self-locking steel bar connection grouting sleeve as shown in the figure includes two different forms of full grouting sleeve and half grouting sleeve. Both the full grouting sleeve and the half grouting sleeve include the sleeve body 1, the sleeve body 1 is provided with a grouting hole 7 and a grouting hole 8, and the sleeve body 1 is provided with a grouting cavity 6, and the grouting cavity 6 communicates with the grouting hole 7 and the grouting hole 8. Ribs 2 or corrugations 3 are set on the inner wall of the grouting cavity 6 to enhance the anchoring performance of the grouting material, and a plurality of tabs 4 are set on the inner wall of the sleeve body 1 . One end of half grouting sleeve has thread 5, and steel bar 10 is connected with thread 5, and threaded connection should meet the requirement of connection strength, especially the connection of larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com