Lens module production device and method of manufacture thereof

A technology of a lens module and a manufacturing method, applied in the field of mobile phone camera lens modules, can solve problems such as uneven fitting, lens skew, lens eccentricity, etc., and achieve the effects of low cost, high quality and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

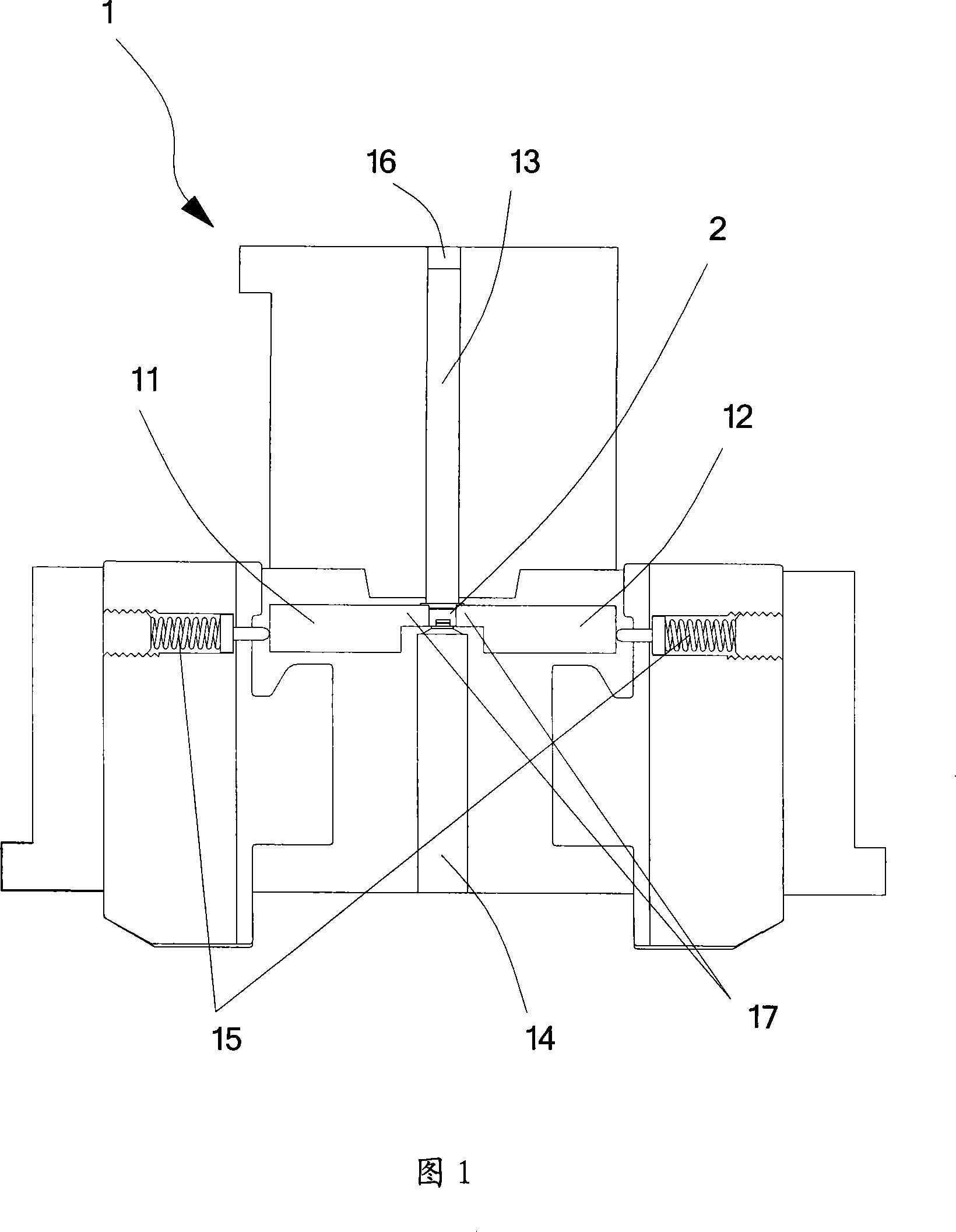

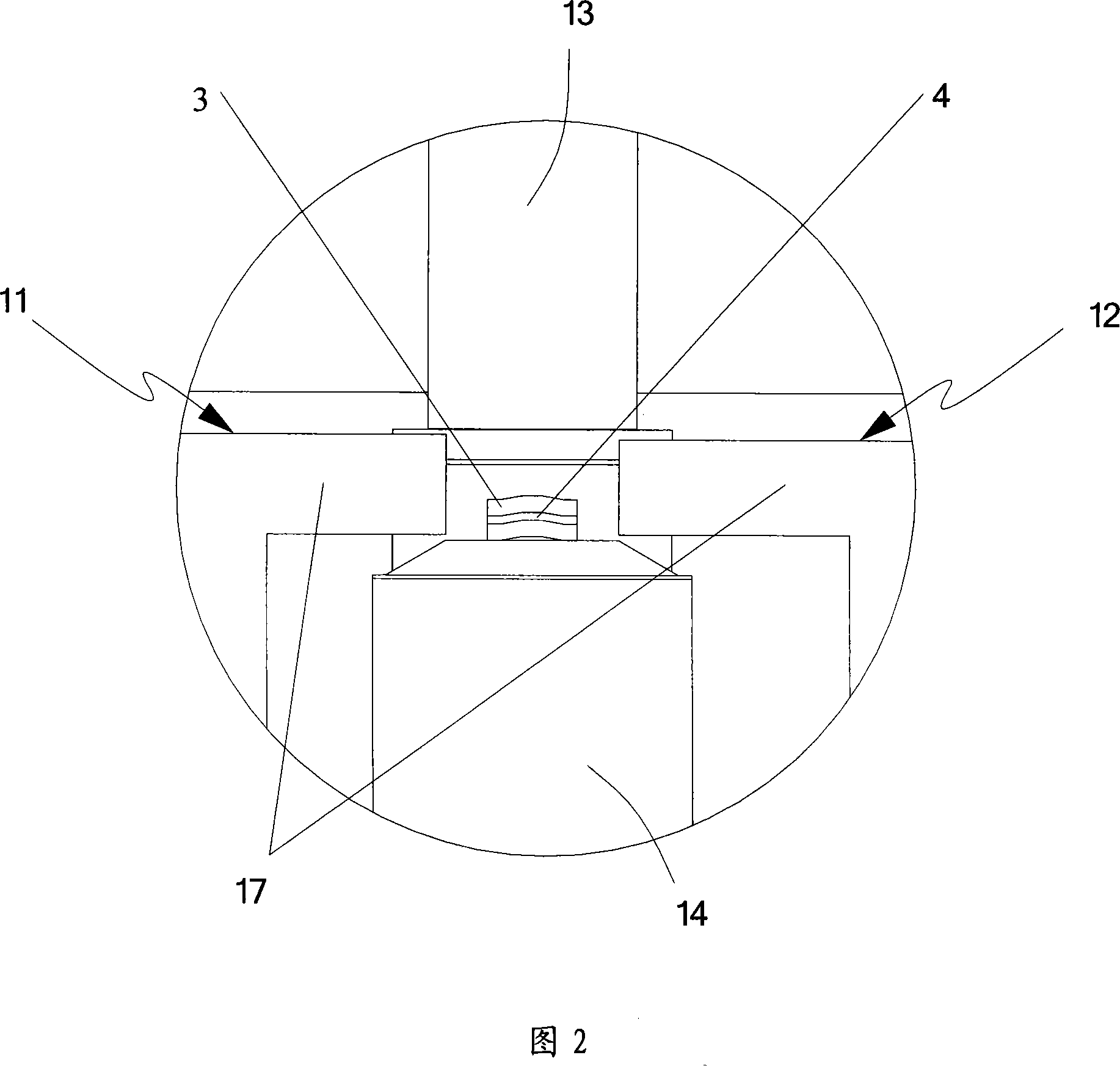

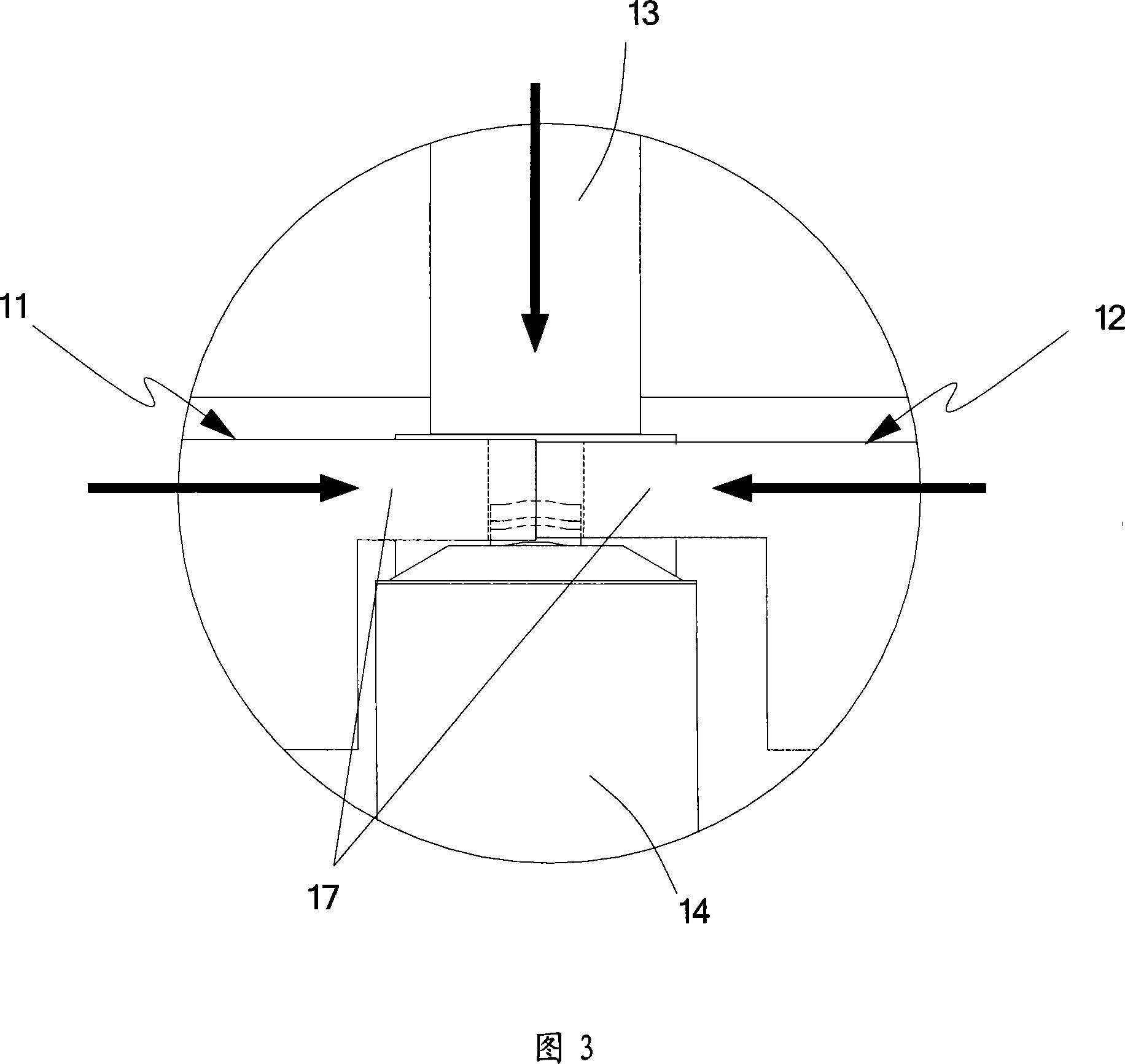

[0021] Please refer to FIG. 1 , which is a schematic structural view of the lens module manufacturing device of the present invention. It can be seen from the figure that the lens module manufacturing device of the present invention at least includes a molding die 1, and the molding die 1 includes a mold cavity 2. 2. Composed of upper and lower film cores 13, 14 and left and right slider film cores 11, 12, a buffer device 16 can be installed above the upper film core 13 or below the lower film core 14 for buffering and adjustment Lens and spacer tolerance, a limit slider 17 can be set at the front ends of the left and right slider film cores 11, 12, and the left and right slider film cores 11, 12 can be designed to be both sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com