Welding fixture and welding method for vacuum tube

A welding fixture and vacuum tube technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of vacuum tube scrapping, affecting production efficiency, wasting manpower and material resources, etc., to ensure performance, simple structure, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

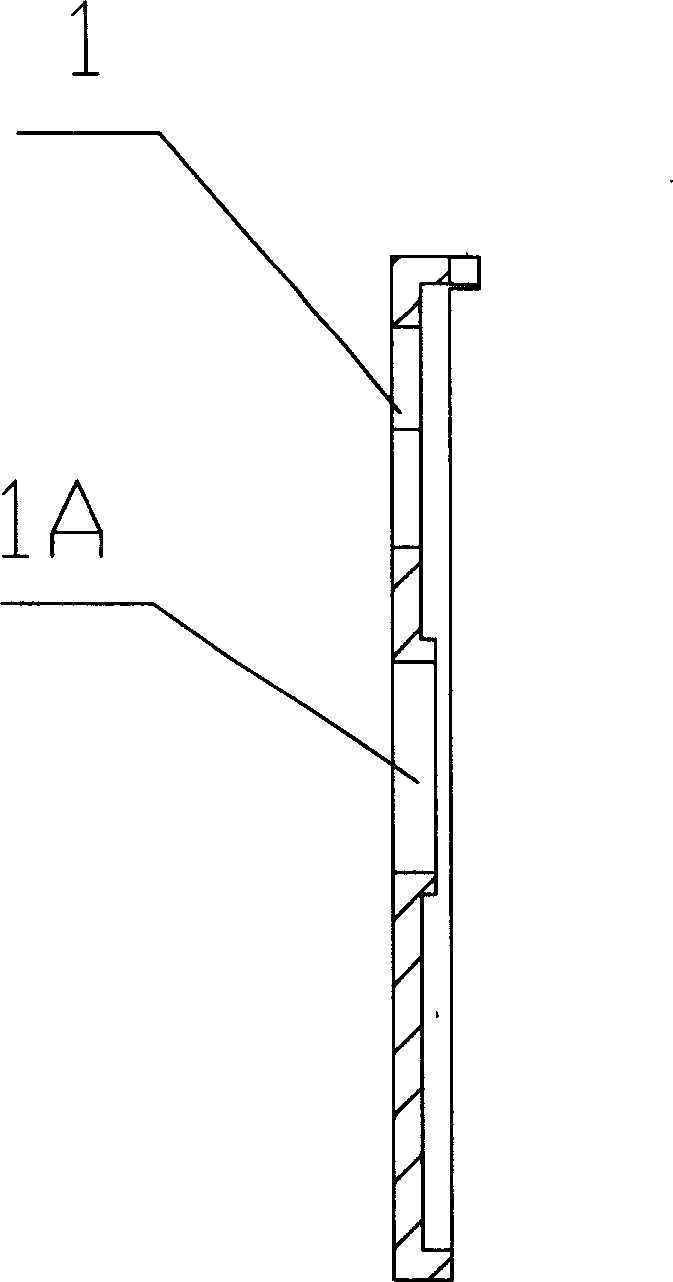

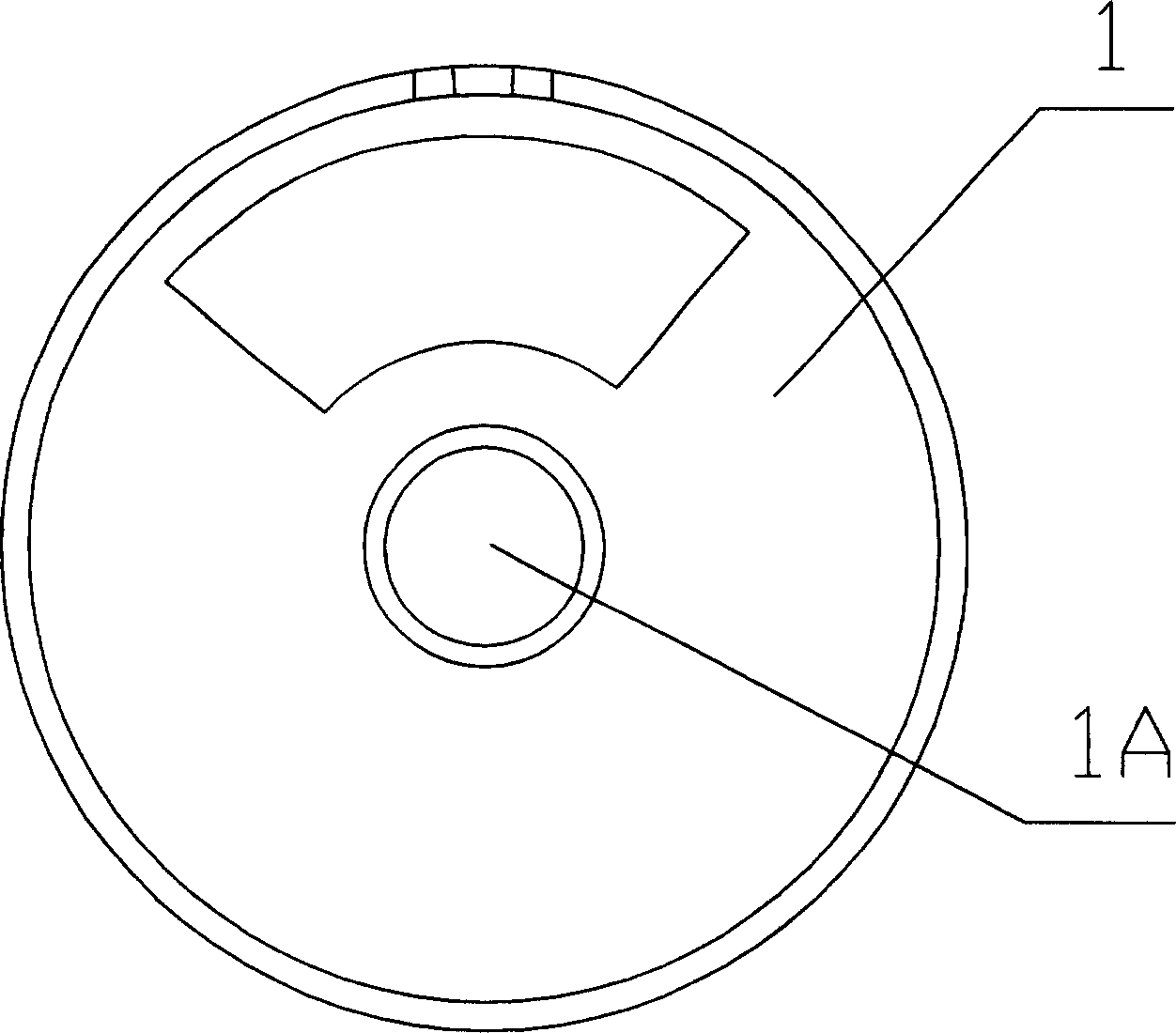

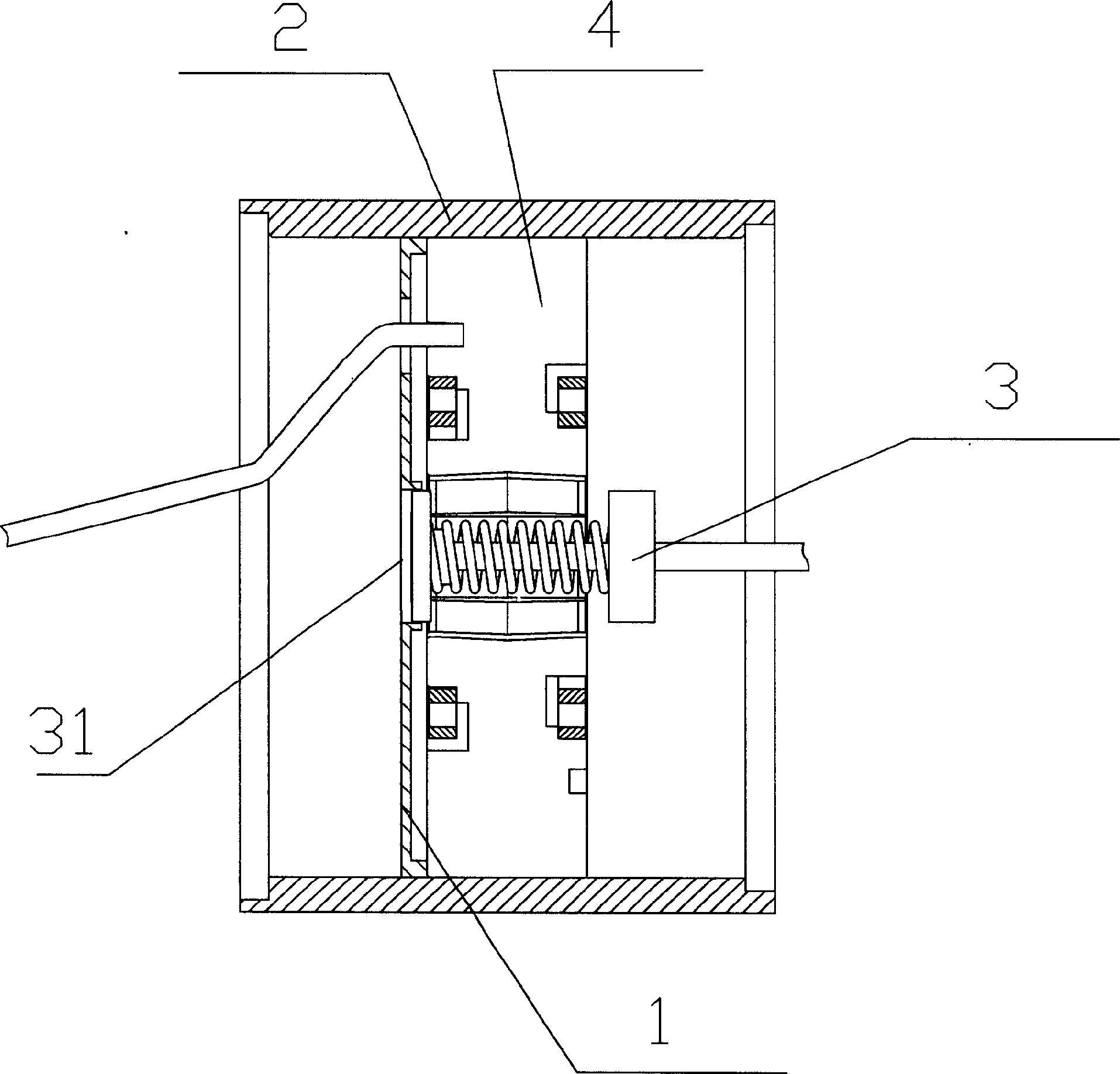

[0015] The present invention is used for the welding jig of vacuum tube, and the outer diameter of the jig 1 made of heat-conducting insulating material is consistent with the inner diameter of the anode cylinder 2, and the middle part of the jig 1 is provided with a through hole 1A concentric with its outer diameter, and the diameter of the through hole 1A is the same as the inner diameter of the anode cylinder 2. The outer diameters of the shielding covers 31 in the filament assembly 3 are consistent.

[0016] The present invention uses above-mentioned welding jig 1 to carry out the method for vacuum tube welding, comprises the following steps:

[0017] 1) Put the clamp 1 whose outer diameter is consistent with the inner diameter of the anode cylinder 2 in the anode cylinder 2;

[0018] 2) Put the shielding cover 31 in the filament assembly 3 into the through hole 1A provided in the middle of the fixture 1 and concentric with its outer diameter;

[0019] 3) Welding the fila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com