Automobile rear axle reducer shell large end face drilling clamp

A technology of automobile rear axle and drilling jig, applied in the direction of drilling dies for workpieces, etc., can solve the problems of inaccurate positioning of machining holes, high labor intensity of workers, etc. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

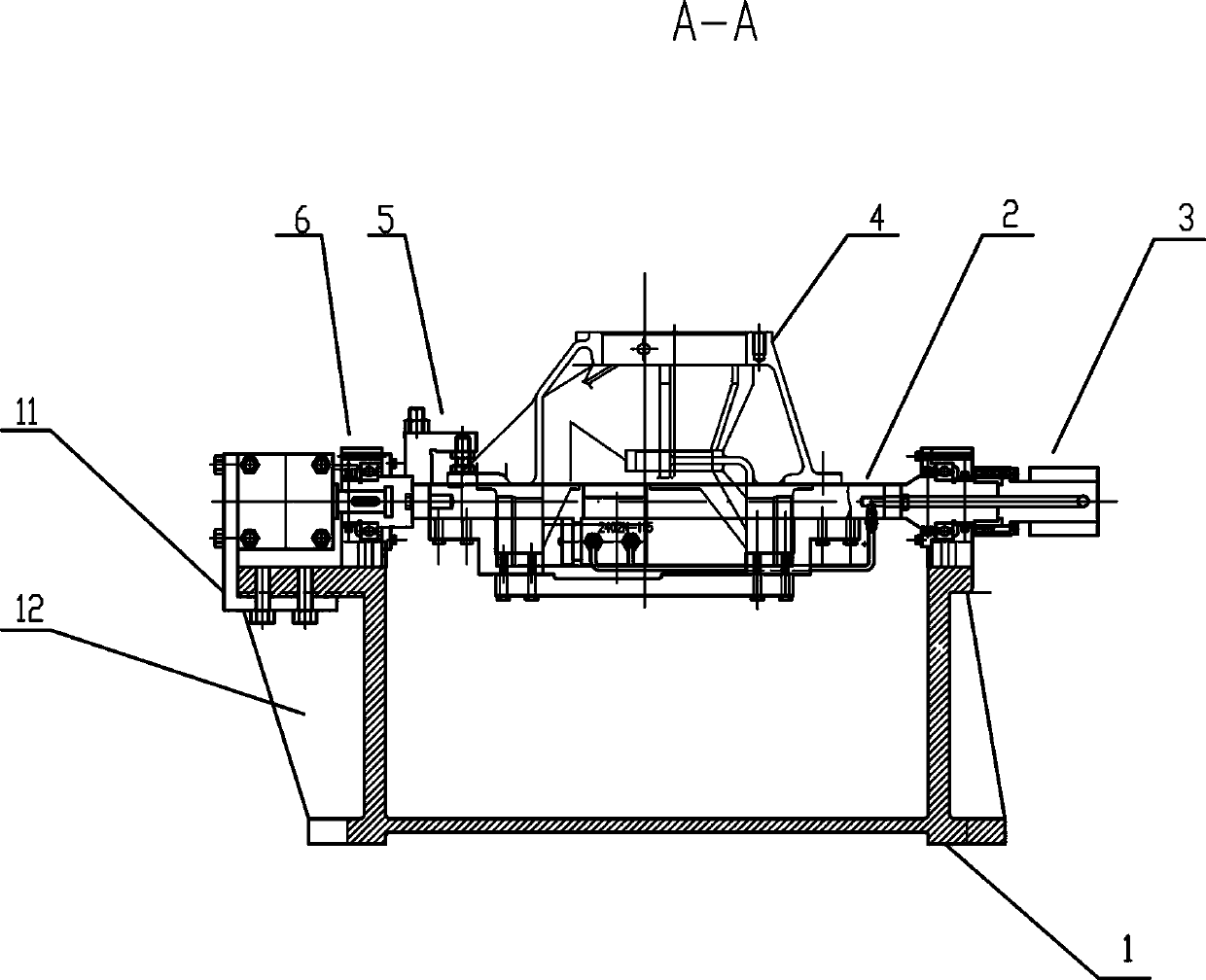

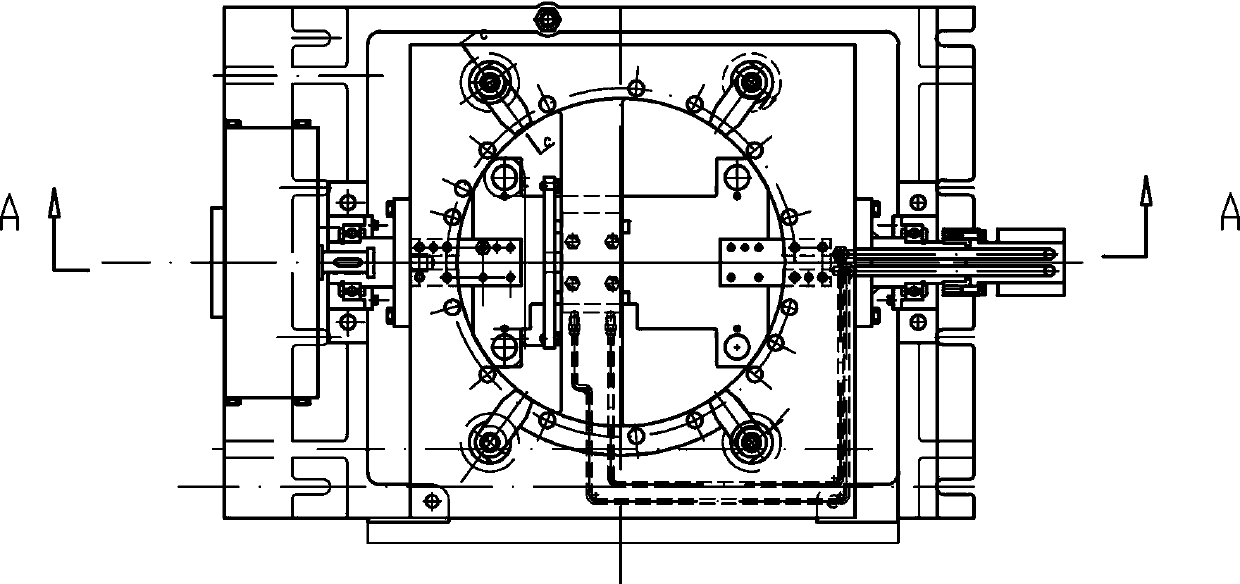

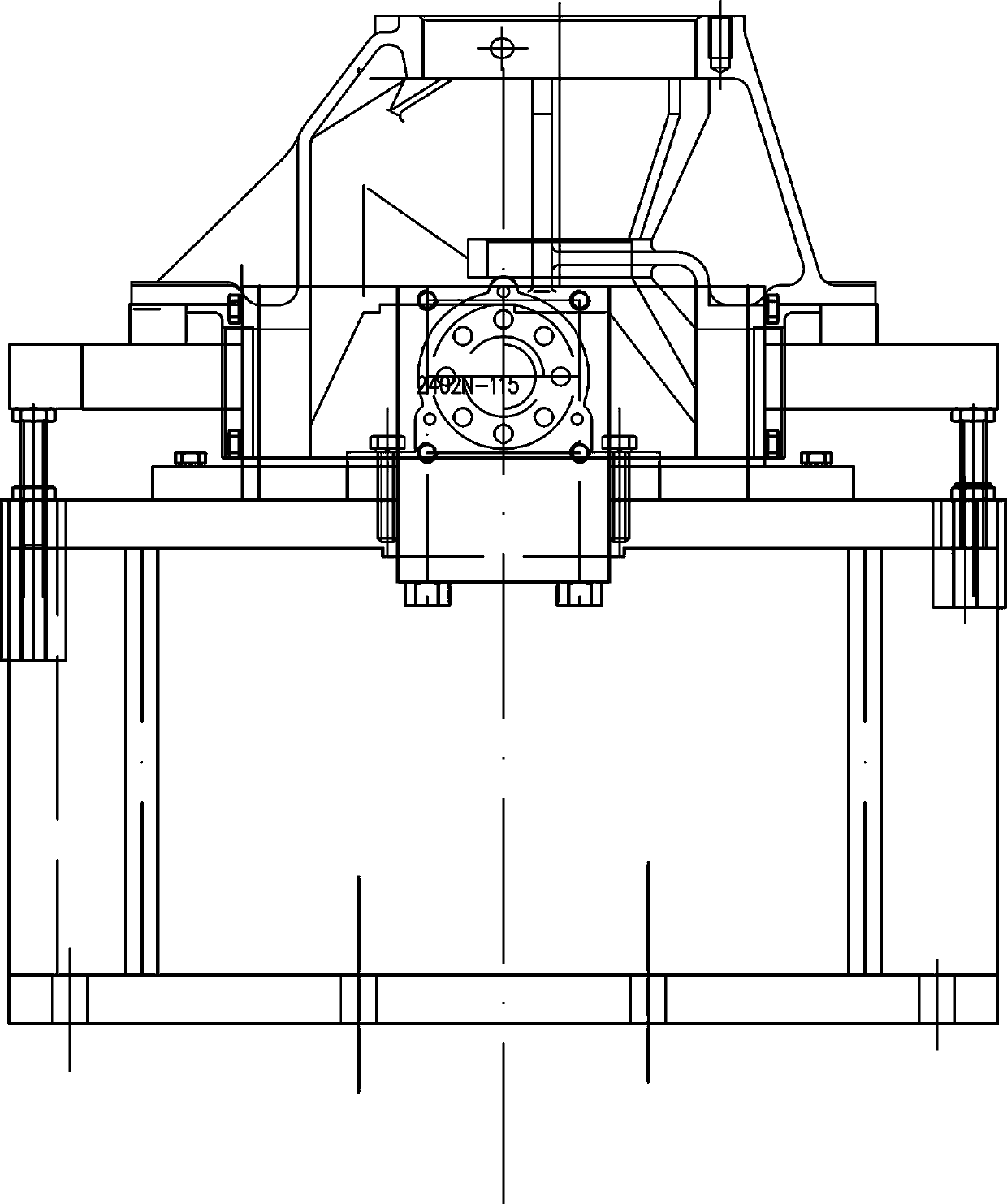

[0023] Such as Figure 1-3 Shown in, a kind of jig for drilling the large end face of the automobile rear axle reducing casing, the bottom of the automobile rear axle reducing casing 4 is provided with a drilling template device 2, and the automobile rear axle reducing casing 4 is fixed on the drilling template device 2 by a clamping device 5, The two ends of the drill template device 2 are respectively connected with the left rotation device 6 and the right rotation device 3 arranged on the clamp bracket 1, the automobile rear axle casing 4 is rotated by the rotary cylinder 61 arranged on the left rotation device 6, and the drill template device 2 Positioning cylinder 21 is provided under the template top plate 22 in the middle, and positioning cylinder 21 is connected with the air passage of the swivel joint 31 of right rotation device 3 through air passage 25.

[0024] With this structure, the automobile rear axle reducing casing 4 connected to the drilling template device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com