Patents

Literature

30results about How to "Resolve twist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

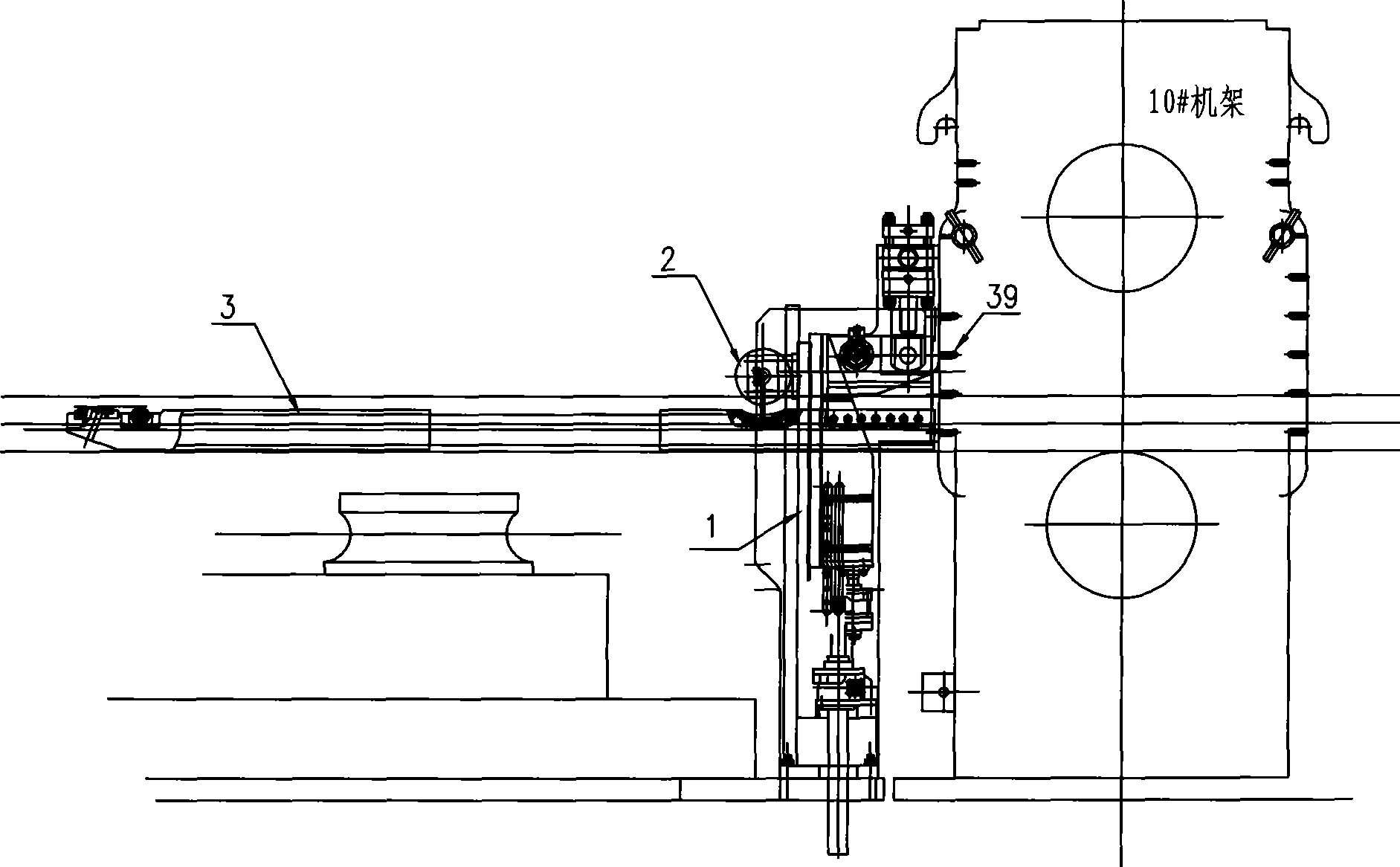

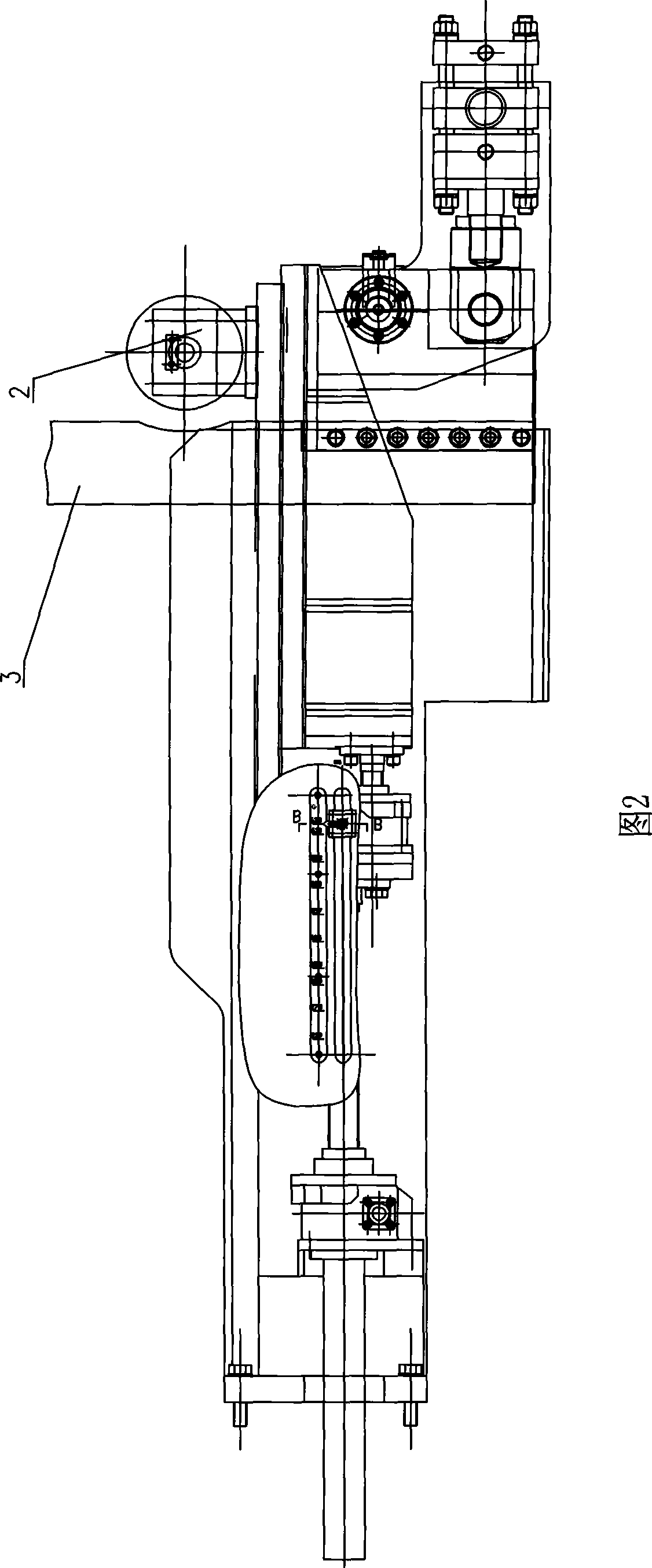

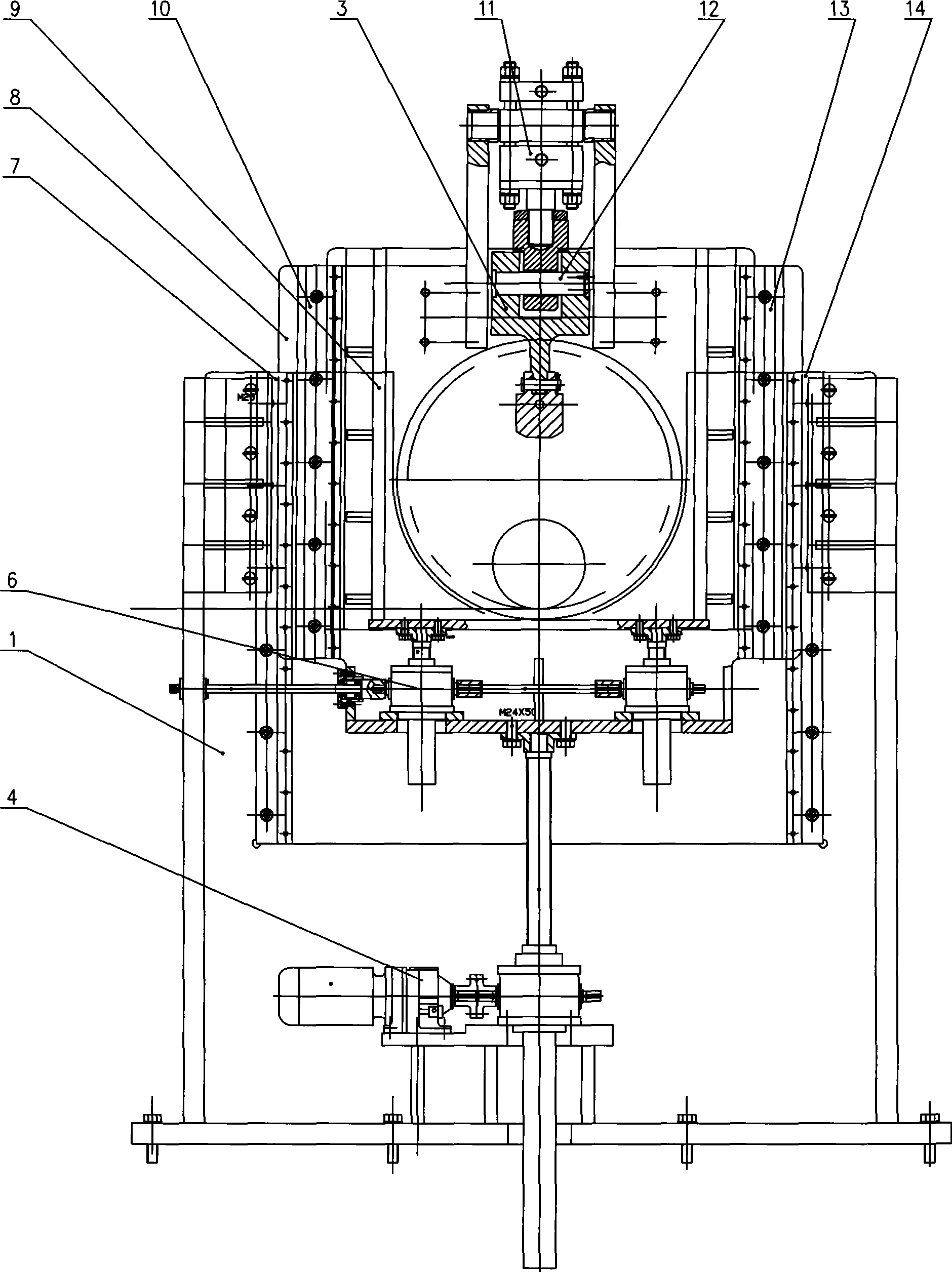

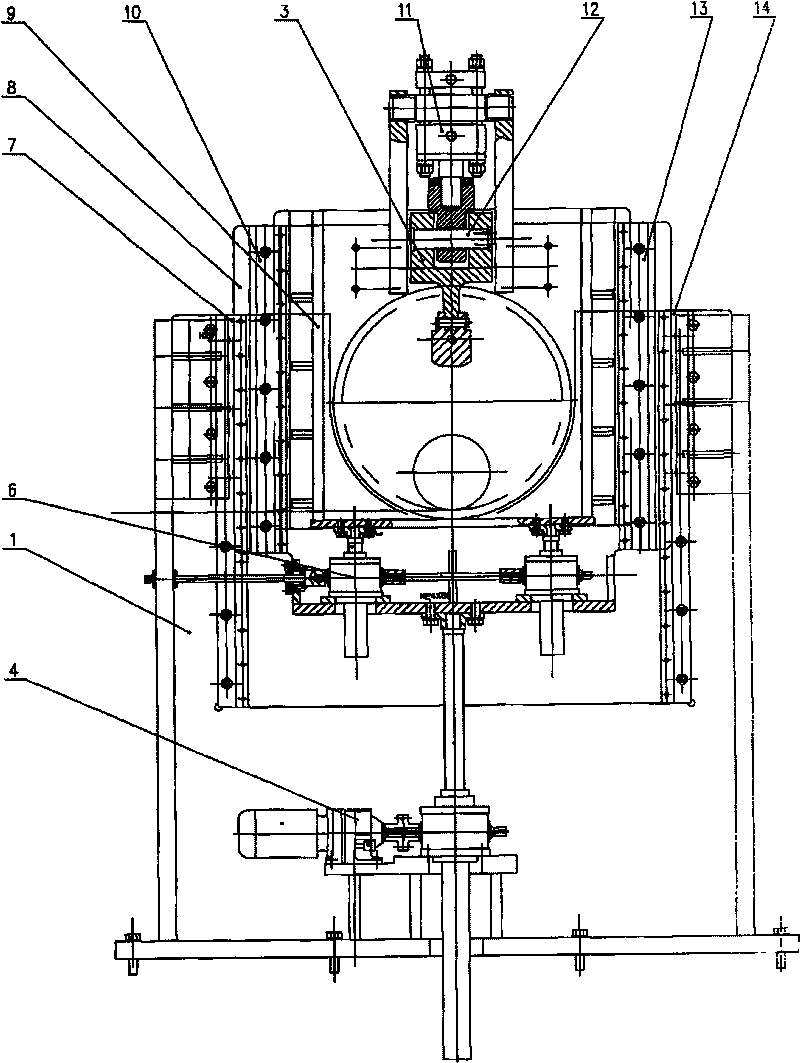

Four-line segmentation rolling technology of deformed steel bar with diameter of 10mm

ActiveCN103071674AIncrease productionReduce labor intensityRollsMetal rolling arrangementsSteel barUltimate tensile strength

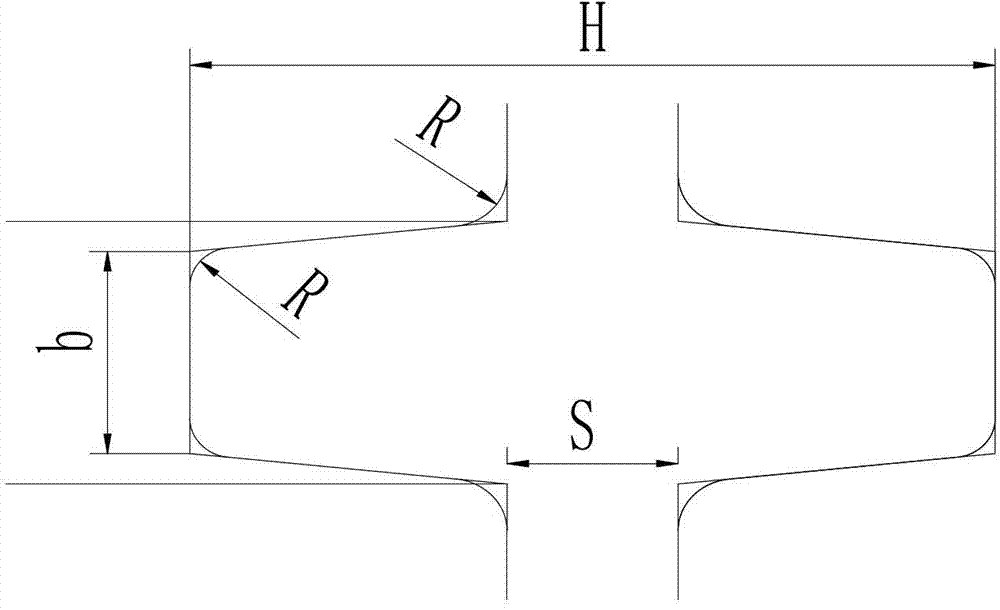

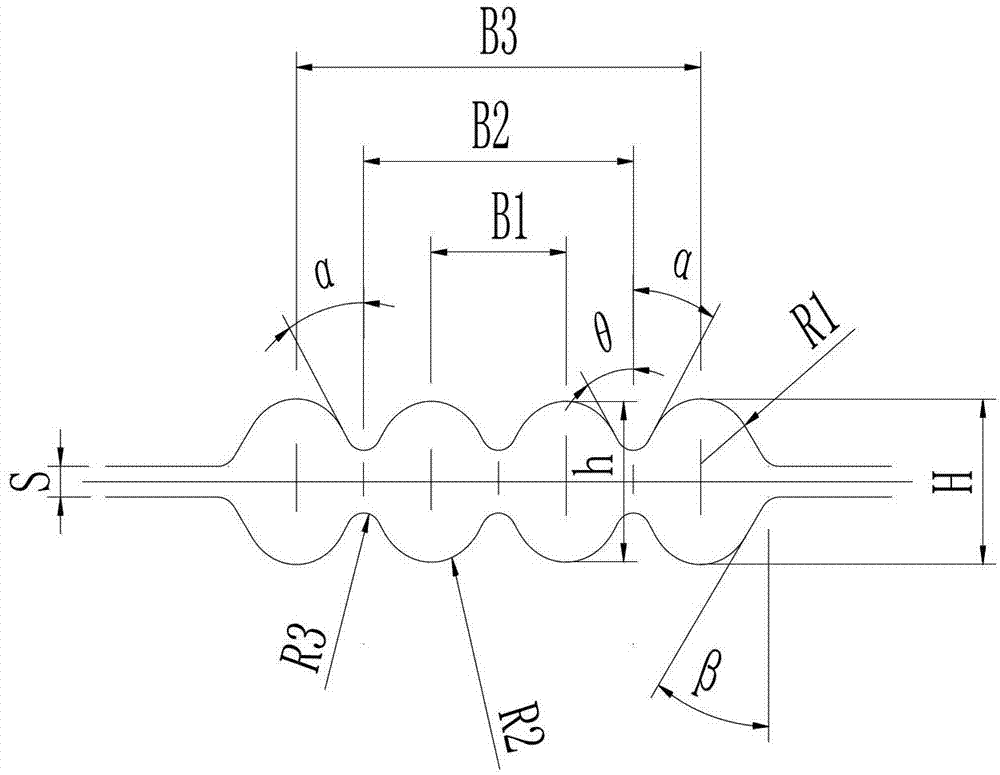

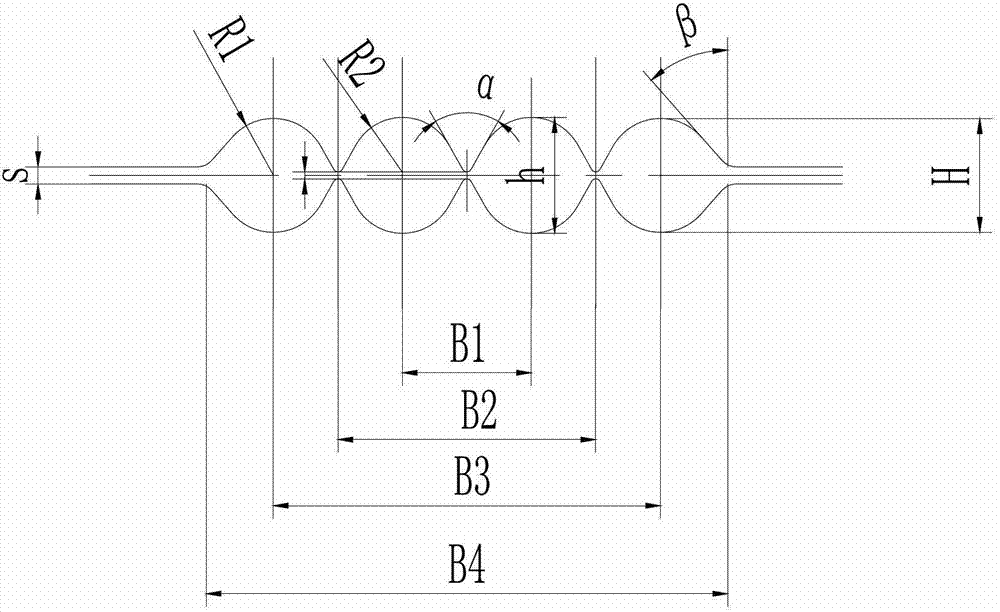

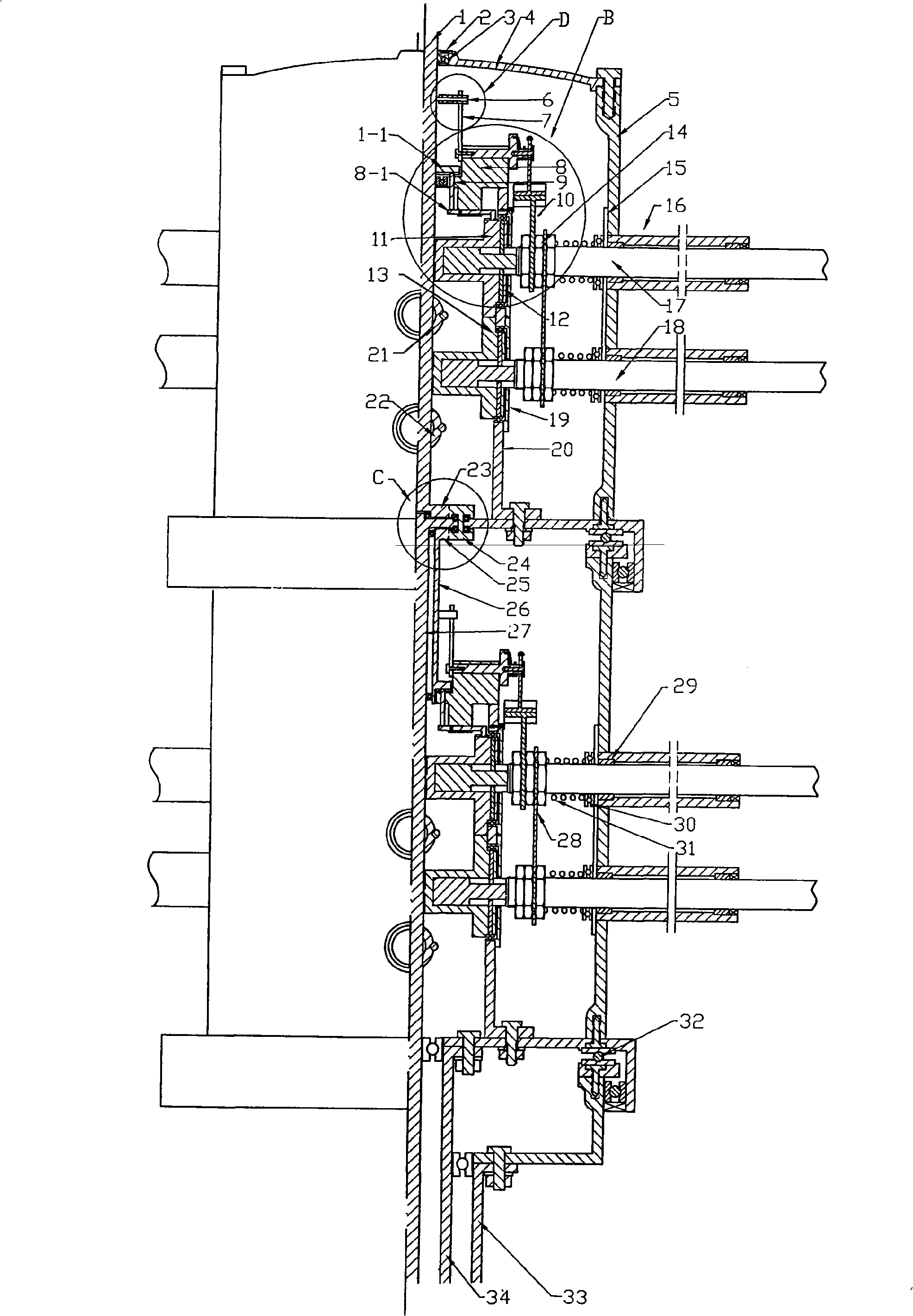

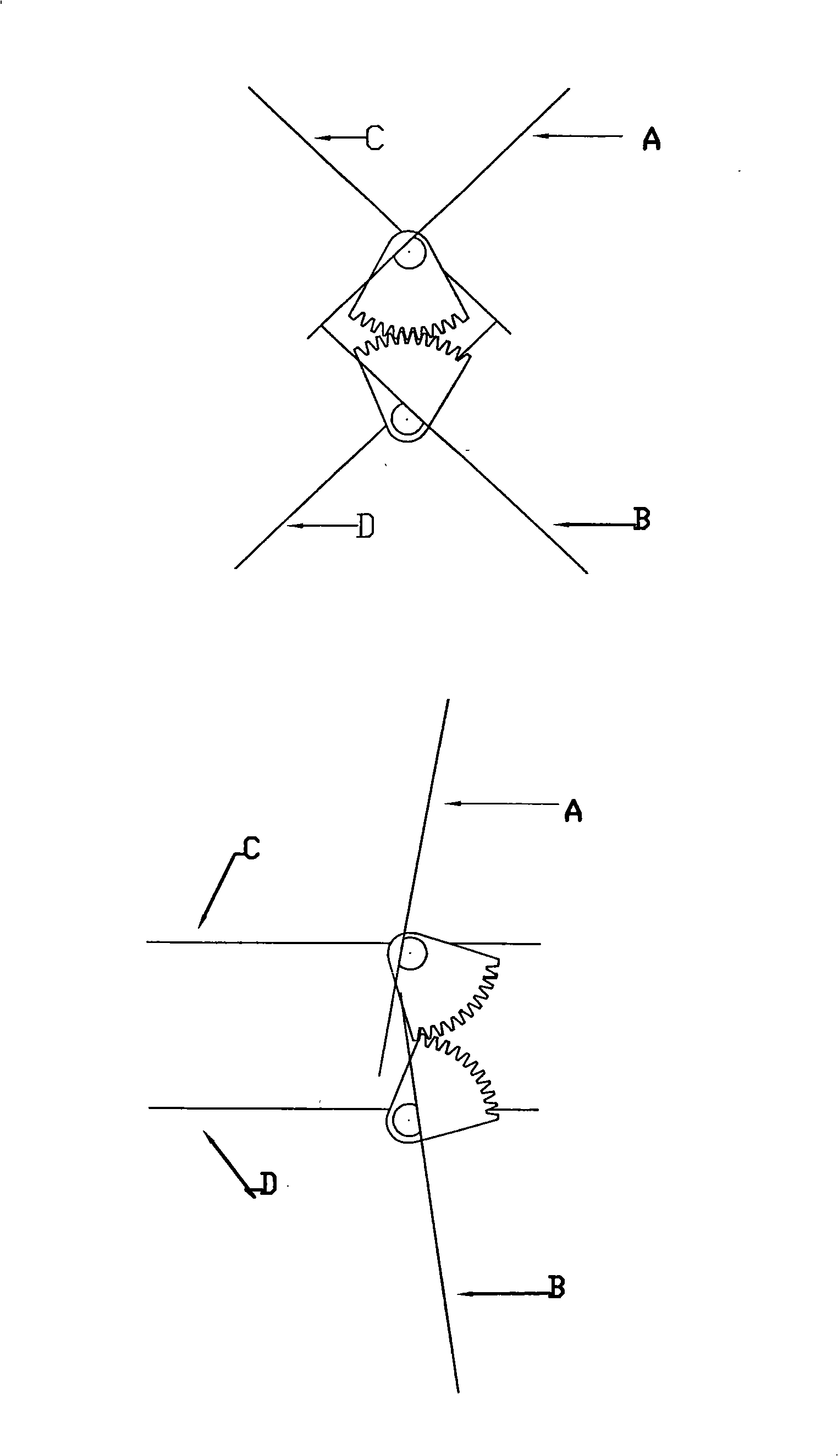

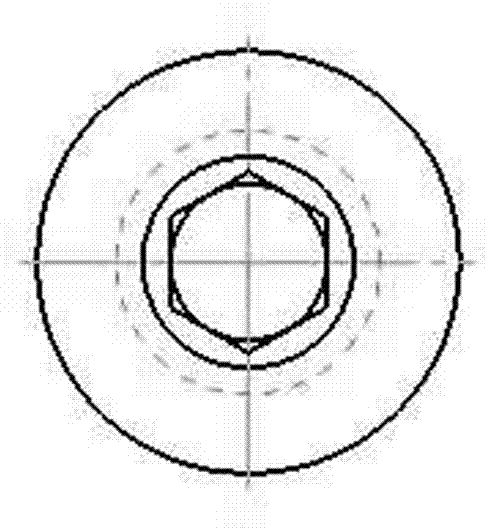

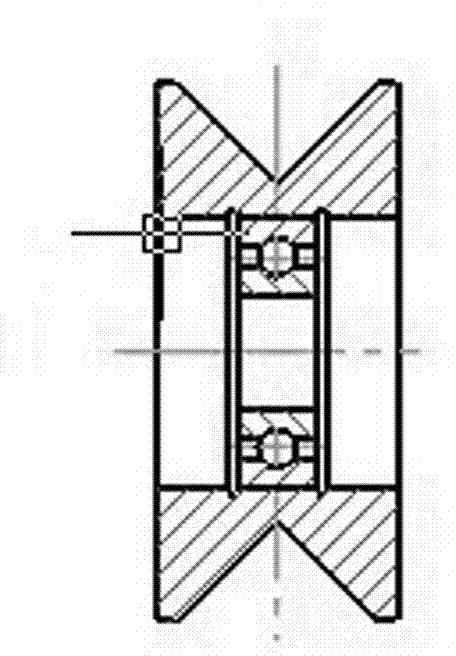

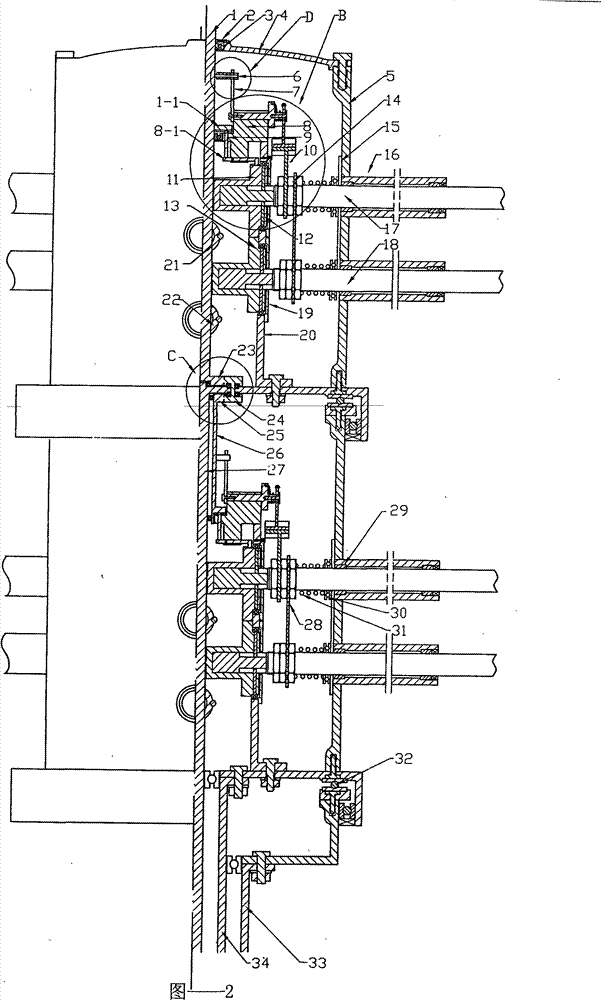

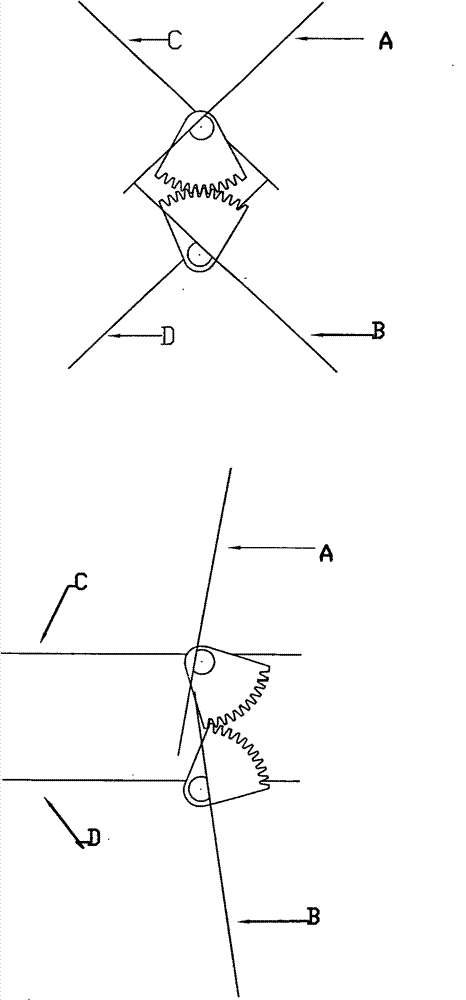

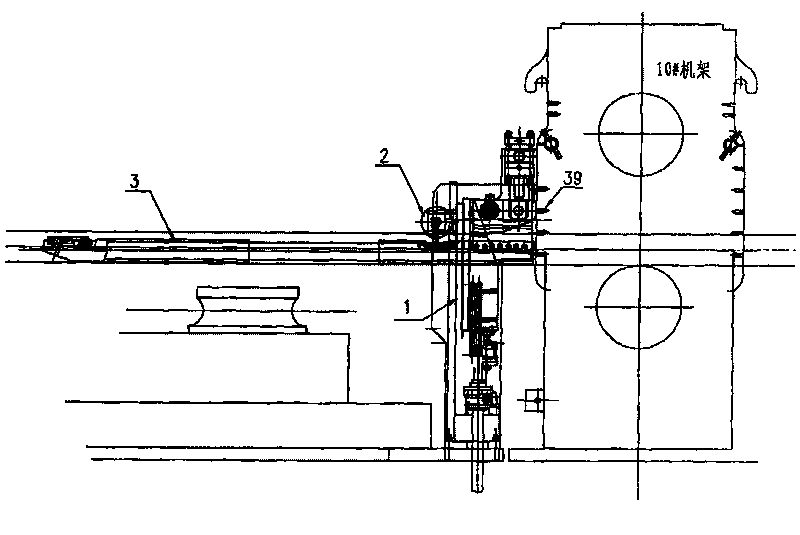

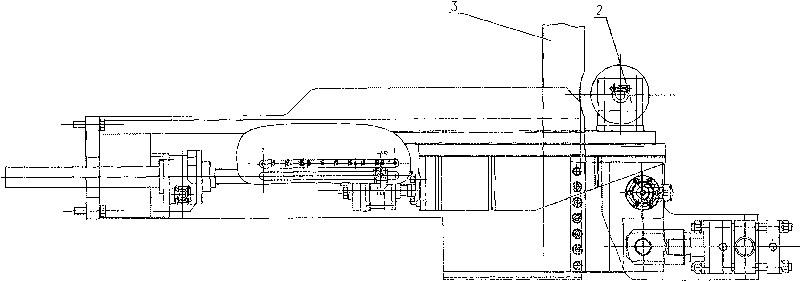

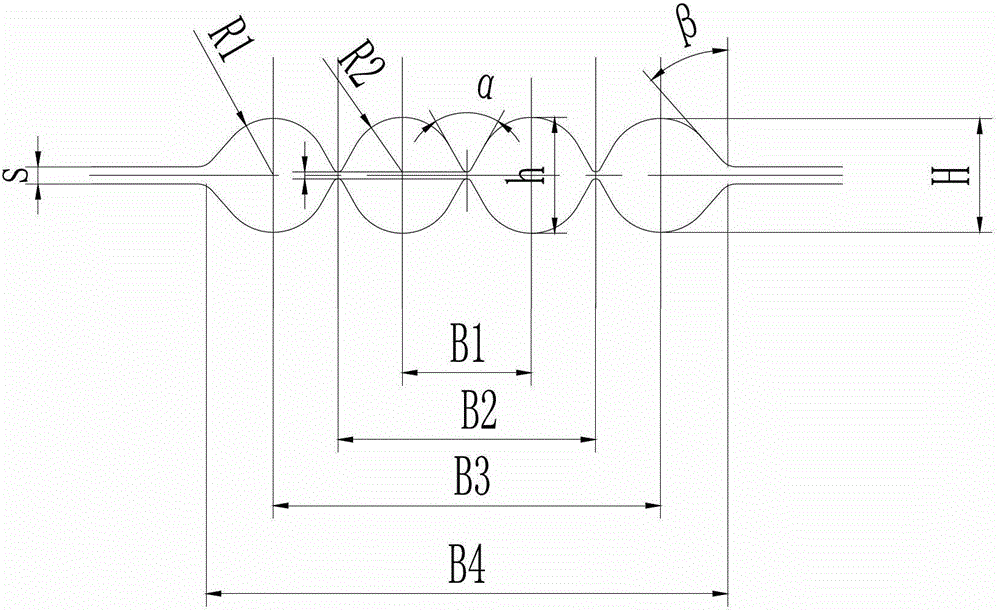

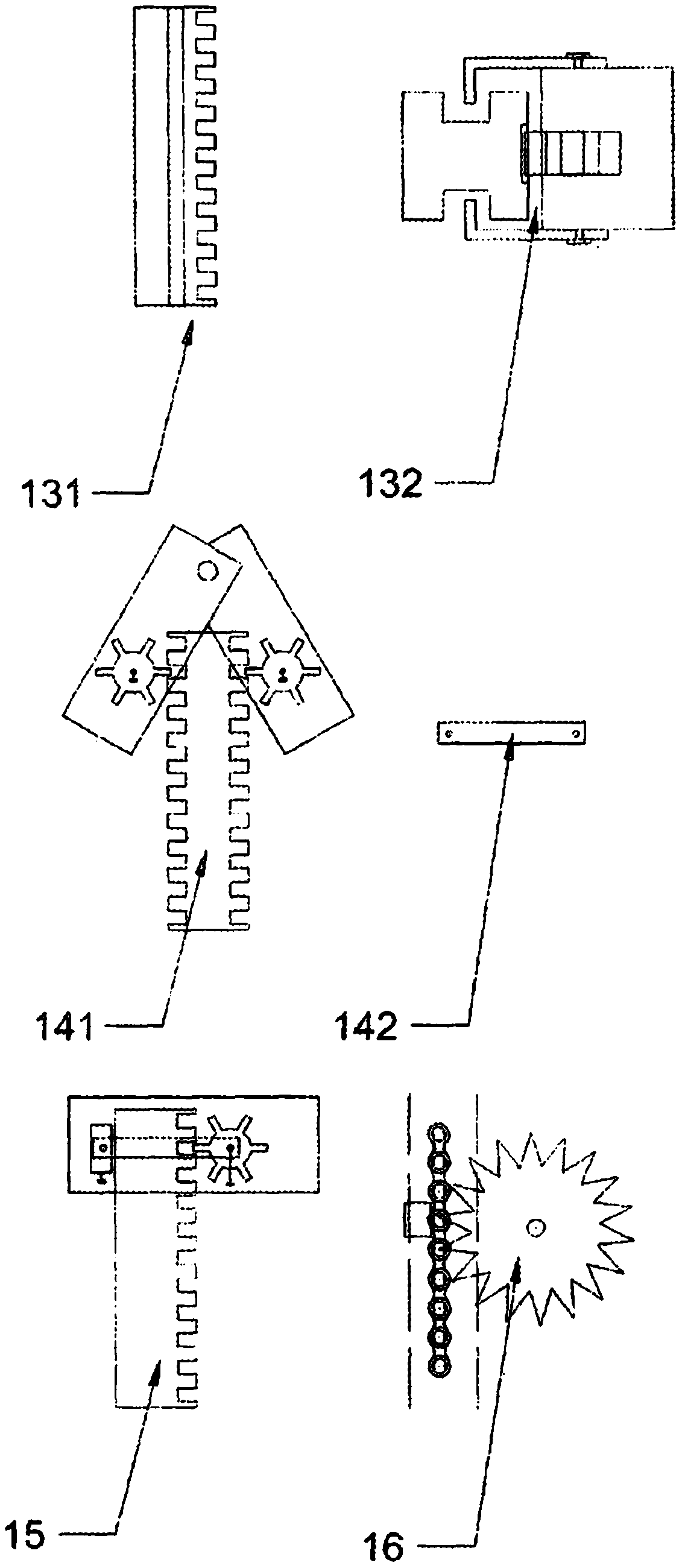

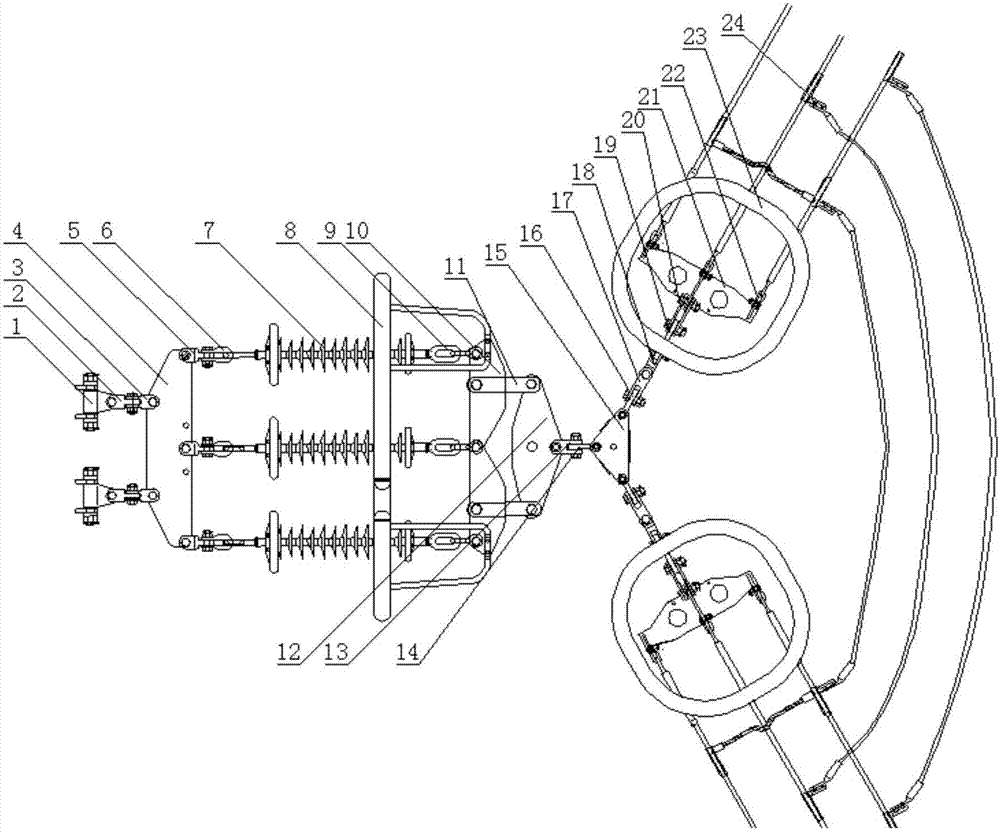

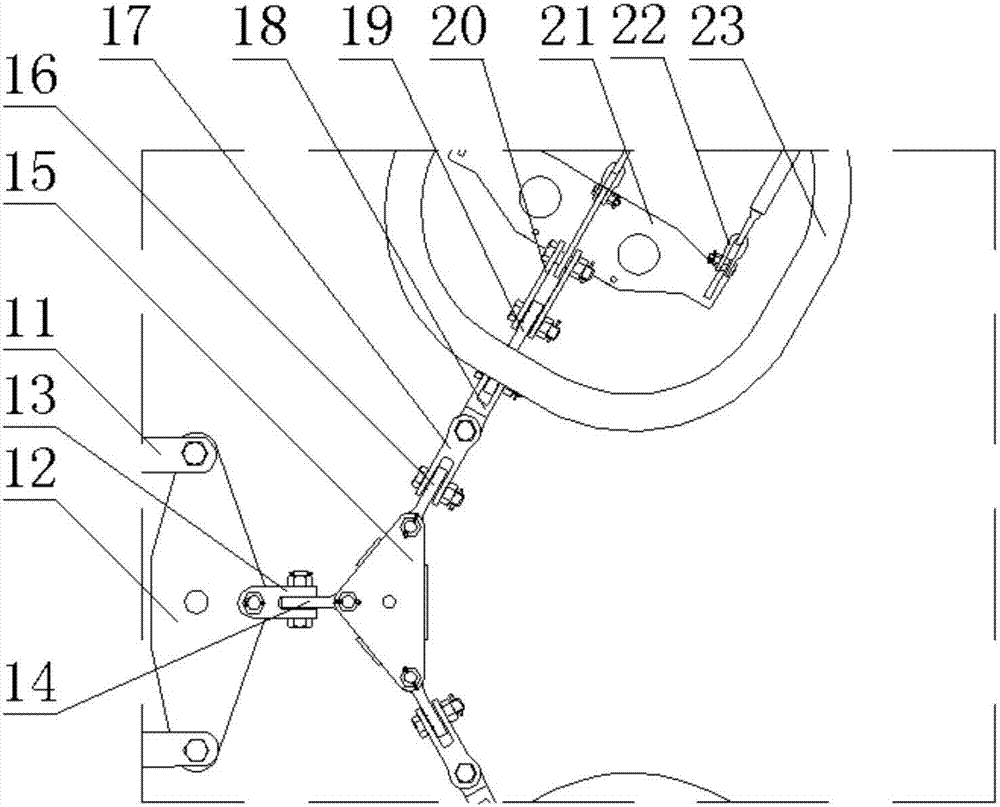

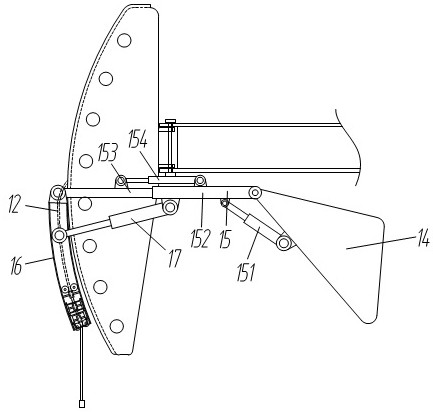

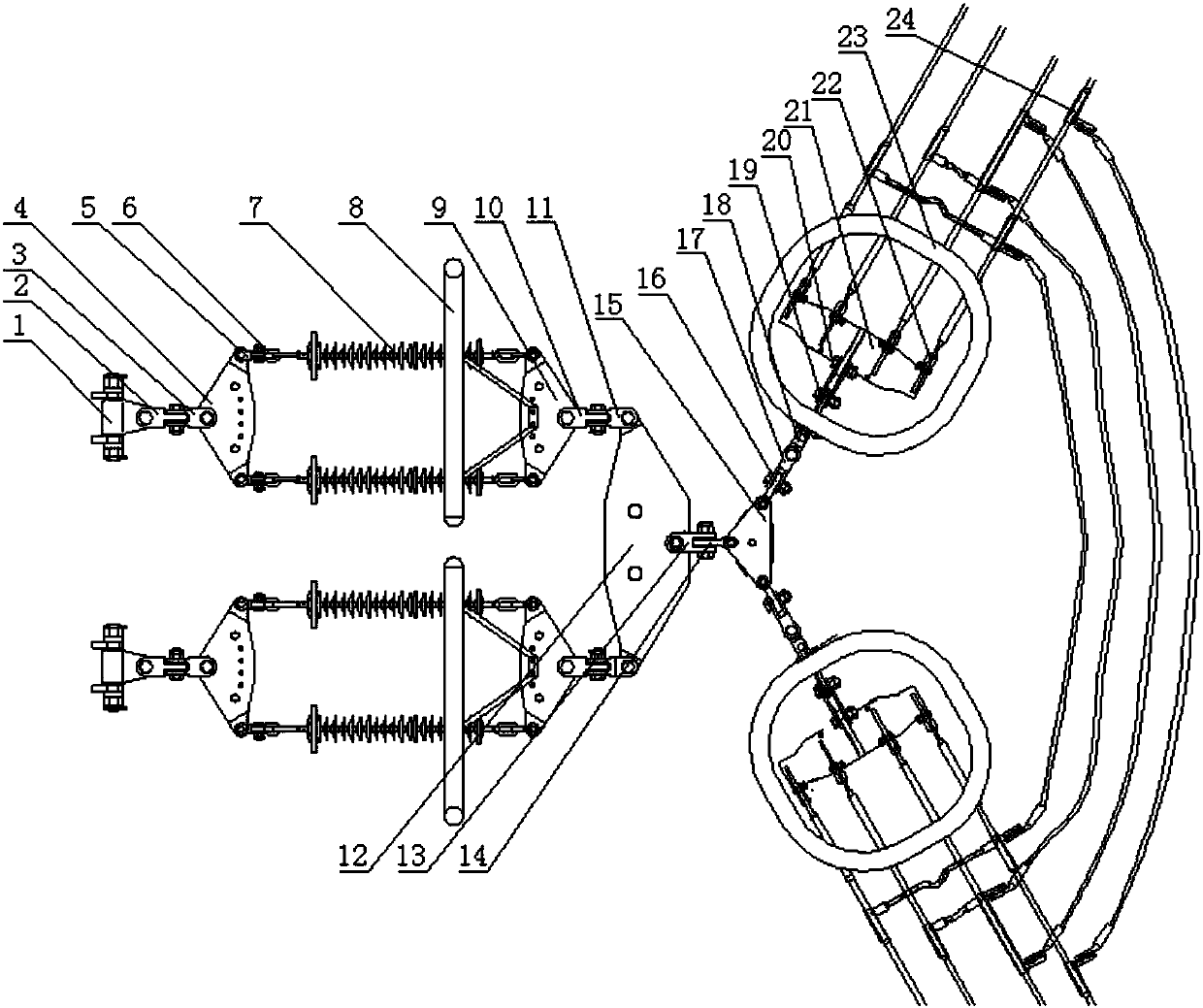

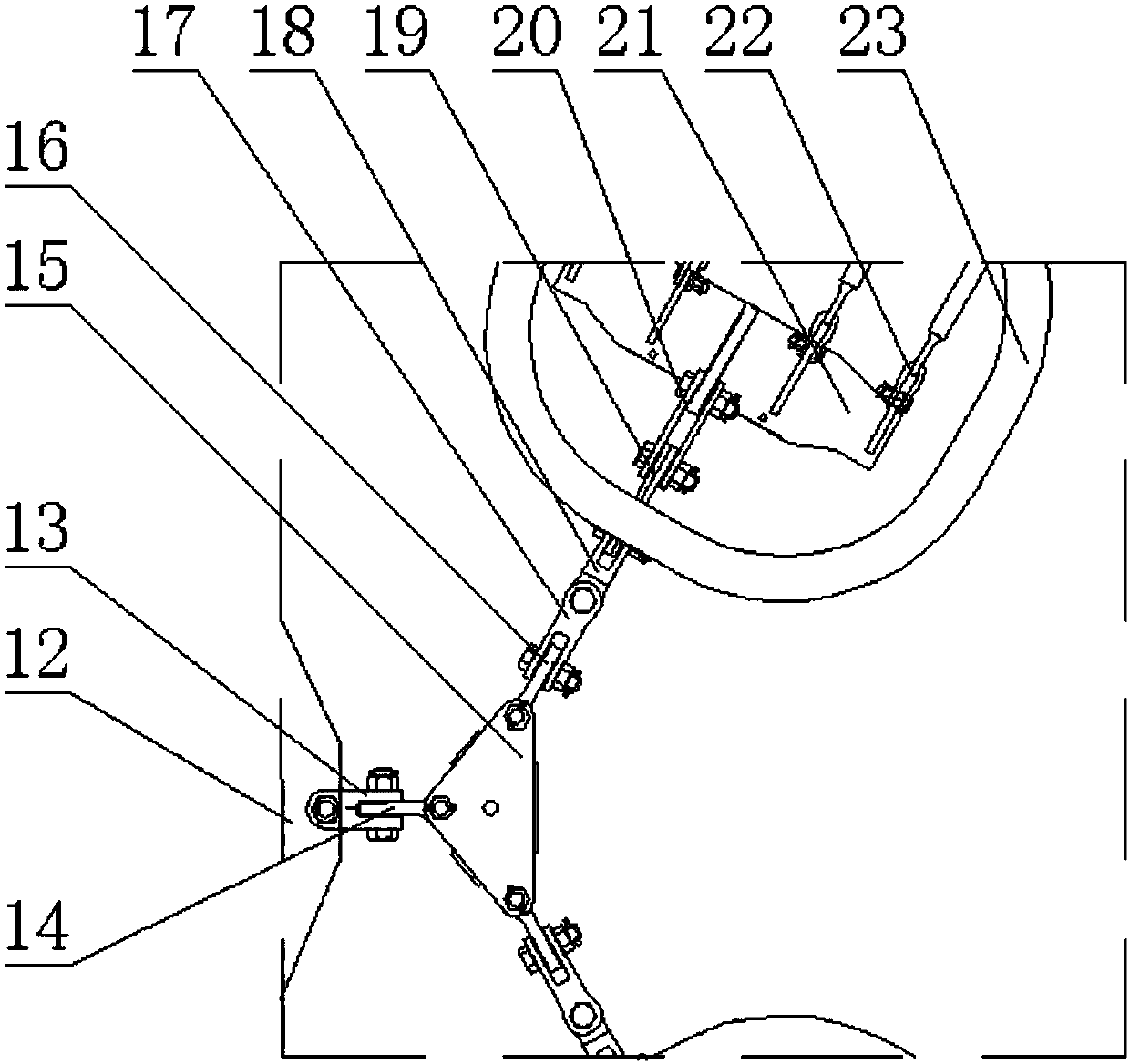

The invention relates to a four-line segmentation rolling technology of a deformed steel bar with a diameter of 10mm, and the technology is characterized in that 150 square billets are sequentially rolled by six rough rolling units and 8 medium rolling units, rolled pieces are machined into flat steel, the rolled pieces then enter a fine rolling unit 15H to be machined into 0.4-mm dog-bone-shaped rolled pieces with the size of the middle part being smaller than that of the two sides, the rolled pieces enter a 16 H / V frame rolling machine for segmentation in a centering way, because the distance of two middle holes is identical in the design of the pre-segmentation and a segmentation hole, the rolled pieces under the pre-segmentation can be precisely centered in the segmentation hole, the rolled pieces are rolled into four parallel-connection rolled pieces with a ligament of 0.7mm, then the four parallel-connection rolled pieces are subjected to three-time segmentation through a front segmentation wheel and a rear segmentation wheel, which are installed on a 16 H / V outlet, then the two middle parallel-connection rolled pieces are twice cut into four independent rolled pieces, the four rolled pieces respectively and individually enter a roll groove passage of 17H and 18H / V frame rolling machines to be respectively rolled into four deformed steel bar finished products with the diameter of 10mm, the same size and the same shape. Through the technology, the yield per hour of the deformed steel bar with the diameter of 10mm is increased, the production cost is reduced, the production efficiency is increased, and the labor intensity of operators is alleviated.

Owner:TIANJIN IRON & STEEL GRP

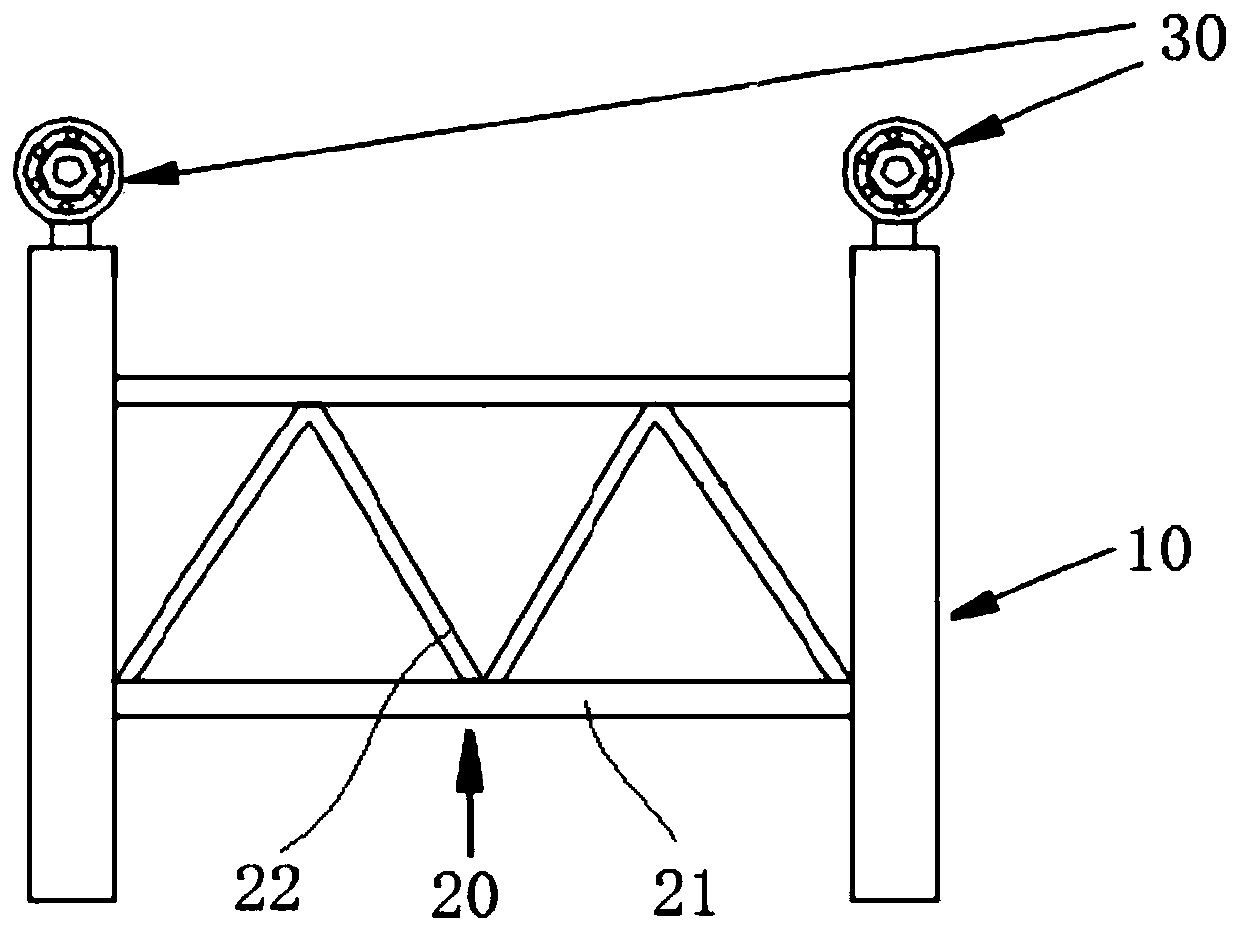

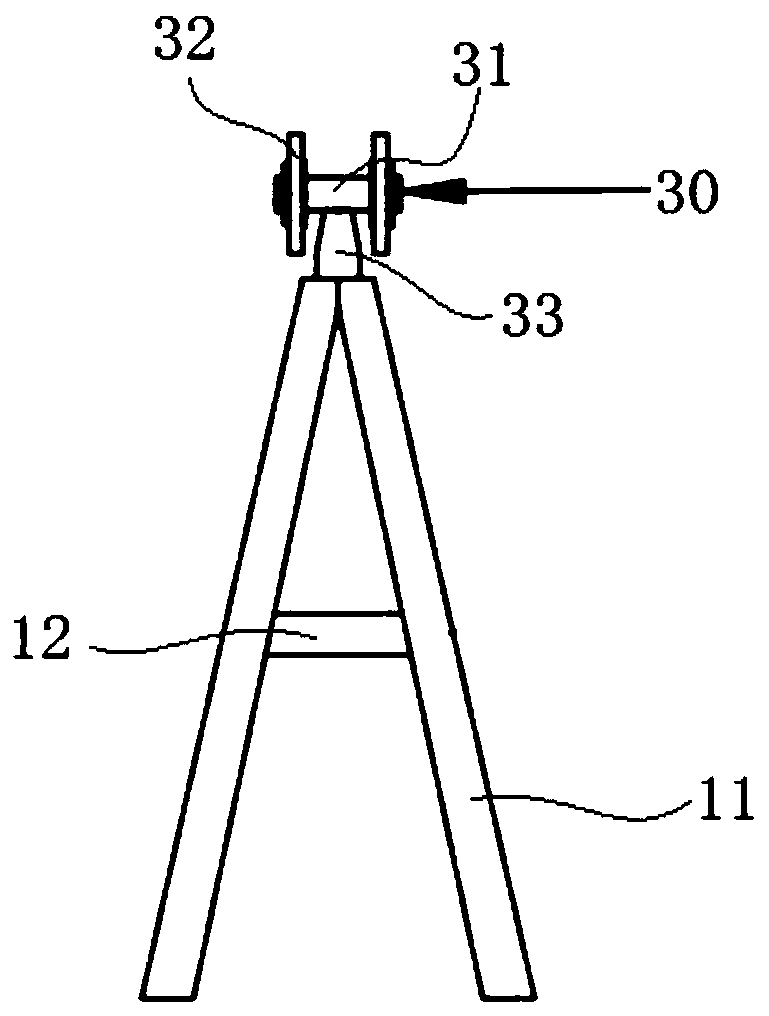

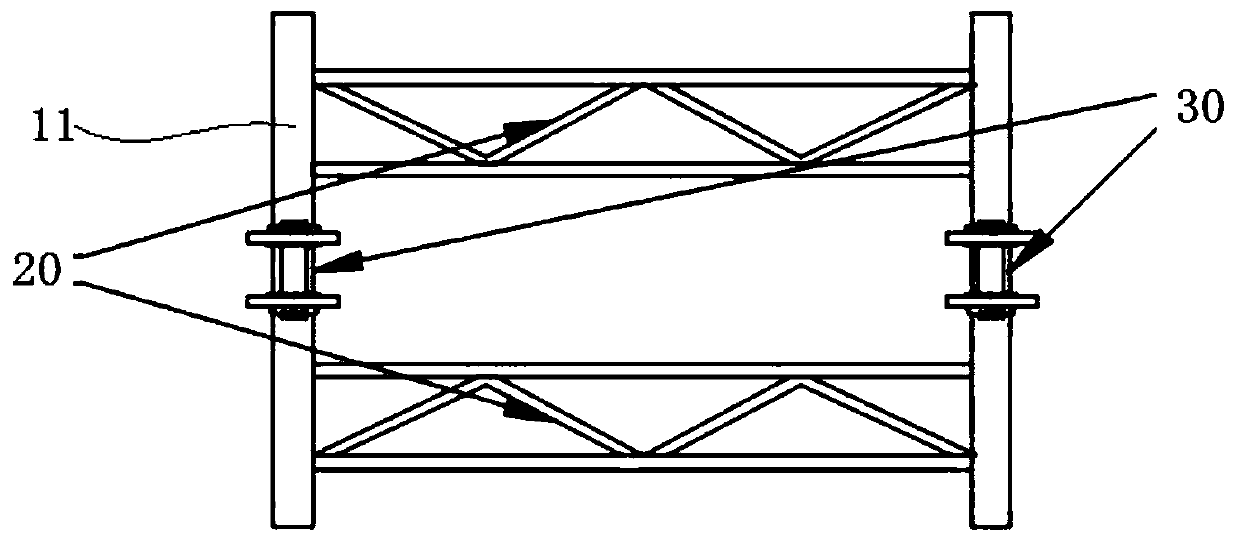

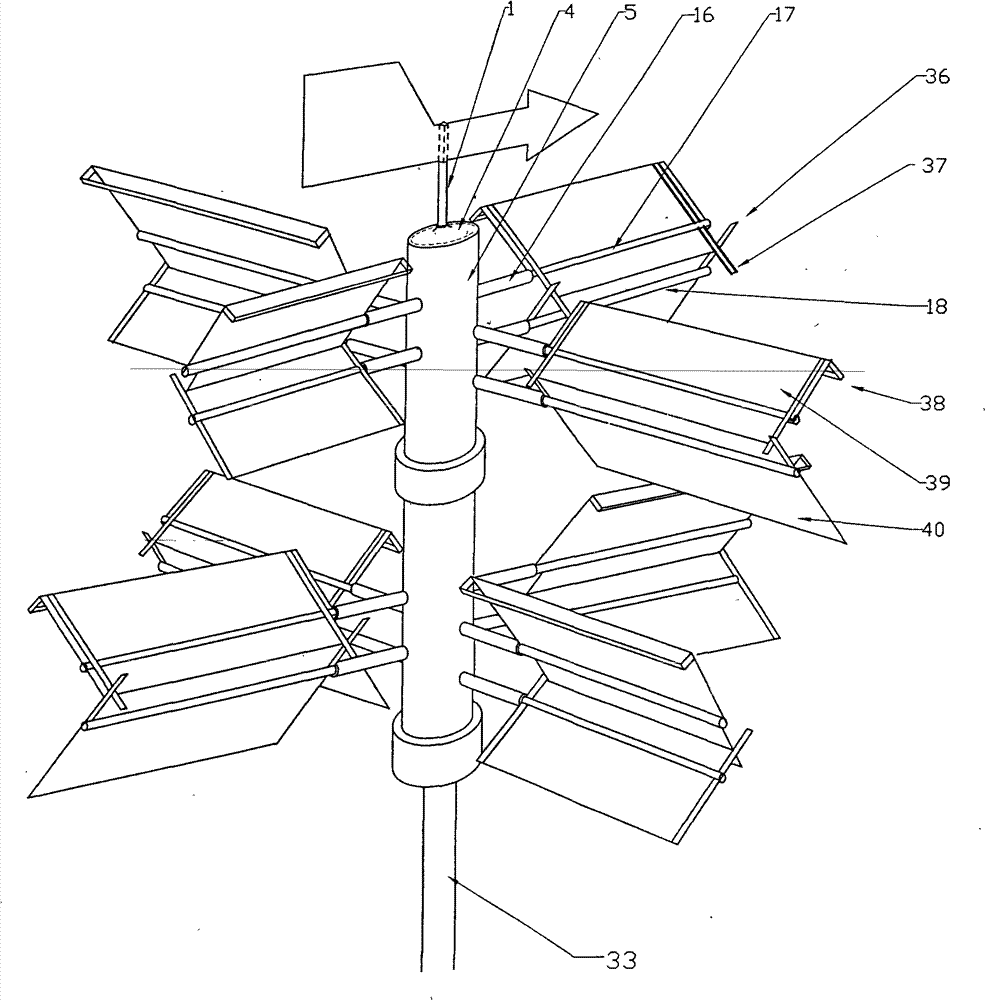

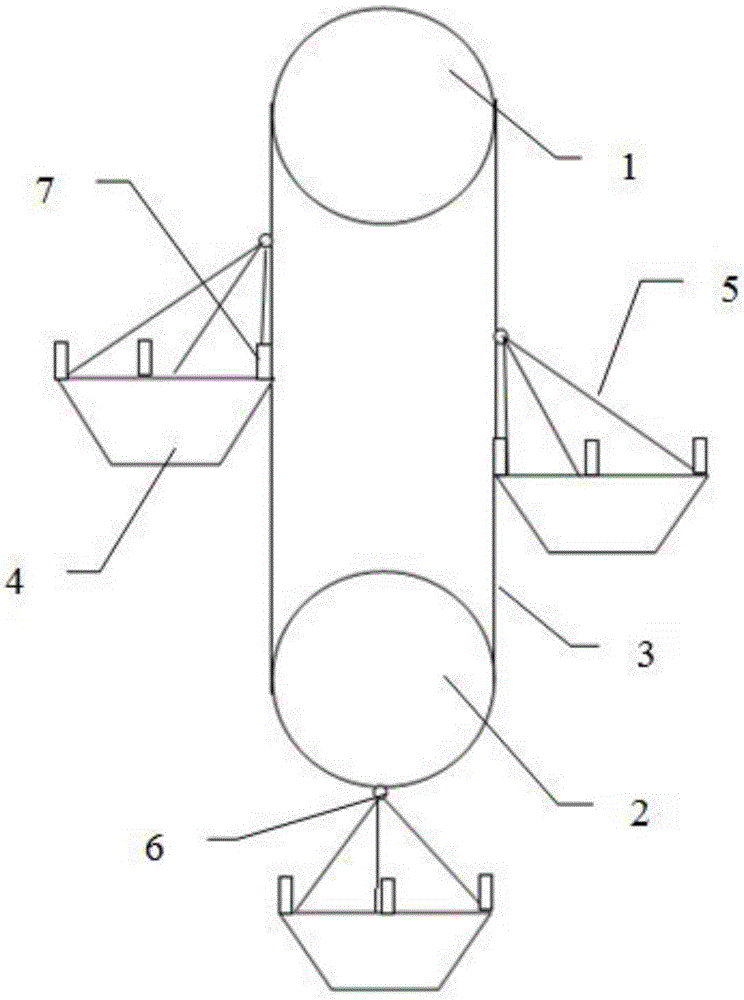

Double-layer reverse rotation vertical-shaft wind-power machine using horizontal combination active wing

ActiveCN101493071AImprove efficiencyCost-effectiveWind motor controlFinal product manufactureWinding machineEngineering

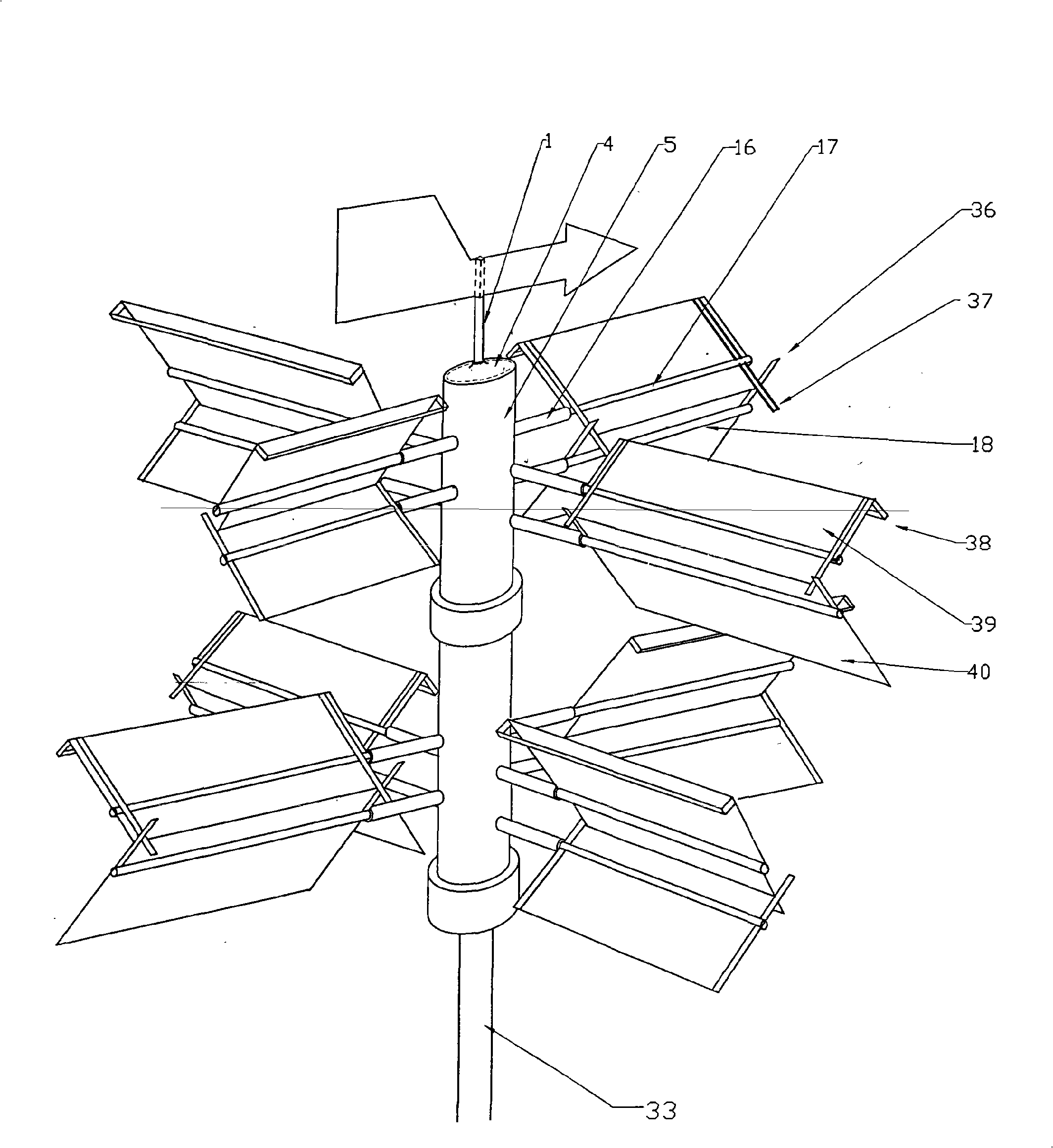

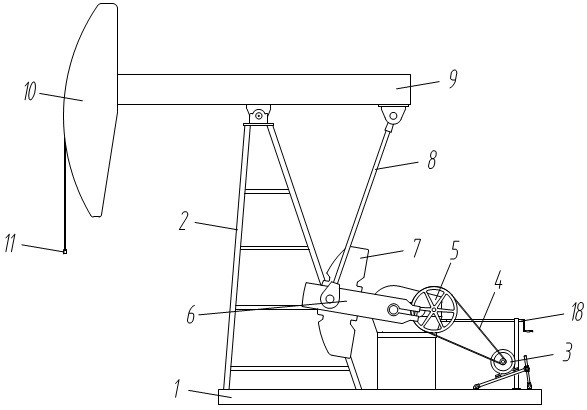

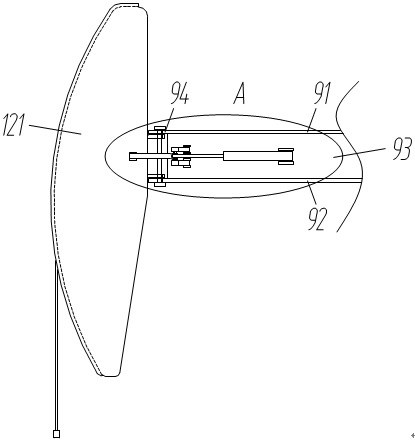

The invention discloses a novel vertical spindle wind machine which is mainly formed by support devices, vanes and the like that are respectively arranged on an upper layer and a lower layer and are almost completely the sane as each other; the wind machine also comprises a movable wing link gear, a speed governing device, a rhachis, a locating device, a limiting device, an auxiliary limiting device and an auxiliary starting device. The movable wing link gear adopts a labile equilibrium form to lead the vane group to easily open and shut, so as to not only ensure the best holding state, but also reduce the requirements for the manufacturing materials, thus greatly improving the cost performance of the wind machine; the machine adopts simple and effective mode of mechanical speed regulation, so as to absolutely ensure the service life of the wind machine; all movable linking parts of the machine are in a state of sealing, so that rain, snow dust and sand are avoided damaging the wind machine; as the machine is designed to be a form of double-layer reverse rotation, the utilization rate of wind energy can be improved, and the torsional force of the whole machine can be reduced; meanwhile, the machine is provided with a device which can keep the whole machine flat, so that the whole machine can be easily put down when being necessary, and the novel vertical spindle wind machine is more suitable for ships. When in design, the processing technique and installation technique are fully taken into consideration, so that the invention is suitable for commercial process.

Owner:王肇泰

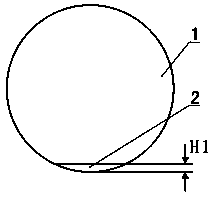

Novel dephosphorization wheel set

InactiveCN102825533AResolve twistSolve problems such as stuckGrinding machinesEngineeringMechanical engineering

Owner:TAIZHOU HONGRUI NEW MATERIAL

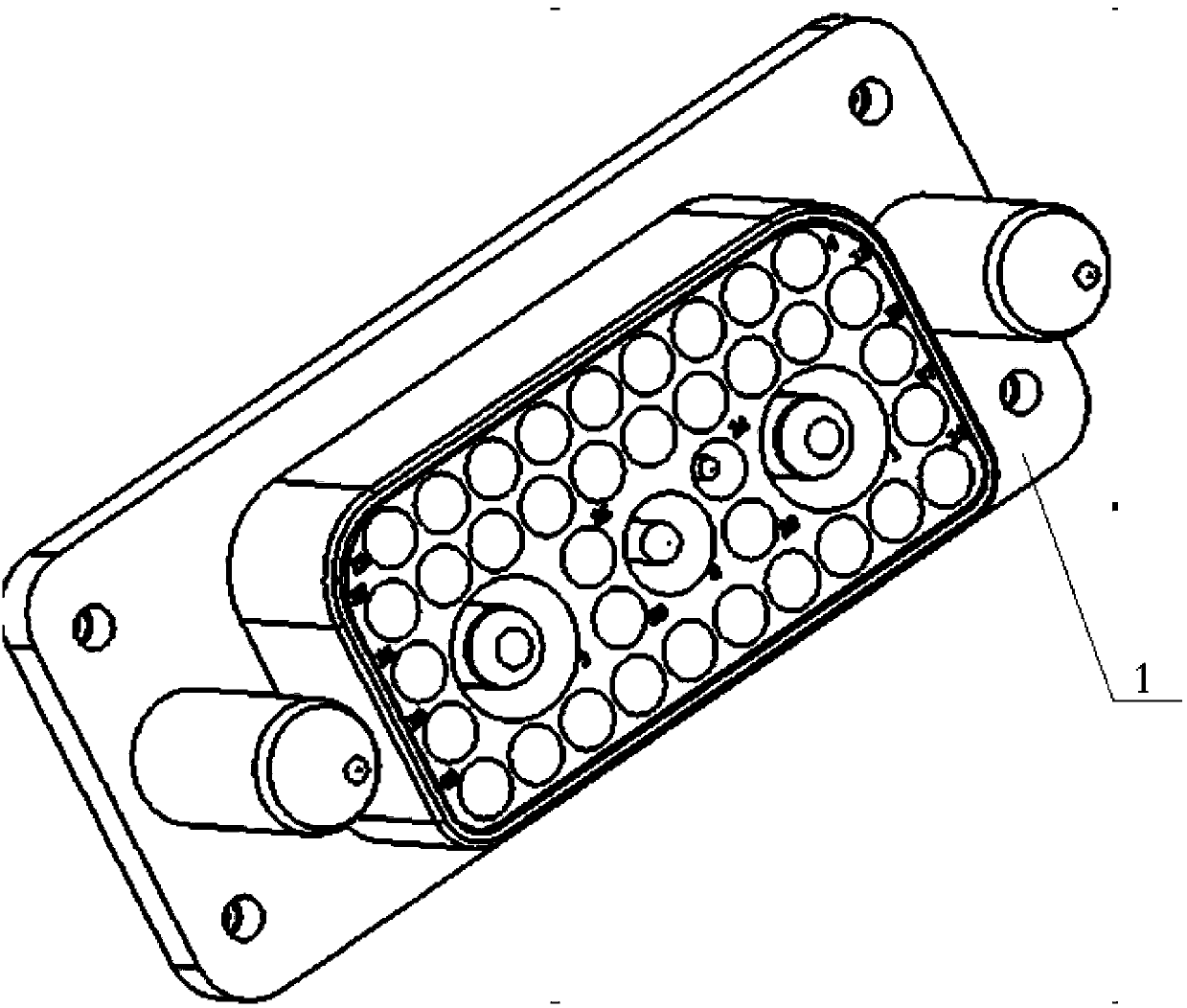

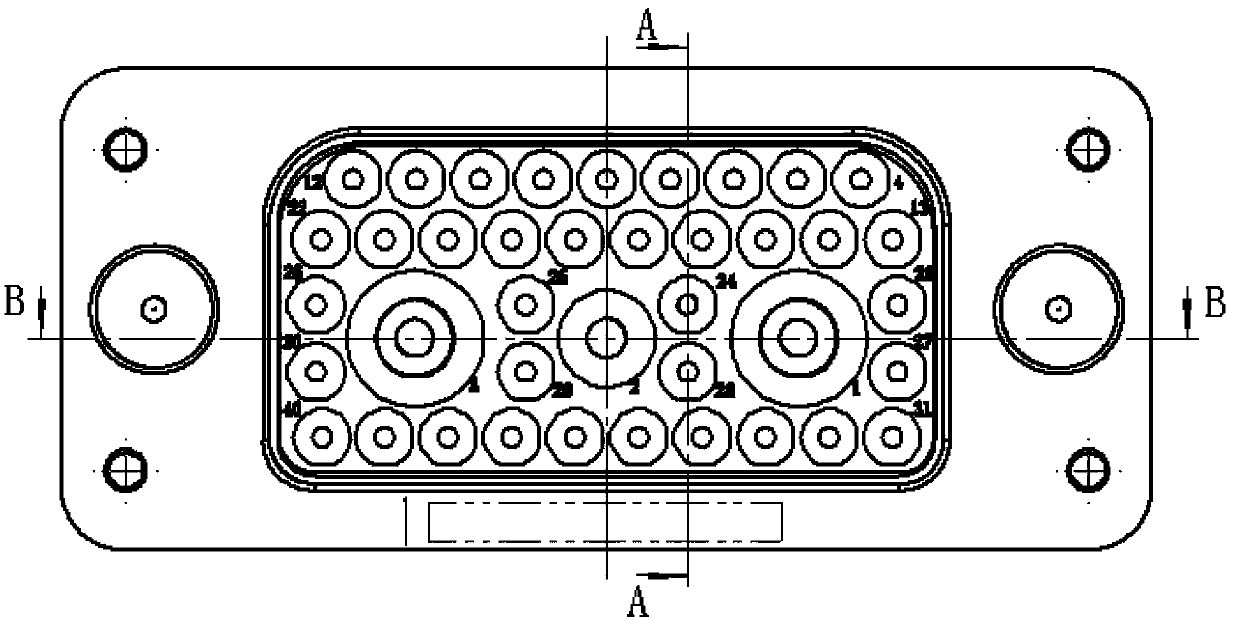

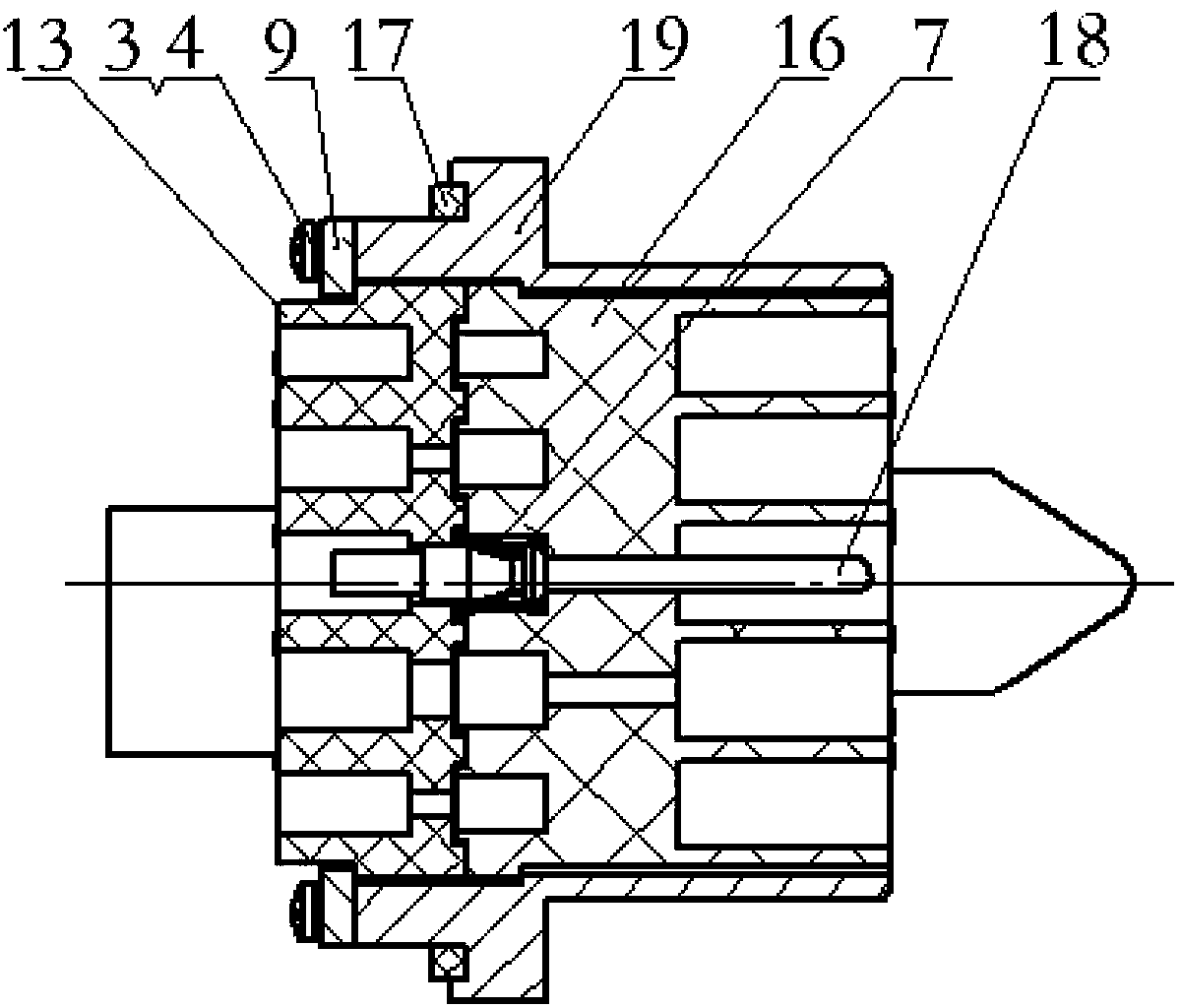

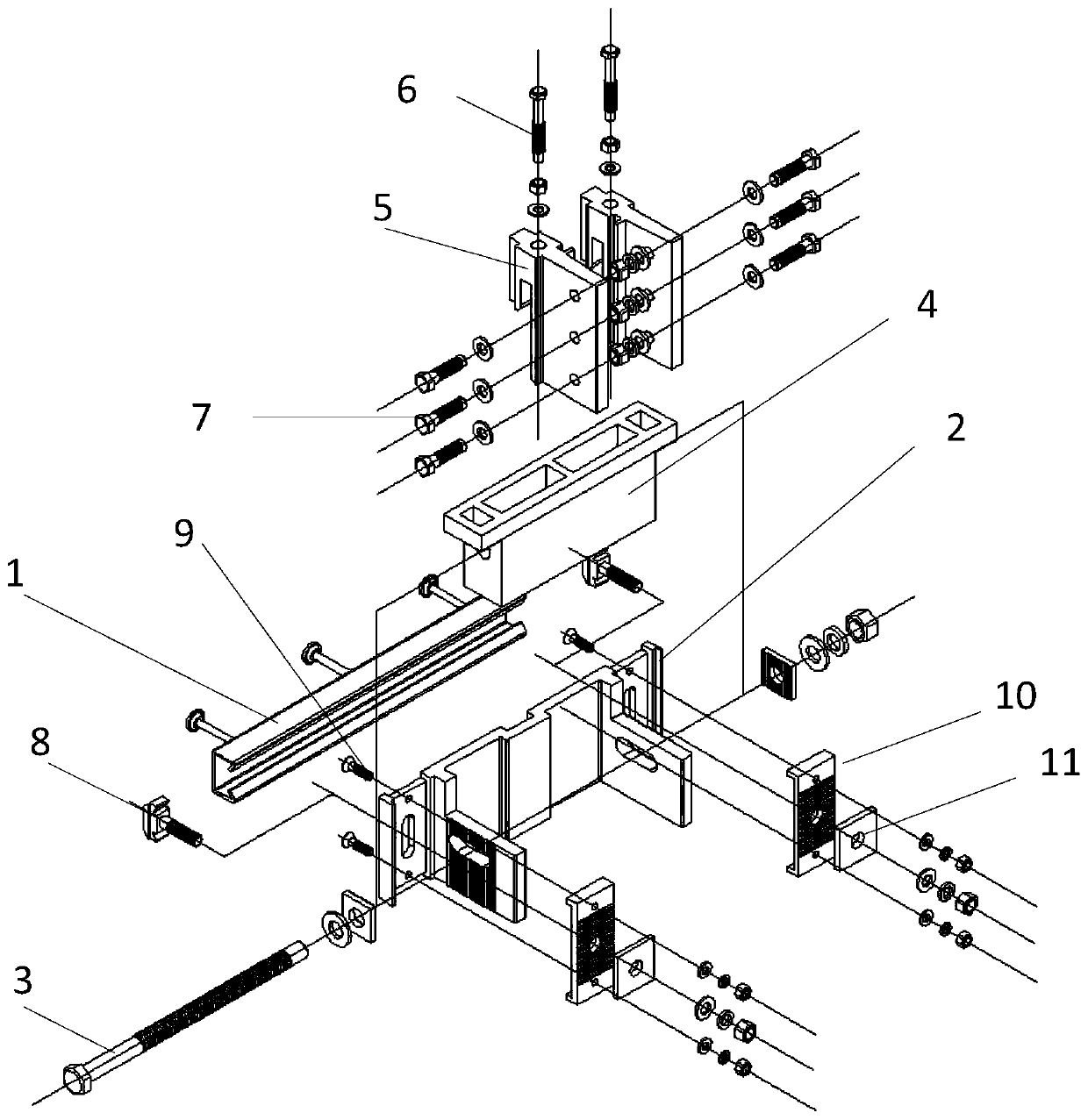

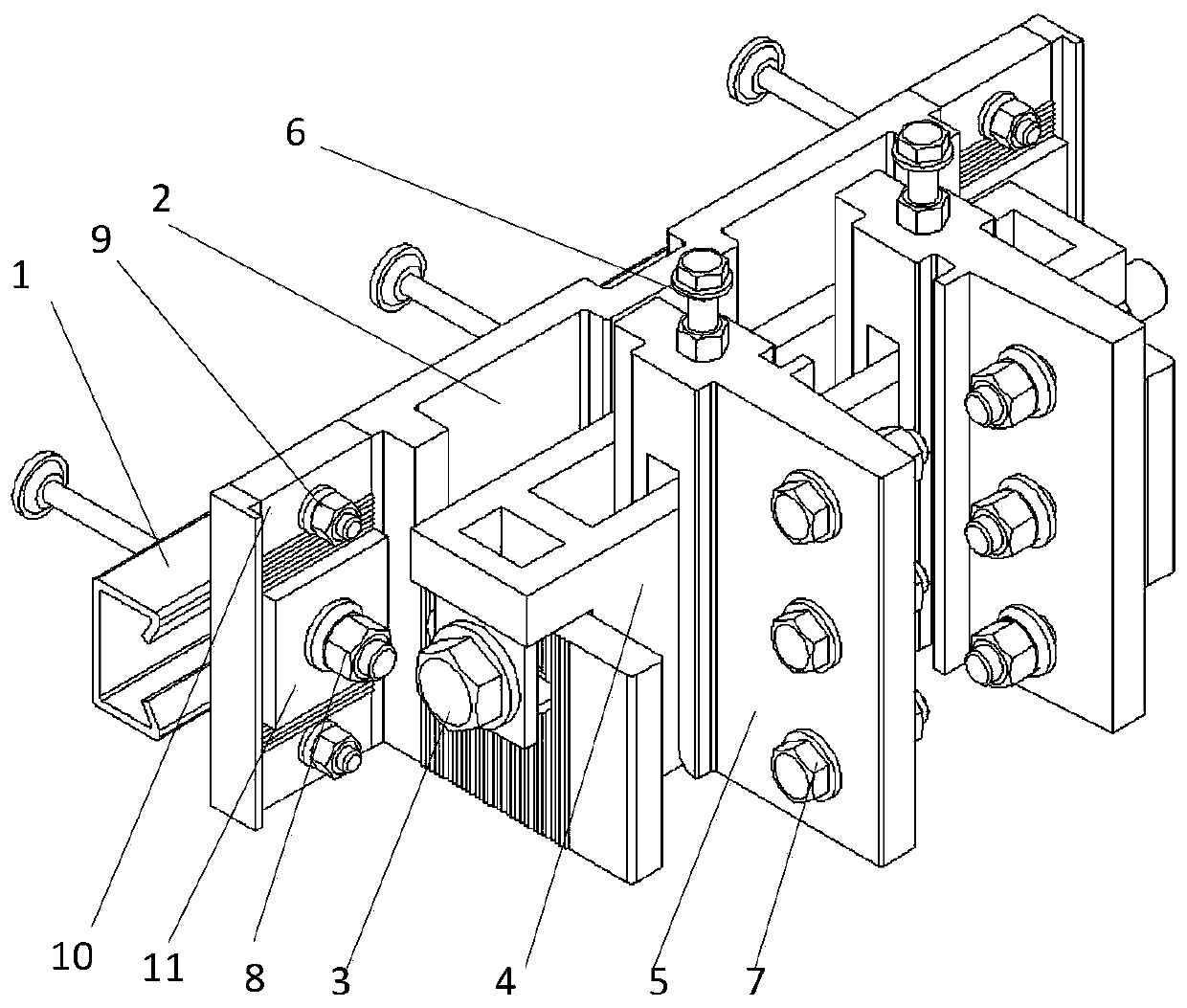

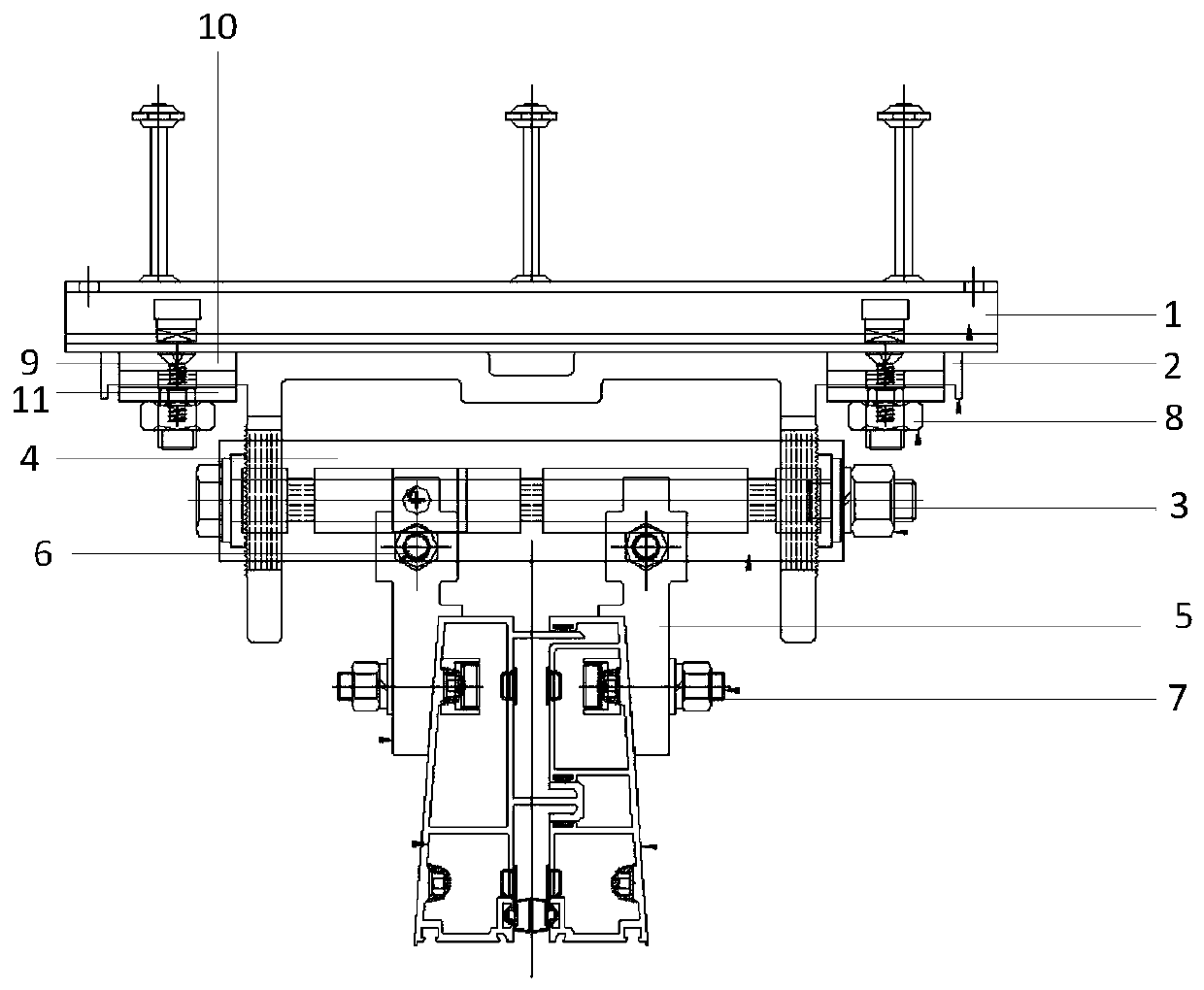

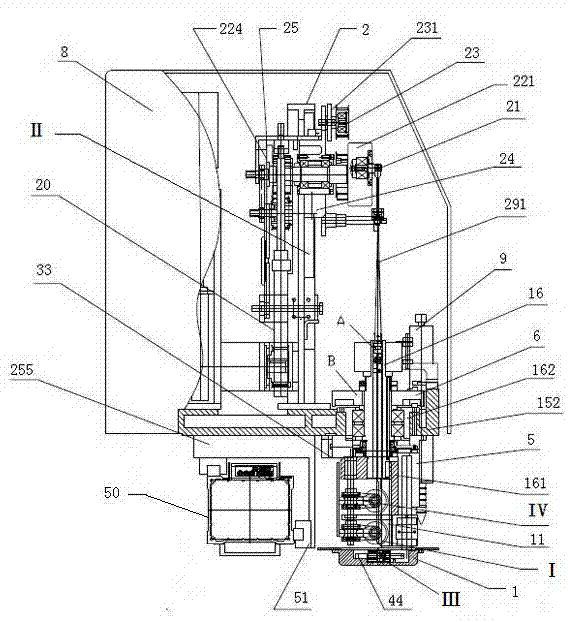

Multiple-freedom-degree floating electric connector with self-calibration function

InactiveCN103390834ARealize self-calibration functionFirmly connectedCoupling device detailsElectricityElectrical connection

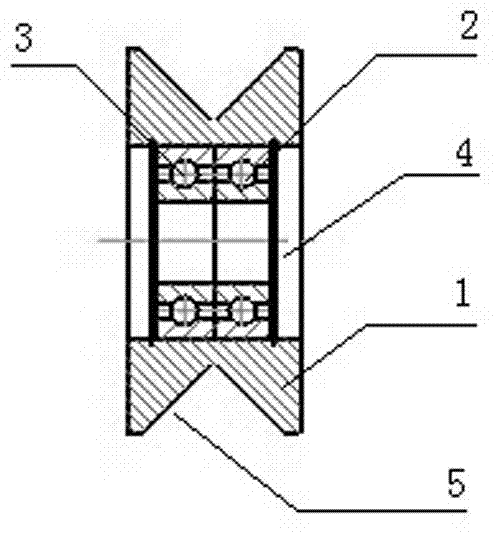

A multiple-freedom-degree floating electric connector with a self-calibration function comprises a plug (1) and a socket (2), and is characterized in that the socket (2) comprises the components as follows: a secondary positioning pin (11), an after-pin insulator (13), a Phi12 contact pin (14), a Phi6 contact pin (15), a before-pin insulator (16), a Phi3 contact pin (18) and a lug casing (19). According to the multiple-freedom-degree floating electric connector with the self-calibration function, the problems of unreliable electrical connection or electrical connection failures caused by multiple-freedom-degree changes such as displacement, torsion and the like produced by a battery in any direction or at any angle of an installation carrier can be solved; at the same time, damage caused by vibration and impact can be effectively eliminated; the electric connector has the characteristics that the electric connector can be connected and separated rapidly, the operation is convenient, the mechanical property is good, the electric connection is reliable, and the like; and the electric connector has larger economic and social values.

Owner:沈阳兴华航空电器有限责任公司

Slot-less rolling technique of rolling section

InactiveCN1833790AResolve twistHighlight substantive featuresRoll mill control devicesMetal rolling arrangementsMaterials scienceRolling mill

A fluteless rolling technology for rolling steel section includes sequentially determining 14 technological parameters including total cross-section shrinkage ratio of the workpiece to be rolled, the pressing down size of each pass, total number of passes, 5 correcting coefficients, etc, and rolling by fluteless rolling mill while regulating the clamp to the workpieces.

Owner:XINJIANG BAYI IRON & STEEL

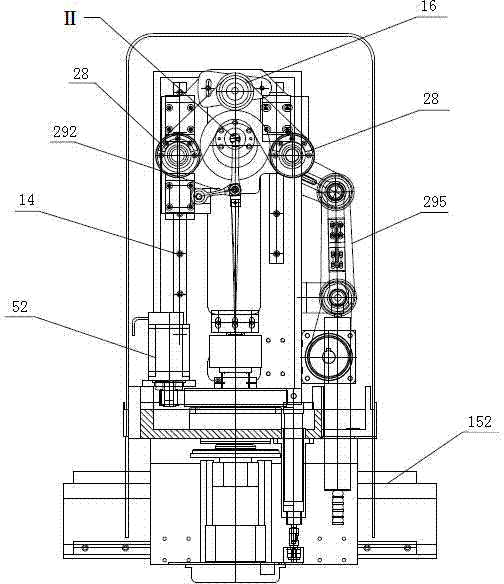

Combination type inner-burr cleaning and weld guiding device

The invention discloses a combination-typed internal burr removing and welding seam guiding device, comprising a fixed bracket, a welding seam guiding roller assembly, and a cutter rod assembly; wherein, the fixed bracket is arranged on the side surface of a forming frame; a large trailing plate which can slide upwards and downwards is arranged on the fixed bracket; one side of the large trailing plate is fixed with the welding seam guiding roller assembly and the other side thereof is provided with a small trailing plate in an upper and lower sliding way; the small trailing plate is provided with an oil cylinder and a cutter rod assembly which are connected with each other. The combination-typed internal burr removing and welding seam guiding device leads the welding seam guiding roller assembly and the cutter rod assembly used for removing the internal burr to be effectively combined together, reduces the parts, simplifies the structure, increases the whole strength, has extremely convenient installation usage and specification replacement, improves the product quality, production efficiency and yield in the production and leads the production cost of the enterprise to be greatly reduced.

Owner:海油发展珠海管道工程有限公司

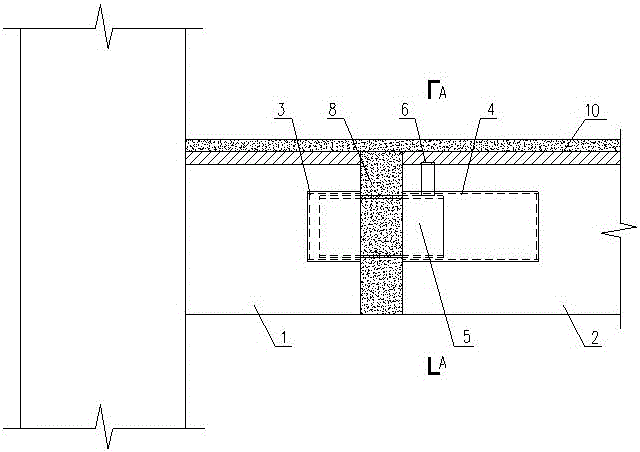

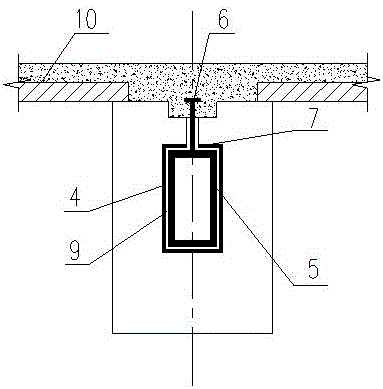

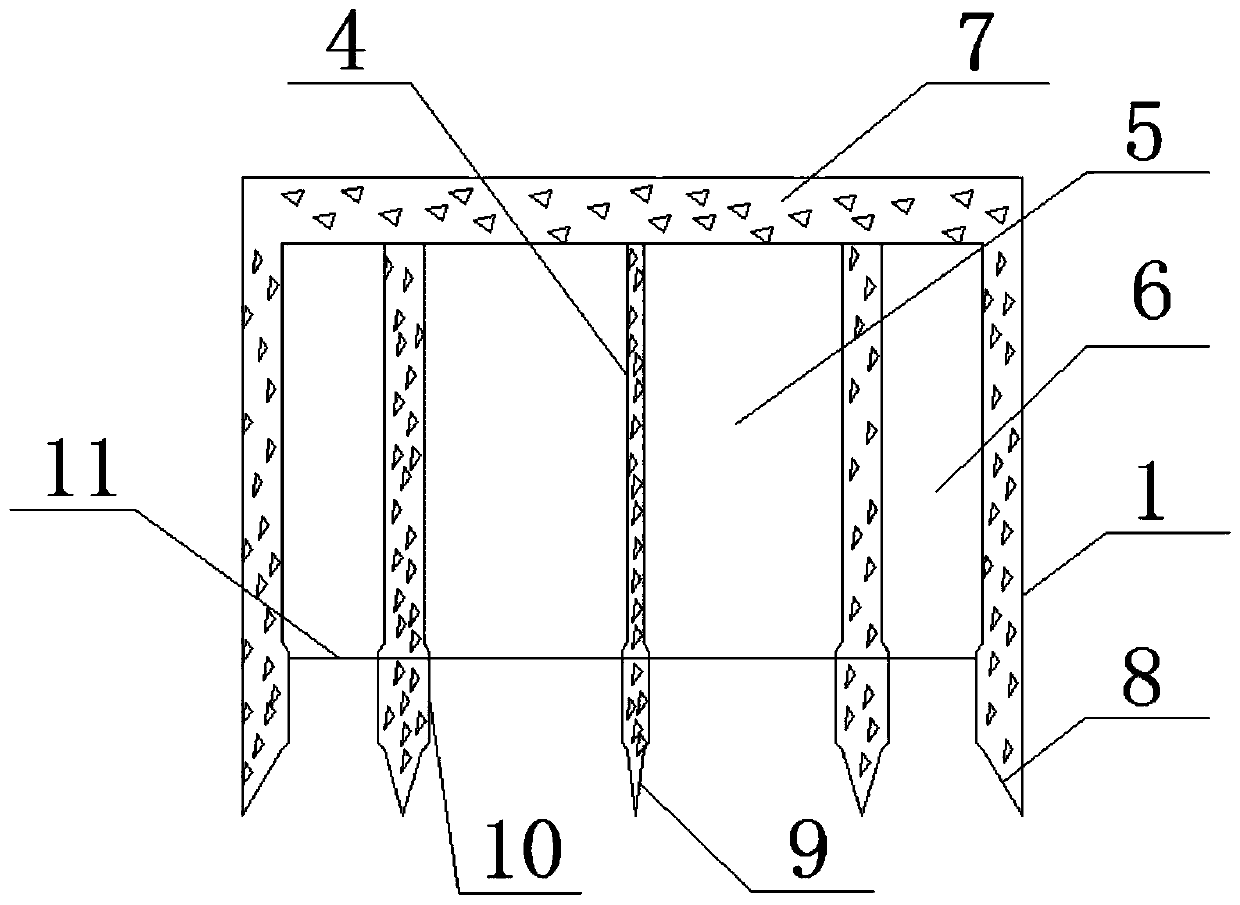

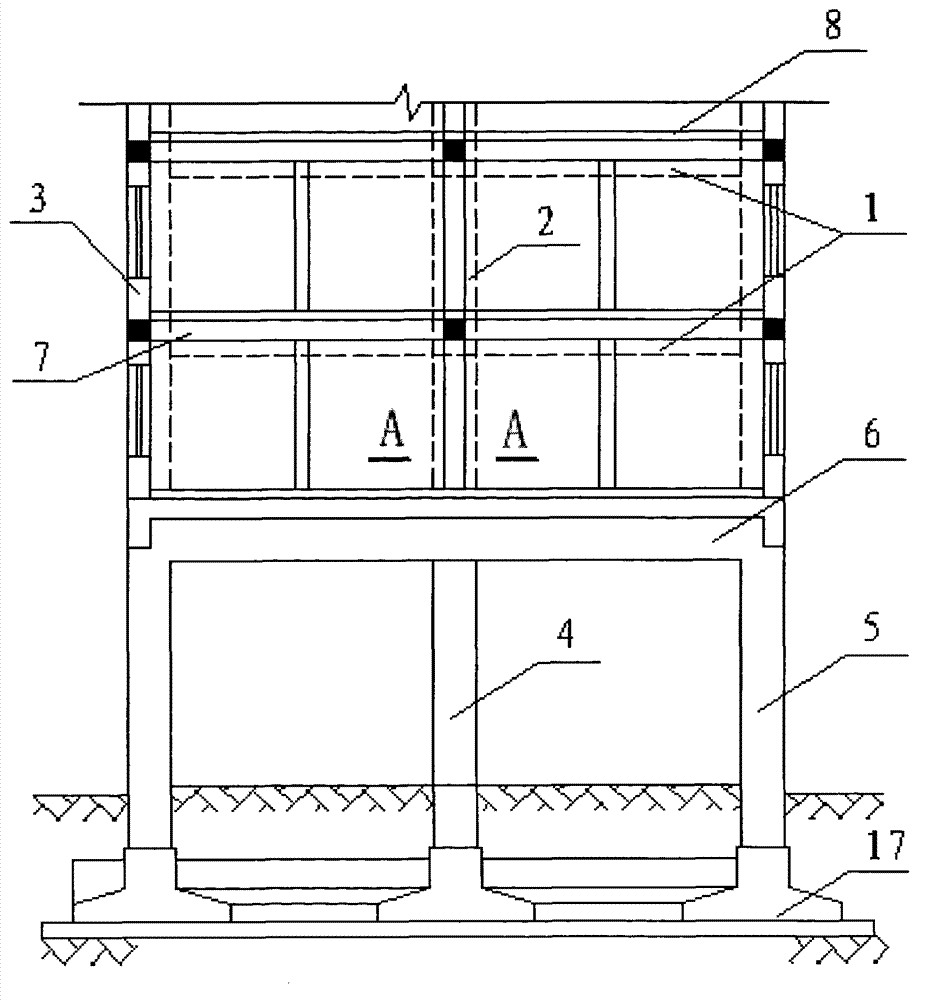

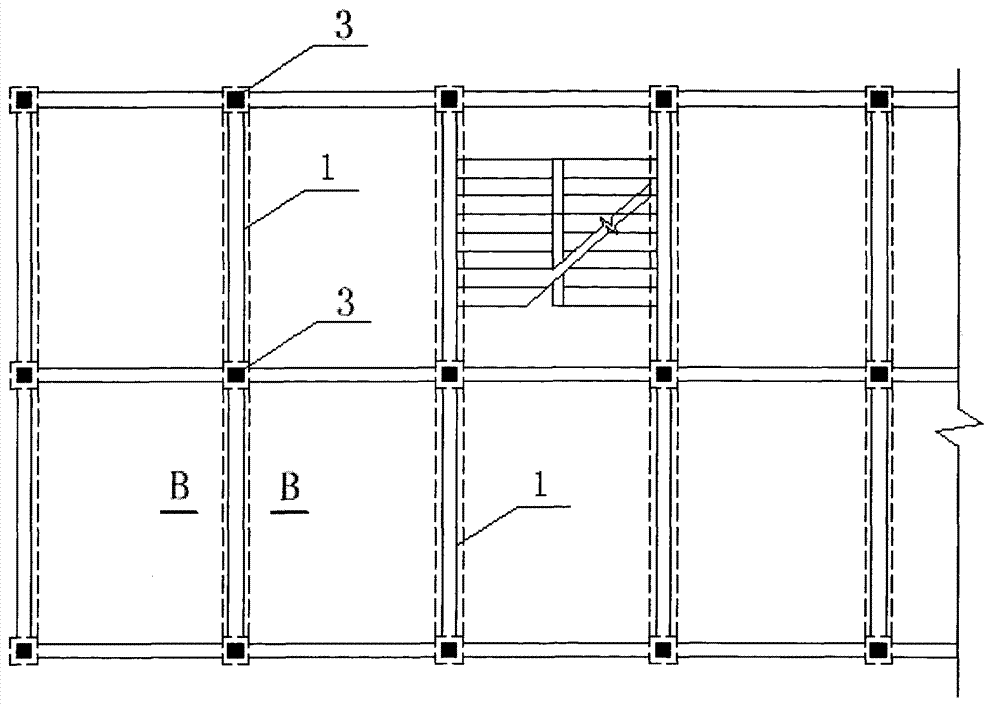

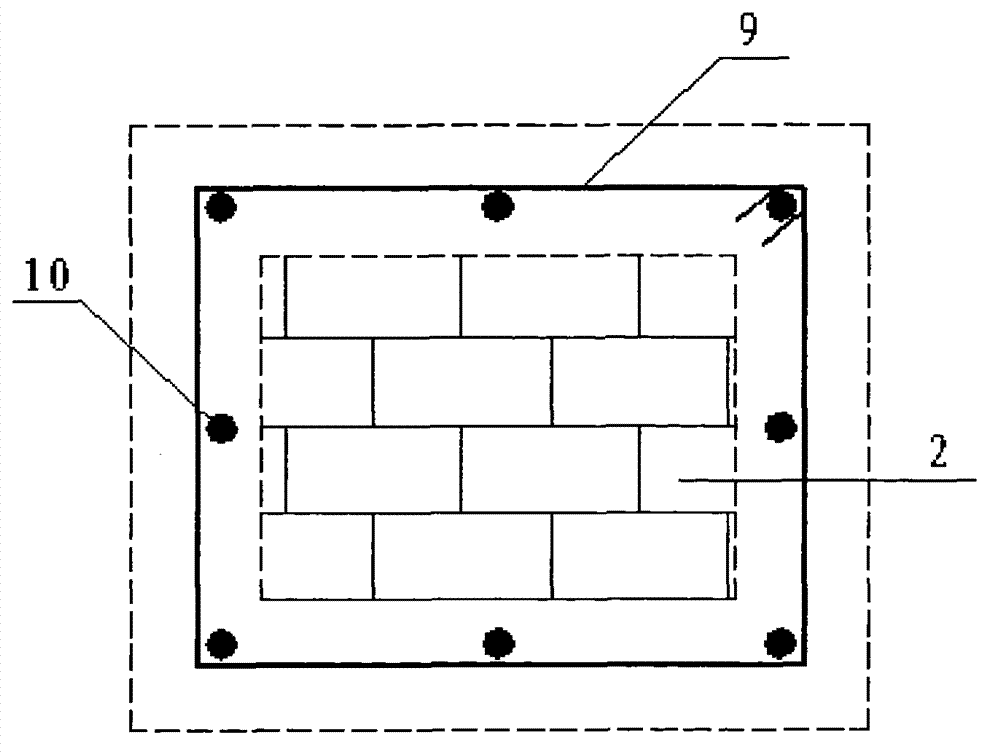

Precast concrete frame beam joint

PendingCN105951985AEasy constructionResolve twistProtective buildings/sheltersShock proofingButt jointEngineering

The invention belongs to a precast concrete frame beam joint of a precast concrete fabricated structure. The technical scheme includes: a first beam section of a precast concrete frame beam is in butt joint with a second beam section of the precast concrete frame beam, and a first square steel pipe is horizontally buried to the end of the first beam section of the precast concrete frame beam; a second square steel pipe is horizontally buried to the second beam section of the precast concrete frame beam, and the first square steel pipe and the second square steel pipe are identical in section; a slide square steel pipe horizontally and internally sleeves the second square steel pipe; a braking device is fixed to the top of the slide square steel pipe, and the top of the second steel pipe is provided with an opening allowing slide of the braking device; the braking device drives the slide square steel pipe to slide in the second square steel pipe to the first square steel pipe; the surface of the slide square steel pipe is coated with a polytetrafluoroethylene film. By modification of a beam column joint of a conventional precast structure into the precast concrete frame beam joint, an anti-seismic concept of 'strong joint and weak component' is realized.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

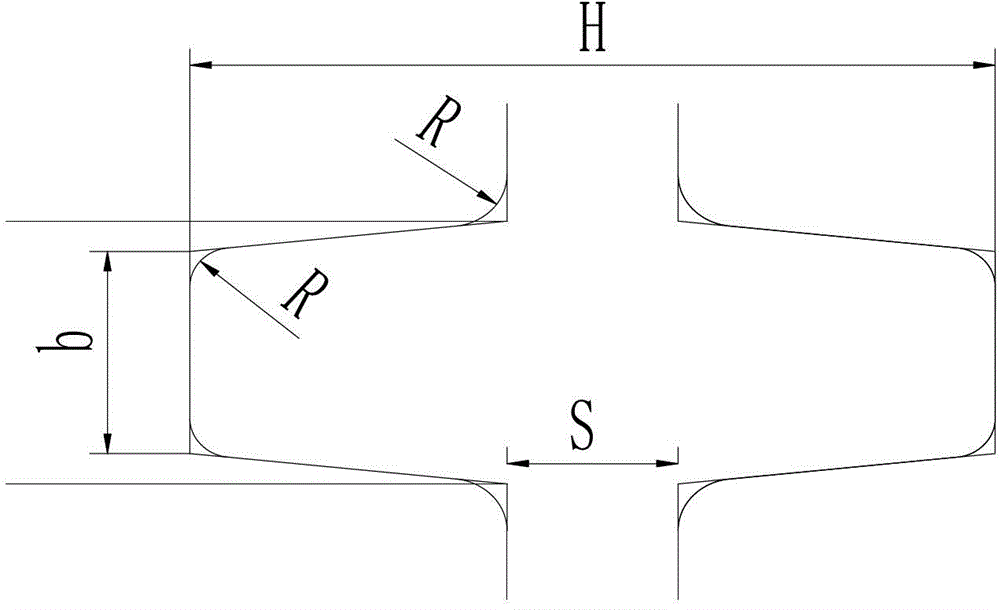

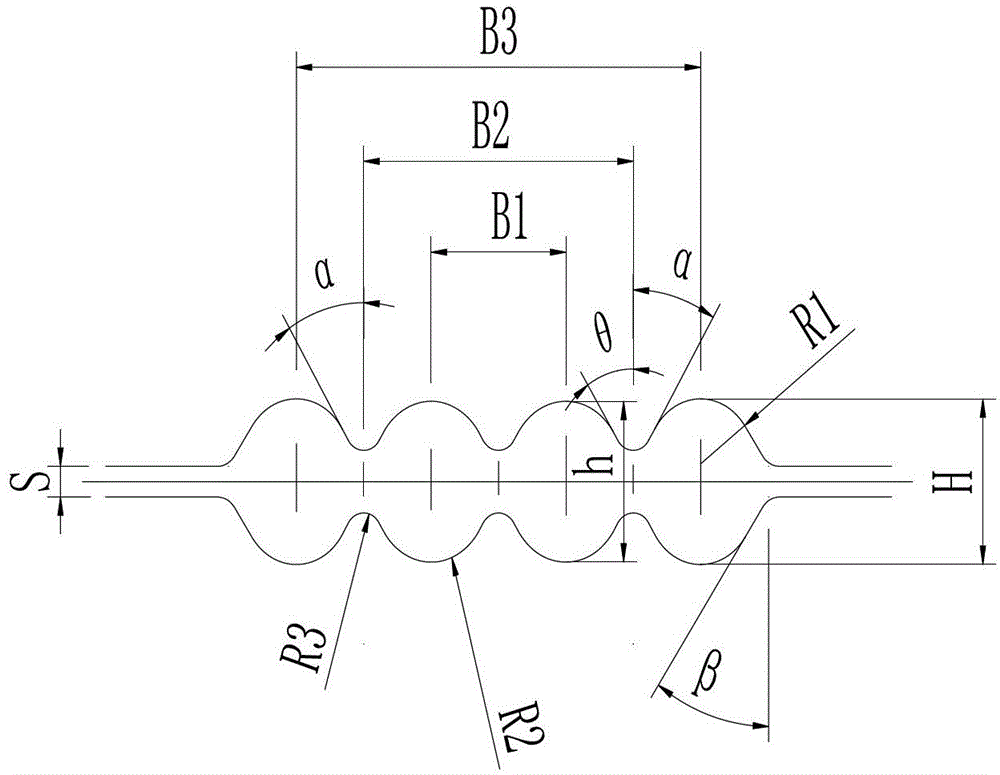

Hot rolling wire rod production method for improving surface quality

InactiveCN110125177AImprove uneven deformationImprove uneven wearMetal rolling arrangementsWire rodEllipse

The invention relates to a hot rolling wire rod production method for improving the surface quality. The steps include billet preparation, heating processing, pass rolling, reducing and sizing, coil collecting and finishing. Rough rolling, intermediate rolling and pre-finish-rolling are included, the step pitch is increased during the heating processing, the box pass is adopted for billets firstly, exchange in the ellipse pass and the circle pass is then achieved, and the square billets are rolled into semi-finished products with circular fracture surfaces; the box pass, ellipse pass and circle pass combined pass is adopted for the rough rolling, the square billets are compressed under large pressure, the box pass is adopted for the first three passes of the rough rolling, box type hole base angles are increased, the ellipse pass and the circle pass are adopted for the fourth pass and the fifth pass of the rough rolling, and the circular shape is achieved after the rough rolling; and induction heating is added between the rough rolling and the intermediate rolling, and the problem that the head and tail temperature difference of red steel heads is large is solved. A spiral guide pipe is added to a lifting spiral pipe structure for the coil collecting, the circle shape of tail portions is regularized through the spiral guide pipe after the tail portions lose tension during the coil collecting, and therefore the circle shape of the tail portions is controlled and the problem that the tail portions are scratched is solved. The hot rolling wire rod production method meets the zero defect quality requirement.

Owner:WUXI XINGCHENG HUAXIN STEEL

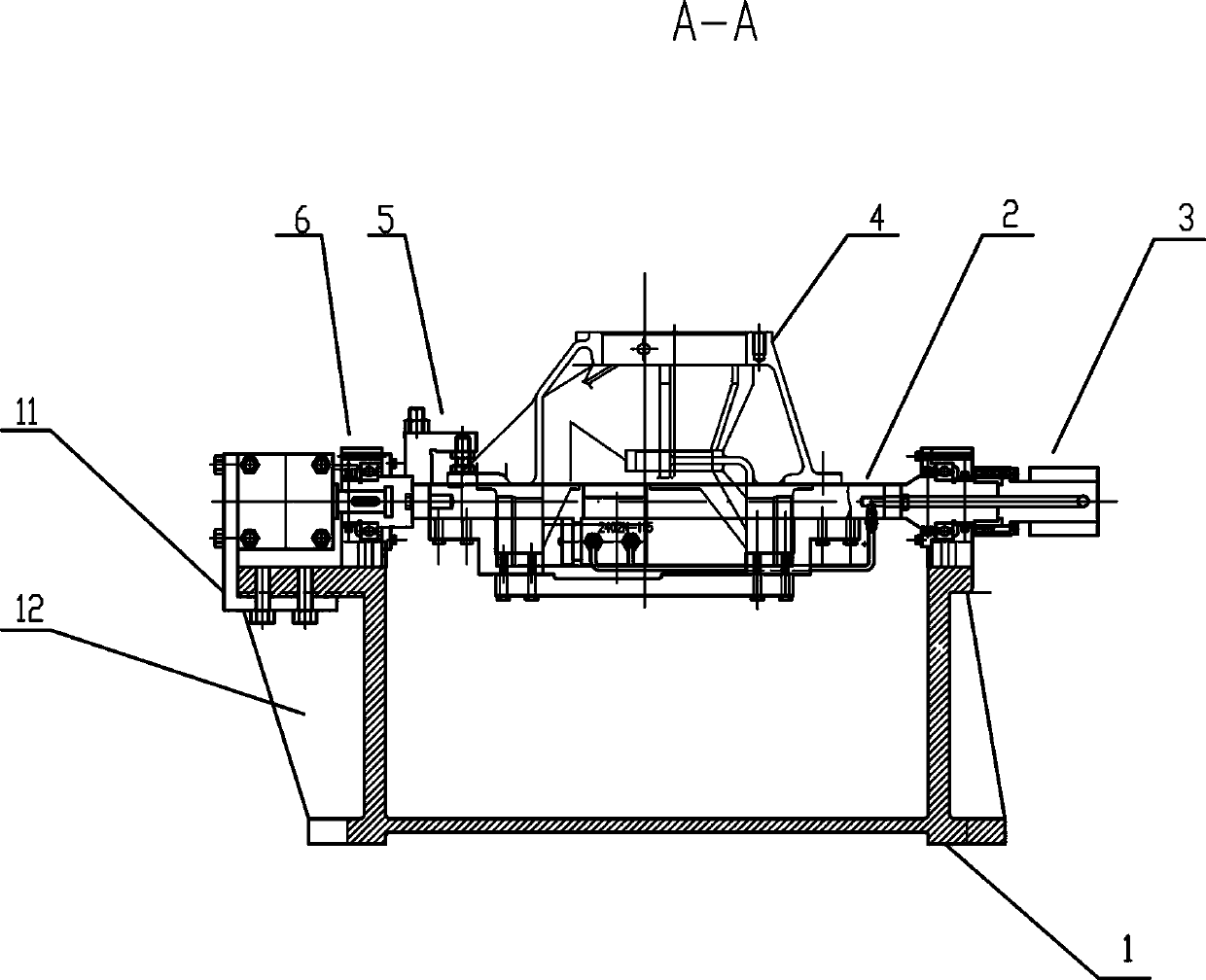

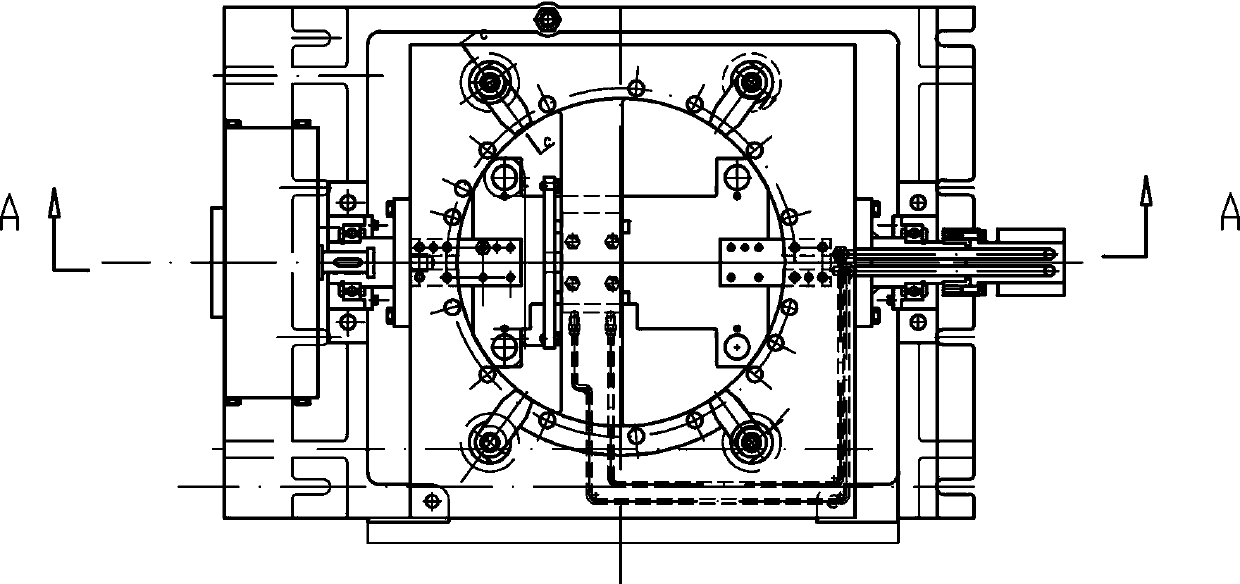

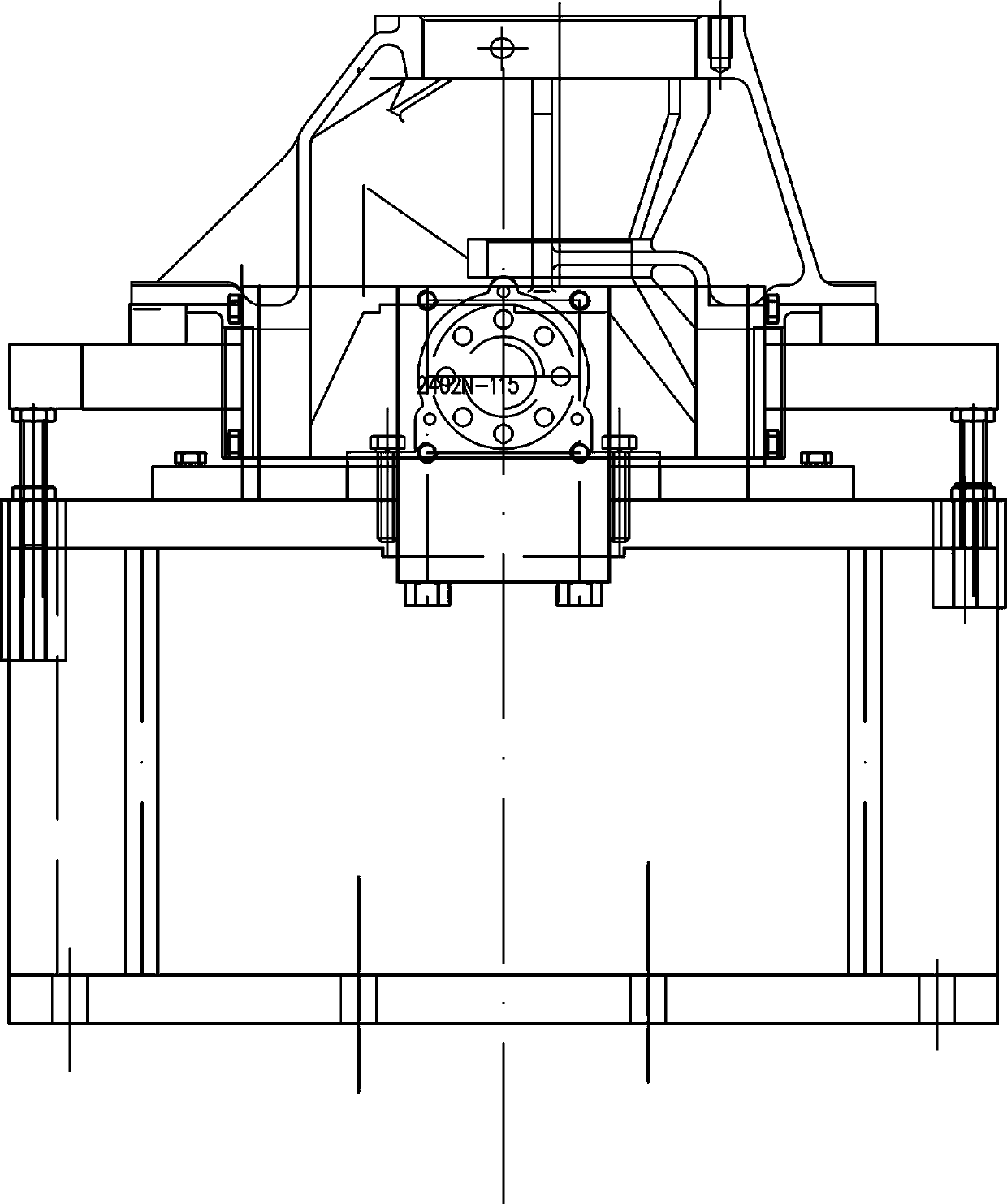

Automobile rear axle reducer shell large end face drilling clamp

Disclosed is an automobile rear axle reducer shell large end face drilling clamp. A drill plate device is arranged at the bottom of an automobile rear axle reducer shell. The automobile rear axle reducer shell is fixed to the drill plate device through a clamping device. The two ends of the drill plate device are connected with a left rotation device and a right rotation device which are arranged on a clamp support correspondingly. The automobile rear axle reducer shell rotates through a rotation air cylinder arranged on the left rotation device. A locating air cylinder is arranged under a drill jig top plate in the drill plate device. The locating air cylinder is connected with an air channel of a rotation connector of the right rotation device through an air passage. According to the automobile rear axle reducer shell large end face drilling clamp provided by the invention, the automatic locating air cylinder and the rotation air cylinder are adopted in the drilling clamp, so that automatic locating and overturning of a workpiece are achieved, and accordingly the precision and quality of hole machining of the workpiece are improved. The automobile rear axle reducer shell large end face drilling clamp is simple in structure, convenient to operate, light, handy and attractive. The problem of air pipe torsion during workpiece overturning is solved, the operation safety is improved, the labor intensity of workers is relieved, and the work efficiency is improved by 20% or above.

Owner:YUANAN YONGAN AUTO AXLE

Wall-type component lateral support device and low cycle repeated loading test device

InactiveCN109708976AImprove accuracyImprove reliabilityMachine part testingMaterial strength using steady torsional forcesHorizontal forceBlock and tackle

The invention provides a wall-type component lateral support device and a low cycle repeated loading test device. The lateral support device comprises one pair of lateral support bodies. One pair of lateral support bodies is fixedly connected through a connection support. One end of each lateral support body is vertical to a pulley group arranged along a length direction. The pulley group can be pressed against the surface of a wall-type component to be tested and can be rotated under the vertical or horizontal force applied by a loading device to the wall-type component to be tested. The other end of the lateral support body is a free end. The free end can be embedded in the lateral support beam of the low cycle repeated loading test device. By using the wall-type component lateral support device, a practical problem that the wall-type component to be tested is not deformed or twisted in a same plane during a low cycle repeated loading test process is solved, and the accuracy and thereliability of a test are effectively increased.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

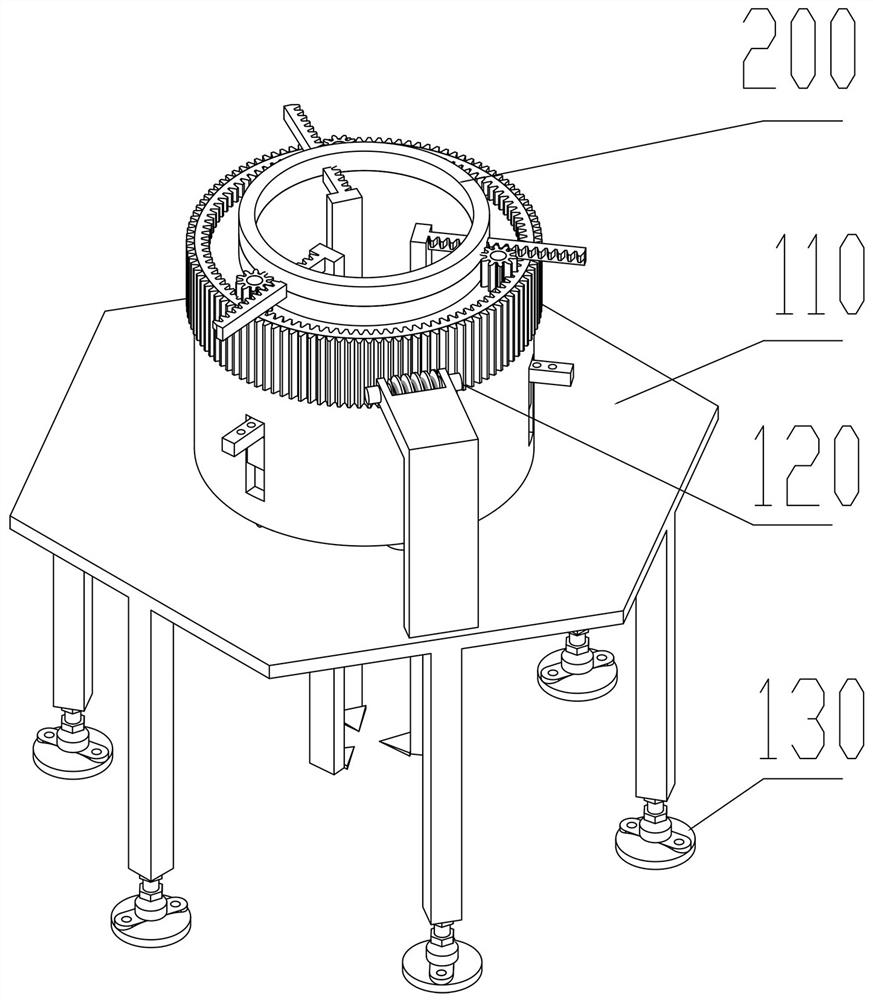

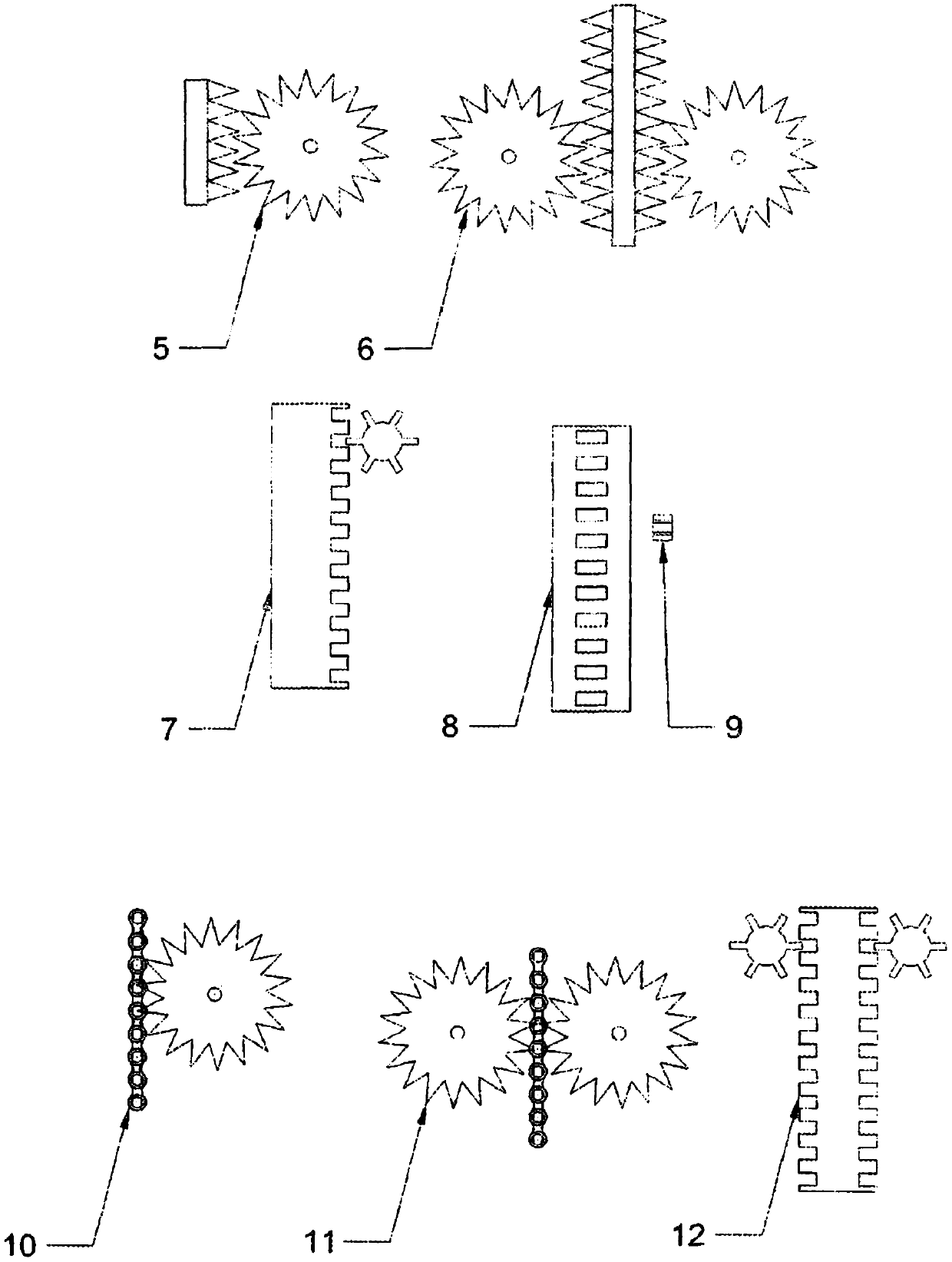

Wiring device for computer room construction

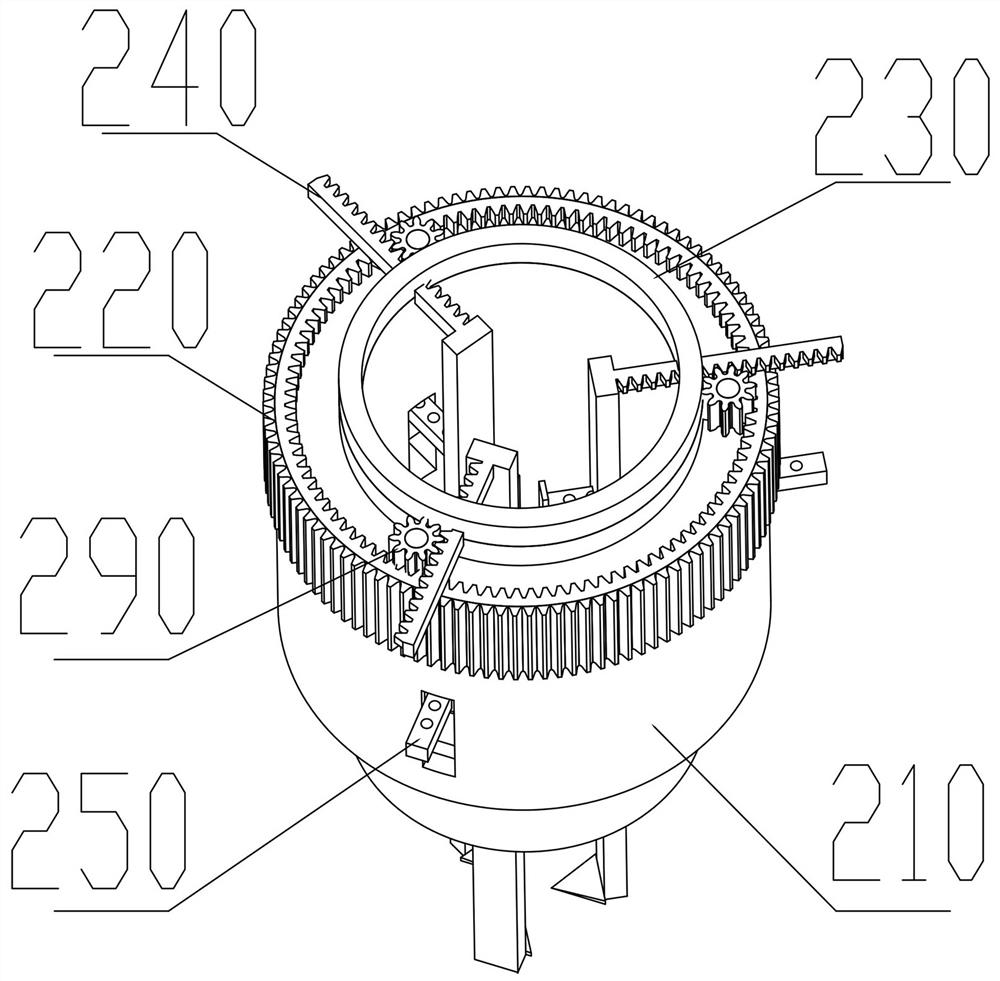

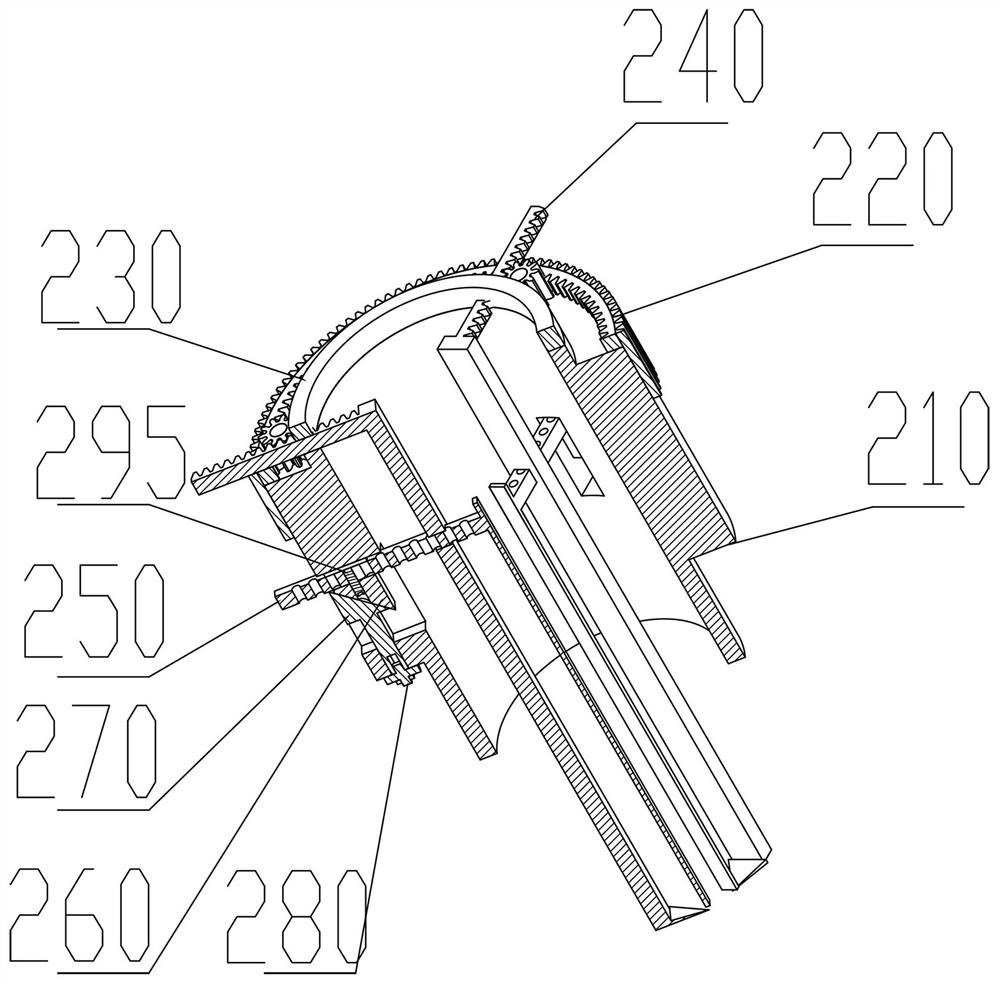

InactiveCN113562531AResolve twistForce balanceFilament handlingApparatus for laying cablesGear wheelScroll wheel

The invention discloses a wiring device for computer room construction. The device comprises a workbench, a worm, an adjusting bolt and an unwinding device, wherein the unwinding device comprises a unwinding base, an outer gear ring, a clamping ring, a supporting rod, a clamping rod, an upper wedge block, a lower wedge block, a rolling wheel and a gear, a workbench hole is formed in the middle of the workbench, a vertical rod is arranged on the upper portion of the right side of the workbench, a worm groove is formed in the upper portion of the vertical rod, a worm hole is formed in the vertical direction of the worm groove, a plurality of supporting legs are arranged on the lower portion of the workbench, the worm is rotationally connected to the worm hole, the worm rotates in the worm hole, the lower portion of each supporting leg is fixedly connected to an adjusting bolt, and the unwinding device is rotationally connected to the workbench hole and rotates in the workbench hole.

Owner:JIAMUSI UNIVERSITY

Method for machining high-precision extrusion die

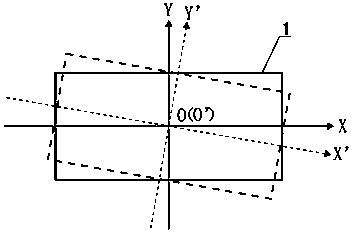

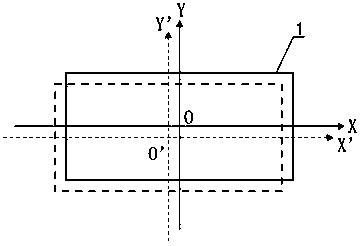

InactiveCN103658894AResolve twistSolve the problem of eccentricityExtrusion diesEngineeringMachining process

The invention discloses a method for machining a high-precision extrusion die. The extrusion die comprises a female die and a male die. Before the female die and the male die are subjected to workpiece standardization, an inward-contracting step face is machined under the surface of a workpiece, wherein the surface of the inward-contracting step face is in the shape of L, and the inward-contracting step face serves as a uniform leveling foundation of follow-up processes; the center point of the workpiece is found before machining and serves as the coordinate center of all the follow-up machining processes, and then positioning is carried out with the inward-contracting step face as the horizontal foundation to carry out machining according to uniform coordinate dimensions. Due to the adoption of the uniform leveling standard, a mold cavity and a mold core of the workpiece do not twist; due to the method that the center point of the workpiece serves as the coordinate center, the mold cavity and mold core of the workpiece will not be eccentric; in this way, the phenomena of twisting and being eccentric are avoided in the workpiece machining process, machining precision and efficiency are obviously improved, the female die and the male die can be matched with each other completely, and the rejection rate is obviously lowered.

Owner:XINGFA ALUMINUM CHENGDU

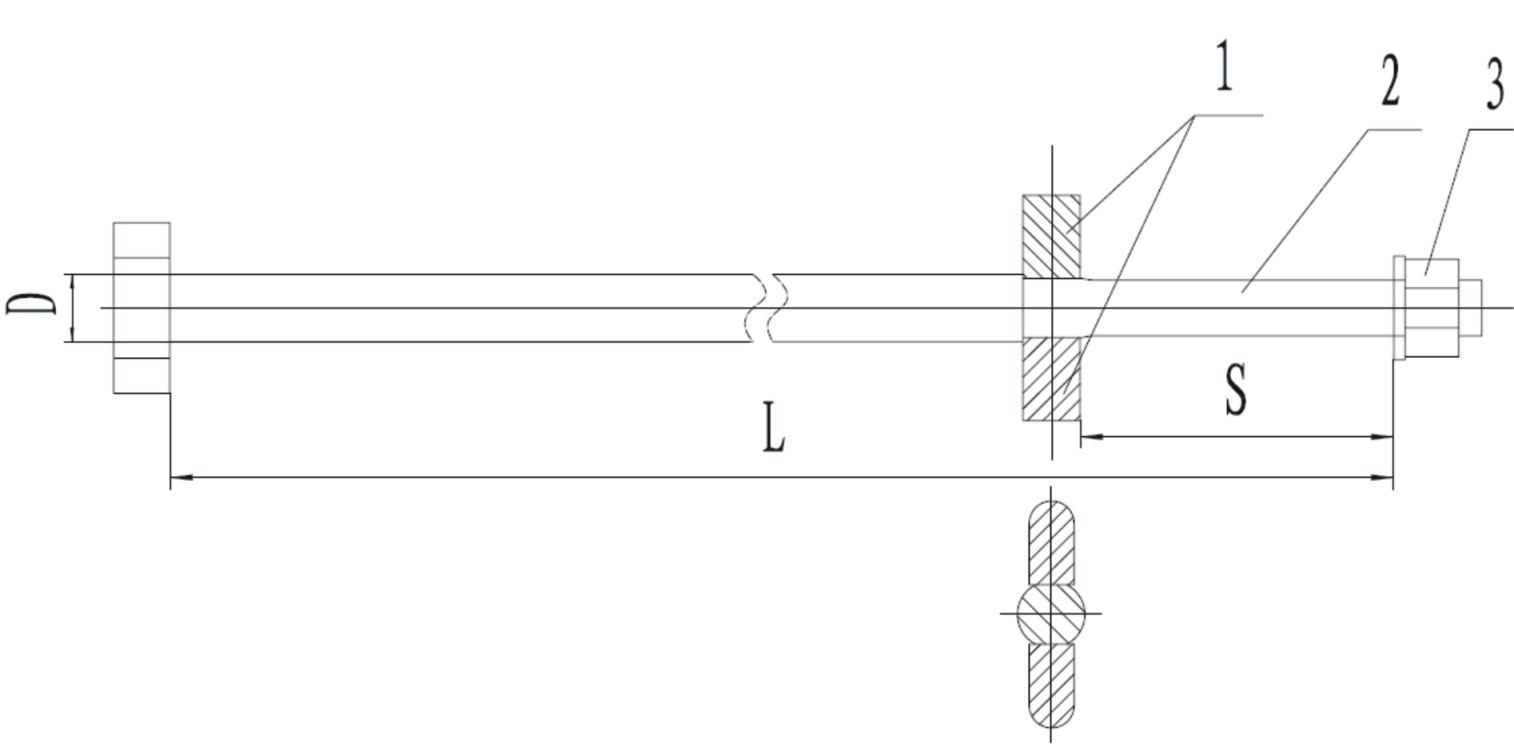

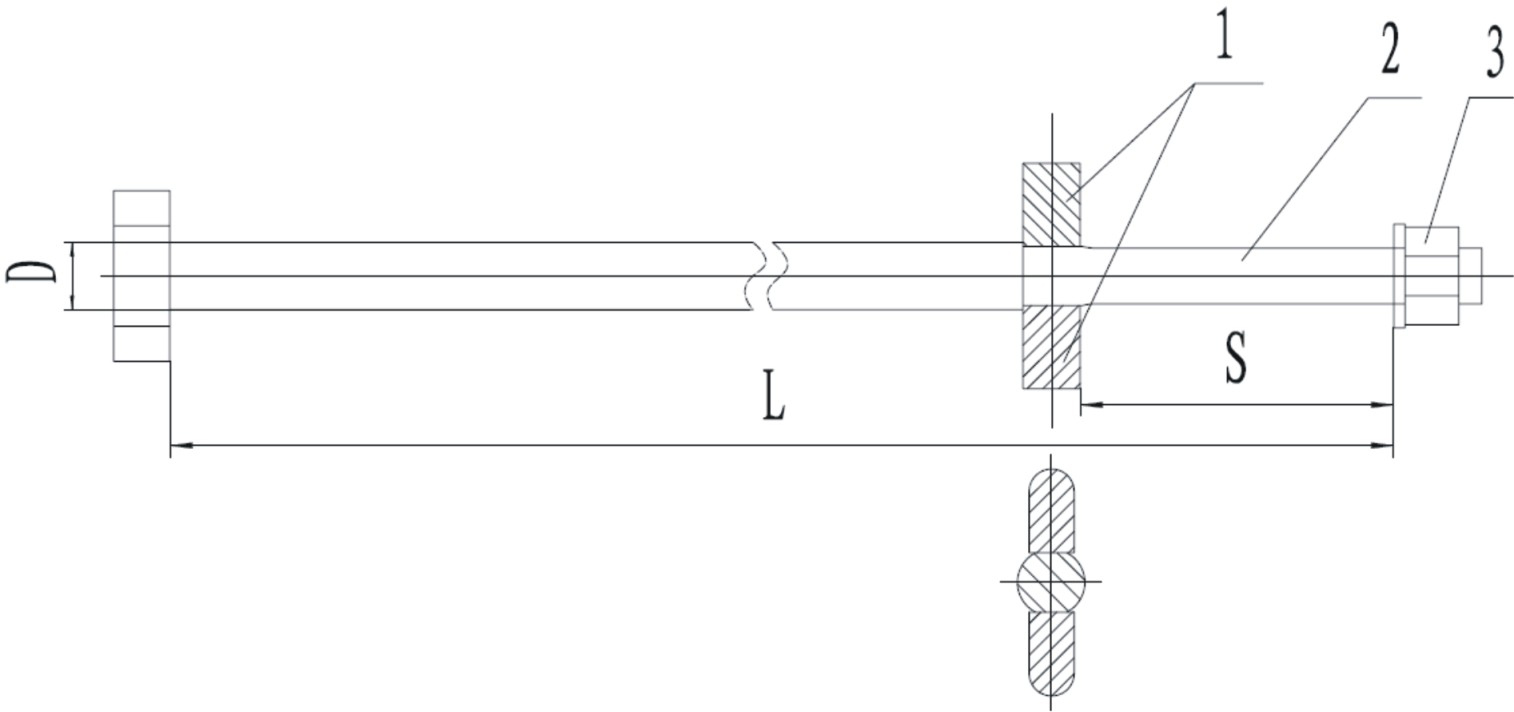

Ultra-long bolt

The invention relates to an ultra-long bolt, which comprises a bolt and a nut, wherein the nut is arranged at the end part of one end of the bolt; key grooves are arranged on two sides at the rod part of the bolt; locking keys are arranged in the key grooves; the length L of the bolt is greater than the diameter D of the bolt by 60 times, i.e., L is greater than 60D; and the distance S between the locking keys and the nut is greater than the diameter D of the bolt by 10 times and is smaller than the diameter D of the bolt by 15 times, i.e., S is greater than 10D but is less than 15D. The ultra-long bolt has a simple structure; and two small planes are processed on the bolt, two key grooves are processed on the small planes, and the locking keys are placed into the key grooves to clamp the bolt, the problem that the rod part of the bolt is twisted along with the screwing in the screwing process of the ultra-long bolt is effectively solved.

Owner:CHINA NORTH IND GRP NO 70 RES INST

Double-layer reverse rotation vertical-shaft wind-power machine using horizontal combination active wing

ActiveCN101493071BImprove efficiencyCost-effectiveWind motor controlFinal product manufactureWinding machineEngineering

The invention discloses a novel vertical spindle wind machine which is mainly formed by support devices, vanes and the like that are respectively arranged on an upper layer and a lower layer and are almost completely the sane as each other; the wind machine also comprises a movable wing link gear, a speed governing device, a rhachis, a locating device, a limiting device, an auxiliary limiting device and an auxiliary starting device. The movable wing link gear adopts a labile equilibrium form to lead the vane group to easily open and shut, so as to not only ensure the best holding state, but also reduce the requirements for the manufacturing materials, thus greatly improving the cost performance of the wind machine; the machine adopts simple and effective mode of mechanical speed regulation, so as to absolutely ensure the service life of the wind machine; all movable linking parts of the machine are in a state of sealing, so that rain, snow dust and sand are avoided damaging the wind machine; as the machine is designed to be a form of double-layer reverse rotation, the utilization rate of wind energy can be improved, and the torsional force of the whole machine can be reduced; meanwhile, the machine is provided with a device which can keep the whole machine flat, so that the whole machine can be easily put down when being necessary, and the novel vertical spindle wind machine is more suitable for ships. When in design, the processing technique and installation technique are fully taken into consideration, so that the invention is suitable for commercial process.

Owner:王肇泰

Combination type inner-burr cleaning and weld guiding device

The invention discloses a combination-typed internal burr removing and welding seam guiding device, comprising a fixed bracket, a welding seam guiding roller assembly, and a cutter rod assembly; wherein, the fixed bracket is arranged on the side surface of a forming frame; a large trailing plate which can slide upwards and downwards is arranged on the fixed bracket; one side of the large trailingplate is fixed with the welding seam guiding roller assembly and the other side thereof is provided with a small trailing plate in an upper and lower sliding way; the small trailing plate is providedwith an oil cylinder and a cutter rod assembly which are connected with each other. The combination-typed internal burr removing and welding seam guiding device leads the welding seam guiding roller assembly and the cutter rod assembly used for removing the internal burr to be effectively combined together, reduces the parts, simplifies the structure, increases the whole strength, has extremely convenient installation usage and specification replacement, improves the product quality, production efficiency and yield in the production and leads the production cost of the enterprise to be greatlyreduced.

Owner:海油发展珠海管道工程有限公司

An automatic magnetic anti-rotation slag fishing machine for swirl wells

ActiveCN103877758BRealize automatic collection and clearingImprove efficiencySettling tanks feed/dischargeCentrifugal force sediment separationSlagAlternating current

The invention discloses an automatic magnetic anti-rotation slag salvaging machine for a whirling well. The automatic magnetic anti-rotation slag salvaging machine comprises a conveyance mechanism and a slag salvaging mechanism, wherein the conveyance mechanism comprises rotating wheels and a conveyor belt, and the rotating wheels comprise a first rotating wheel and a second rotating wheel, and the conveyor belt is wound around the exteriors of the first rotating wheel and the second rotating wheel and is driven by the rotating wheels to rotate; the slag salvaging mechanism is formed by a plurality of conical slots, an opening is formed in the top of each conical slot, the sidewall and bottom of each conical slot are latticed and are formed by hollow tubes with magnetism conduction capability, the surface of each hollow tube is provided with a plurality of bulges for increasing the surface area of each hollow tube, the conical slots are connected with the conveyor belt and are driven by the conveyor belt to rotate, the conical slots are connected with the conveyor belt through hinges, and an alternating current coil capable of generating magnetic force is arranged in each hollow tube forming the conical slots; the sidewall of each conical slot is provided with a first groove, and the conveyor belt is provided with protruded strips matched with the first grooves at positions corresponding to the conical slots.

Owner:青岛正大正电力环保设备有限公司

Four-line segmentation rolling technology of deformed steel bar with diameter of 10mm

ActiveCN103071674BIncrease productionReduce labor intensityRollsMetal rolling arrangementsSteel barUltimate tensile strength

The invention relates to a four-line segmentation rolling technology of a deformed steel bar with a diameter of 10mm, and the technology is characterized in that 150 square billets are sequentially rolled by six rough rolling units and 8 medium rolling units, rolled pieces are machined into flat steel, the rolled pieces then enter a fine rolling unit 15H to be machined into 0.4-mm dog-bone-shaped rolled pieces with the size of the middle part being smaller than that of the two sides, the rolled pieces enter a 16 H / V frame rolling machine for segmentation in a centering way, because the distance of two middle holes is identical in the design of the pre-segmentation and a segmentation hole, the rolled pieces under the pre-segmentation can be precisely centered in the segmentation hole, the rolled pieces are rolled into four parallel-connection rolled pieces with a ligament of 0.7mm, then the four parallel-connection rolled pieces are subjected to three-time segmentation through a front segmentation wheel and a rear segmentation wheel, which are installed on a 16 H / V outlet, then the two middle parallel-connection rolled pieces are twice cut into four independent rolled pieces, the four rolled pieces respectively and individually enter a roll groove passage of 17H and 18H / V frame rolling machines to be respectively rolled into four deformed steel bar finished products with the diameter of 10mm, the same size and the same shape. Through the technology, the yield per hour of the deformed steel bar with the diameter of 10mm is increased, the production cost is reduced, the production efficiency is increased, and the labor intensity of operators is alleviated.

Owner:TIANJIN IRON & STEEL GRP

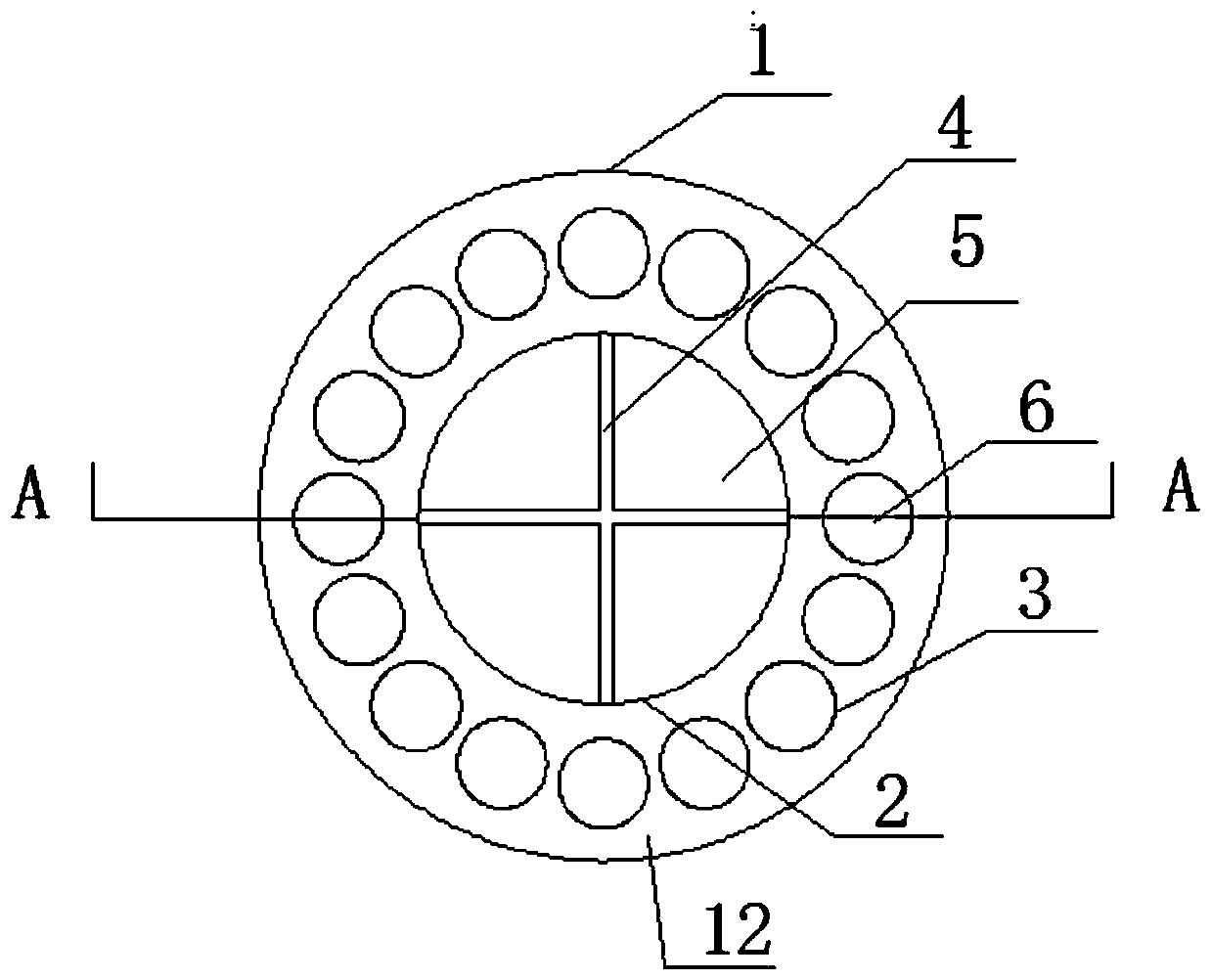

Construction method for suspension bridge gravity type anchorage porous annular foundations

InactiveCN111074925AReduce solid areaReduce areaSuspension bridgeBulkheads/pilesArchitectural engineeringRebar

Owner:中建桥梁有限公司 +1

Space three-dimensional multidirectional-adjusting aluminum alloy support system

The invention provides a space three-dimensional multidirectional-adjusting aluminum alloy support system. The space three-dimensional multidirectional-adjusting aluminum alloy support system comprises a halfen groove and an aluminum alloy buried plate, one end of the halfen groove is arranged a wall body in the X-axis direction and closely provided with the aluminum alloy buried plate, a connecting device and vertical plates are arranged on the two sides of the aluminum alloy buried plate correspondingly, and the connecting device comprises a first kidney-shaped hole formed in the Z-axis direction; T-shaped bolts, aluminum alloy transfer weights and aluminum alloy transfer cushion blocks are arranged at the two ends of the connecting device in a matched mode correspondingly, and threads are arranged on the connecting faces of the aluminum alloy transfer weights and aluminum alloy transfer gaskets; the threads are arranged on the outer surfaces of the vertical plates, second kidney-shaped holes are formed in middles of the vertical plates in the Y-axis direction, aluminum alloy transfer weight keys and aluminum alloy hanging weights are arranged between the vertical plates on the two sides in an embedded mode, and balance bolts transversely penetrating through the aluminum alloy transfer weight keys are arranged in the second kidney-shaped holes in a matched mode; and hanging grooves are symmetrically formed in the two sides of the upper surfaces of the aluminum alloy transfer weight keys, the aluminum alloy hanging weights are arranged on the hanging grooves in a hung modethrough U-shaped hooks, and fine-adjusting bolts are arranged at the tops of the U-shaped hanging grooves. The space three-dimensional multidirectional-adjusting aluminum alloy support system has theadvantages of three-dimensional multiple adjustment, accuracy and stability.

Owner:江苏苏鑫装饰(集团)公司

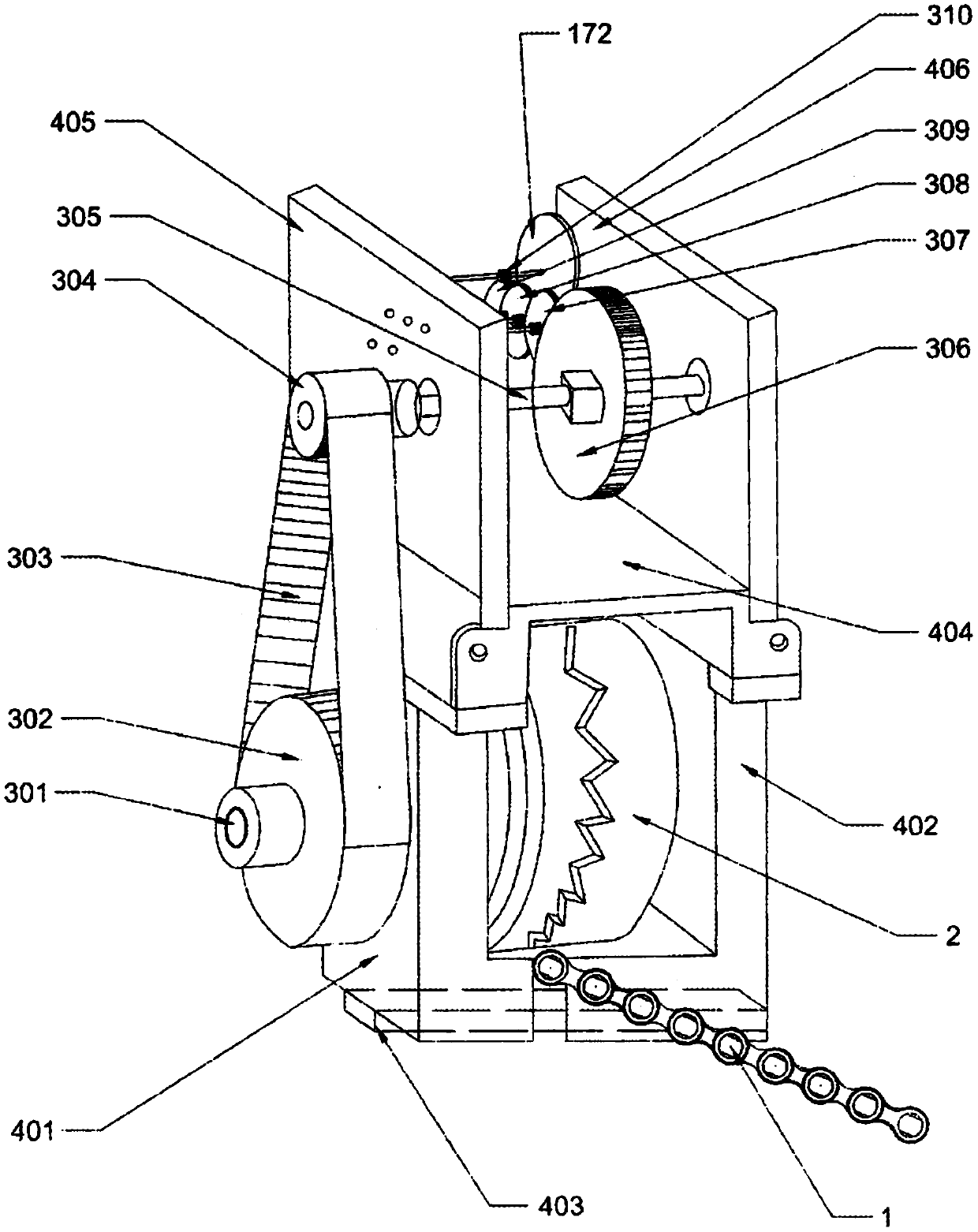

Slow descending device

InactiveCN110755765AResolve twistSolve the entanglementBuilding rescueClassical mechanicsControl theory

The invention discloses a slow descending device, more particularly relates to a single-way type slow descending device which can be used for descending multiple persons at a time and belongs to the field of high-rise rescue. Two defects exist in an existing slow descending device, one defect is that the work principle of the slow descending device determines that the slow descending device can beonly used by one person once at the same time, and efficiency is low; and the other defect is that when a fire happens, if multiple persons use multiple sets of slow descending devices, the lower ends of ropes are likely to be twisted and entangled together, and normal implementation of the function is hindered. By means of the slow descending device, a rack is used for limiting the distance of rotating engagement, the falling energy is transmitted to an energy consumption mechanism, a whole composed of the rack, the energy consumption mechanism and a transmission mechanism can be engaged with a path to slide on the designated path, and therefore the function of conducting descending along the designated path is achieved. A single descending path is adopted in the structure, and the problems of twisting and entangling of the ropes in traditional design are solved. A structure capable of clamping the path is designed on the rack of the structure, multiple pieces of equipment can be clamped at the same time on the path, and the purpose of descending multiple persons at the same time is achieved.

Owner:王青松

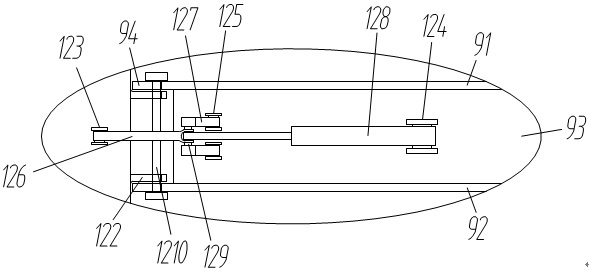

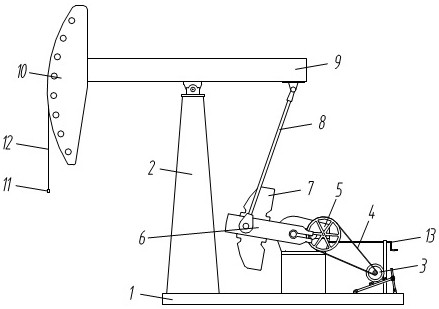

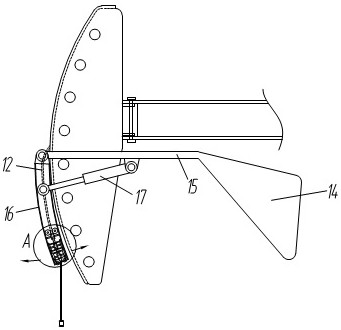

Horse head assembly for pumping unit

The invention belongs to the technical field of petroleum field operation devices, and provides a horse head assembly for a pumping unit which is provided with a base, a supporting frame, a driving motor and a reduction gearbox are fixed to the base, the driving motor is connected with the reduction gearbox through a belt, an output shaft of the reduction gearbox is connected with a crank, a balance block is arranged on the crank, and a connecting rod is hinged to the crank. The connecting rod is hinged to one end of the walking beam, the walking beam is rotatably supported on the supporting frame, the horse head is fixed to the other end of the walking beam, the beam hanger is connected to the lower portion of the horse head, the walking beam is provided with a top plate, a bottom plate and two side plates, the side plates are symmetrically arranged between the top plate and the bottom plate, the side plates are welded to the top plate and the bottom plate respectively, and a connecting base is formed at one end of the walking beam. The connecting base is used for hinging a horse head. Compared with the prior art, the device has the following beneficial effects that when an oil well needs to be maintained, the horse head located above the oil well is rotationally moved away, and meanwhile the problem that in the prior art, the horse head deflects towards one side, and consequently a walking beam is twisted can be solved.

Owner:东营高航技术有限公司

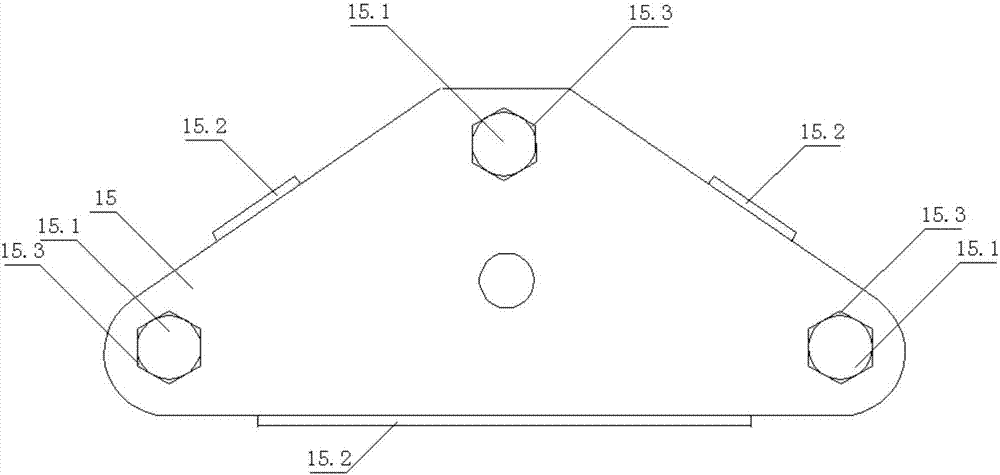

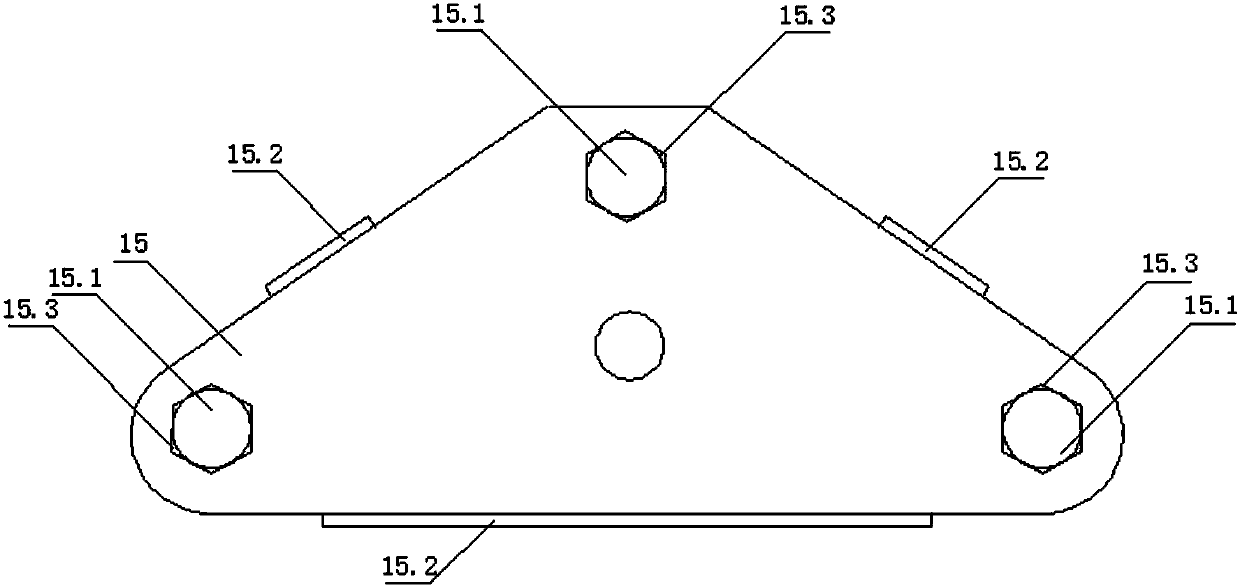

A hanging tension series connection structure

ActiveCN105846380BImprove flexibilityResolve twistSuspension arrangements for electric cablesSuspension/strain insulatorsEngineeringMechanical engineering

The present invention discloses a connection structure for a suspension strain insulator string. The connection structure comprises a pre-positive unit, a double-layer set square (15) and a second-change six-link plate (21). The double-layer set square (15) is provided with three string hanging holes (15.1). The second-change six-link plate (21) is provided with two string lifting holes (31) and six ring hanging holes (32). The pre-positive unit is connected with one string hanging hole (15.1) of the double-layer set square (15). The other two string hanging holes (15.1) of the double-layer set square (15) are respectively connected with the string lifting holes (31) of the second-change six-link plate (21) on the front and rear sides of the suspension strain insulator string. The ring hanging holes (32) of the second-change six-link plate (21) are connected with a wire (37). Based on the above structure, the functional requirements of turning around a corner, bearing the wire pressure, preventing the falling of the string, isolating a failure, adjusting the height of a tower and the like can be met. Meanwhile, the twisting problem of link plates can be well solved and the construction cost is lowered. Moreover, the direct jump-through is realized and the construction cost is lowered.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

Slot-less rolling technique of rolling section

InactiveCN100369680CResolve twistHighlight substantive featuresRoll mill control devicesMetal rolling arrangementsMaterials scienceRolling mill

Owner:XINJIANG BAYI IRON & STEEL

Method for lengthening columns, adding beams, resisting earthquakes and reinforcing for bottom frame structure

ActiveCN103046766BImprove seismic strengthImprove integrityBuilding repairsShock proofingBrickFloor slab

The invention relates to a method for lengthening columns, adding beams, resisting earthquakes and reinforcing for a bottom frame structure. According to the method, sections of original frame columns are expanded in the bottom frame structure, so that expanded frame columns extend in a uniform section mode to an upper brick-concrete structure till the top of the brick-concrete structure to form a penetrating whole body. Simultaneously, longitudinal beams and transverse beams are added on a bearing wall body of the original brick-concrete structure, added beams are in rigid connection with newly lengthened constructional columns, steel bars are embedded on the original floor and newly added beam portions, newly added beams are effectively connected with the original floor, and one-piece pouring is conducted for newly added longitudinal beams, newly added transverse beams and newly lengthened constructional columns, so that the original floor, newly added beams and newly lengthened columns form an integrated body. By the aid of the method, the load-carrying system of the structure can be changed, the original bottom frame structure system is changed into the frame structure system, the earthquake resistant strength of the structure is improved, and the integrity of the structure is enhanced.

Owner:贵州建工安顺建筑工程有限公司

Beam-pumping unit device

The invention belongs to the technical field of petroleum field operation devices, and provides a beam-pumping unit device which is provided with a base, a supporting column, a driving motor and a reduction gearbox are fixed to the base, the driving motor is connected with the reduction gearbox through a belt, an output shaft of the reduction gearbox is connected with a crank, a balance block is arranged on the crank, and a connecting rod is hinged to the crank. The connecting rod is hinged with one end of the walking beam, the walking beam is rotatably supported on the support frame, the other end of the walking beam is fixedly provided with a horse head, the lower part of the horse head is connected with a beam hanger through a steel wire rope, the pumping unit is provided with a brake device, and the pumping unit is provided with a detachable steel wire rope guide assembly. The device has the following beneficial effects that the steel wire rope and the polished rod can be located on the same vertical line, the steel wire rope is supported by the multiple rolling wheels and protected, and long-term use cannot be affected due to direction change of the steel wire rope.

Owner:山东柏源技术有限公司

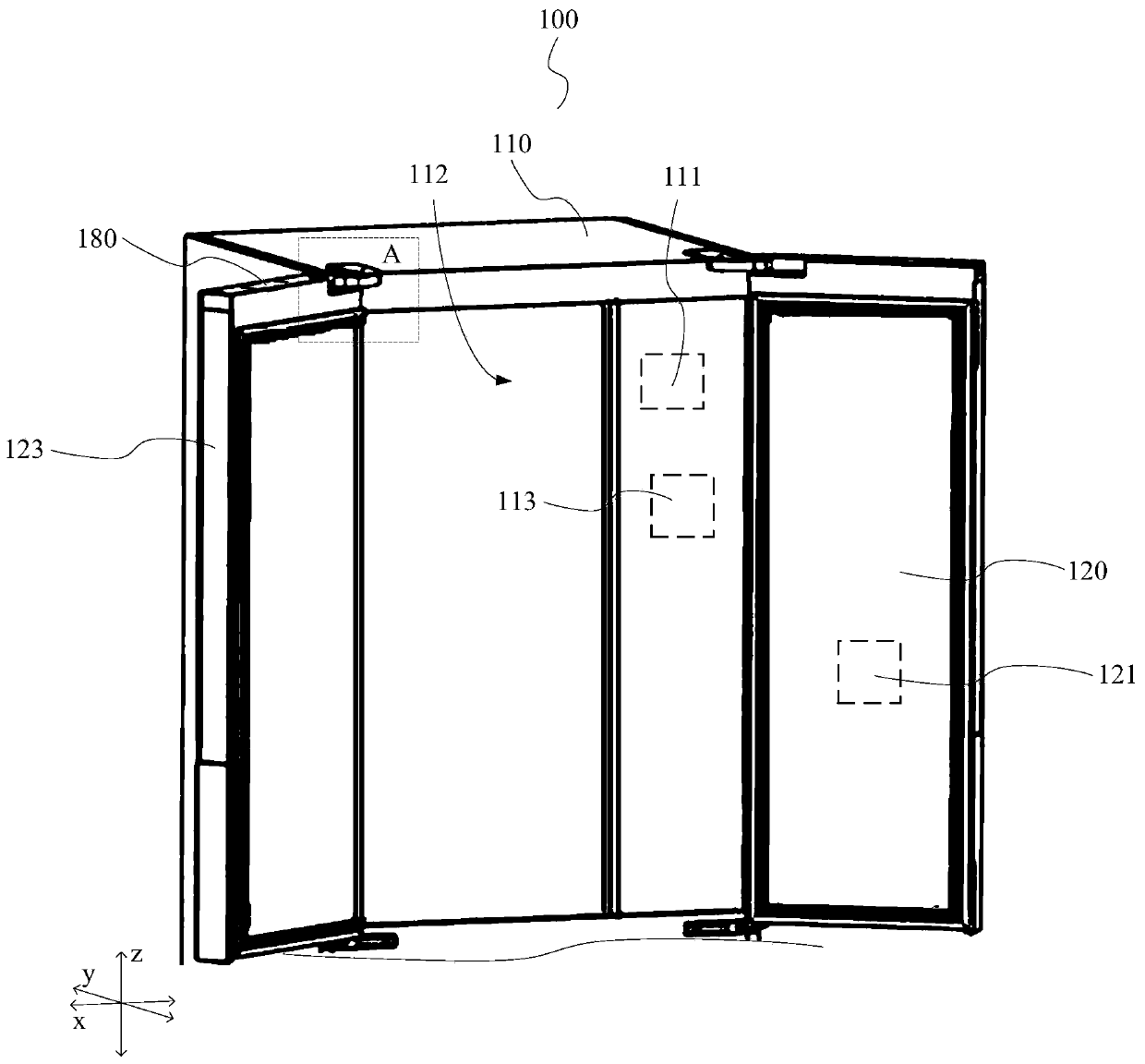

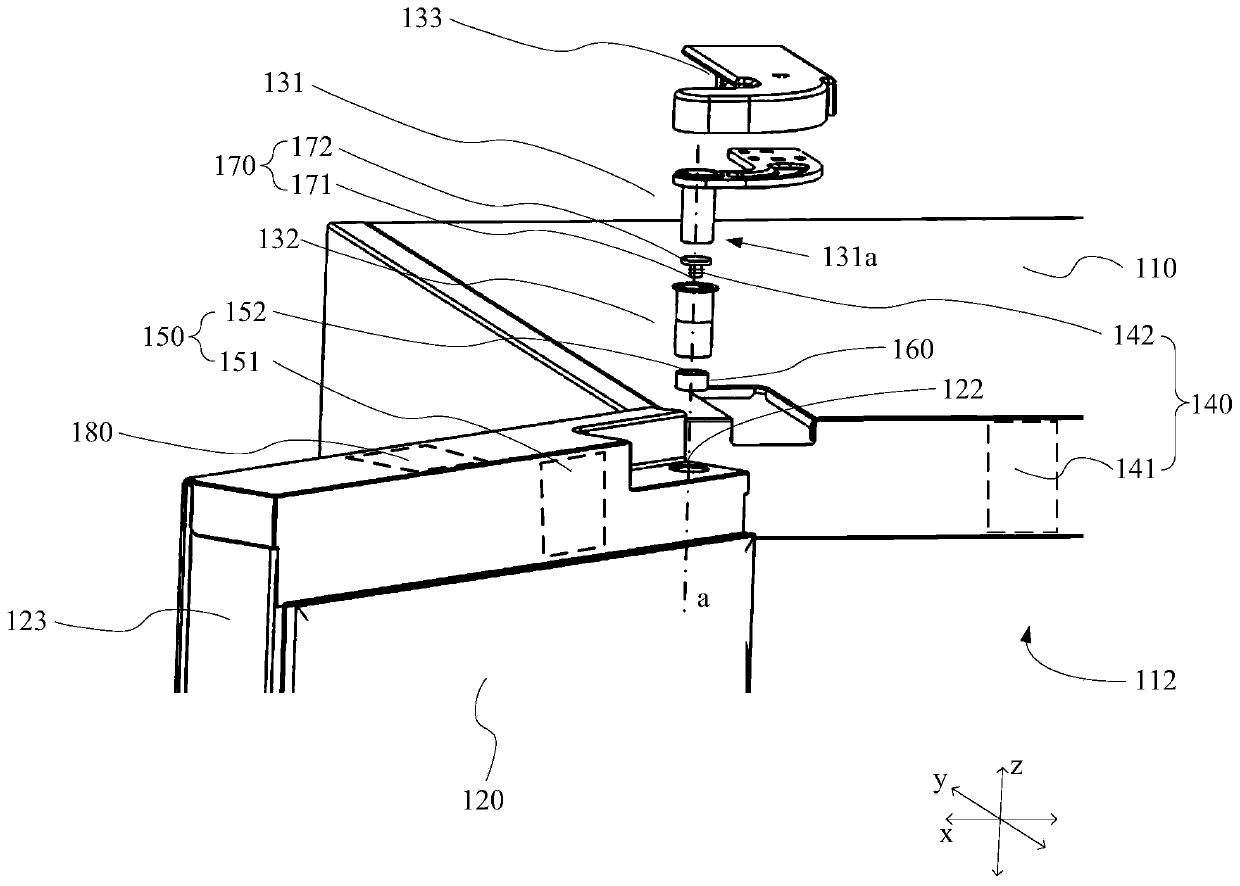

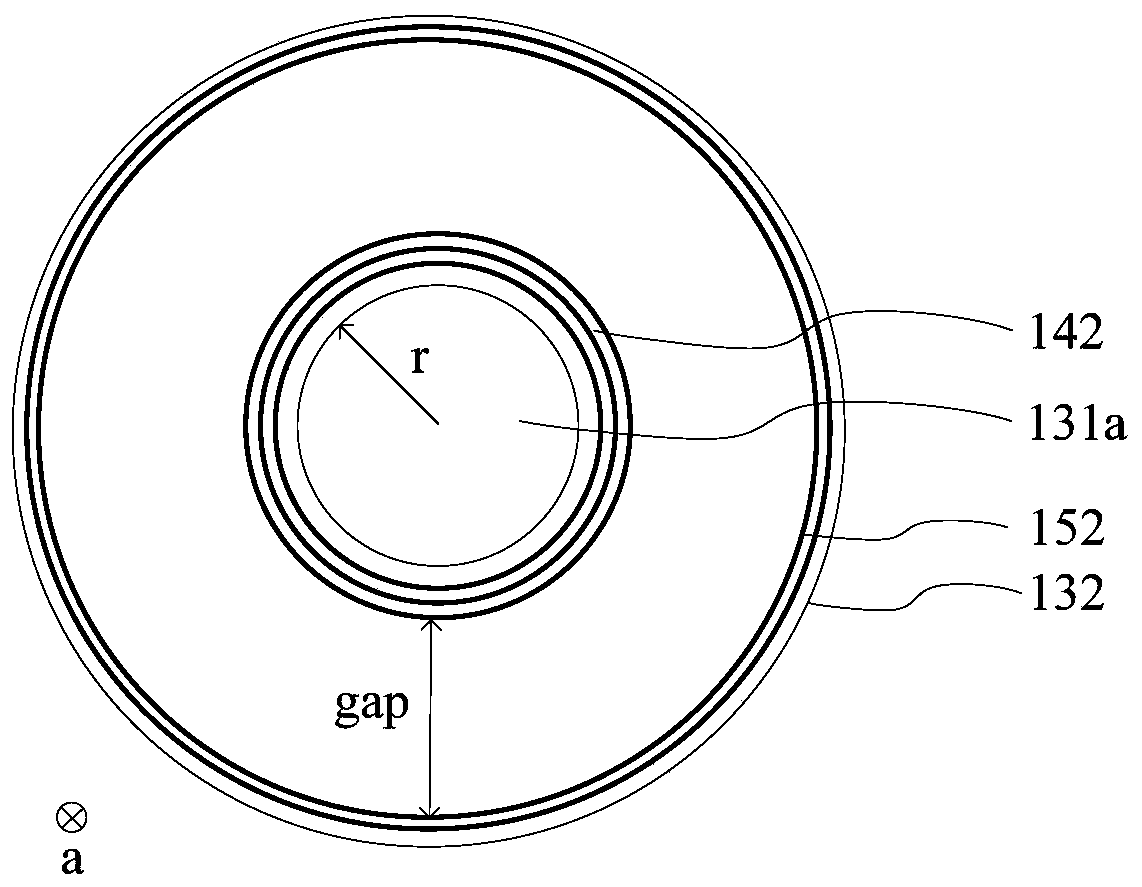

Household appliance

PendingCN111384785AImprove reliabilitySolve threading problemsCircuit arrangementsTelecommunicationsControl engineering

The invention discloses a household appliance, which comprises a main body and a door body, wherein the main body is provided with a power supply module and has an opening; the main body is connectedto the door body through a hinge; the door body is used for opening or closing the opening, the door body is provided with a power utilization module, the hinge comprises a hinge shaft, the door bodyis provided with a shaft hole suitable for accommodating the hinge shaft, and the door body can rotate around the hinge shaft. The household appliance further comprises a wireless power transmitting device and a wireless power receiving device, wherein the wireless power transmitting device is arranged in the hinge and connected with the power supply module; the wireless power receiving device isarranged in the shaft hole and is connected with the power utilization module; and the wireless power transmitting device is coupled with the wireless power receiving device so as to carry out wireless power transmission. Through the scheme provided by the invention, the threading problem of a wire harness at the hinge can be effectively solved, the power supply and communication functions based on the hinge without the threading structure are realized, and the power supply effect on a user module on the door body is ensured while the overall reliability of the household appliance is improved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

A hanging tension series connection device

ActiveCN105633890BImprove flexibilityResolve twistArrangements for reliveing mechanical tensionEngineeringTower

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP +1

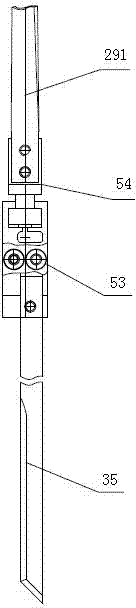

cutting machine head

ActiveCN103112028BThe detection value is accurateEliminate vibrationSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to a machine head of a cutting machine, belongs to a component of the cutting machine, and is applied to the cutting field. The machine head of the cutting machine comprises a pressing and feeding device and a cutter grinding device, and is characterized by further comprising a cutter deviation-correcting device and a shock absorption device. The cutter deviation-correcting device comprises a guide wheel frame, a pressing wheel and a position sensor on an elastic arm, wherein a pressing disc is provided with the guide wheel frame, and the guide wheel frame is provided with the pressing wheel and a rear pressing wheel. The shock absorption device comprises a servo motor, a first synchronous belt wheel group and a vibration shaft, wherein the servo motor is arranged on a machine head vertical fixing frame through a motor fixing seat, and the vibration shaft is connected on a machine head seat. Due to the fact that the cutter deviation-correcting device and the shock absorption device are arranged on the machine head, the deviation between top-layer material and bottom-layer material is well controlled, and noise in the cutting process is lowered.

Owner:HANGZHOU ECHO SCI TECH

Galvanized steel wire for high-strength and high-torsion bridge cable and its preparation process

ActiveCN109055679BMeet development requirementsDramatic organizational changeFurnace typesHeat treatment bathsWire rodEngineering

Owner:武汉钢铁有限公司

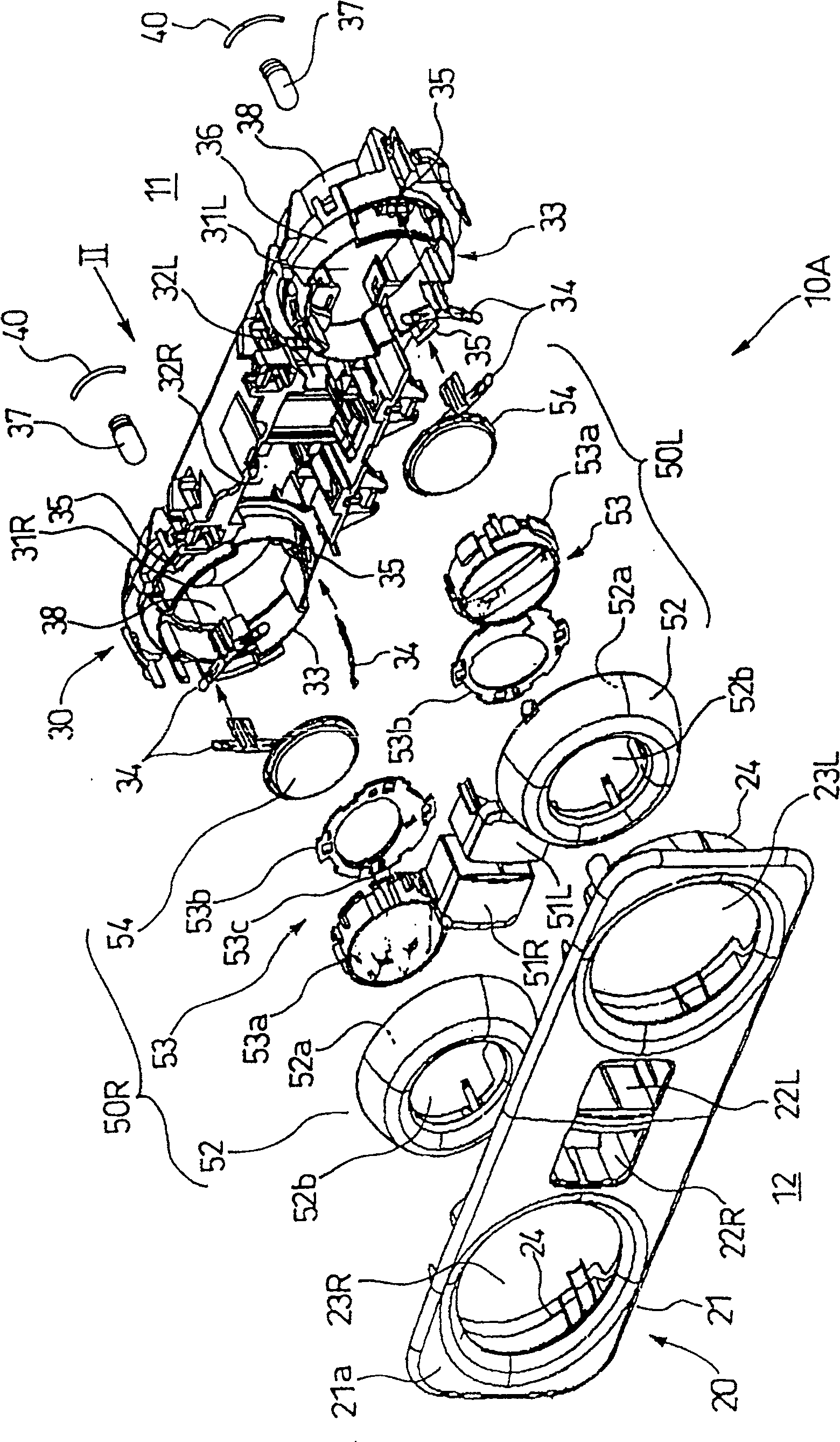

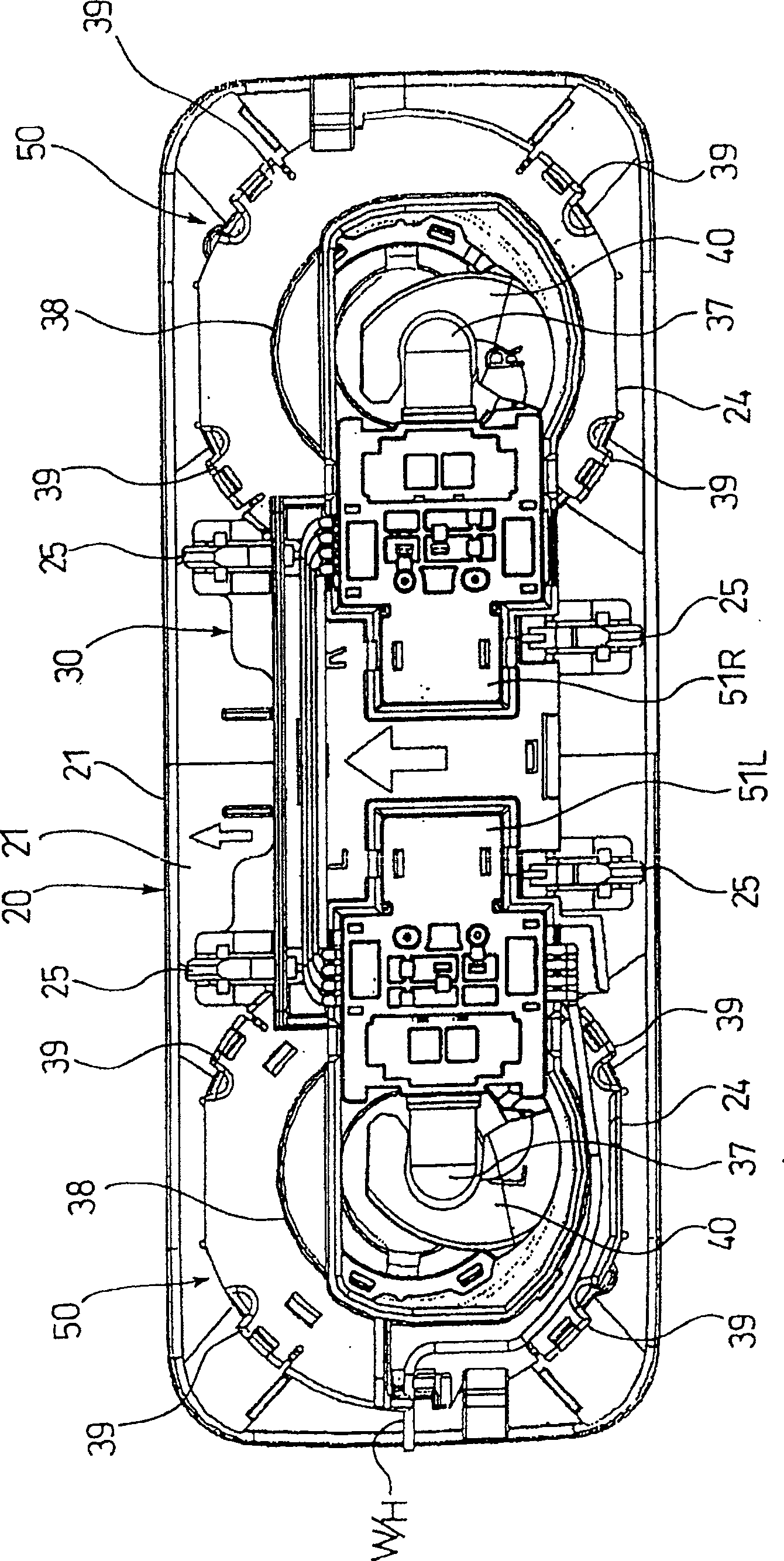

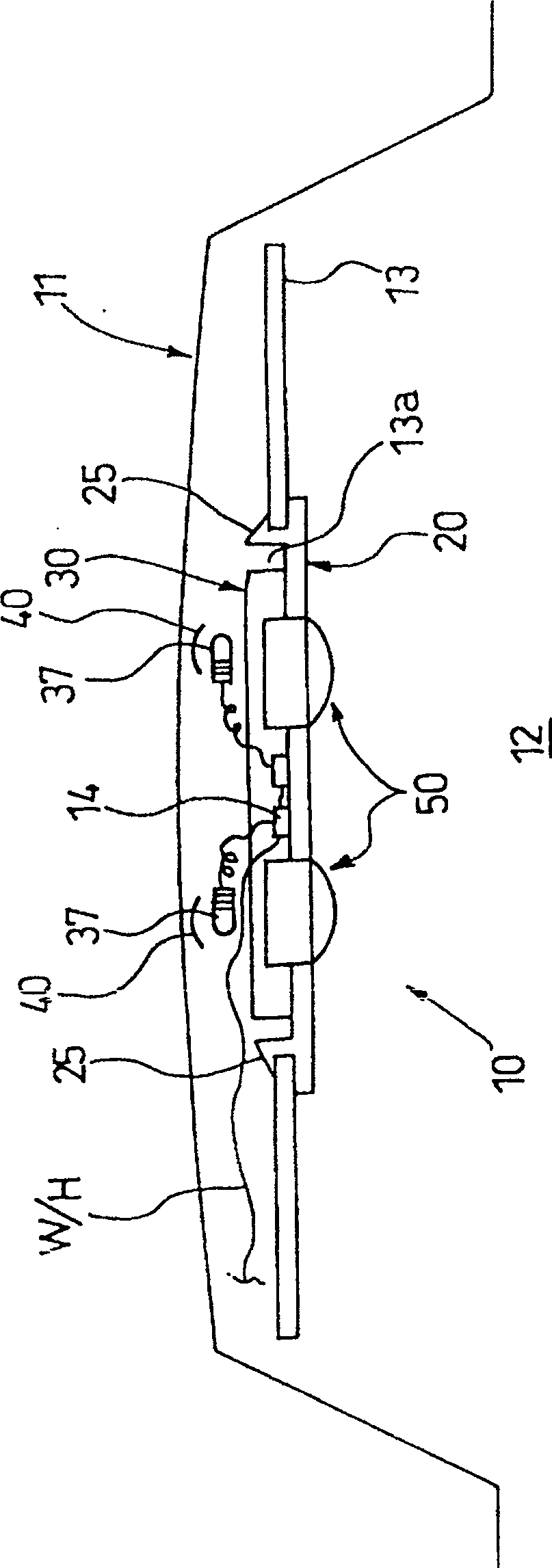

Indoor lamp

When the glass frame portion 52 turns over an angle to adjust the lighting direction, the lens 54 and the reflector 40 rotate angularly thereupon, but the bulb 37 does not rotate angularly thereupon because it is fixed on the lamp body 30, so that the connection The harness W / H on the bulb 37 cannot be twisted. Therefore, the problem of the wire harness W / H being twisted due to the twisting of the beam wire W / H when adjusting the lighting direction in the conventional structure is avoided. In addition, the lens 54 and the reflection plate 40 can be angularly rotated synchronously so that the reflected light on the reflection plate 40 always illuminates a predetermined portion of the lens 54 . Therefore, the light beam emitted from the bulb 37 can be efficiently irradiated on the object to be illuminated. There is a notch 41 on the reflector 40 to facilitate the installation of the bulb 37 and the reflector 40 .

Owner:YAZAKI CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com